Solid elastomer coating-free veneer overlay technique

A veneer and veneer technology, which is applied in decorative arts, planers, decorative structures, etc., can solve the problems of increasing operators and process links, increasing work environment pollution, and extending damage to consumers, so as to reduce process links and shorten The time of veneer hot pressing and the effect of omitting glue coating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail.

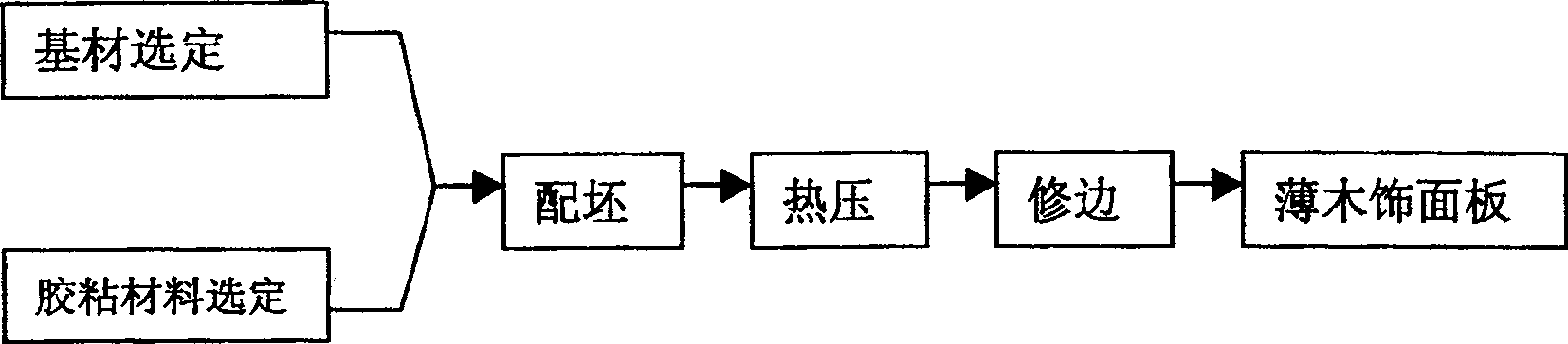

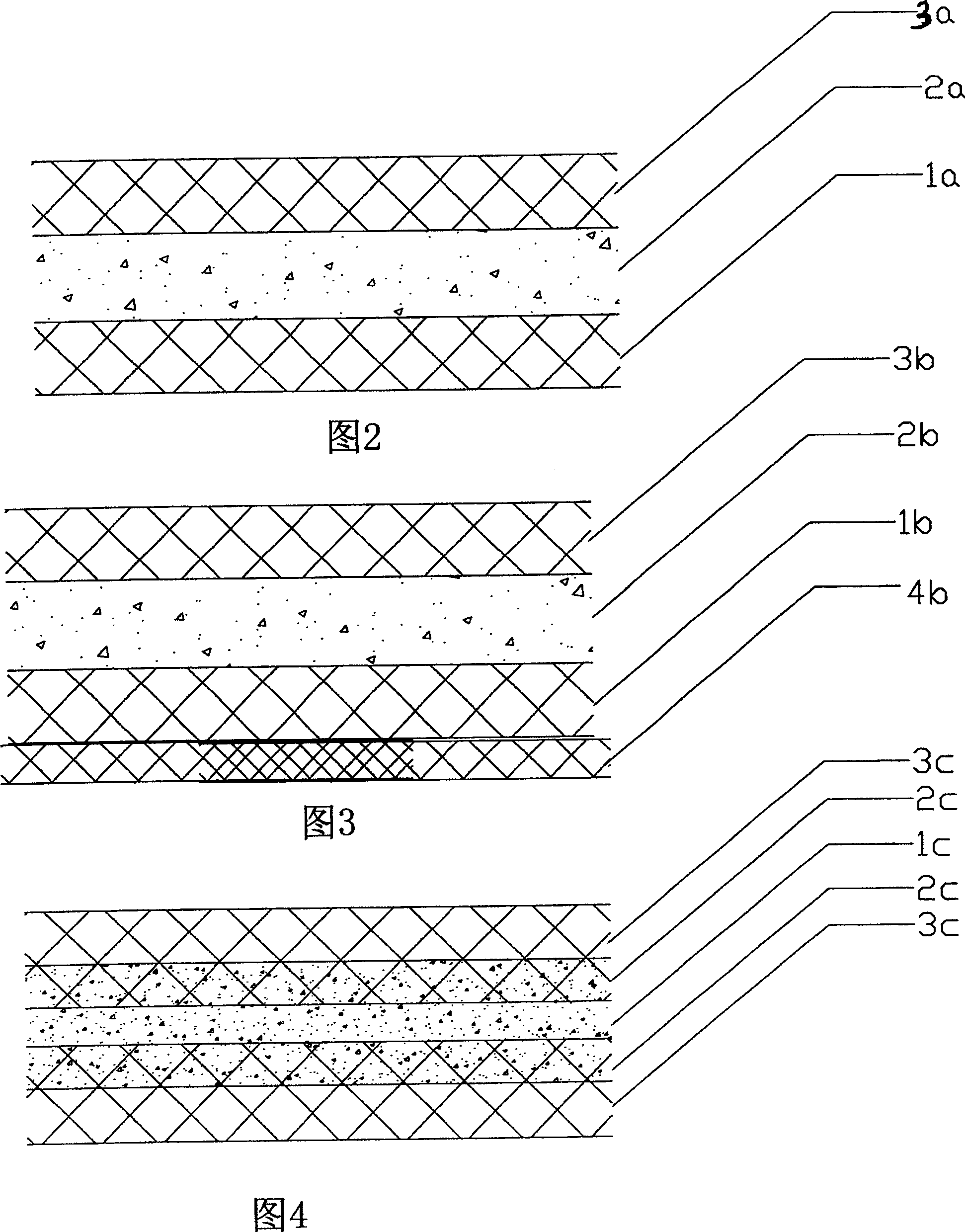

[0028] Figure 1 to Figure 4 As shown, the process of dry glue-free veneer veneer includes the steps of base material selection, adhesive material selection, base preparation, hot pressing, and edge trimming. The base material selection includes sanding Wood-based panels and thin veneers that have been properly spliced; wood-based panels require sanded density boards and particle boards that are suitable for veneering; the adhesive material selected in the step of selecting adhesive materials is melamine film paper, which is glue The base paper of film paper is impregnated and dried with melamine resin or melamine modified urea-formaldehyde resin; the base paper of film paper is made of α-cellulose pulp with high cellulose content; in order to obtain good products, the quality of base paper for film paper is required Main technical indicators: ① Quantitative 22±2g / m 2 ; ② Long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com