Novel conveying device with both paper folding and upwarp-preventing functions

A transmission device and functional technology, which is applied in the field of new transmission devices, can solve problems such as affecting the process and prone to warping, and achieve the effects of saving manpower and material resources, saving time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

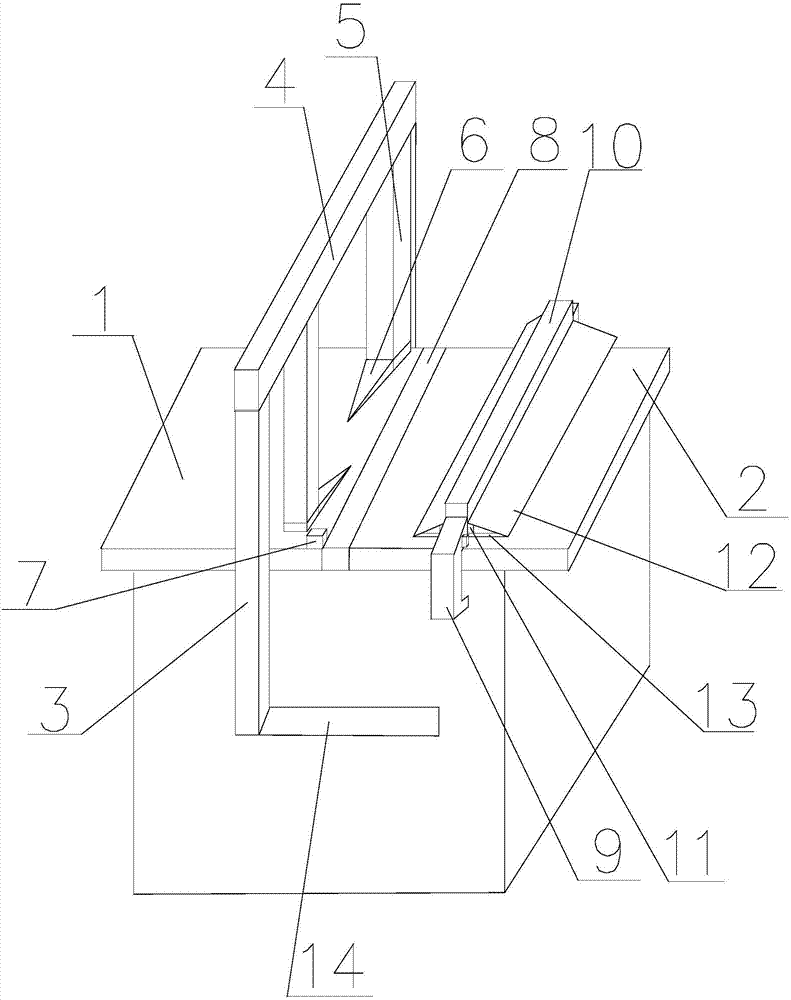

[0024] like figure 1 As shown, the present invention has a new type of conveying device with paper folding and anti-warping functions, including paper and a conveying device. The conveying device includes a conveyor belt A1 and a conveyor belt B2 located on the left and right sides of the conveyor. The conveyor belt A2 and the conveyor belt B2 There are telescopic telescopic rods 8 connected between them, and support rods A3 are vertically connected on the opposite two sides of the transmission device, and a connecting rod 4 is connected between the supporting rods A3, and the connecting rod 4 is connected with Two vertical retractable pressure rods 5, the pressure rods 5 are located on the side of the conveyor belt A1 close to the telescopic rod 8, and the side of the conveyor belt A1 close to the telescopic rod 8 is connected with a sensor for sensing the position of the paper A7; the opposite sides of the transmission device are vertically connected with telescopic support ...

Embodiment 2

[0026] The novel conveying device with functions of folding paper and anti-warping at the same time includes paper and a conveying device, and the conveying device includes a conveyor belt A1 and a conveyor belt B2 located on the left and right sides of the conveyor, and the conveyor belt A2 and the conveyor belt B2 are connected There are retractable telescopic rods 8, on the opposite sides of the transmission device, there are vertically connected support rods A3, a connecting rod 4 is connected between the supporting rods A3, and two connecting rods are connected on the connecting rod 4. A vertical retractable pressure rod 5, said pressure rod 5 is located on the side of the conveyor belt A1 close to the telescopic rod 8, and the side of the conveyor belt A1 close to the telescopic rod 8 is connected with a sensor A7 for sensing the position of the paper; On the opposite two sides of the conveying device, telescopic support rods B9 are vertically connected, and fixed rods 10...

Embodiment 3

[0028] The novel conveying device with functions of folding paper and anti-warping at the same time includes paper and a conveying device, and the conveying device includes a conveyor belt A1 and a conveyor belt B2 located on the left and right sides of the conveyor, and the conveyor belt A2 and the conveyor belt B2 are connected There are retractable telescopic rods 8, on the opposite sides of the transmission device, there are vertically connected support rods A3, a connecting rod 4 is connected between the supporting rods A3, and two connecting rods are connected on the connecting rod 4. A vertical retractable pressure rod 5, said pressure rod 5 is located on the side of the conveyor belt A1 close to the telescopic rod 8, and the side of the conveyor belt A1 close to the telescopic rod 8 is connected with a sensor A7 for sensing the position of the paper; On the opposite two sides of the conveying device, telescopic support rods B9 are vertically connected, and fixed rods 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com