Automatic surface cleaning and protecting device for drilled hardware fittings

An automatic cleaning and protective device technology, which is applied in the direction of feeding device, maintenance and safety accessories, drilling/drilling equipment, etc., can solve the problems of large labor consumption, automatic cleaning of hardware accessories, insufficient drilling stability, etc., and achieve improvement Working environment and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

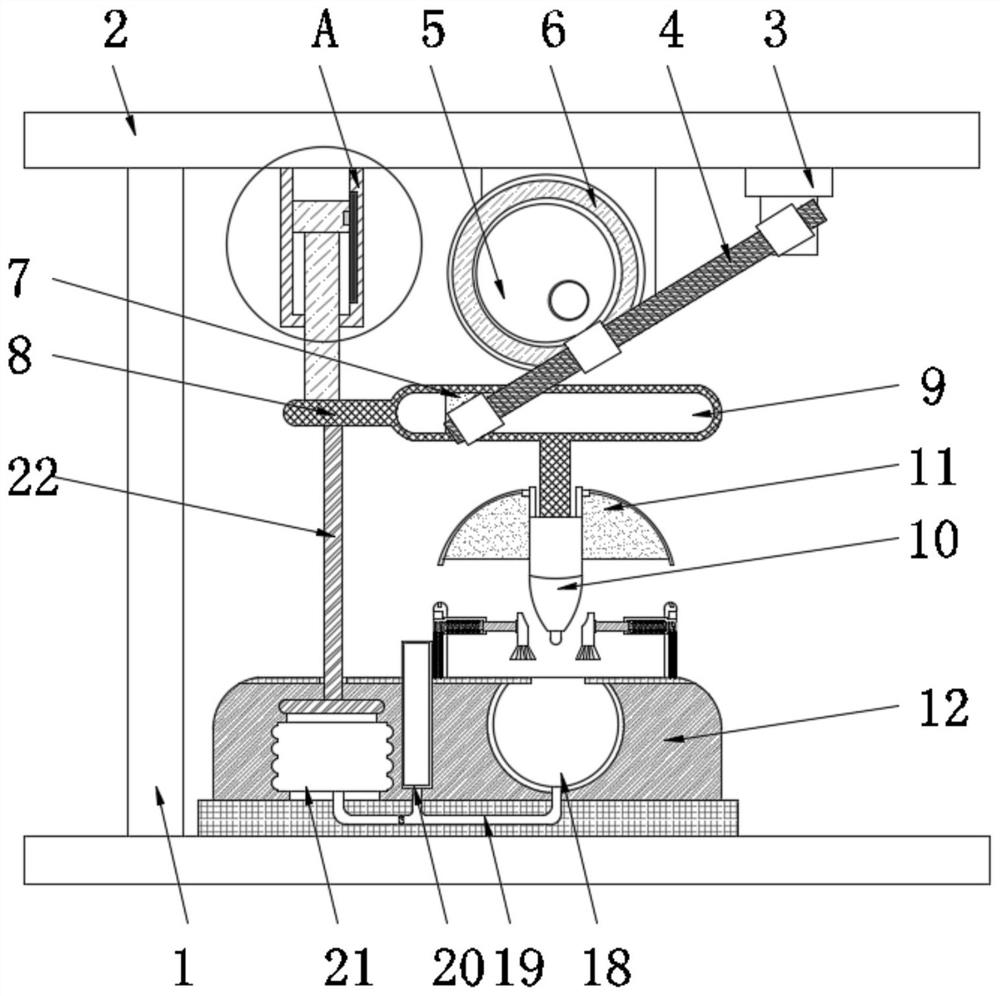

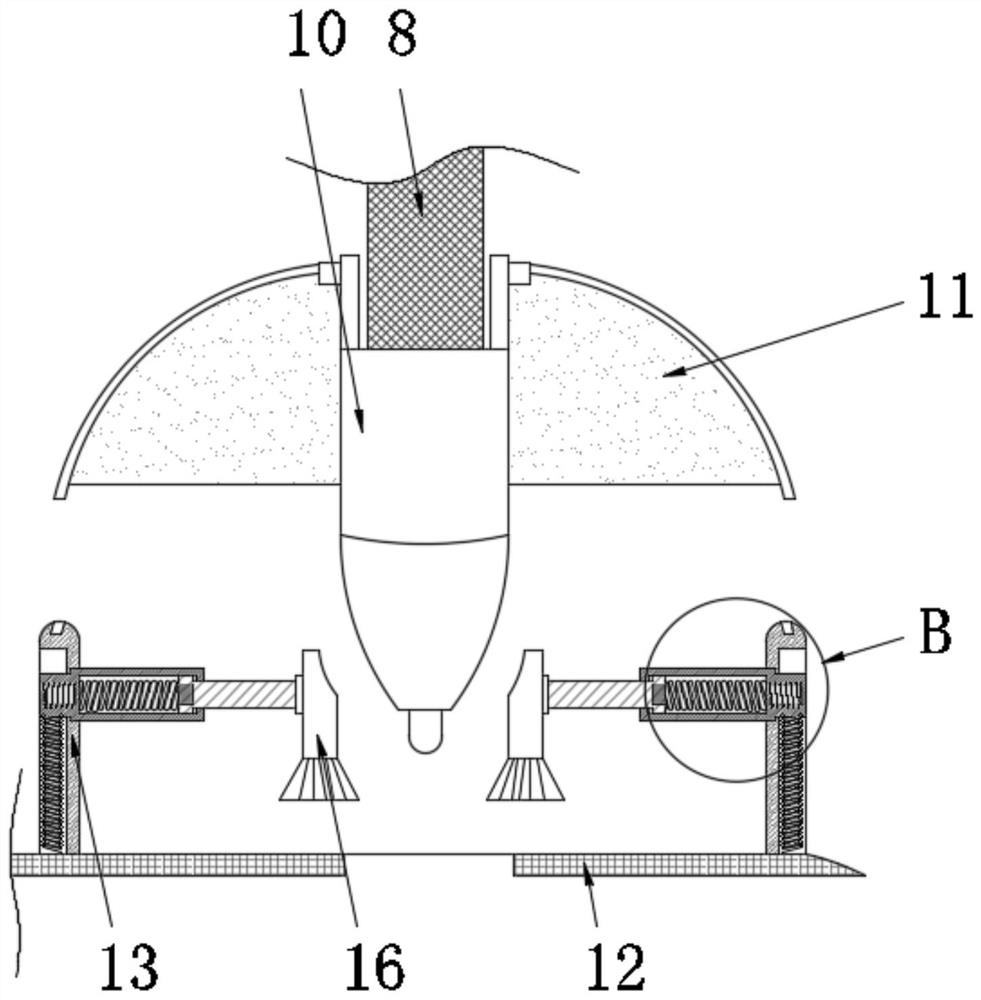

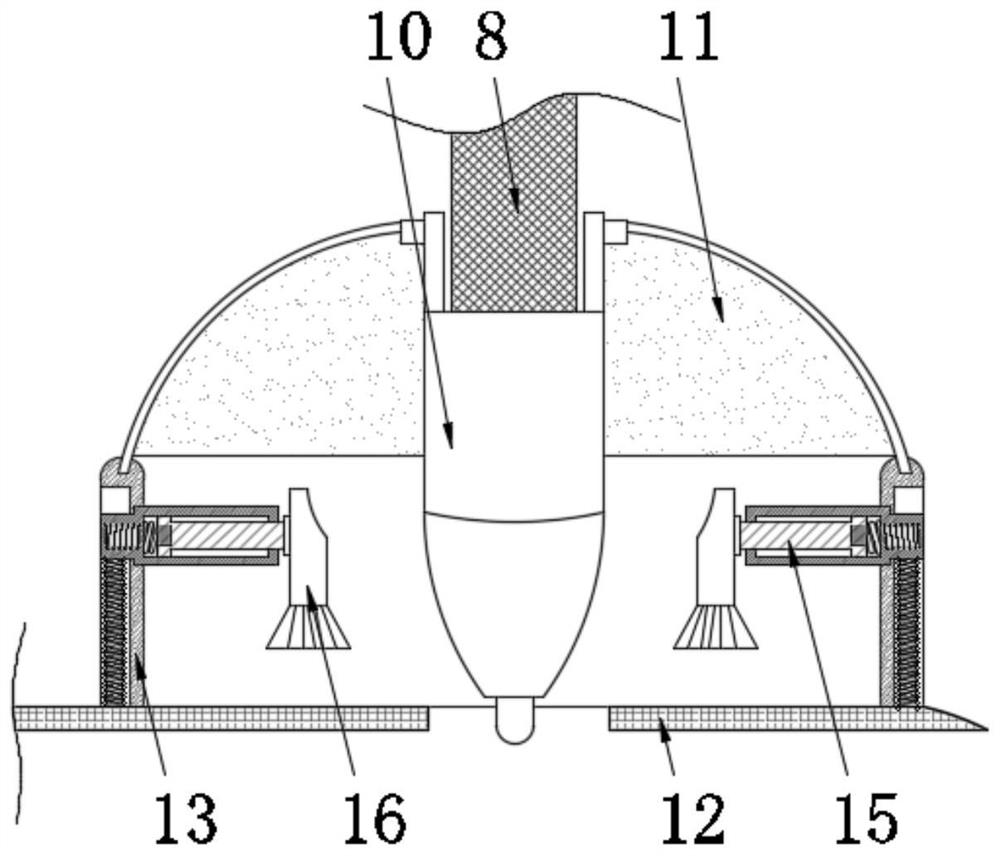

[0022] The invention provides an automatic cleaning protection device for the surface of hardware fittings after drilling, as attached figure 1 to attach Figure 5 Shown: including the base 1, the top of the base 1 is fixedly installed with a horizontal plate 2, the lower surface of the horizontal plate 2 is fixedly installed with a bearing seat 3, the front side of the bearing seat 3 is movably installed with a transmission rod 4, and the middle part of the transmission rod 4 is behind The surface is fixedly installed in the arc groove 6 opened by the disc 5, the rear surface of the disc 5 is fixedly installed with a motor, and the end of the transmission rod 4 is movably connected with a moving block 7, and the transmission rod 4 is inclined based on the bearing seat 3 design, the moving block 7 is slidably installed in the sliding hole 9 provided inside the movable fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com