Stable construction device

A construction device and stable technology, applied in bridge form, shaft equipment, shaft lining and other directions, can solve the problems of inability to accommodate, construction efficiency or cost impact, stagnation, etc., to improve space utilization, convenient and efficient pouring, and enhance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

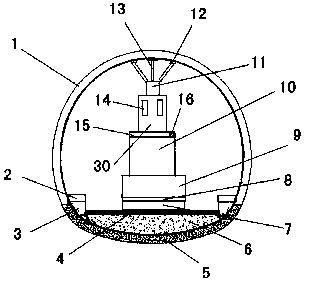

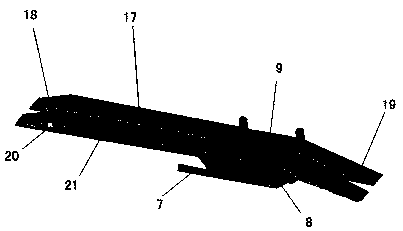

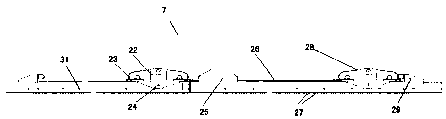

[0043] As shown in the figure: a stable construction device, including templates, driving devices, support blocks, connecting rods, walking systems, bases, main bridges, square platforms, support columns, workbenches, traction claws, traction rods, traction wheels, Retractable platform, retractable guardrail, front axle, slope, rear axle, traction rope bayonet, concrete slab; the base is provided with a front axle oil cylinder and a rear axle oil cylinder; wherein the walking system includes a track, a first bracket , rollers, track wheels, traction parts, chains, buffer pads, second brackets, limiters;

[0044] Wherein the bottom of the base is provided with supporting legs, and the supporting legs include a connecting frame, a mounting hole, a universal hinge, a foot, and a rubber pad; bolts pass through the mounting holes to connect the connecting frame to the base Above, the two ends of the connecting frame are respectively provided with a universal hinge, the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com