On-line monitoring system and method for suspension steel wire rope for hoisting container

A monitoring system and wire rope technology are applied in the field of on-line monitoring systems for hoisting container suspension wire ropes, which can solve the problems of high energy loss, large interference, and difficulty in monitoring suspension wire ropes, and achieve the effects of good reliability, safety, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

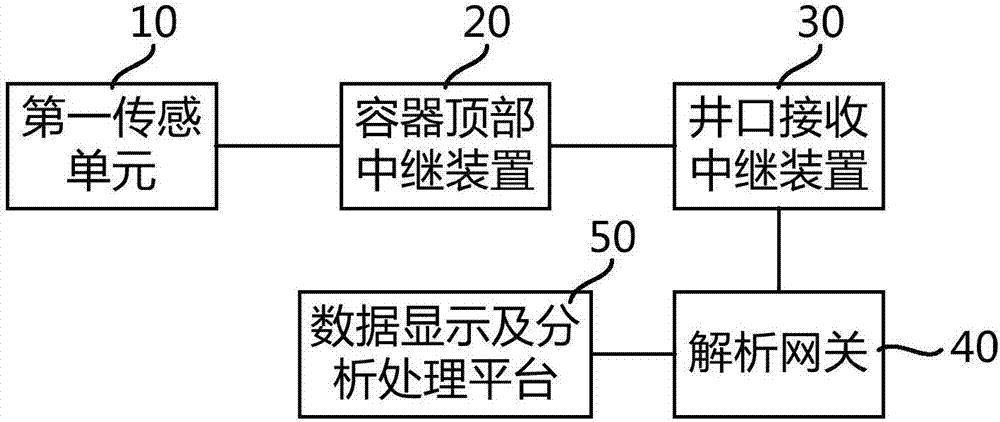

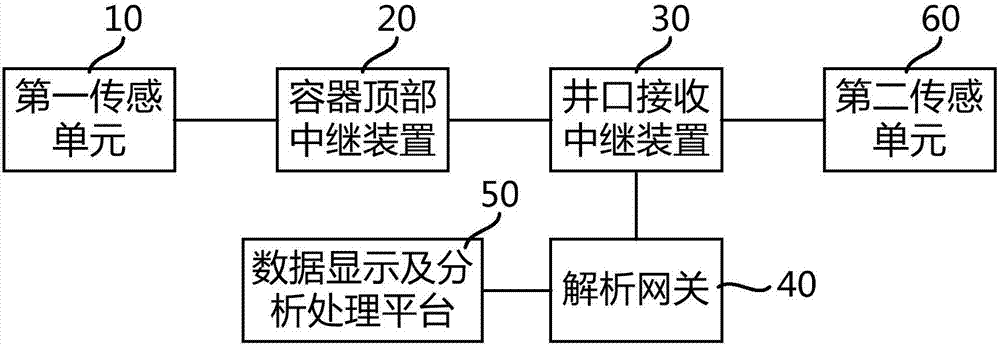

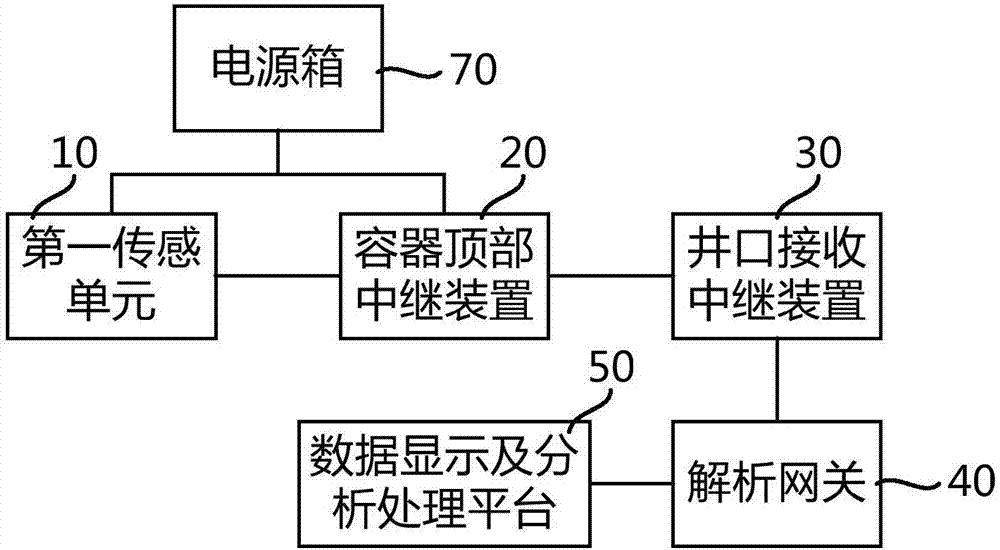

[0070] Such as figure 1 As shown, it is a principle schematic diagram of an embodiment of the online monitoring system for the suspension steel wire rope of the hoisting container of the present invention. combine Figure 4-6 As shown in the layout schematic diagram, the online monitoring system for the suspension steel wire rope of the lifting container in this embodiment includes: a first sensing unit 10, a container top relay device 20, a wellhead receiving relay device 30, an analysis gateway 40, and a data display and analysis processing platform 50.

[0071] The first sensing unit 10 is used for real-time acquisition of a first state parameter that can characterize the suspension wire rope 3 . Wherein, the first sensing unit 10 may include a plurality of oil pressure sensors 11, which are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com