Display device and color film substrate and manufacturing method thereof

A technology of color film substrate and manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., and can solve the problems of wide black matrix width, side light leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

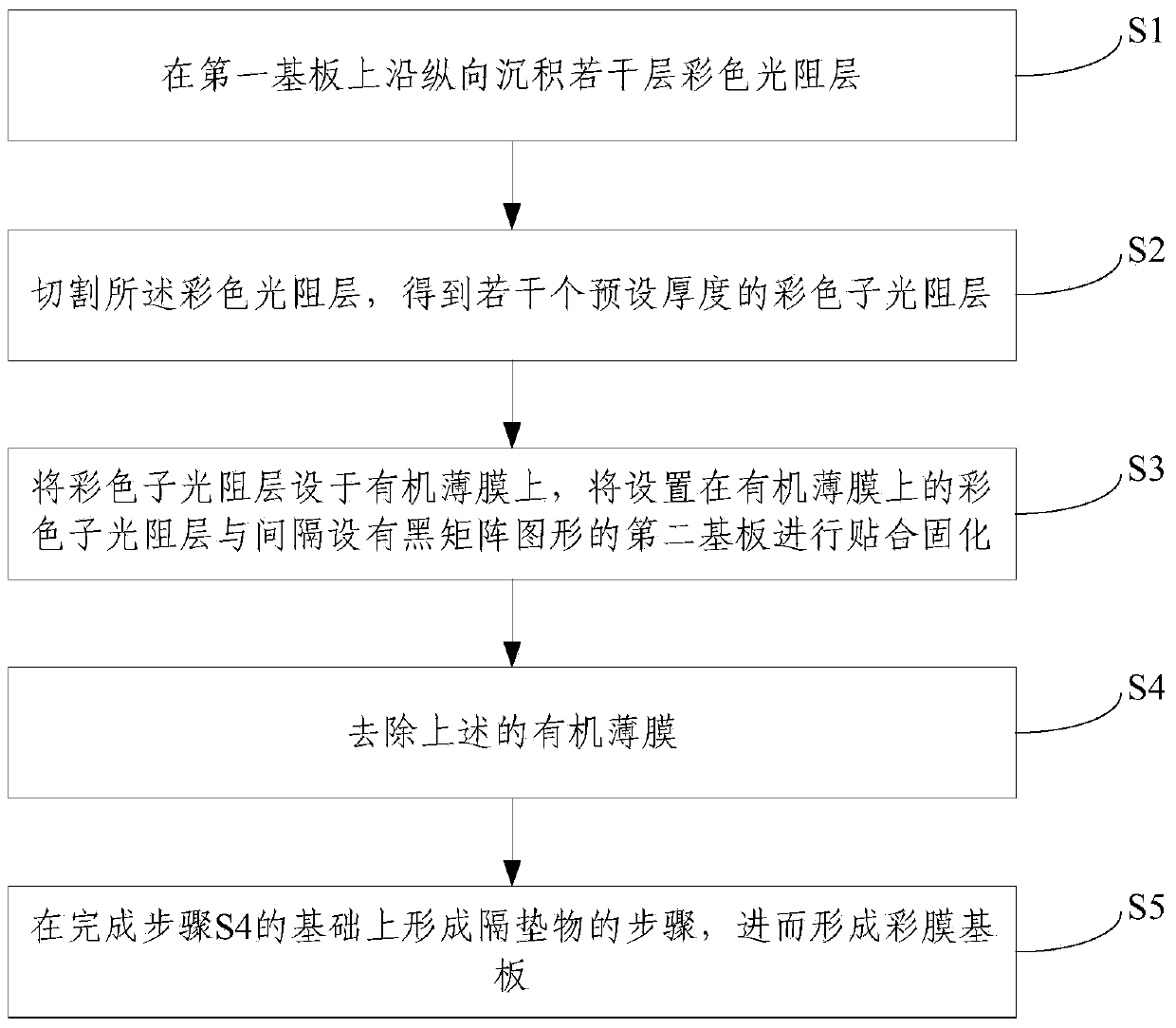

[0035] like Figure 2~3 As shown, the present invention provides a method for manufacturing a color filter substrate, which includes the following steps:

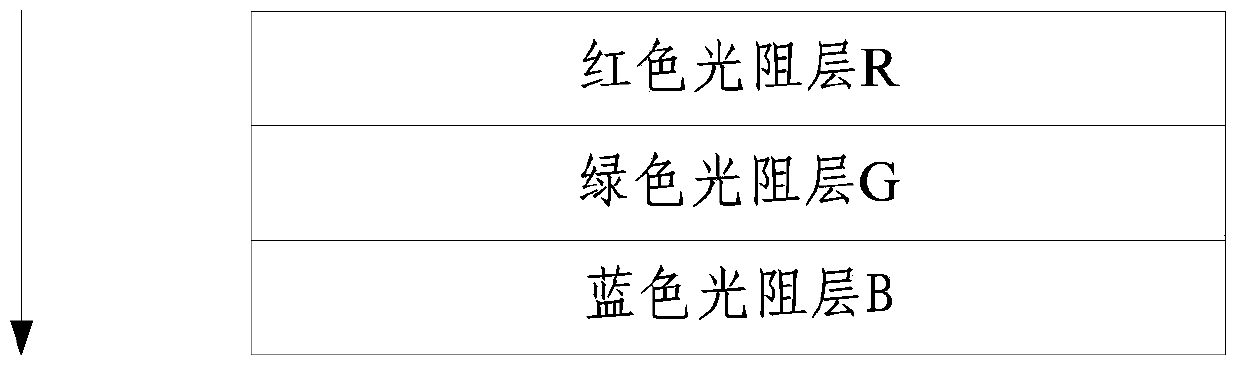

[0036] Step S1, depositing several layers of color photoresist layers on the first substrate 1 along the longitudinal direction;

[0037] Specifically, in this step, the color photoresist layer at least includes a red photoresist layer R, a green photoresist layer G and a blue photoresist layer B. The red photoresist layer R, the green photoresist layer G and the blue photoresist layer B are respectively deposited on the first substrate 1 (such as glass) along the longitudinal direction (in the direction of the arrow), and the deposition order of the colors of the color photoresist layers is not specified. limited.

[0038] In actual production, the photoresist layer can be made of resin material.

[0039] In addition, the thickness of each film layer can be made according to the required pixel size. For example, if the ...

Embodiment 2

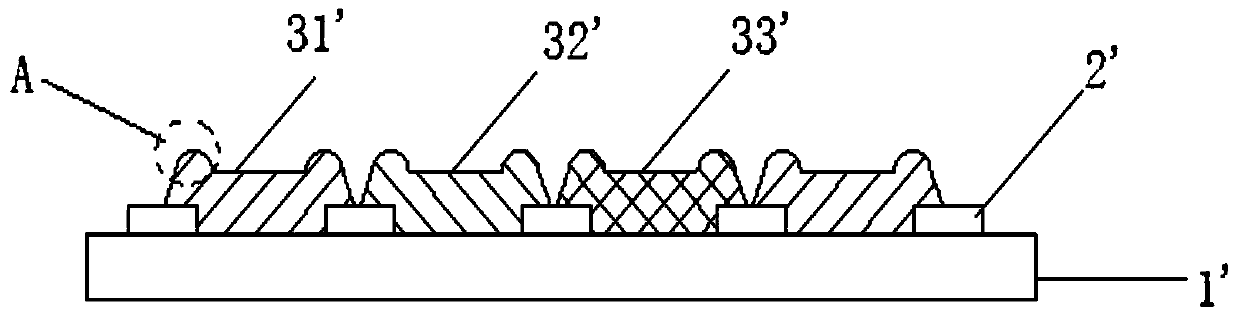

[0053] like Figure 5 As shown, the present invention also provides a color filter substrate, including: a first substrate 1, a color photoresist layer arranged laterally adjacent to the first substrate, and the color photoresist layer at least includes a red photoresist layer 2, Blue photoresist layer 3 and green photoresist layer 4;

[0054]The second substrate 8 is provided with a black matrix pattern 7, and the first substrate 1 and the second substrate 8 are bonded together. The black matrix 7 is located at the adjacent junction of the color photoresist layers of different colors. location.

[0055] With the color filter substrate of the above structure, there is no space between photoresist layers of different colors, and a black matrix is arranged on the color photoresist layer. Since the black matrix is located above the color photoresist layer, it can play a light-shielding effect on the one hand. On the other hand, the width of the black matrix can be reduced; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com