Molding technology and equipment for container top panels

A molding process and molding equipment technology, which is applied in the field of container roof molding technology and equipment, can solve the problems of high labor intensity, low equipment utilization rate, and low production efficiency, so as to reduce the requirement of raw material width, improve production efficiency, and improve production efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

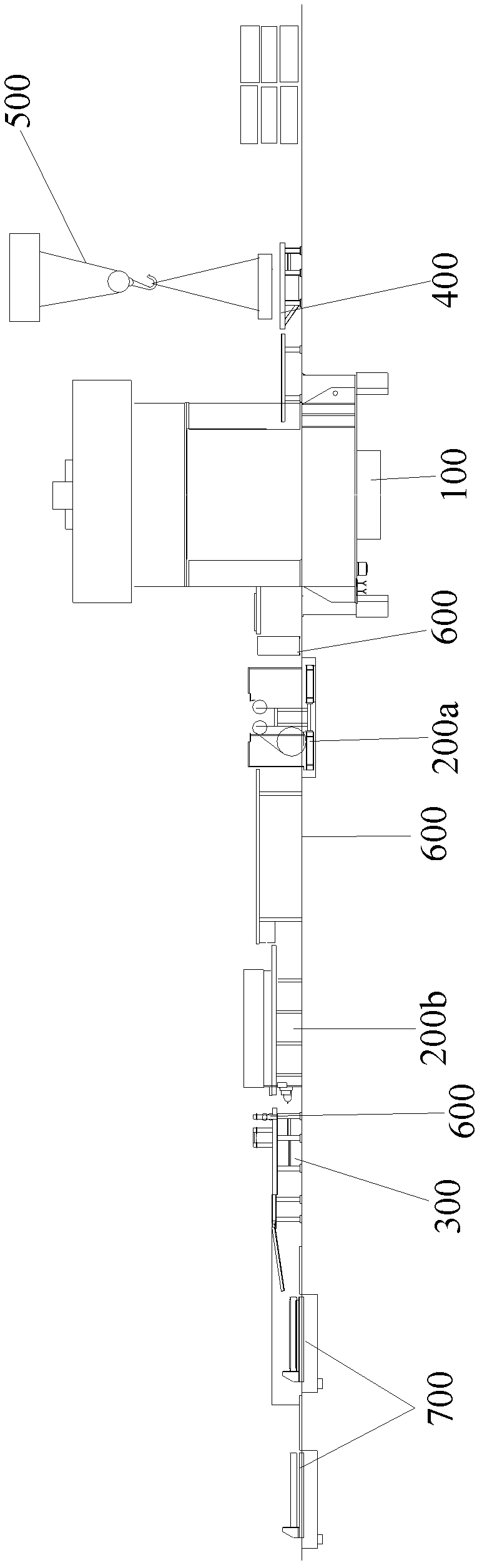

[0031] refer to figure 1 , is a schematic diagram of a steel plate stamping production line in Embodiment 1 of the container roof forming process provided by the present invention. As shown in the figure, the production line equipment is as follows: a pressing machine 100, an edge trimming machine 200a, an edge trimming machine 200b, and a shaping machine 300 arranged successively from right to left are used to press steel plates on the pressing machine 100, the edge trimming machine 200a, the trimming machine 200b and the automatic transport device 400 shifted between the trimming machine 300, the above equipments work in an orderly manner under the control of a control system (not shown in the figure).

[0032] In this embodiment, the forming machine 100 is provided with a forming die (not specifically shown in the figure) capable of forming at least two bosses on the steel plate at one time. The molding die specifically includes an upper mold base and a lower mold base, wh...

Embodiment 2

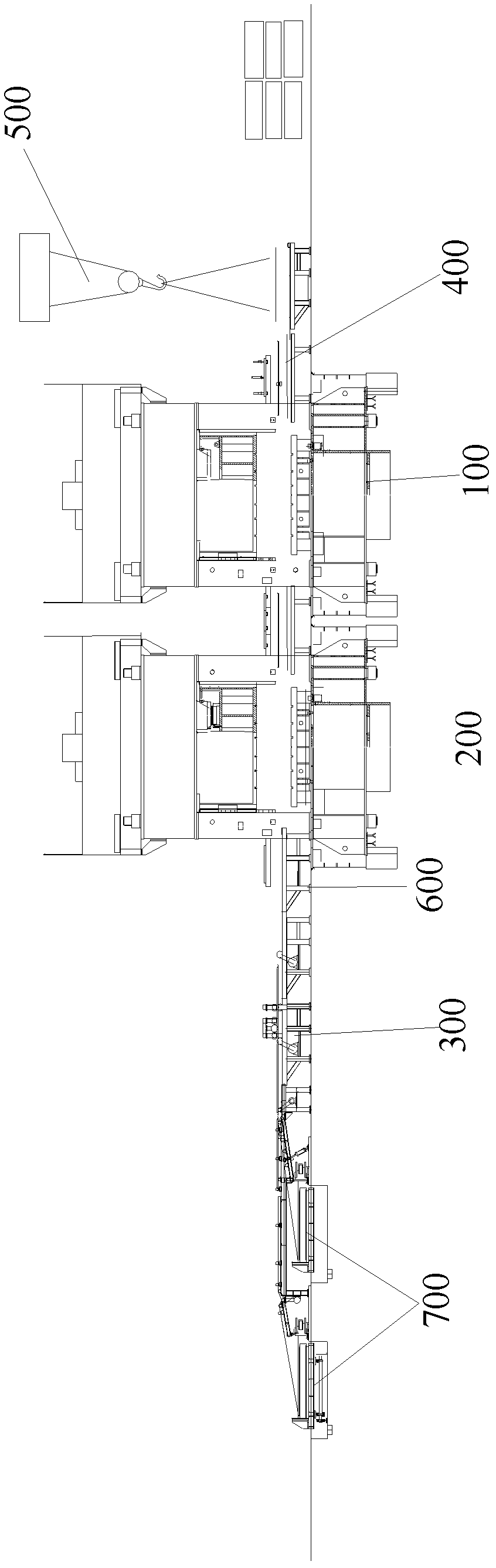

[0040] refer to figure 2 , shows the second embodiment of the container roof molding process. This embodiment and figure 1 The forming process in the first embodiment is basically the same, the difference is that the trimming die provided on the trimming machine 200 is a punching die or a blanking die, and the four sides of the steel plate can be trimmed simultaneously by corresponding program control. Using this trimming machine 200 to trim the steel plate has higher efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com