Device for cleaning bottled beverage after filling

A post-cleaning and beverage technology, applied in synchronous devices, bottle filling, packaging, etc., can solve the problems of insufficient cleaning and inability to be cleaned, and achieve the effect of improving the cleaning effect and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

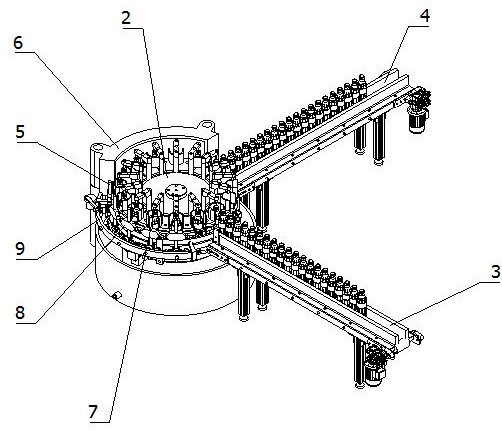

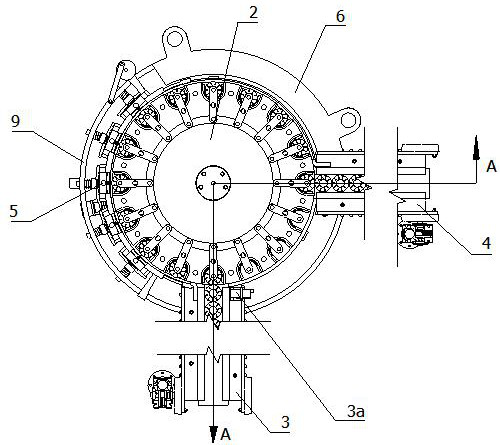

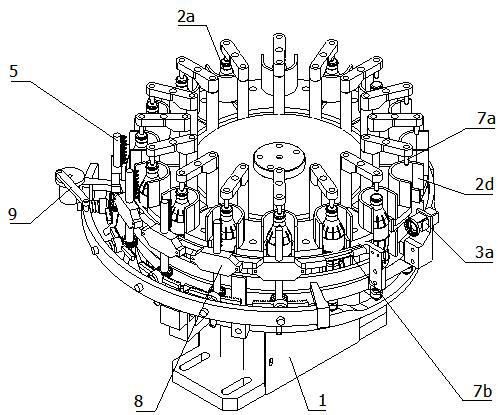

[0049] like Figure 1-Figure 6 As shown, this application provides:

[0050] A device for cleaning bottled beverages after filling, including a workbench 1, a transfer plate 2 is arranged on the workbench 1, and a feed conveyor 3 and a discharge conveyor 4 are arranged on the side of the transfer plate 2. The direction in which the feeding conveyor 3 conveys the beverage bottles 2a is perpendicular to the direction in which the discharging conveyor 4 outputs the beverage bottles 2a, and the edge of the transfer plate 2 is evenly opened along its circumferential direction with a number of U-shaped holes for the beverage bottles 2a to be inserted into. The bottom of the transfer plate 2 is also coaxially and fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com