Counterpoint method of applique embroidery surface mounting

A patching and patching technology, applied in the field of patchwork embroidery, can solve the problems of affecting machine production efficiency, not very objective income, and high clothing prices, making the patching process convenient and fast, and solving the problems of patch alignment and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

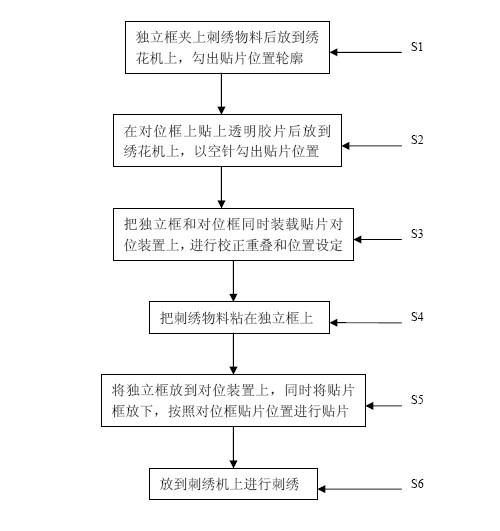

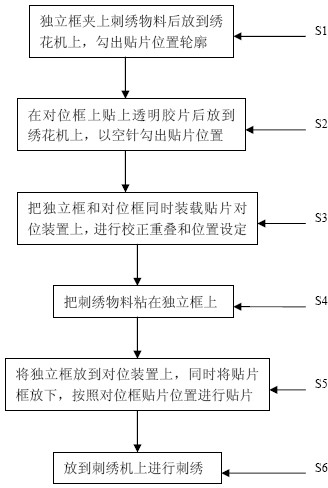

[0018] A method for aligning appliqué embroidery patches according to the present invention, the method for aligning patches has six main steps, as shown in the attached instructions figure 1 shown.

[0019] Step 1 s1: Put the base fabric on the independent embroidery frame and clamp it tightly so that the surface of the base fabric is very smooth, then put the independent embroidery frame with the base fabric on the embroidery machine, and place the patch on the embroidery material The outline is embroidered.

[0020] Step 2 s2: Paste a transparent film on the alignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com