A motor rotation positioning structure and kitchen waste disposer

一种定位结构、定位销的技术,应用在机械领域,能够解决落入厨余垃圾处理器的内部、弄脏厨余垃圾处理器、残渣无法全部落入等问题,达到落料准确、确保准确性、避免定位误差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

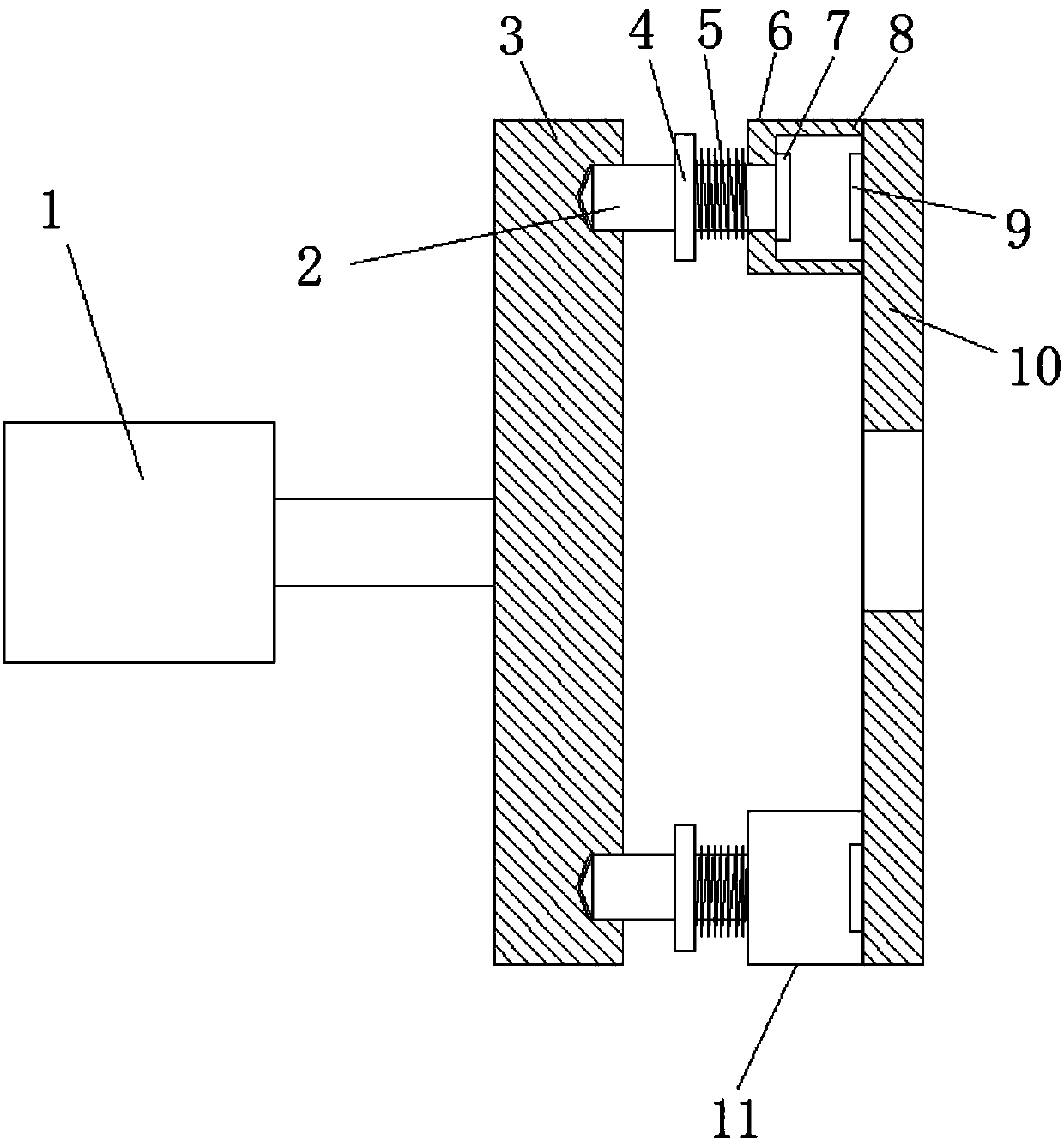

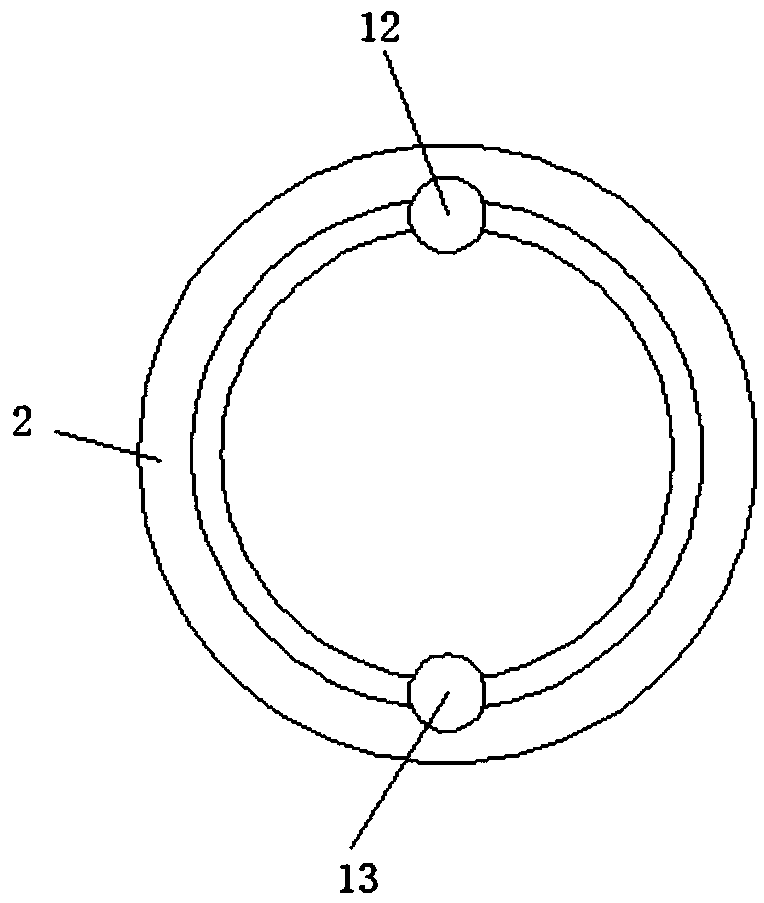

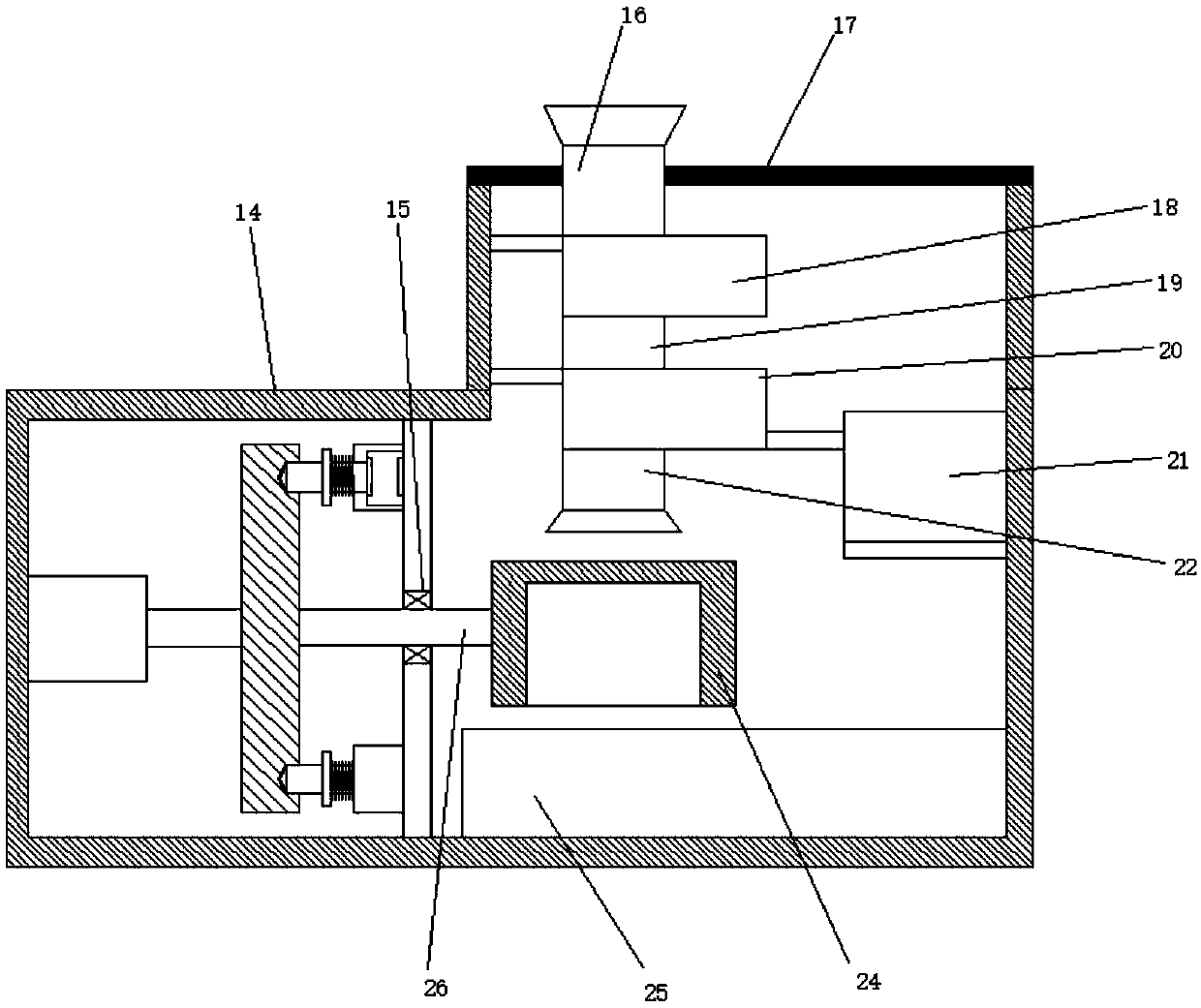

[0020] refer to Figure 1-3 , a motor rotation positioning structure, including a motor 1, a turntable 3, a first limit device 6, a second limit device 11 and a fixed plate 10, the end of the output shaft of the motor 1 is equipped with a turntable 3, and the output of the motor 1 The shaft is perpendicular to the surface of the turntable 3, and the side of the turntable 3 away from the motor is provided with an annular chute, and the cross section of the chute is tapered, and the bottom of the chute is provided with a symmetrical first positioning hole 12 and a second positioning hole 13. The side of the turntable 3 away from the motor is provided with a fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com