Lateral taping mechanism of full automatic edge bander

An edge banding machine, fully automatic technology, applied in book binding, book case for binding, printing, etc. It can solve the problems that the raised edges cannot be rolled at the same time, the production efficiency is low, and it is difficult to realize the folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

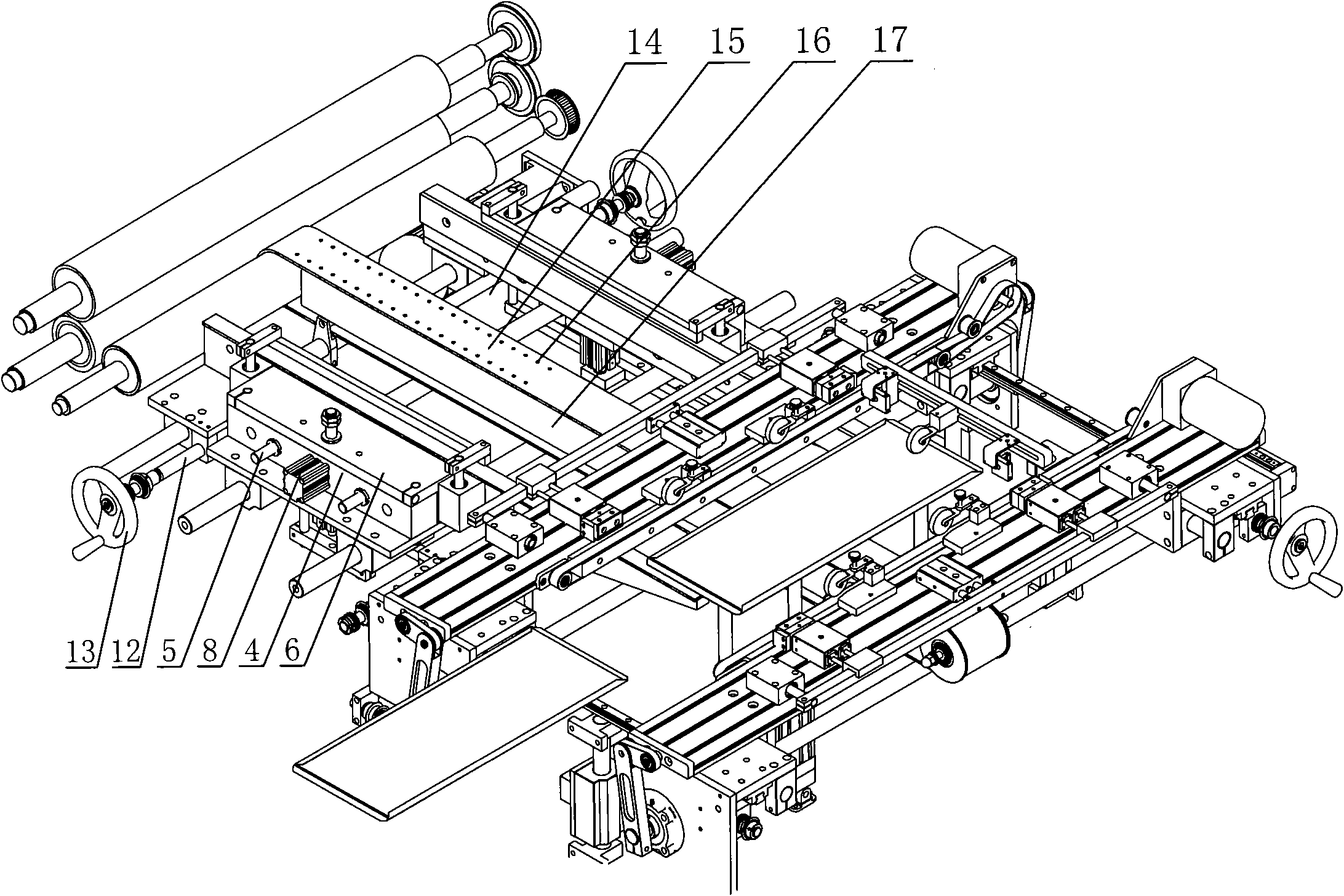

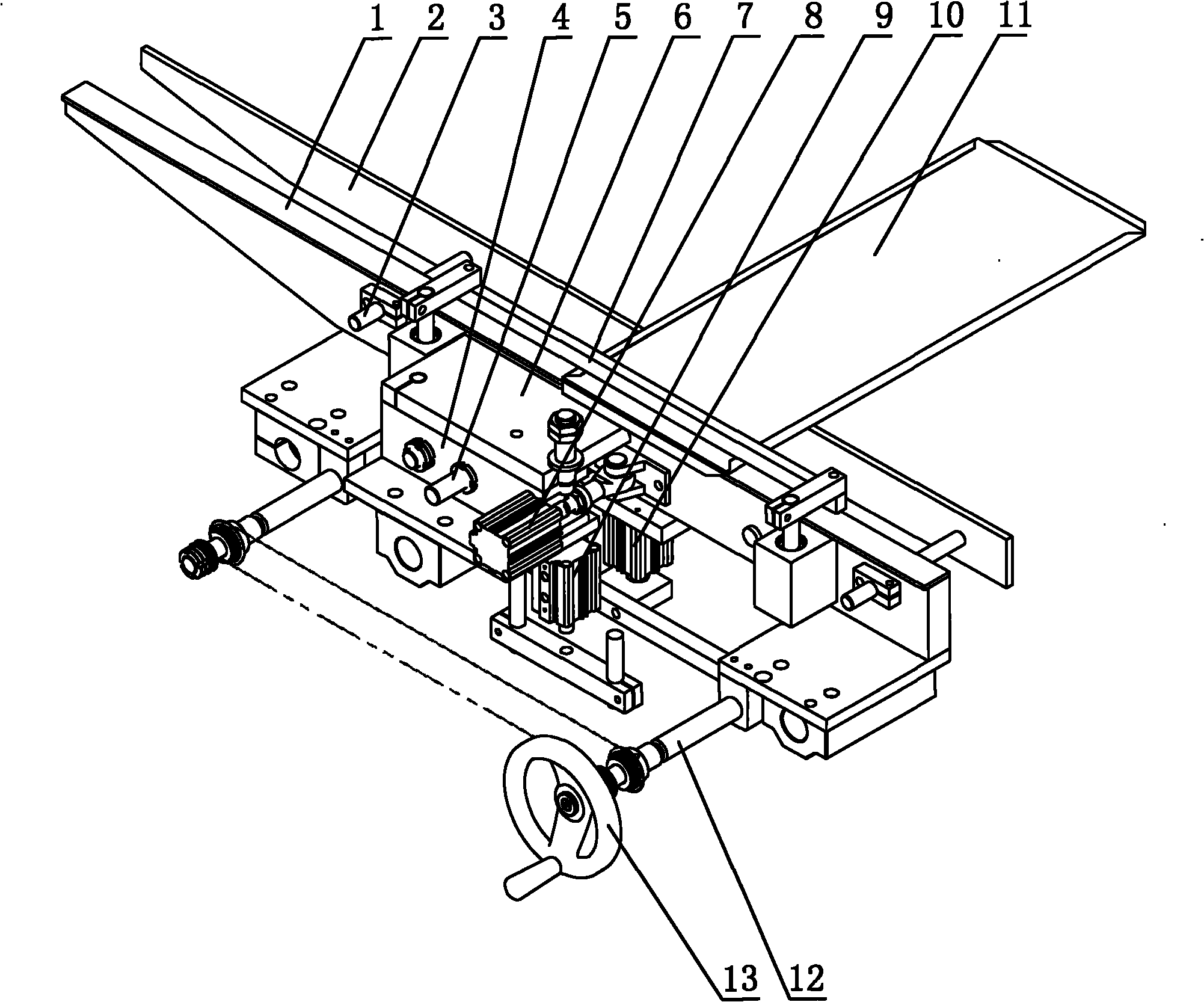

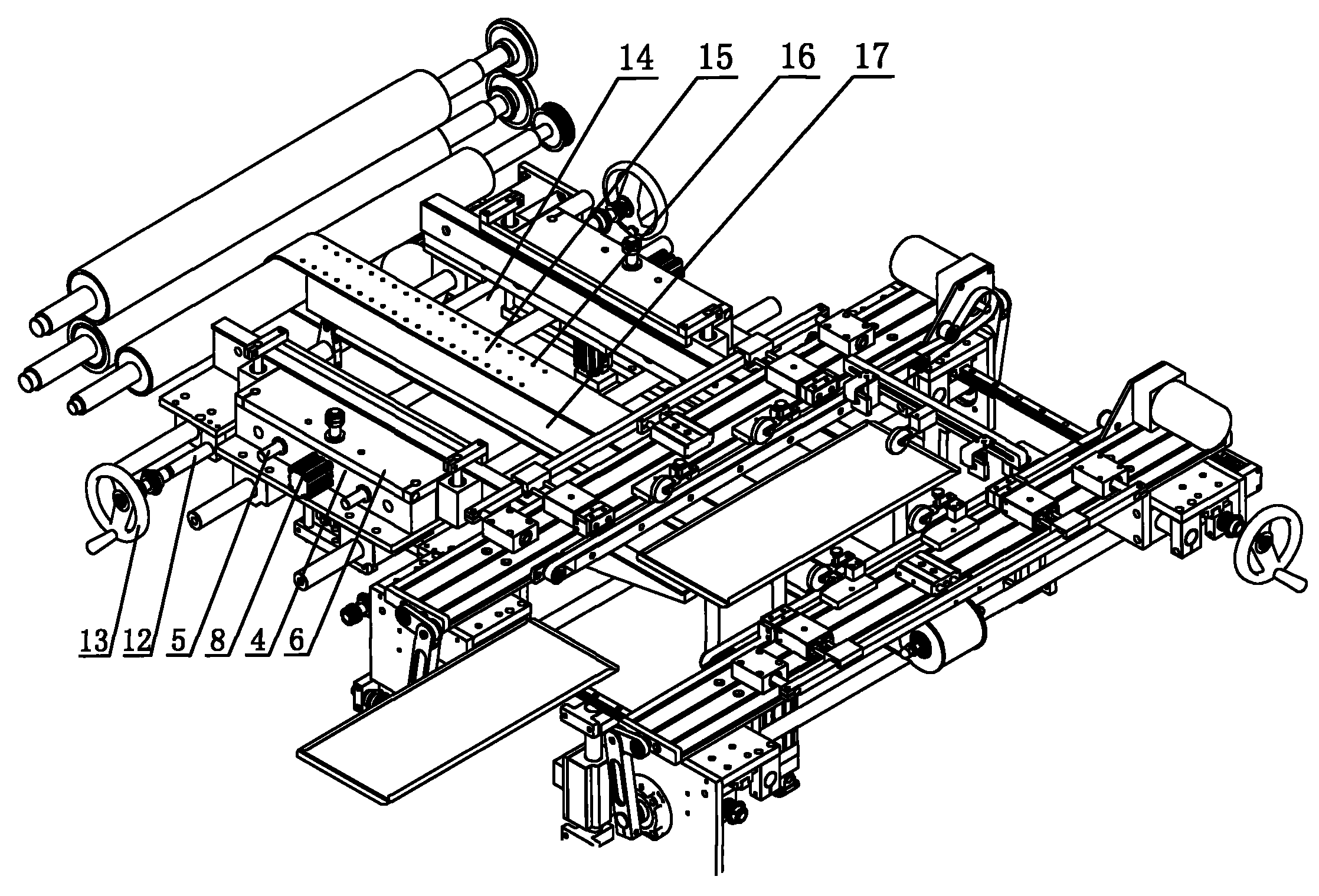

[0013] Referring to the accompanying drawings, the horizontal hemming mechanism of this kind of fully automatic edge banding machine has a frame on which a conveying platform 14, a flanging device and a positioning beam 7 are arranged, and the conveying platform 14 includes a moving plate 1 , supporting plate 1 and suction belt 15, described suction belt 15 is provided with air hole 16, and described air hole 16 is connected with vacuum bellows 17, and described mobile plate 1 is arranged on the both sides of supporting plate 2, and both are formed by The connecting rod 3 is connected, and the user can adjust the position of the supporting plate 2 by moving the connecting rod 3. When the cardboard 11 is too long, the supporting plate 2 can be used to support the cardboard, so as to prevent the cardboard from sinking due to being too long. The positioning beam 7 and the flanging device are all installed on the moving plate 1, and the moving plate 1 can move on the frame through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com