Copper nanowire/graphene composite material and preparation method and application thereof

A technology of copper nanowires and composite materials, applied in conductive materials, conductive materials, nanotechnology and other directions, can solve the problems of difficulty in controlling the oxygen content of reduced graphene oxide and the limitation of electrical conductivity, and achieve a convenient, fast and universal realization process. High performance, excellent antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Ultrasonic disperse 30 mg of copper nanowires with an average diameter of 50 nm and 20 mg of graphene in 1.2 mL of deionized water to obtain a mixed dispersion; wherein graphene is prepared by non-oxidative exfoliation of graphite, and its average sheet thickness is 1 nm, mixed with Doped with 3wt% sulfur and 10wt% nitrogen;

[0043] 2) vacuum filter the mixed dispersion obtained in step 1), the pore size of the filter membrane used is 0.45 μm, and then dry the filter cake to obtain a composite film with a thickness of 40 μm and an electrical conductivity of 2.88×10 4 S / m.

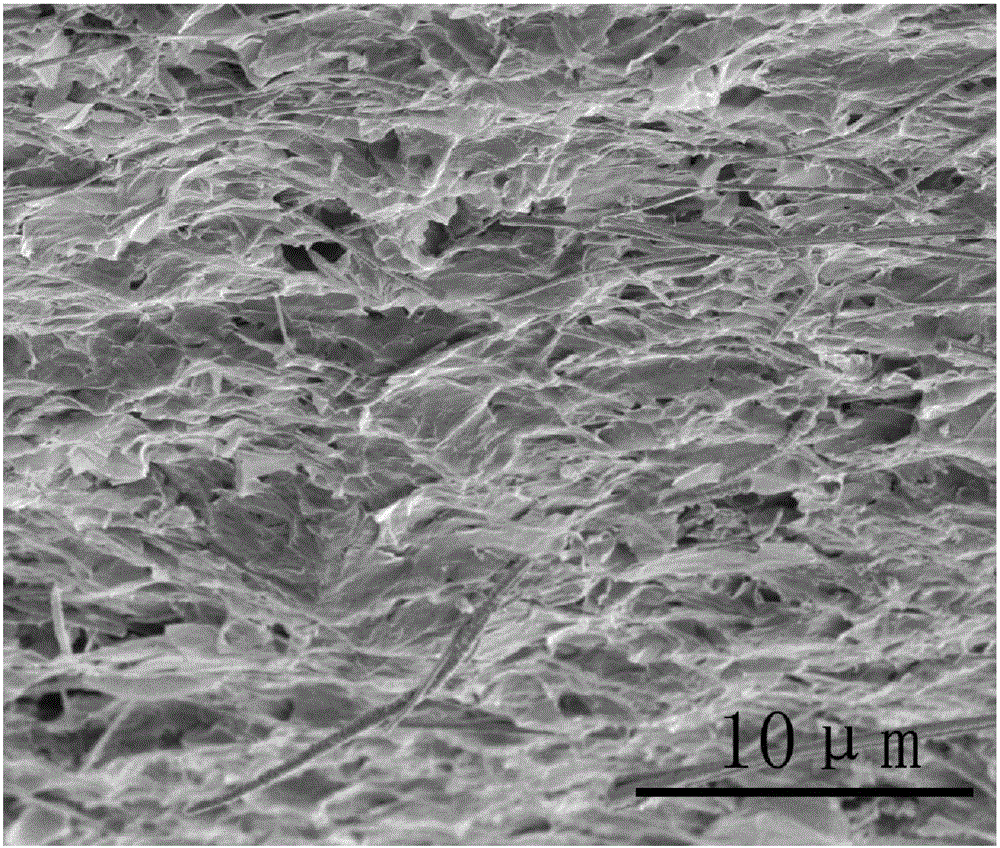

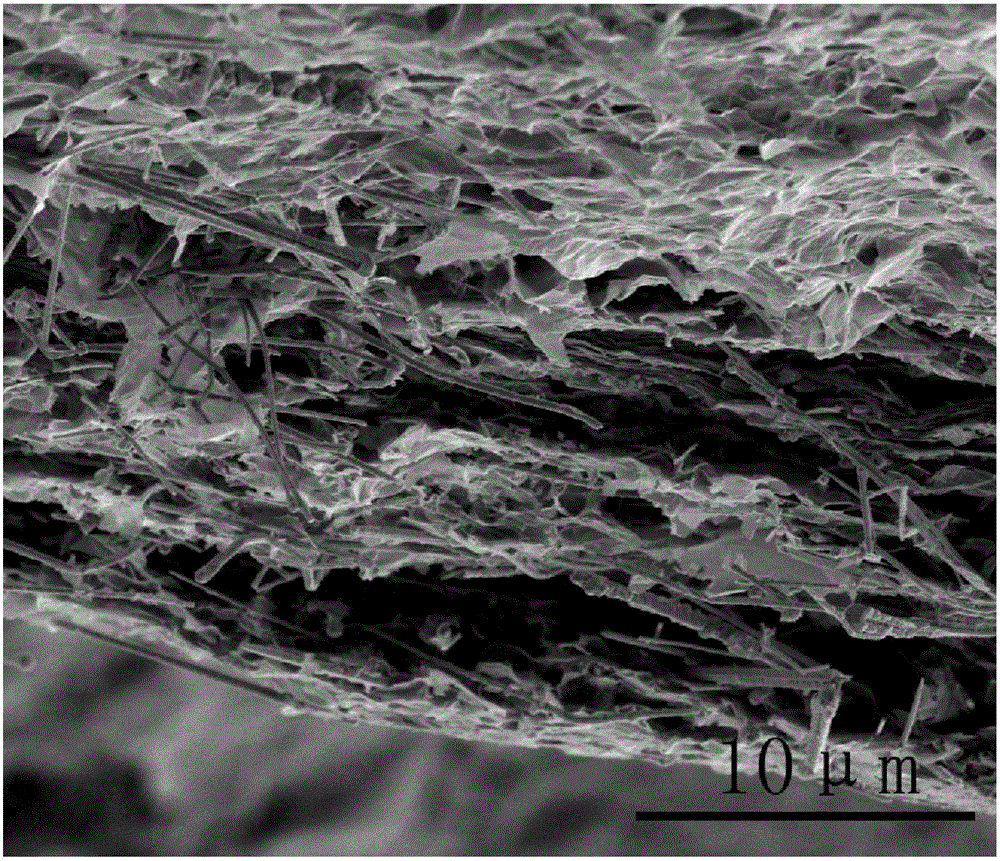

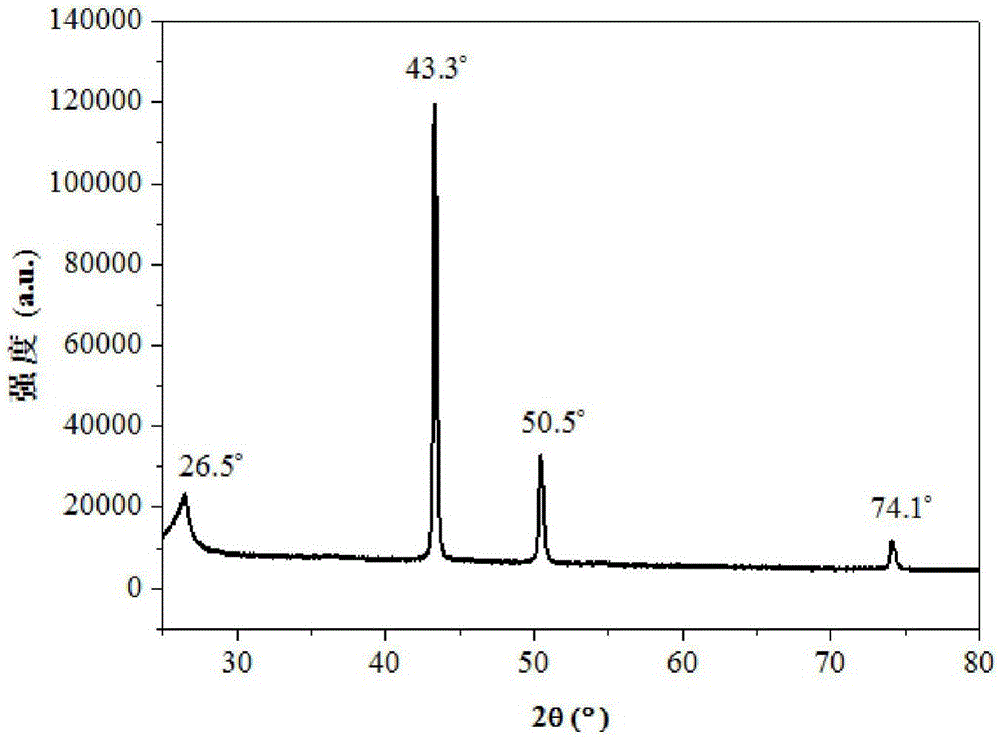

[0044] Observe the product obtained in embodiment 1 under a scanning electron microscope, as figure 1 and figure 2 As shown, it can be seen that the composite film retains the sheet-like structure of graphene, and copper nanowires are embedded on each graphene sheet and covered by graphene layers. In this way, there is a protective barrier between the copper nanowires and the outside world, w...

Embodiment 2

[0054] The only difference from Example 1 is that the average sheet thickness of graphene is 5nm. The electrical conductivity of the obtained composite film is 1.5×10 4 S / m, its conductivity is 90% of the initial conductivity after being placed in the air at room temperature for 60 days.

Embodiment 3

[0056] The only difference from Example 1 is that the average sheet thickness of graphene is 8nm. The electrical conductivity of the obtained composite film is 1.3×10 4 S / m, its conductivity is 92% of the initial conductivity after being placed in the air at room temperature for 60 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com