Glass tube conveying mechanism and full-automatic continuous tube-inserting machine using same

A glass tube and intubation machine technology, applied in glass forming, glass blowing, glass manufacturing equipment and other directions, can solve problems such as affecting production progress, high operator requirements, and danger, and improve product output and quality. , scientific and reasonable structural design, the effect of improving output and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

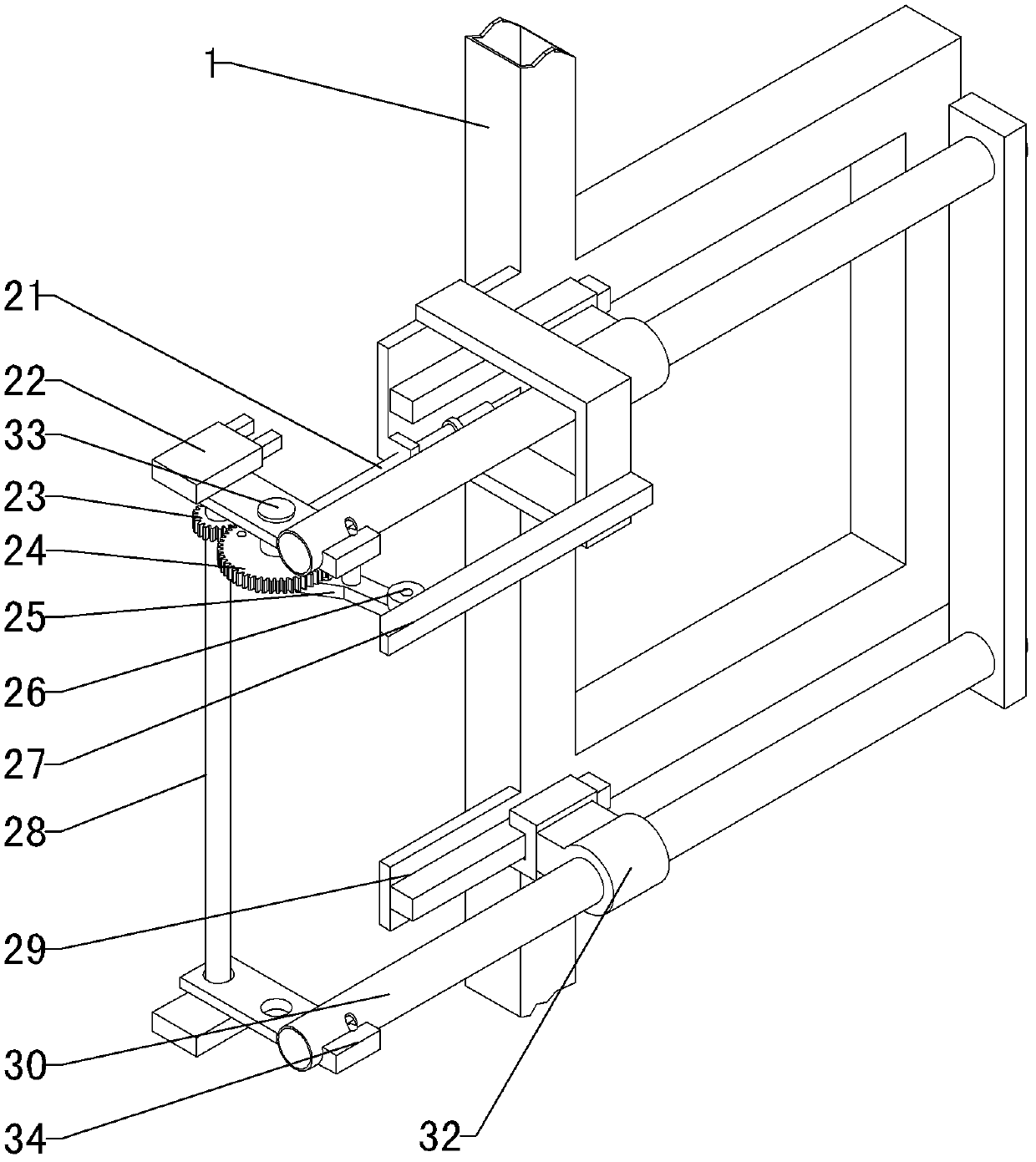

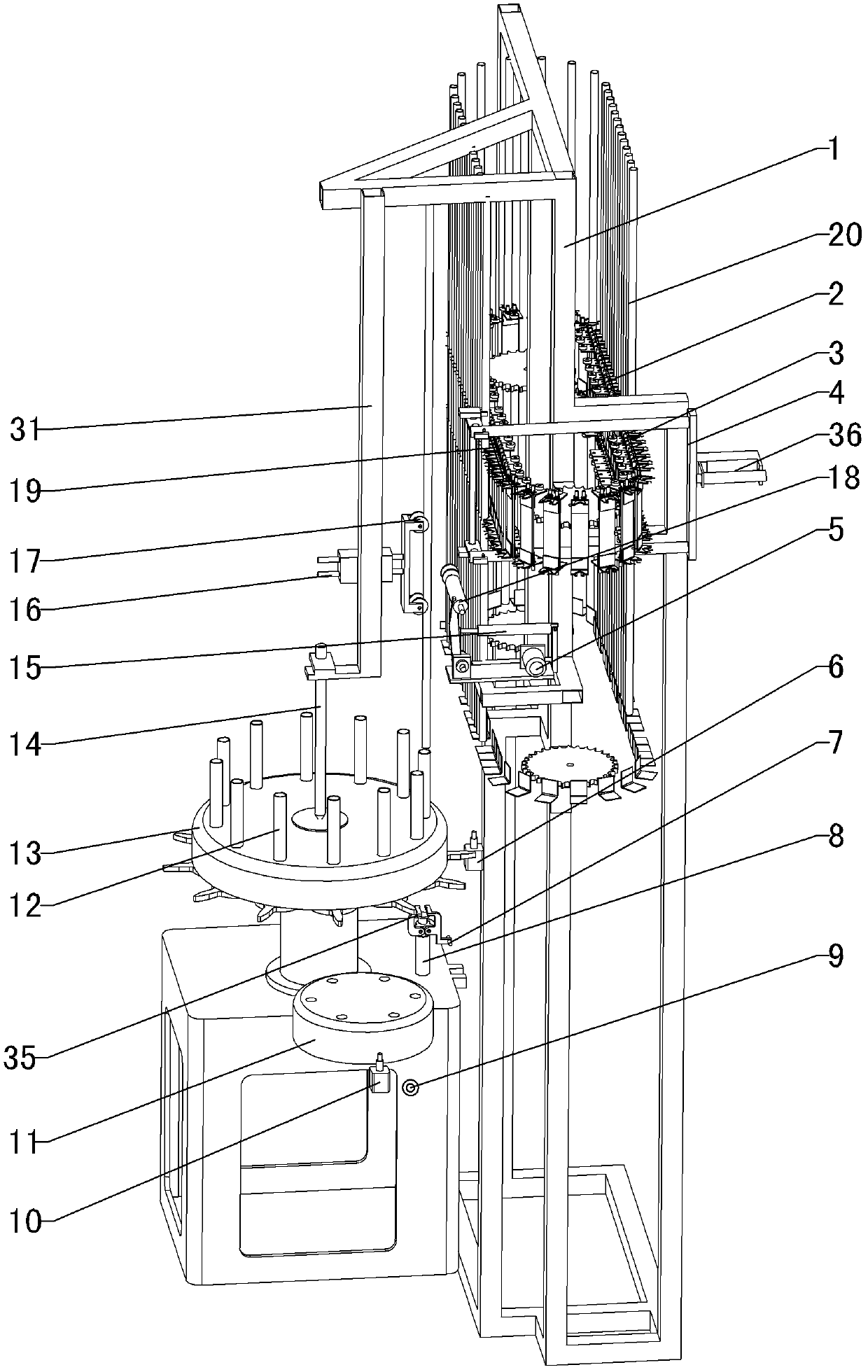

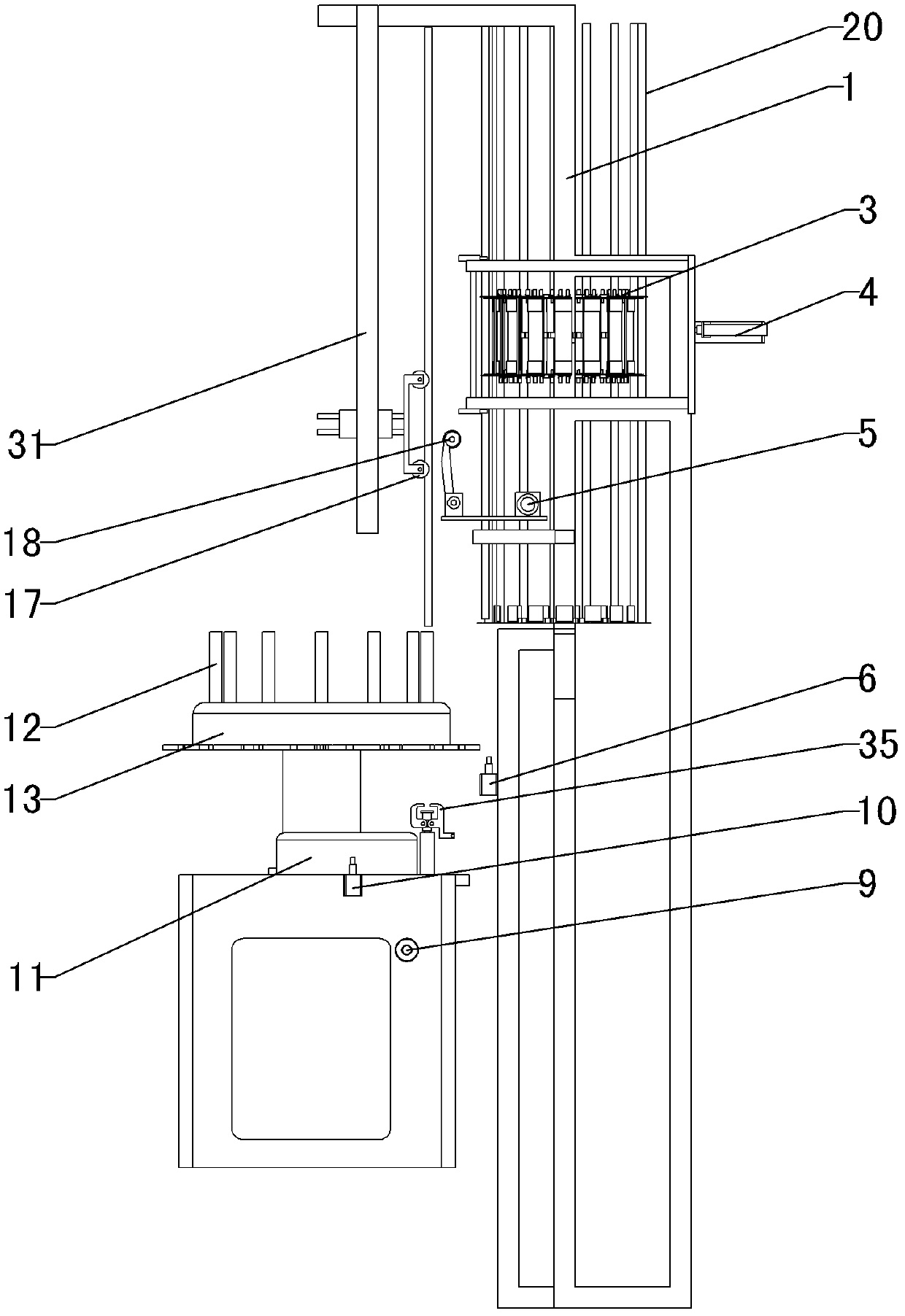

[0026] Refer to attached figure 1 :

[0027] This kind of glass tube feeding mechanism is a push rod brake rotation structure, including a push rod 30 that can move back and forth relative to the frame 1, an air claw rotating device and an air claw 22 that are movably connected to the front end of the push rod 30, and the push rod 30 is connected to the feeder. The tube cylinder 36 is connected, and is installed on the guide rail 29 of the frame 1 through the slider 32. The front end of the push rod 30 is provided with a connecting plate 34, and the connecting plate 34 is equipped with an air claw rotating device. The rotating shaft 28 passes through the installation of the connecting plate 34 front end. The hole is coupled with the air gripper 22 .

[0028] The air claw rotating device comprises a pinion 23 installed on the rotating shaft 28, a bull gear 24 meshed with the pinion 23, a stop lever 21, a rocking arm 25 and a cam bar 27 matched with the roller 26 at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com