Working method of airborne occupant multi-stage airbag cooperative buffer seat

A working method and airbag technology, applied in vehicle seats, special positions of vehicles, transportation and packaging, etc., can solve the problems of secondary collision between human body and combat vehicle, slow exhausting speed, damage to airborne occupants, etc. Simple operation, simple structure and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

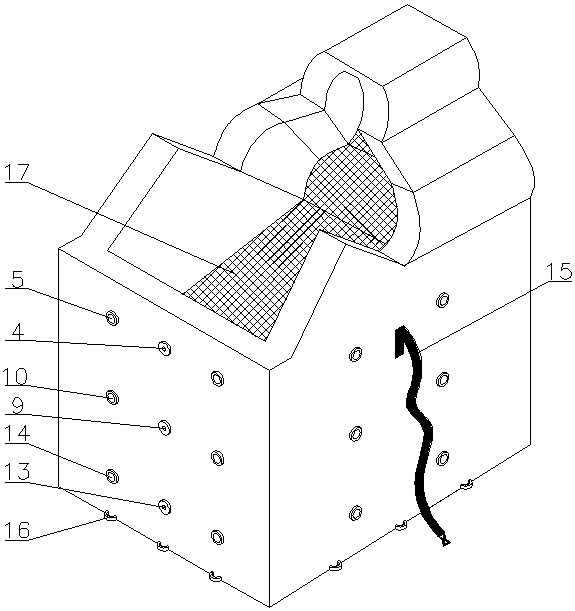

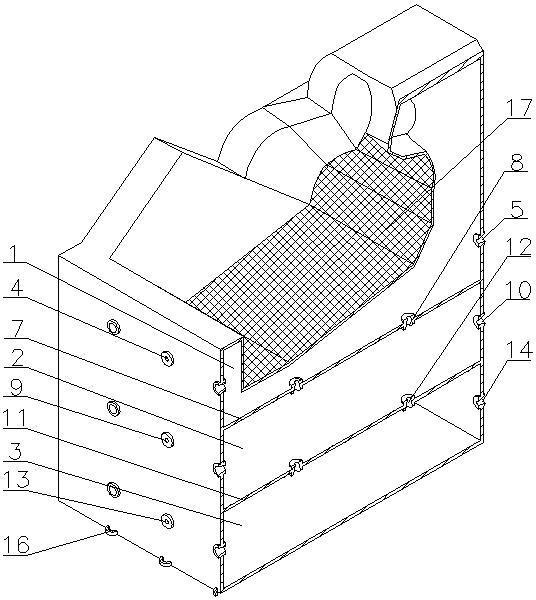

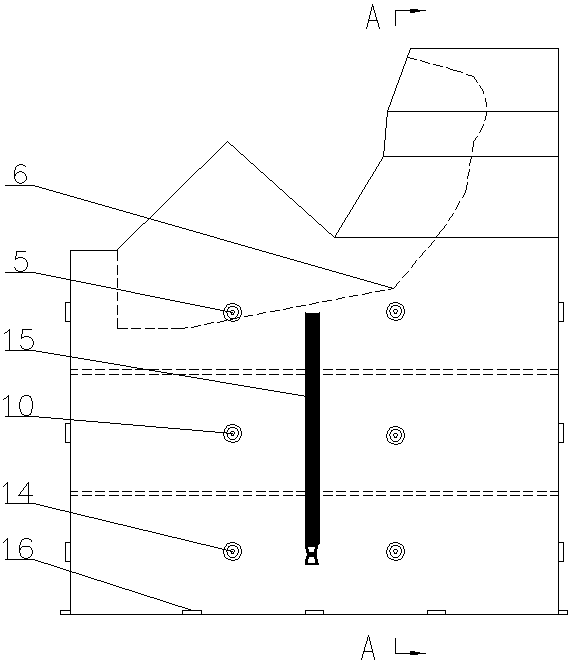

[0032] As shown in the figure: a working method of a multi-stage airbag cooperative cushioning seat for airborne occupants. The multistage airbag cooperative cushioning seat includes an upper air chamber 1, a middle air chamber 2 and a lower air chamber 3; the upper air chamber 1. The middle air chamber 2 and the lower air chamber 3 are arranged in a superimposed manner from top to bottom; the upper air chamber 1 is provided with an upper air chamber recess 6 that matches the optimal landing posture of the airborne occupants; the surface of the upper air chamber 1 An upper air chamber inflation valve 4 is provided, eight upper air chamber exhaust valves 5 are provided on the surface of the upper air chamber 1, and an air chamber diaphragm 7 is arranged between the upper air chamber 1 and the middle air chamber 2. The air chamber diaphragm 7 There are four combined exhaust valves one 8.

[0033] As shown in the figure: the surface of the central air chamber 2 is provided with a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com