Quick conveying device for clothes hanger of garment hanging system

A hanger and hanging technology, which is applied in the field of speed delivery devices, can solve problems such as jamming and poor working stability of rail shifting devices, and achieve the effects of reducing quantity, simple structure and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

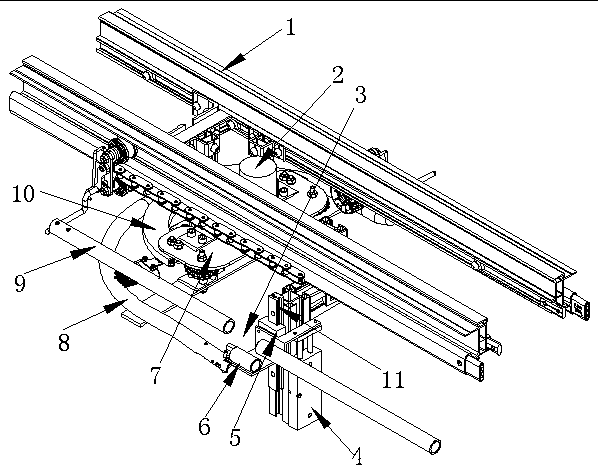

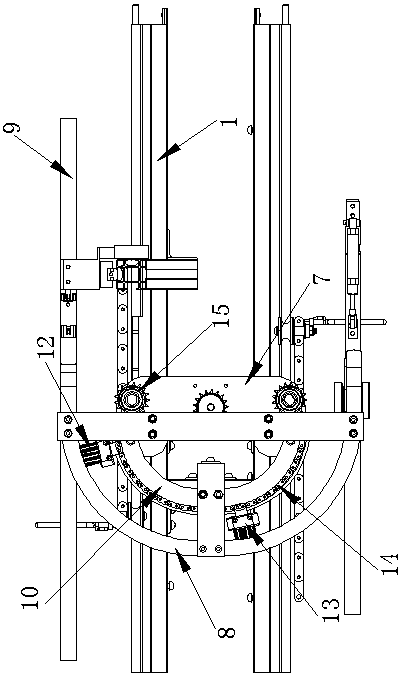

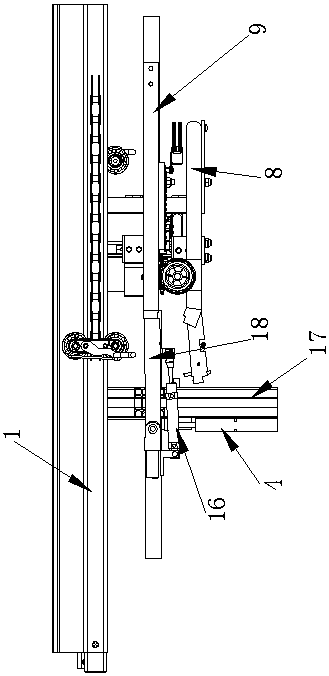

[0026] Combined with the accompanying drawings in the description, the clothes hanger express device of the garment hanging system is used to transfer the clothes hangers between the opposite sides of the ring rail 9, especially for transferring the clothes hangers between the opposite sides of the ring rail 9 in the width direction. transfer between. The opposite two sides of the ring rail 9 are respectively provided with an opening 3 and a partition, and the opening 3 and the partition are all formed by cutting off a section of the ring rail 9 . The lower side of the ring rail 9 is provided with a curved rail 8 along the horizontal direction, and the upper side of the curved rail 8 is provided with a driving mechanism, and the driving mechanism is adapted to the direction of the curved rail 8 . The driving mechanism is provided with some driving parts. Driven by the driving mechanism, these driving parts drive the clothes hanger on the curved rail 8 from the inlet end to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com