Touch panel and method for forming touch panel

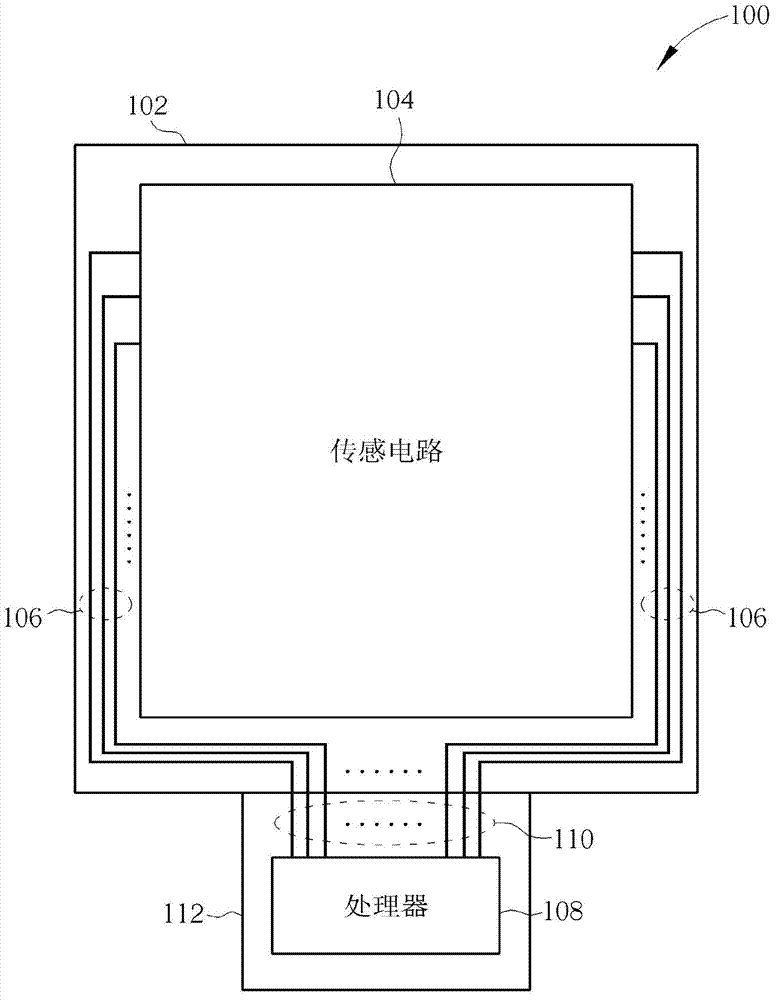

A touch panel and one-sided technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of manpower consumption, cost, complicated process steps, and difficult alignment of wires 106 and 110 , to achieve the effect of fast and convenient manufacturing process and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

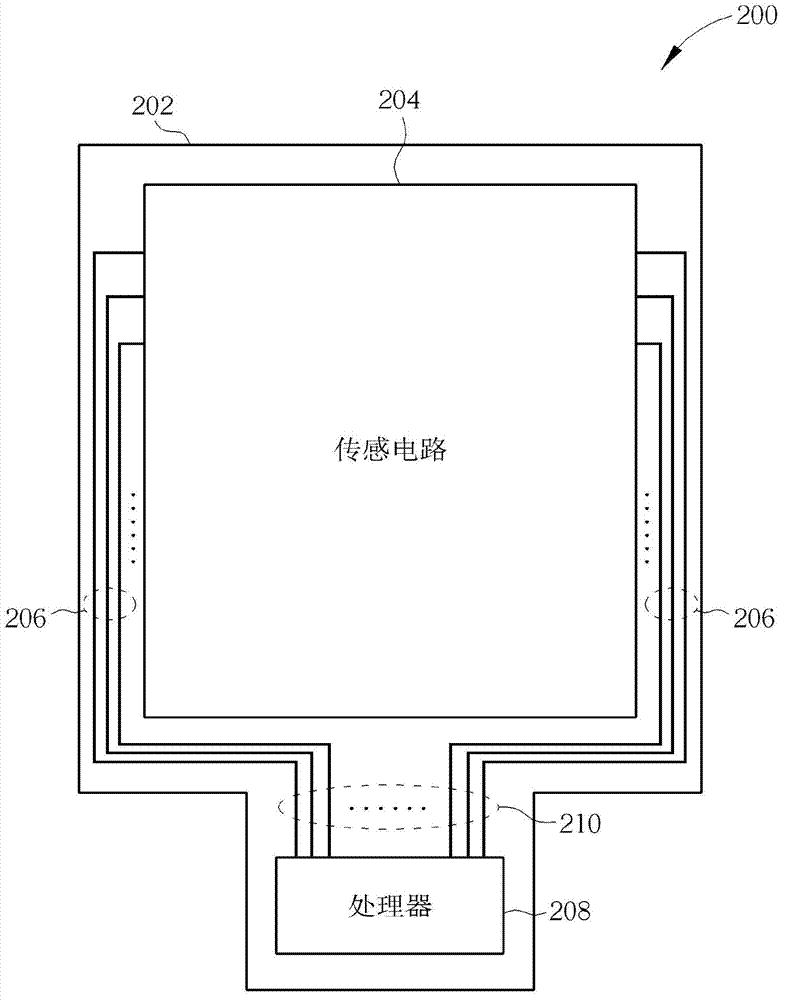

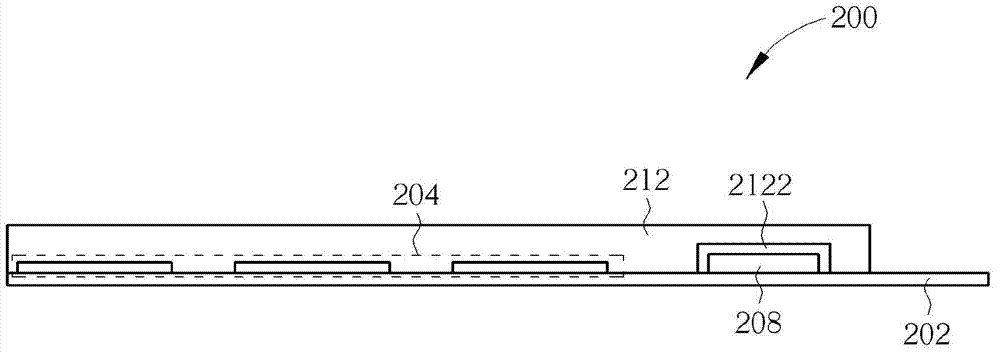

[0027] An embodiment of the present invention provides a touch panel 200, wherein the touch panel 200 includes an adhesive film 202 and a protective glass 212, and the adhesive film 202 can be polyethylene terephthalate (PET) Film or polyethylene naphthalate (polyethylene naphthalate, PEN) film. But the present invention is not limited to the film 202 being a polyethylene terephthalate film or a polyethylene naphthalate film. That is, the adhesive film 202 can be other optically transparent adhesive molds. Please refer to figure 2 , figure 2 is a schematic diagram for explaining the adhesive film 202 . Such as figure 2 As shown, the sensing unit of the sensing circuit 204 , the first wire 206 coupled to the sensing circuit 204 , and the second wire 210 coupled between the first wire 206 and the processor 208 are formed on the adhesive film 202 . The sensing unit of the sensing circuit 204 , the first wire 206 and the second wire 210 can be formed on the adhesive film 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com