Method of preparing container roof plate

A manufacturing method and container technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, feeding devices, etc., can solve the problems of scattered production equipment layout, low equipment utilization rate, large workshop area, etc., to achieve automatic production and improve Production efficiency and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

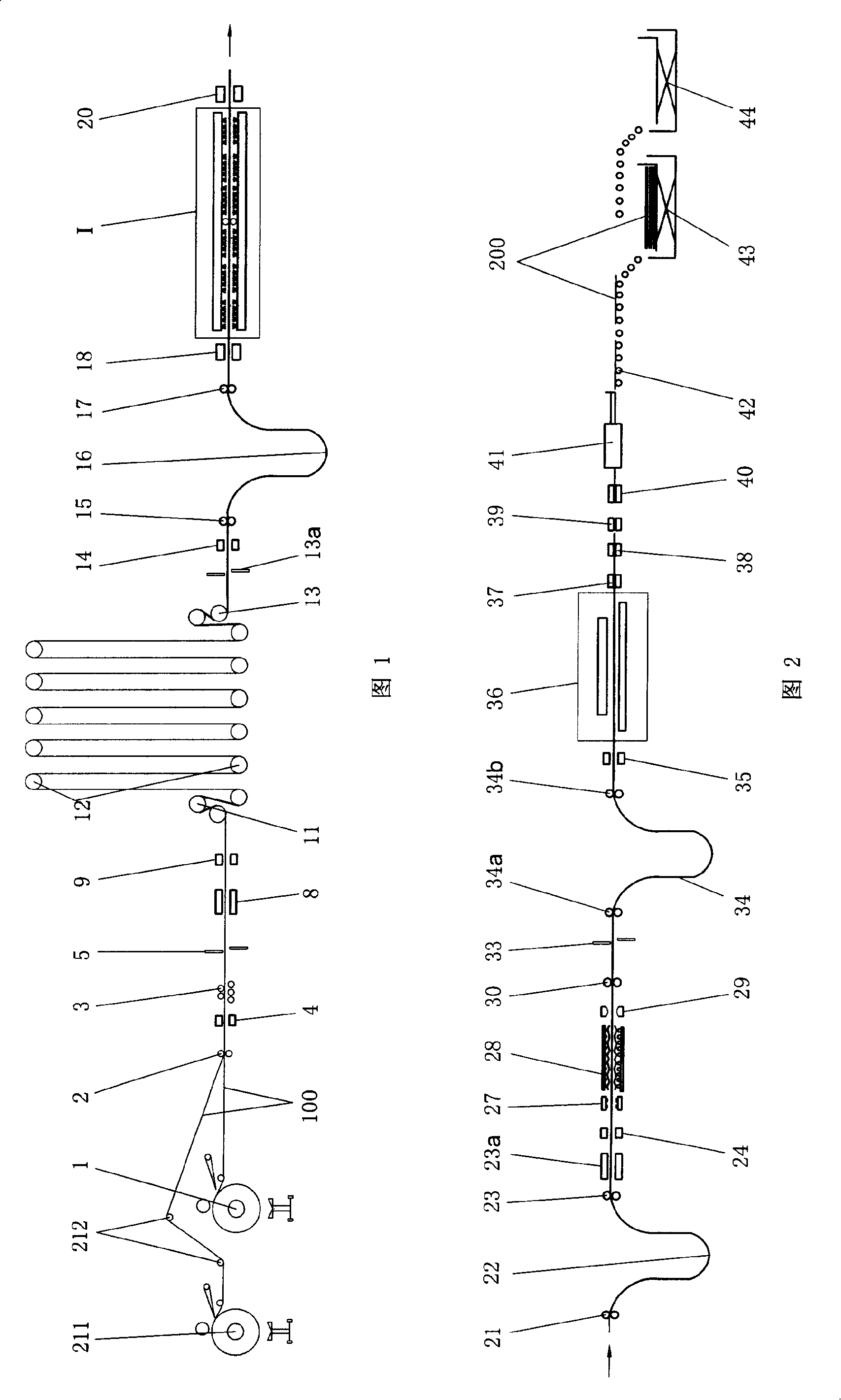

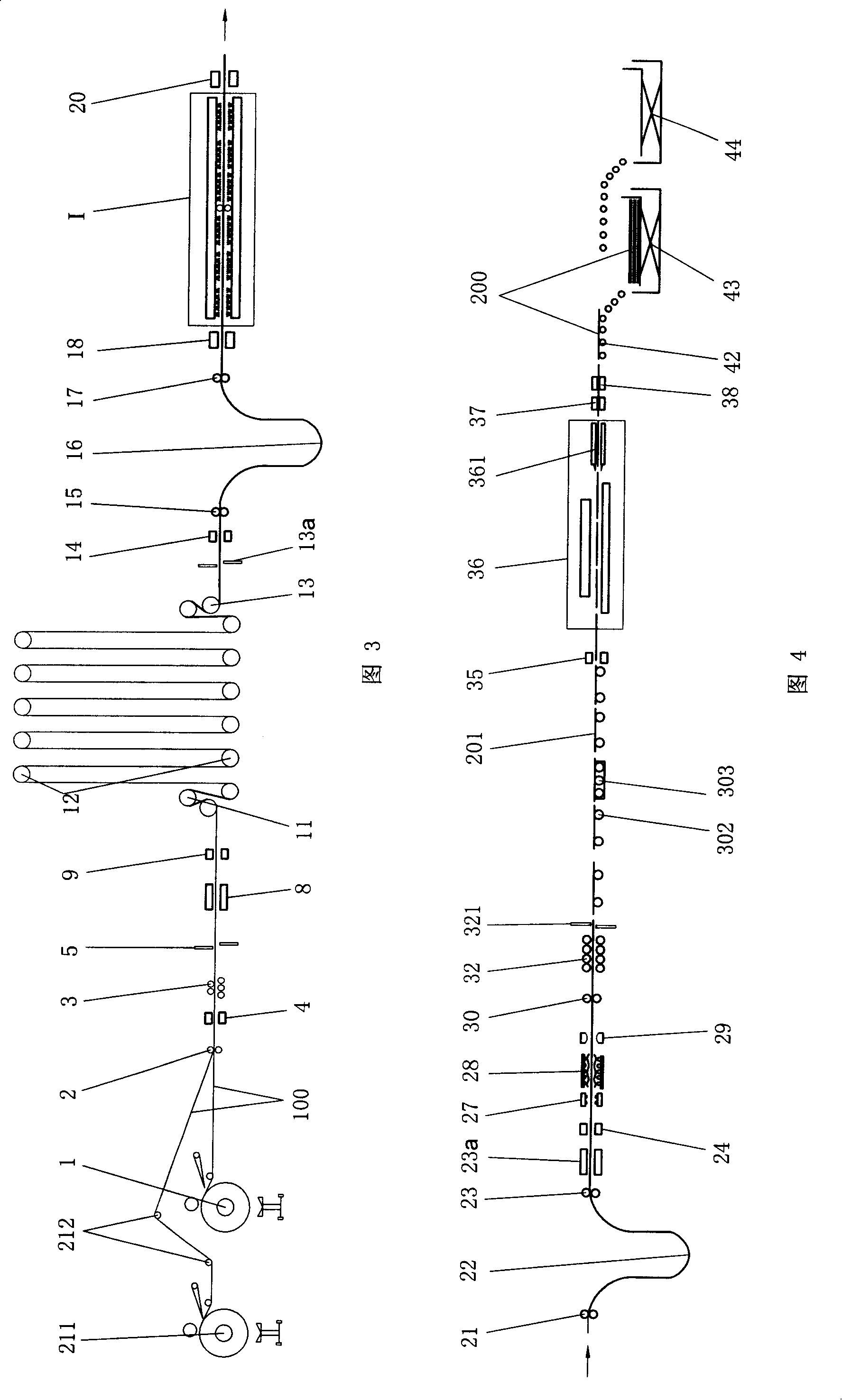

[0060] Fig. 1 and Fig. 2 show the schematic diagram of the production line of Embodiment 1 of the manufacturing method of the container roof according to the present invention. As shown in Figure 1 and Figure 2, the production line equipment of this embodiment is arranged as follows:

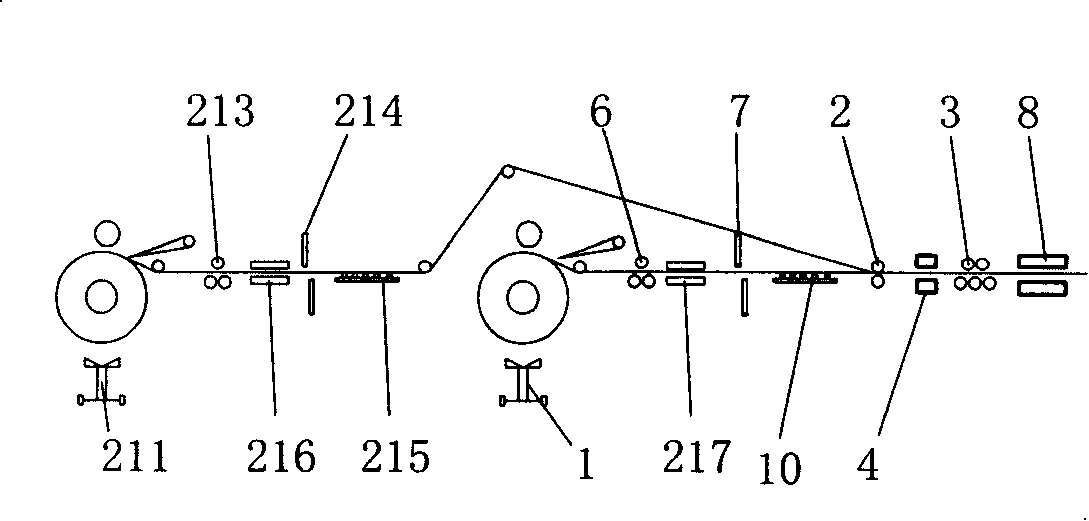

[0061] Two sets of uncoiling equipment and one set of leveling equipment are used for coil uncoiling and leveling. The two sets of uncoiling equipment are arranged successively along the steel plate conveying direction. The leveling equipment is a steel plate leveler 3 arranged behind the uncoiler 1 . The continuous steel plate 100 output by the subsequent uncoiler 211 is guided by a steel plate guiding device 212 (guide rollers, guide wheels, etc. can be used).

[0062] Before the steel plate leveling machine 3, a pinch roller 2 and a plate centering device 4 are arranged to feed and center the continuous steel plate 100. Behind the steel plate leveling machine 3, a steel plate shearing devic...

Embodiment 2

[0107] Fig. 3 and Fig. 4 show the schematic diagrams of the production line of Embodiment 2 of the manufacturing method of the container roof of the present invention. As shown in Fig. 3 and Fig. 4, the equipment layout and functions of the production line of this embodiment are generally the same as those of the embodiment, the difference is that after the pinch roller 30, a sheet material positioning and shearing device 321 (such as a positioning shearing machine) is arranged successively or other sheet material positioning and cutting equipment), sheet material conveying device 302 (such as conveying roller table, belt conveying device, etc.), sheet material conveying device 302 includes driving roller 303, and sheet material conveying device 302 conveys the sheet material 201 after cutting Before the roll forming equipment 36 , a sheet material centering device 35 is provided in front of the press forming equipment 36 to ensure that the sheet material 201 is centered and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com