Patents

Literature

44results about How to "Improve shell breaking rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

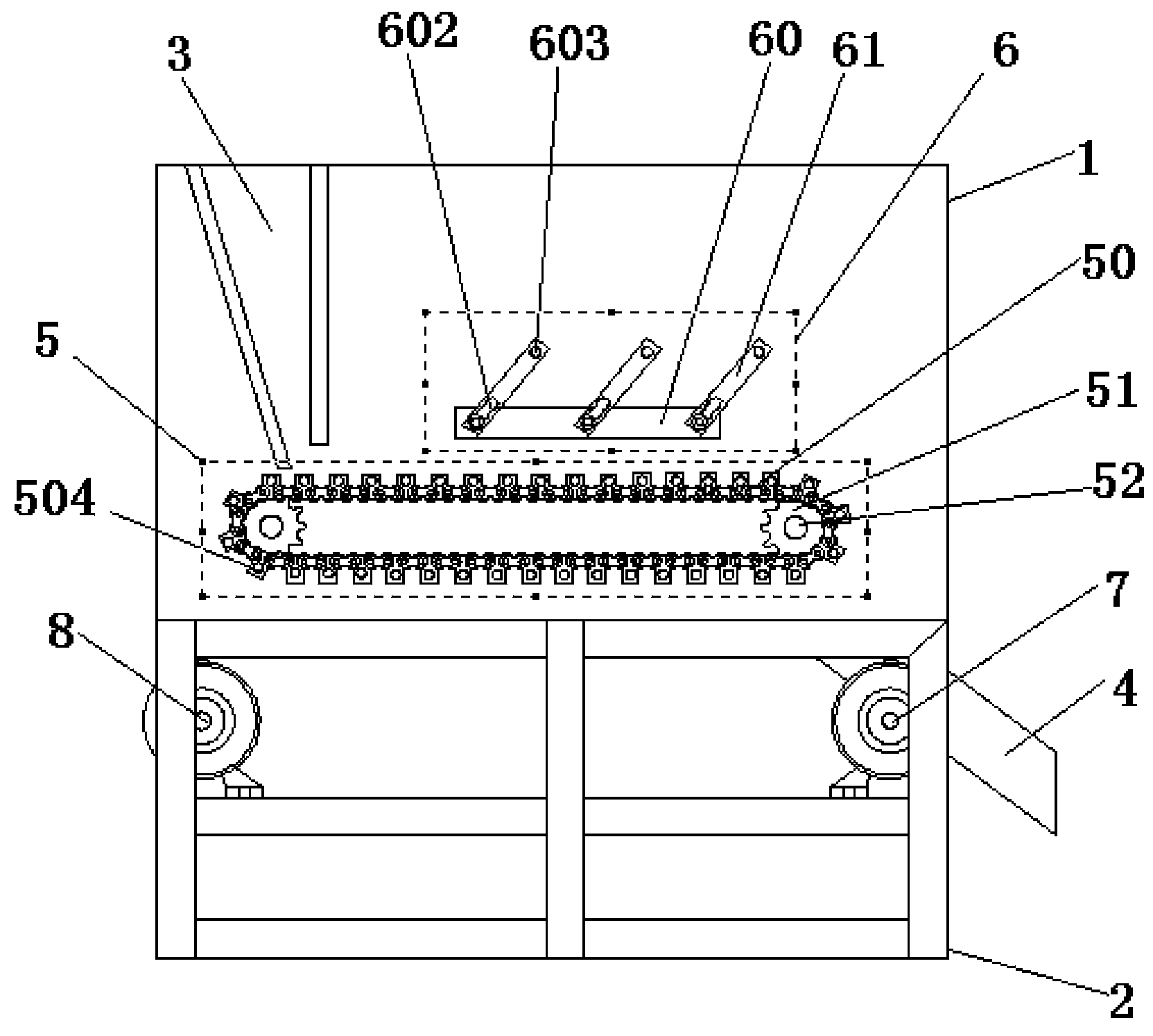

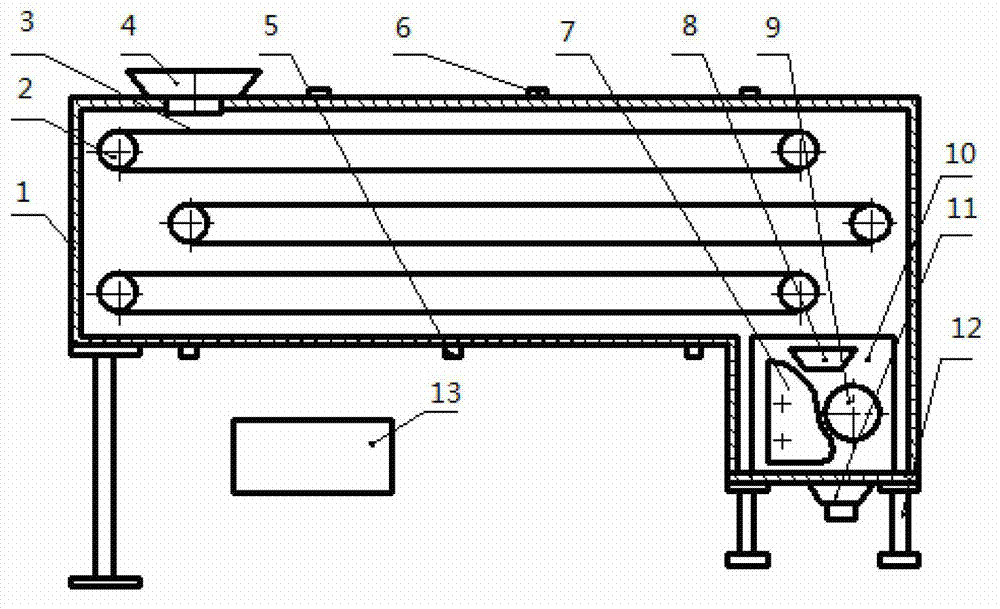

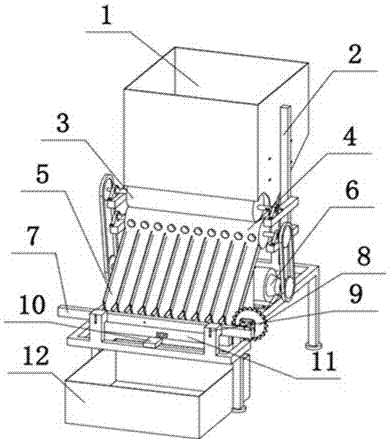

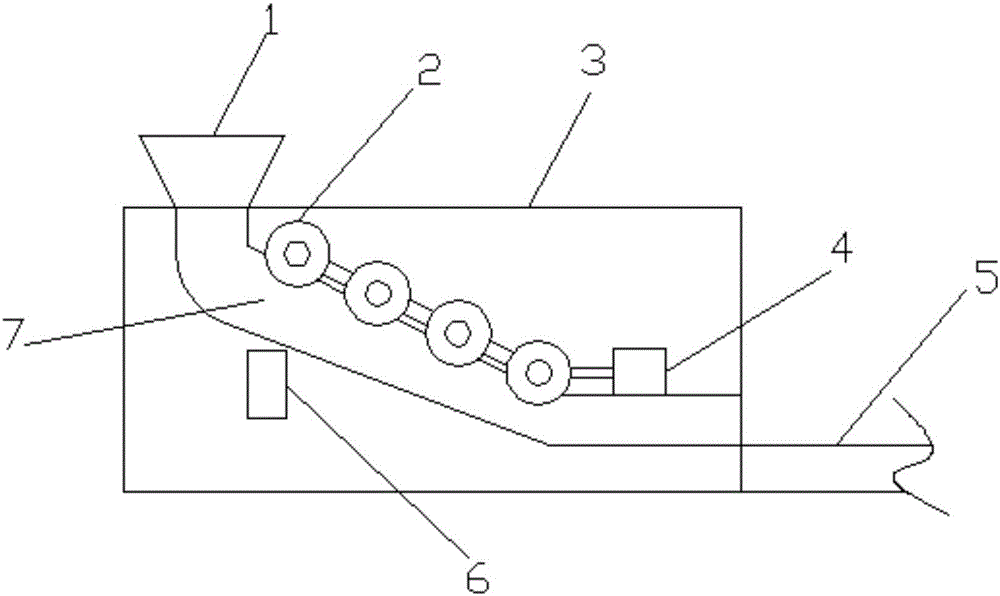

Extruding and rubbing type walnut shell breaking device

The invention provides an extruding and rubbing type walnut shell breaking device which comprises a box body and a rack. The box body is arranged on the rack. A feeding port is arranged on the top surface of one side of the box body. A discharging port is arranged on the bottom surface of the other side of the box body. A conveyer and a shell breaker are arranged inside the box body. The conveyer is located at a horizontal position between the feeding port and the discharging port and used for conveying walnuts which fall into the conveyer from the feeding port to the discharging port. The shell breaker is located above the conveyer and used for breaking shells of the walnuts conveyed by the conveyer. When the extruding and rubbing type walnut shell breaking device is used, the walnuts are placed into the feeding port, fall onto a conveying chain due to gravity, and rotate along with the conveying chain; the walnuts are extruded by a pressing plate and rubbed by rollers, so that it is guaranteed that the shells of the walnuts are completely broken. According to the extruding and rubbing type walnut shell breaking device, the distance between the pressing plate and the conveying chain can be adjusted according to the sizes of the walnuts, the walnuts are rubbed in the extrusion process so that the shells of the walnuts are completely broken, and therefore the extruding and rubbing type walnut shell breaking device has the advantages of being high in work efficiency, shell breaking rate and perfect kernel rate, low in cost and convenient to use.

Owner:SHAANXI UNIV OF SCI & TECH

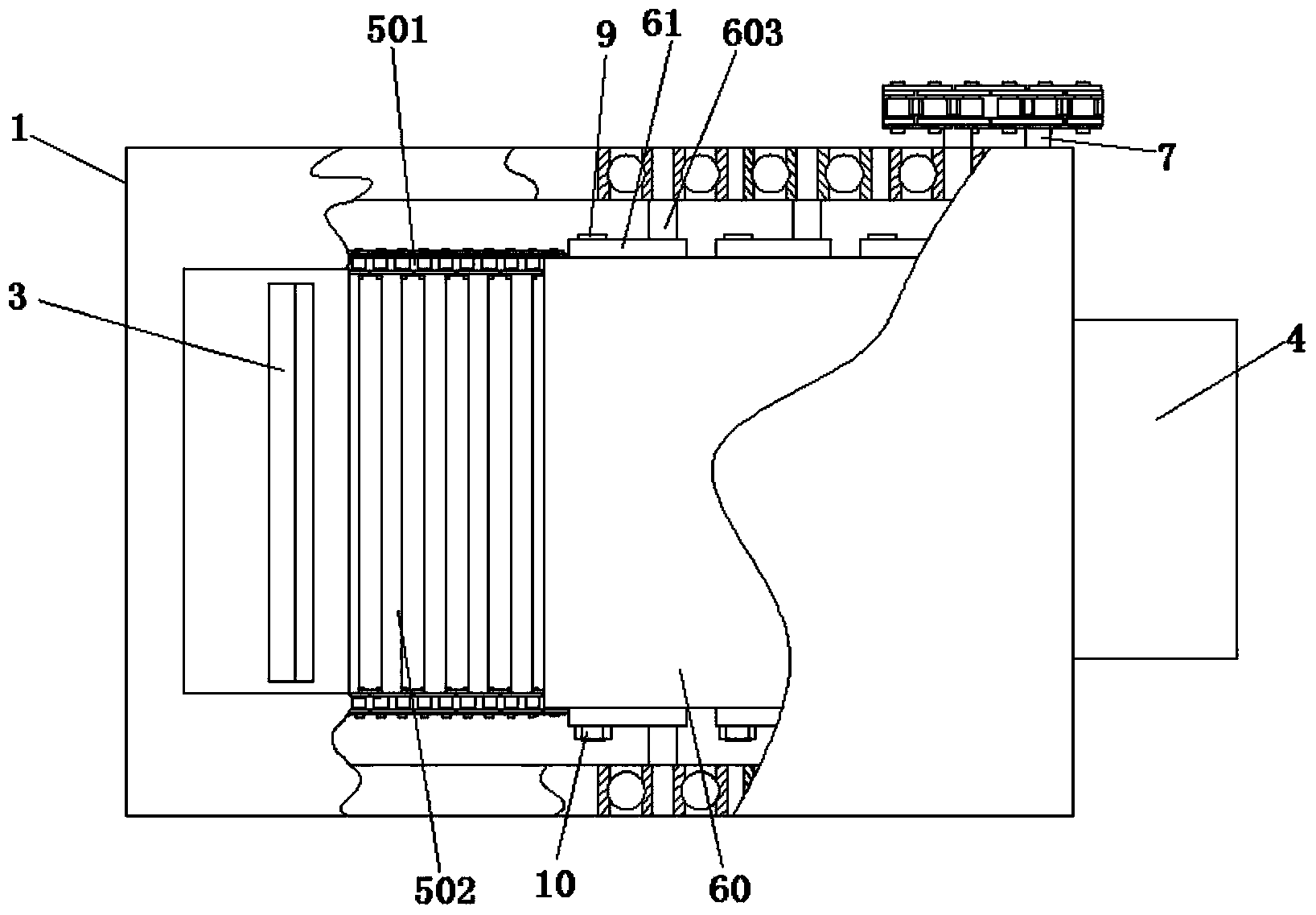

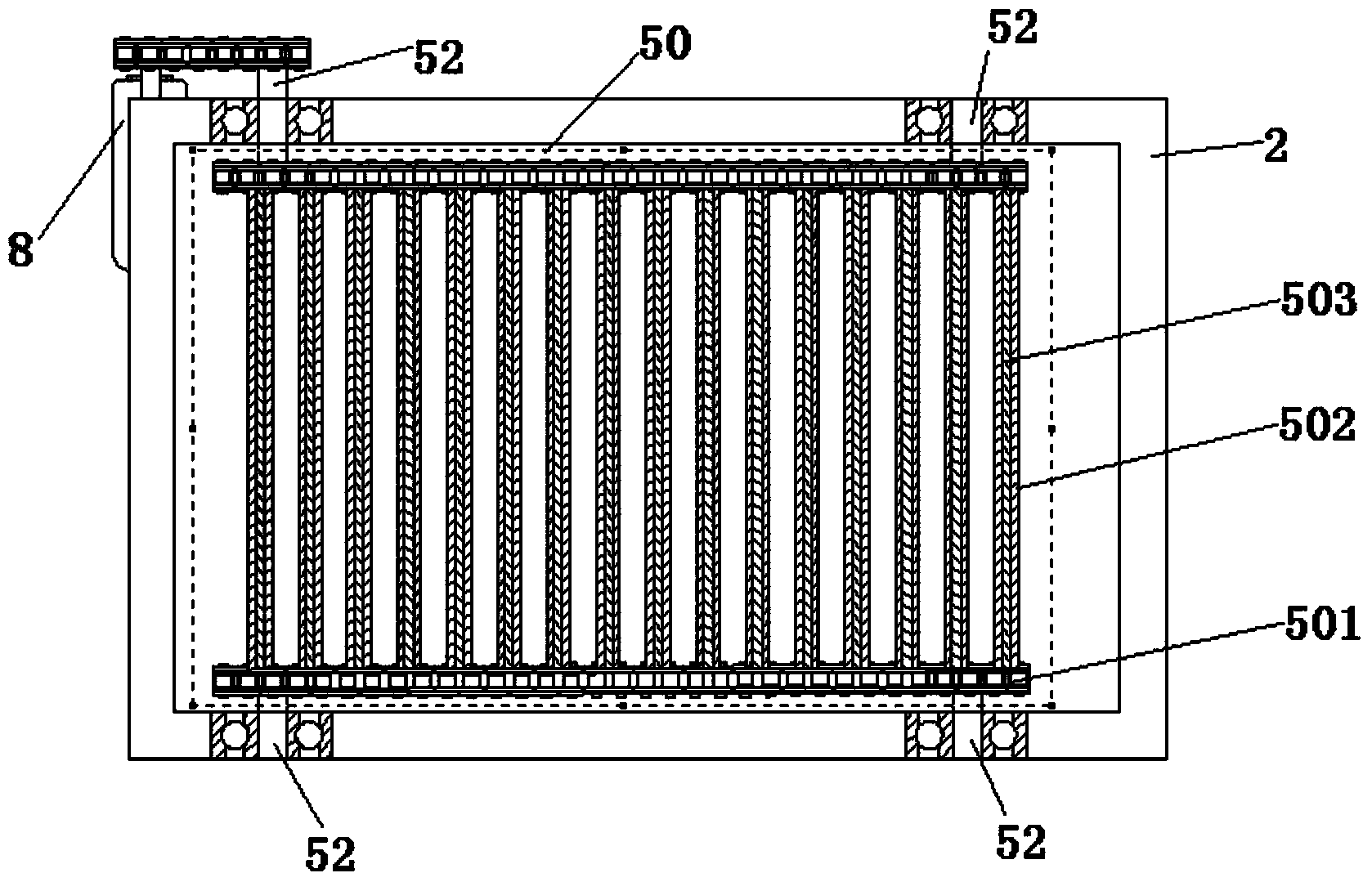

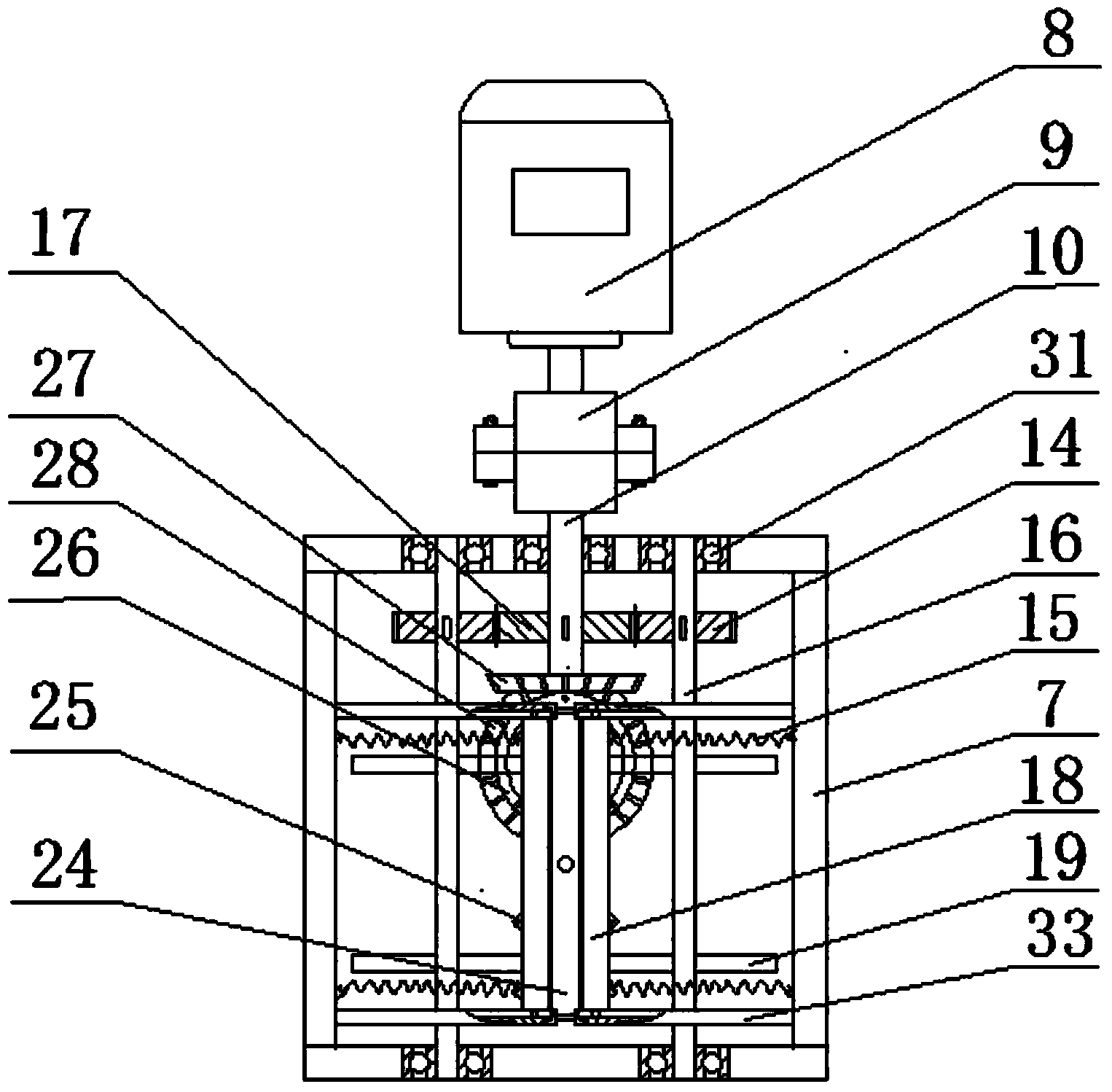

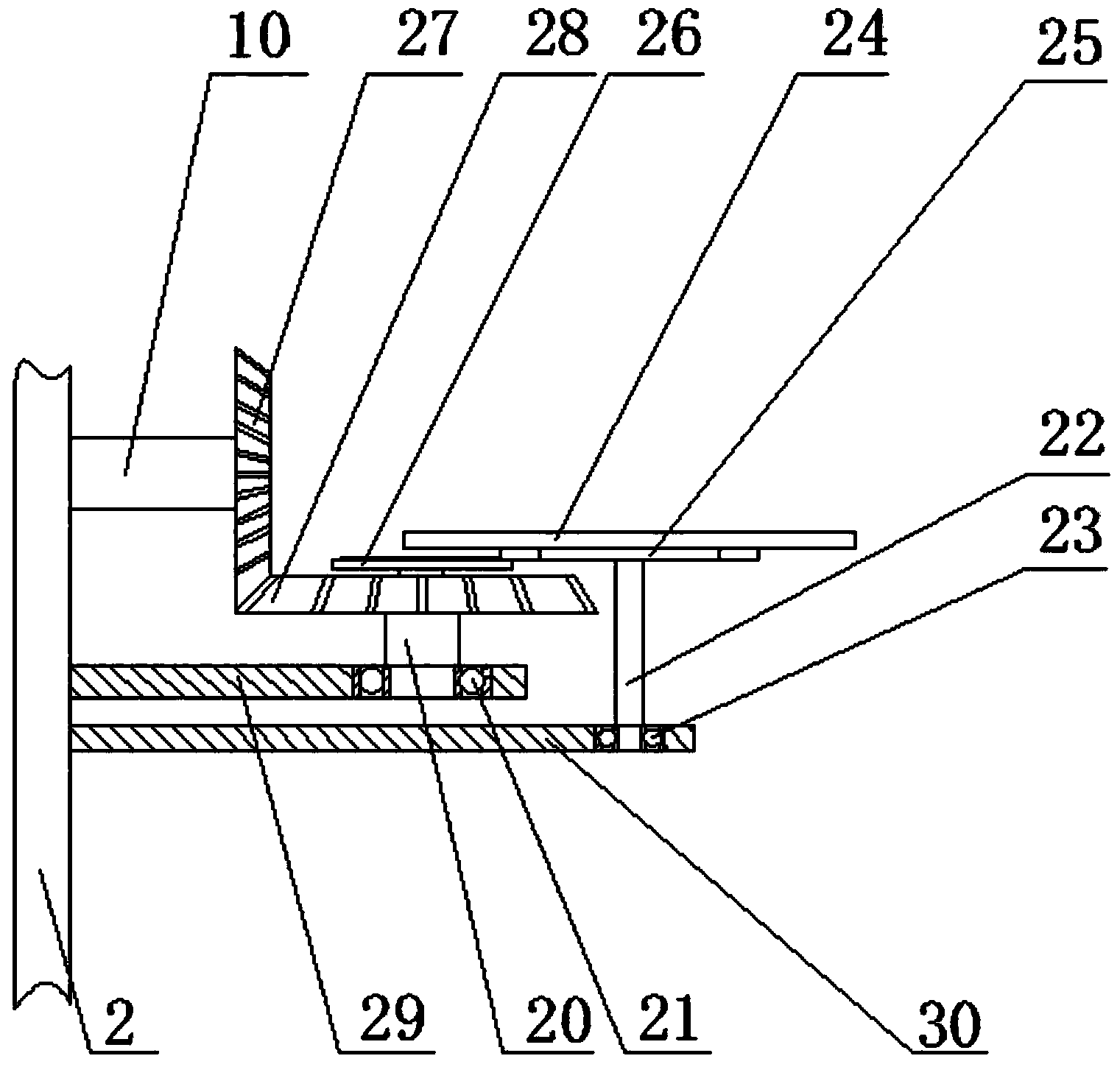

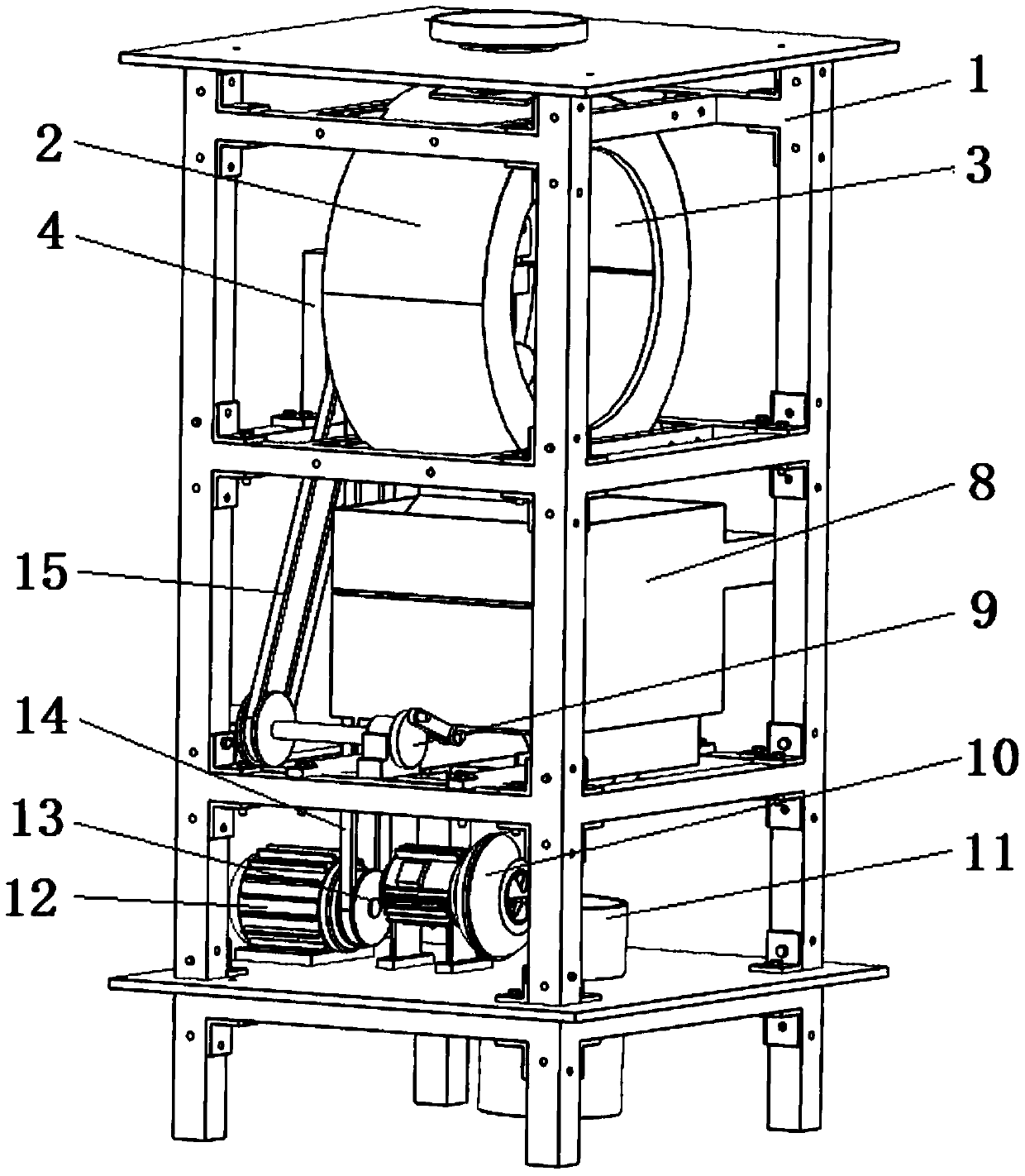

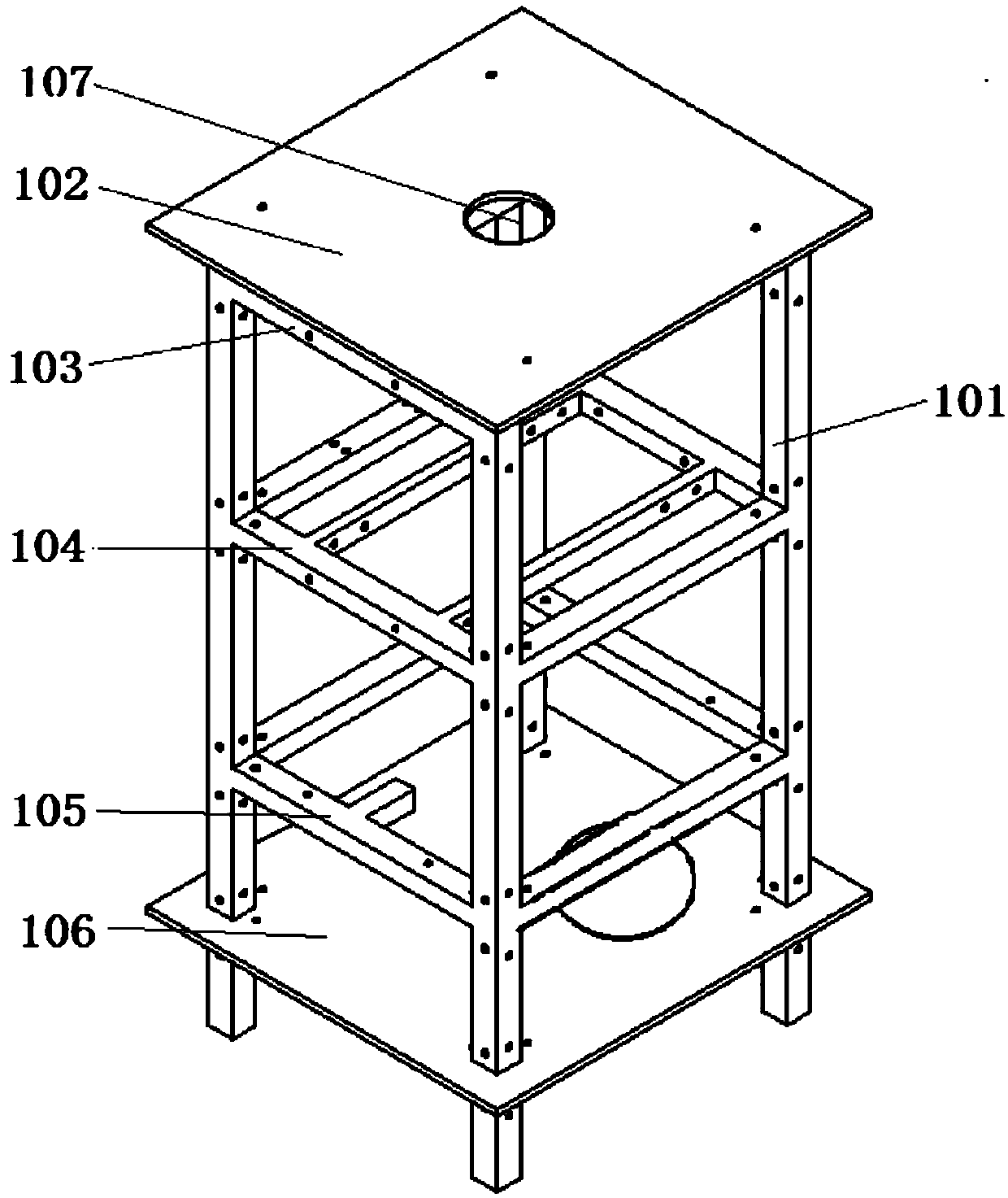

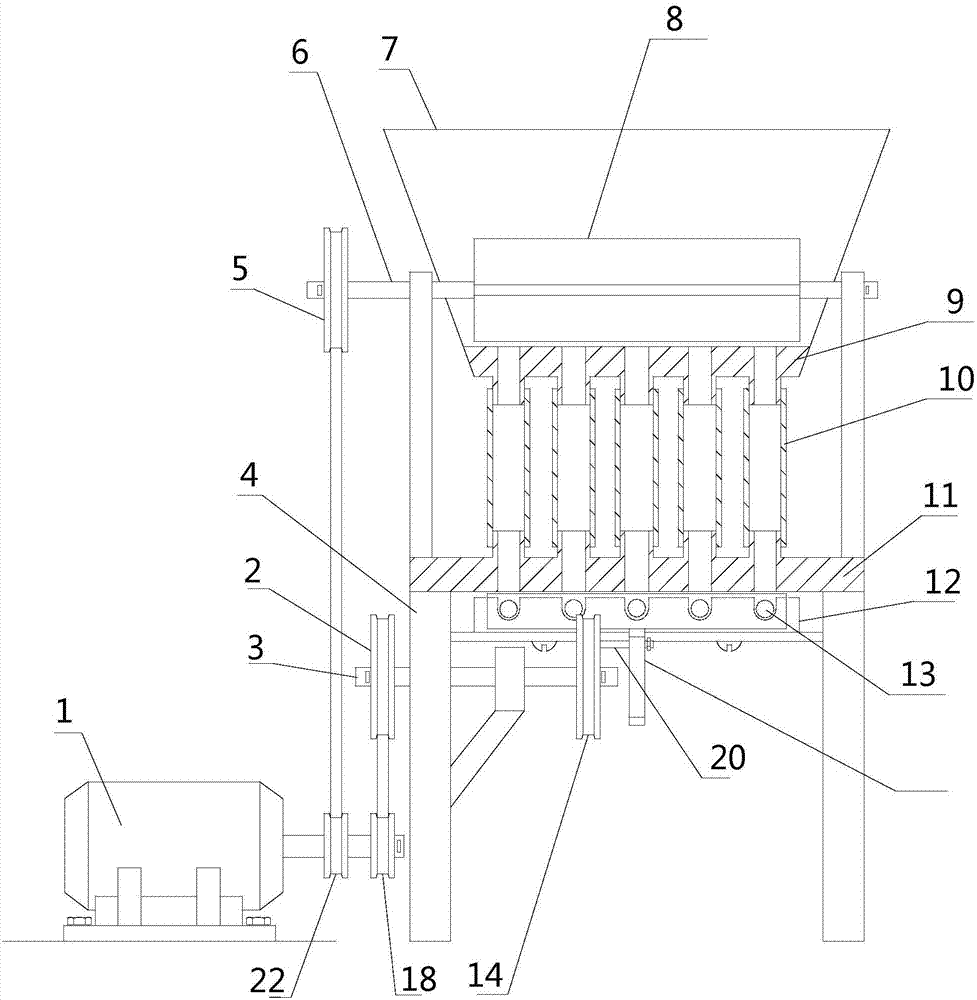

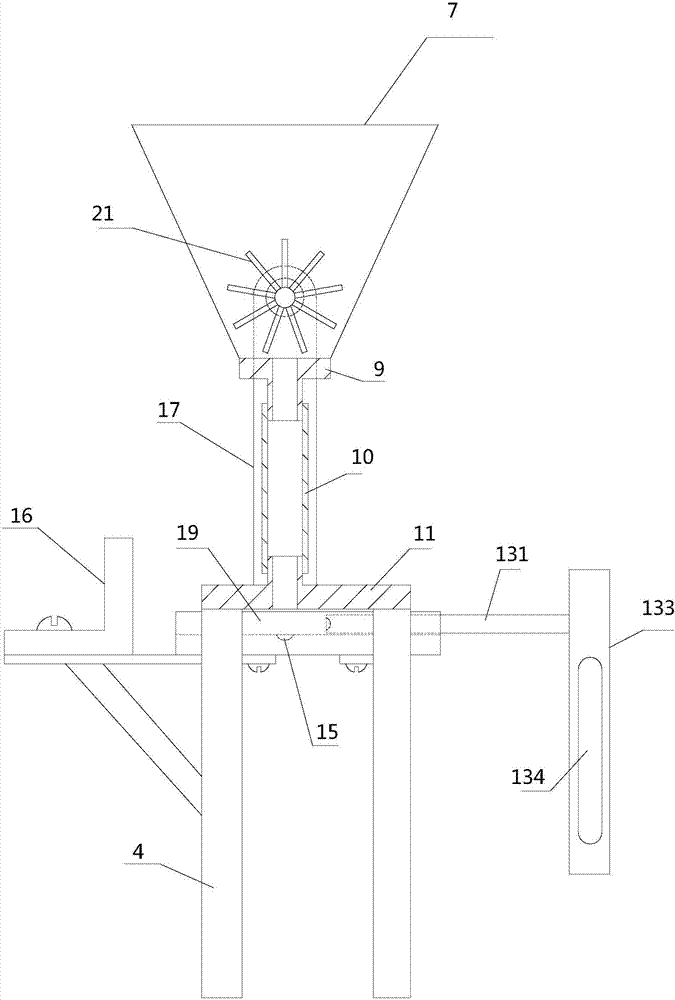

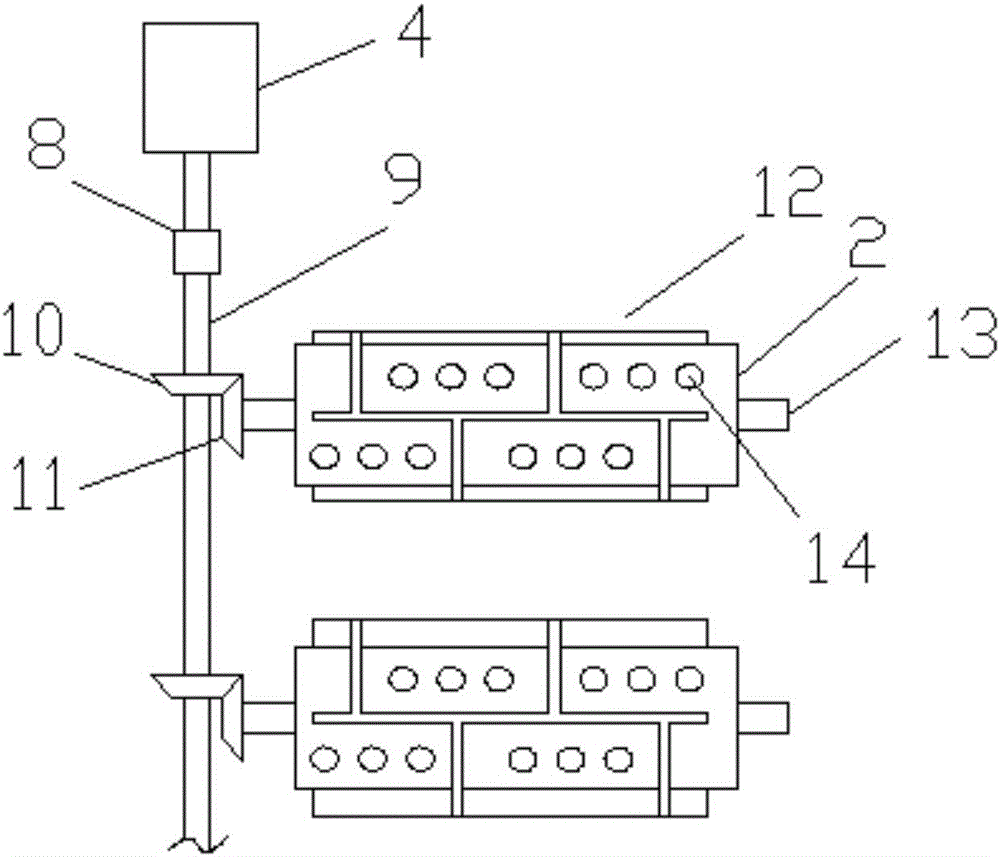

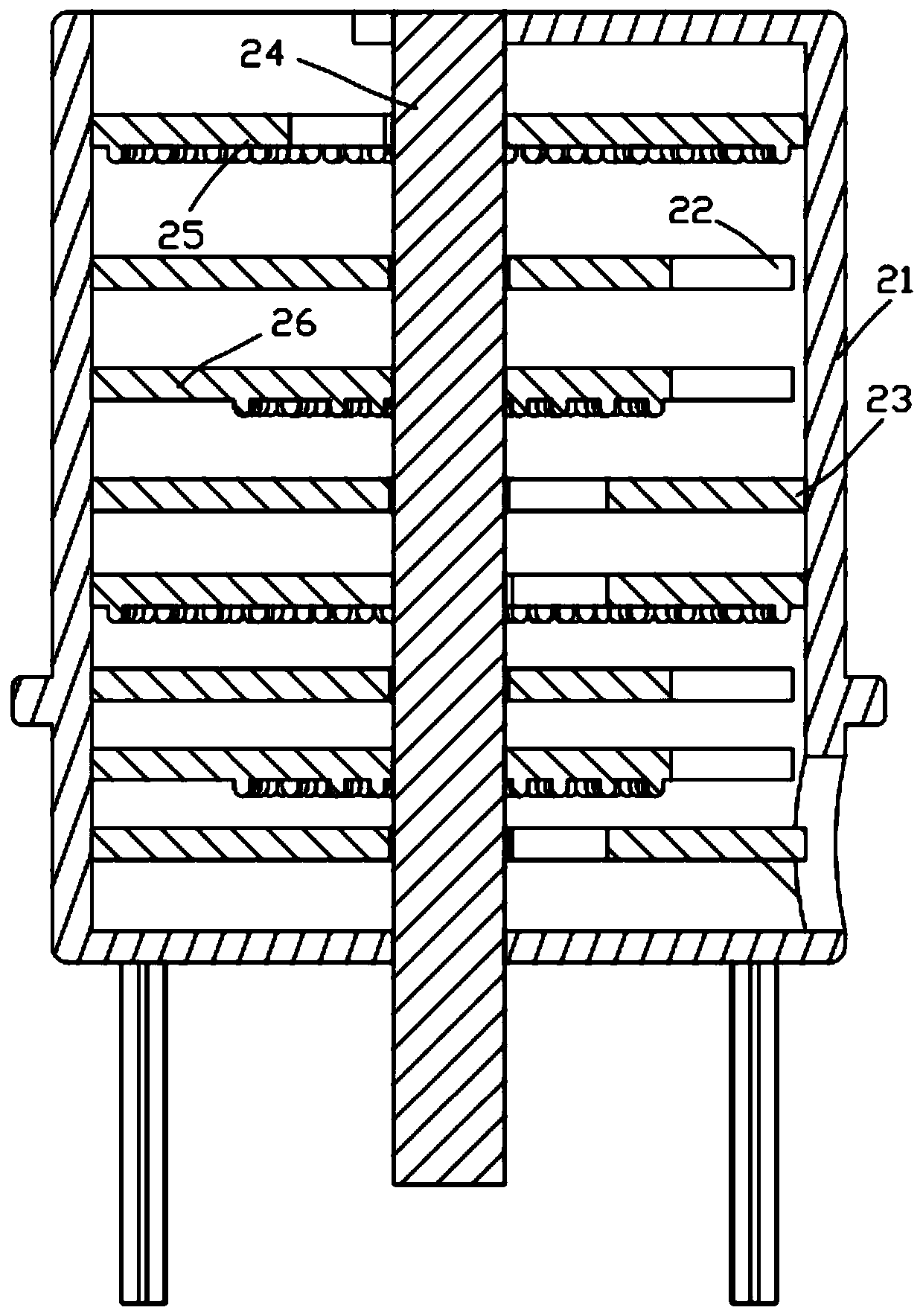

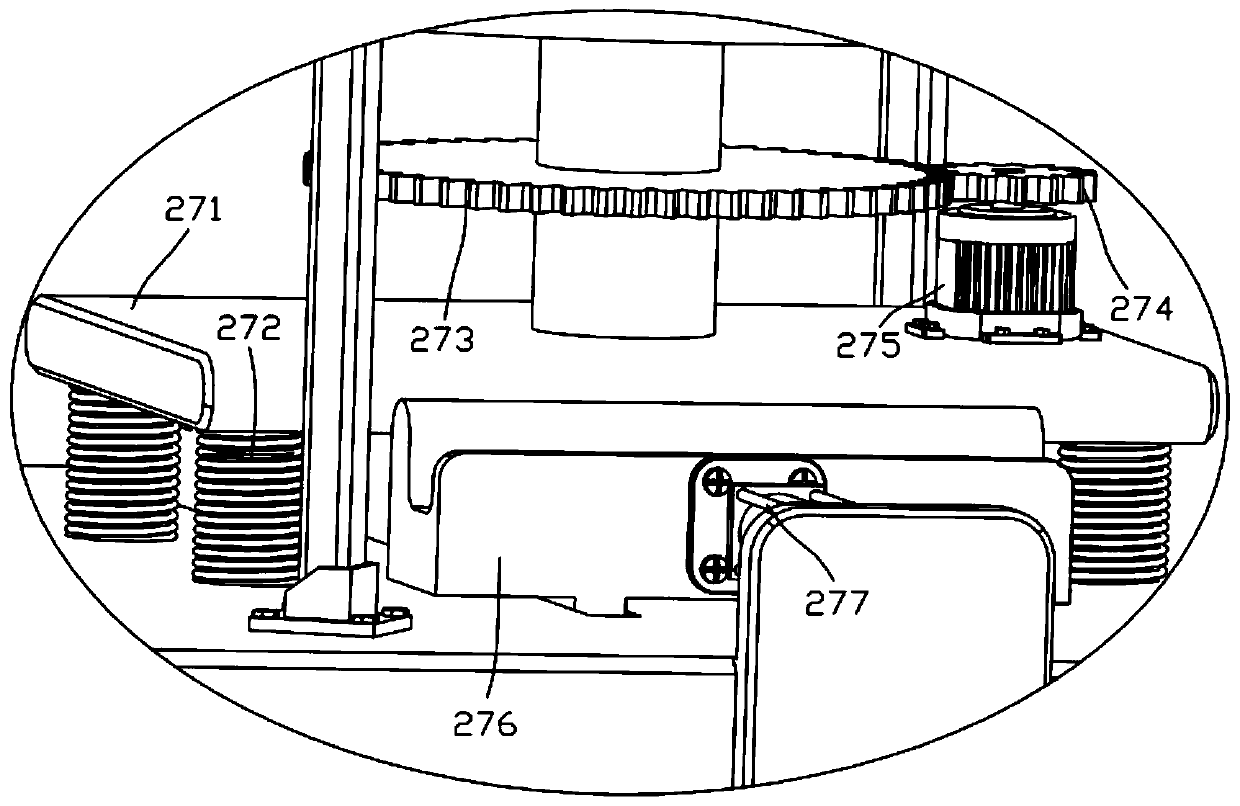

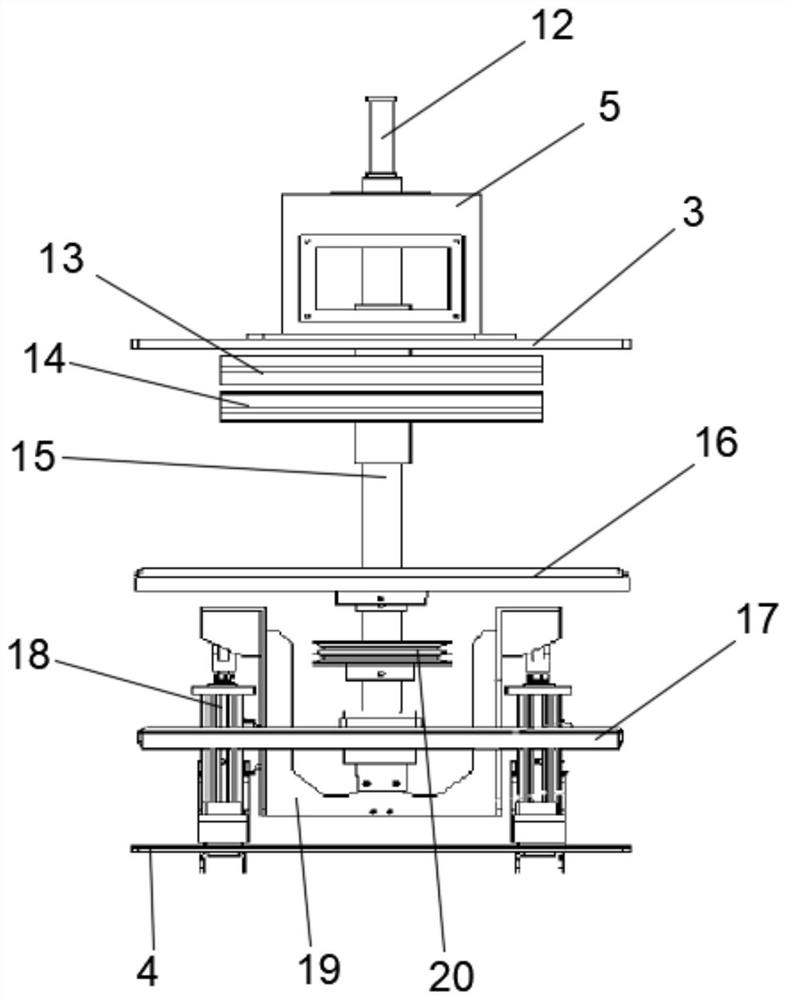

Dual-directional extrusion-type hull breaking equipment for walnuts

The invention discloses dual-directional extrusion-type hull breaking equipment for walnuts. A feeding hole is formed in the top face of a box; a discharge hole is formed in the bottom face of the box; a feeding device, an extrusion device and a supporting device are arranged in the box in sequence from top to bottom; the feeding device is located right below the feeding hole; the extrusion device is located right below the feeding device; the supporting device is located right below the extrusion device; the walnuts falling into the feeding device from the feeding hole are conveyed into the extrusion device through the feeding device and extruded for hull breaking; during an extrusion process, the supporting device plays a supporting role on the walnuts; after extrusion is finished, the walnuts fall into the discharge hole from the supporting device; the hull breaking equipment also comprises an electric motor and a coupling, wherein the electric motor is used for providing energy for the equipment; the coupling is used for transmitting the energy; the electric motor and the coupling are located outside the box. According to the dual-directional extrusion-type hull breaking equipment disclosed by the invention, directional extrusion can be performed on the walnuts, and enough power can be provided during the extrusion process, so that hulls of the walnuts are fully broken; the dual-directional extrusion-type hull breaking equipment has the characteristics that the work efficiency is high, the hull breaking rate is high, the rate of perfect kernel is high, the cost is low, and the use is convenient.

Owner:SHAANXI UNIV OF SCI & TECH

Chestnut shell breaking method

Owner:SHAANXI UNIV OF SCI & TECH

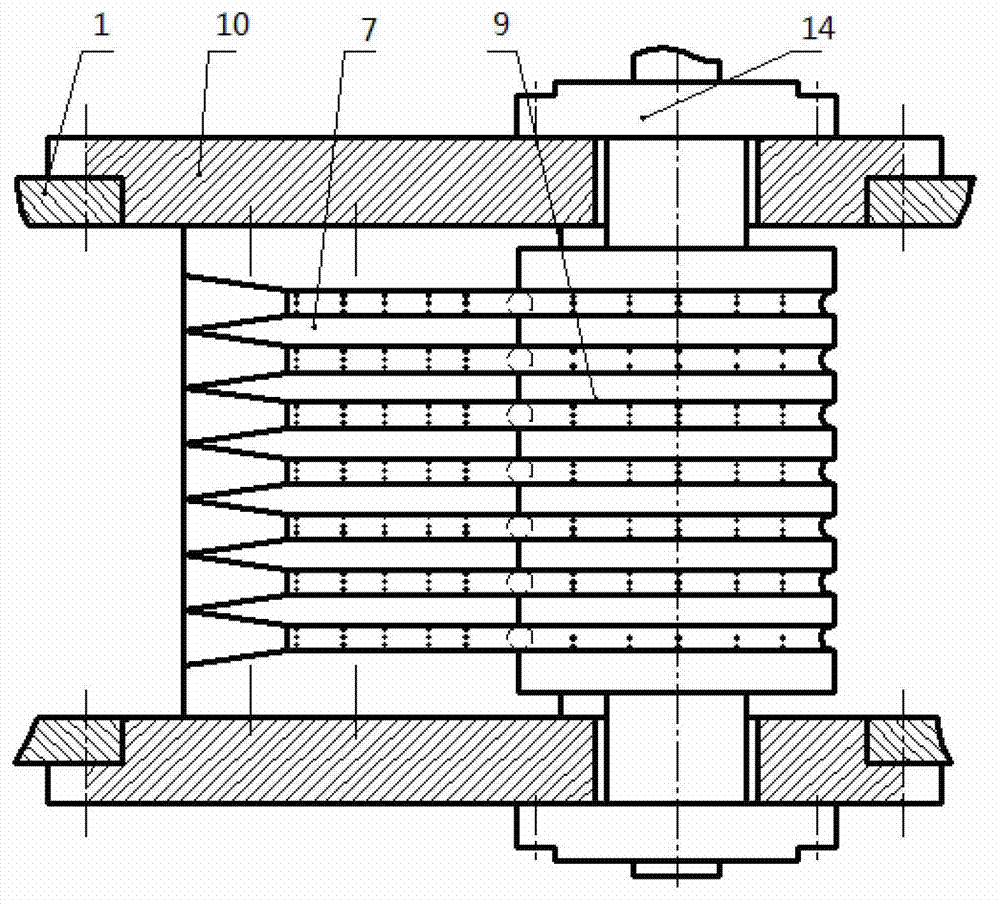

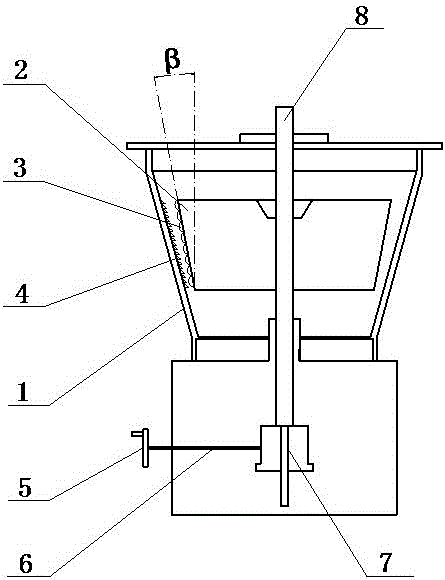

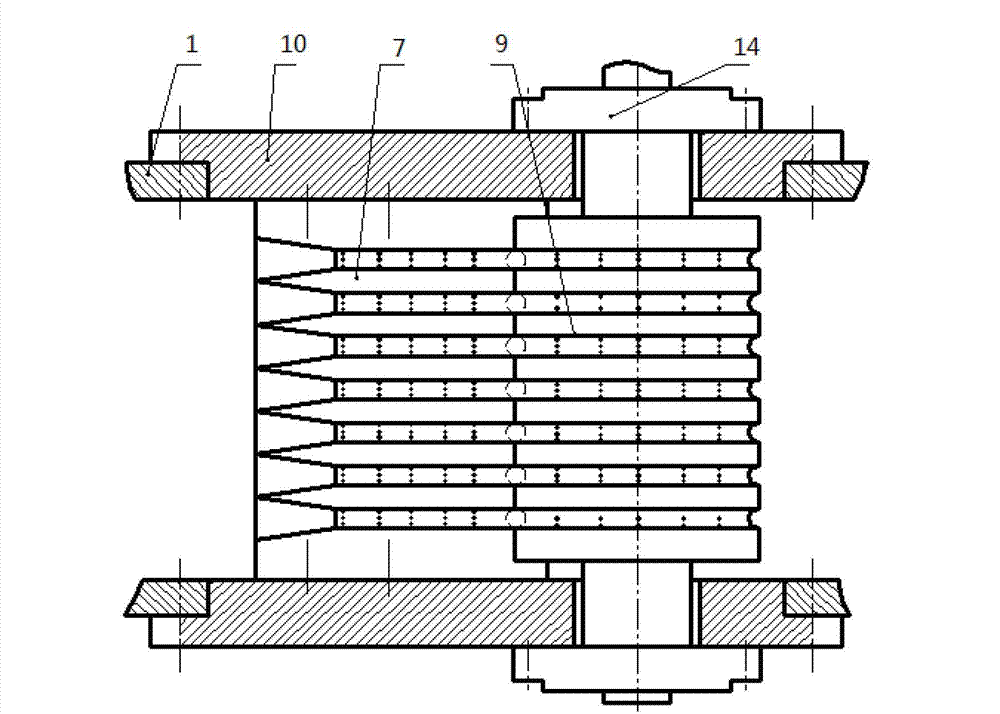

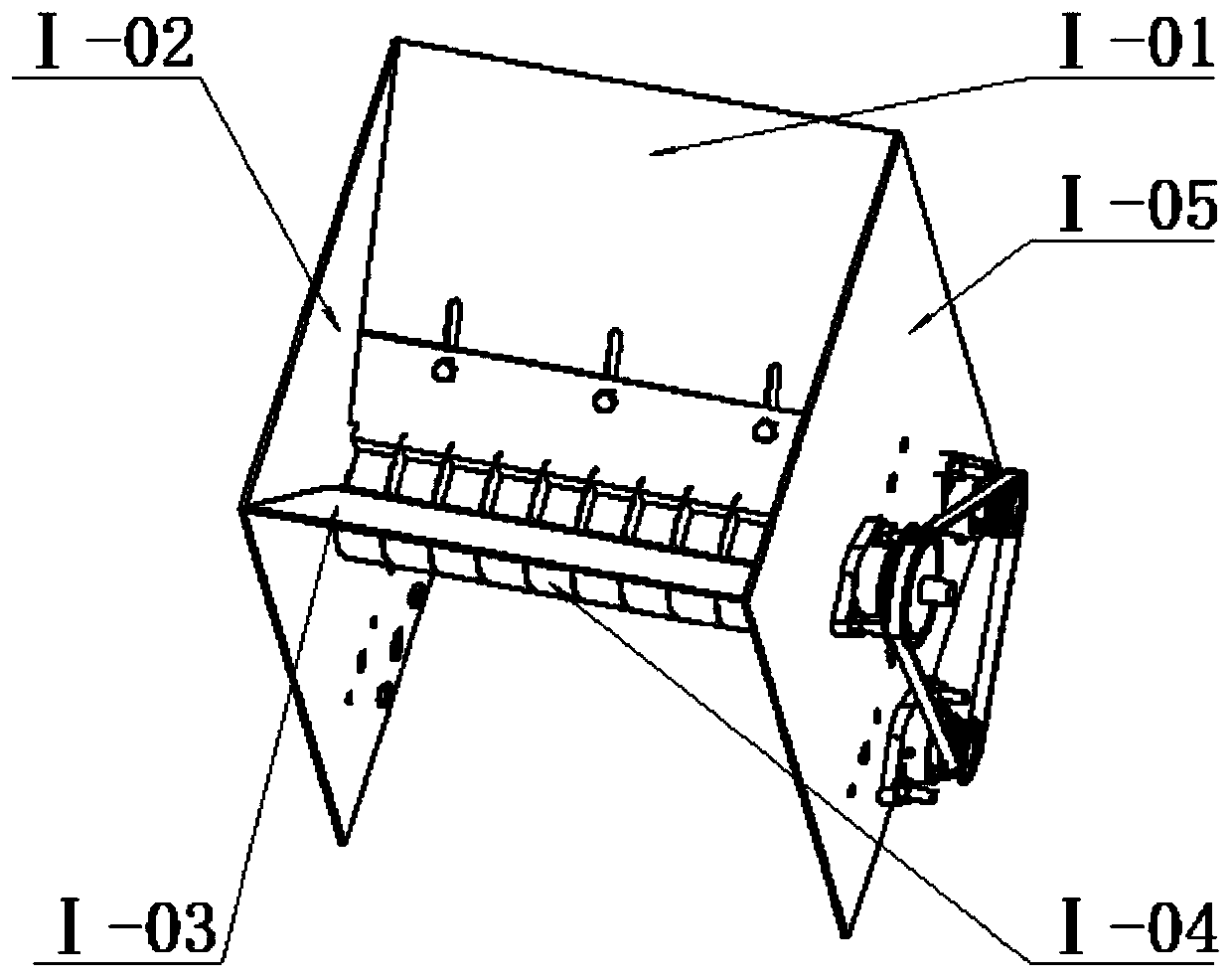

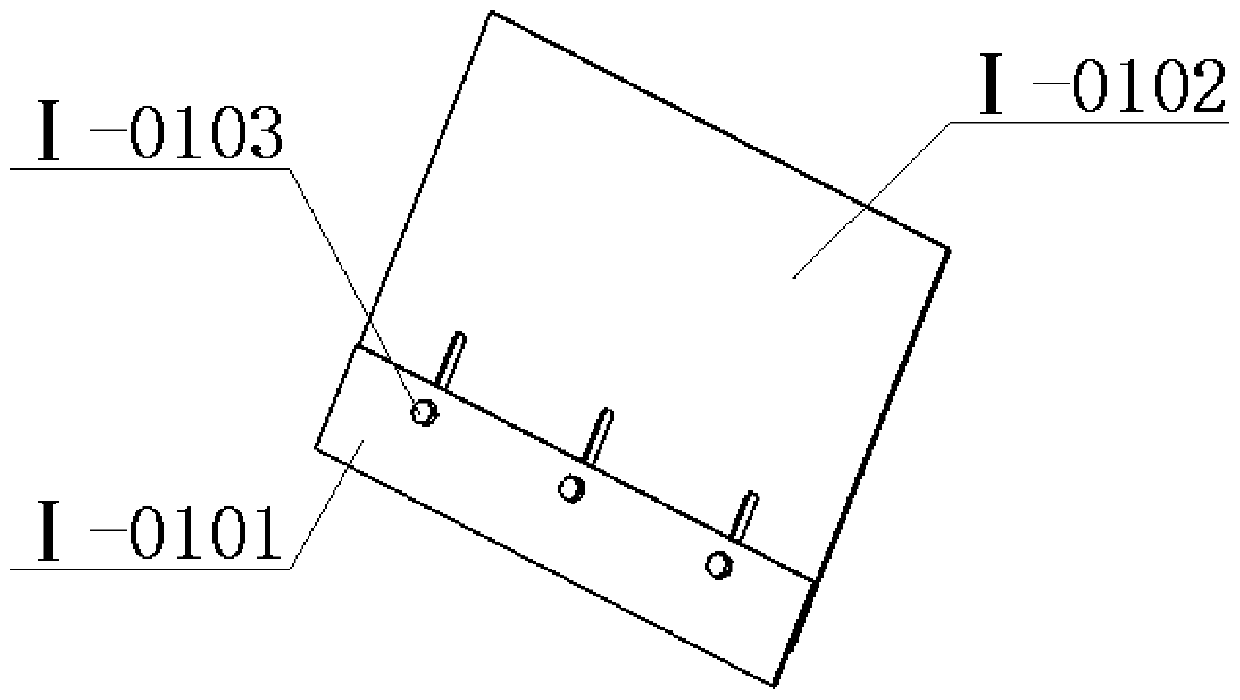

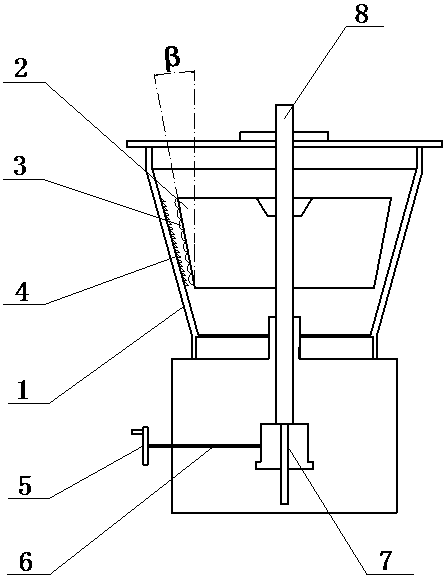

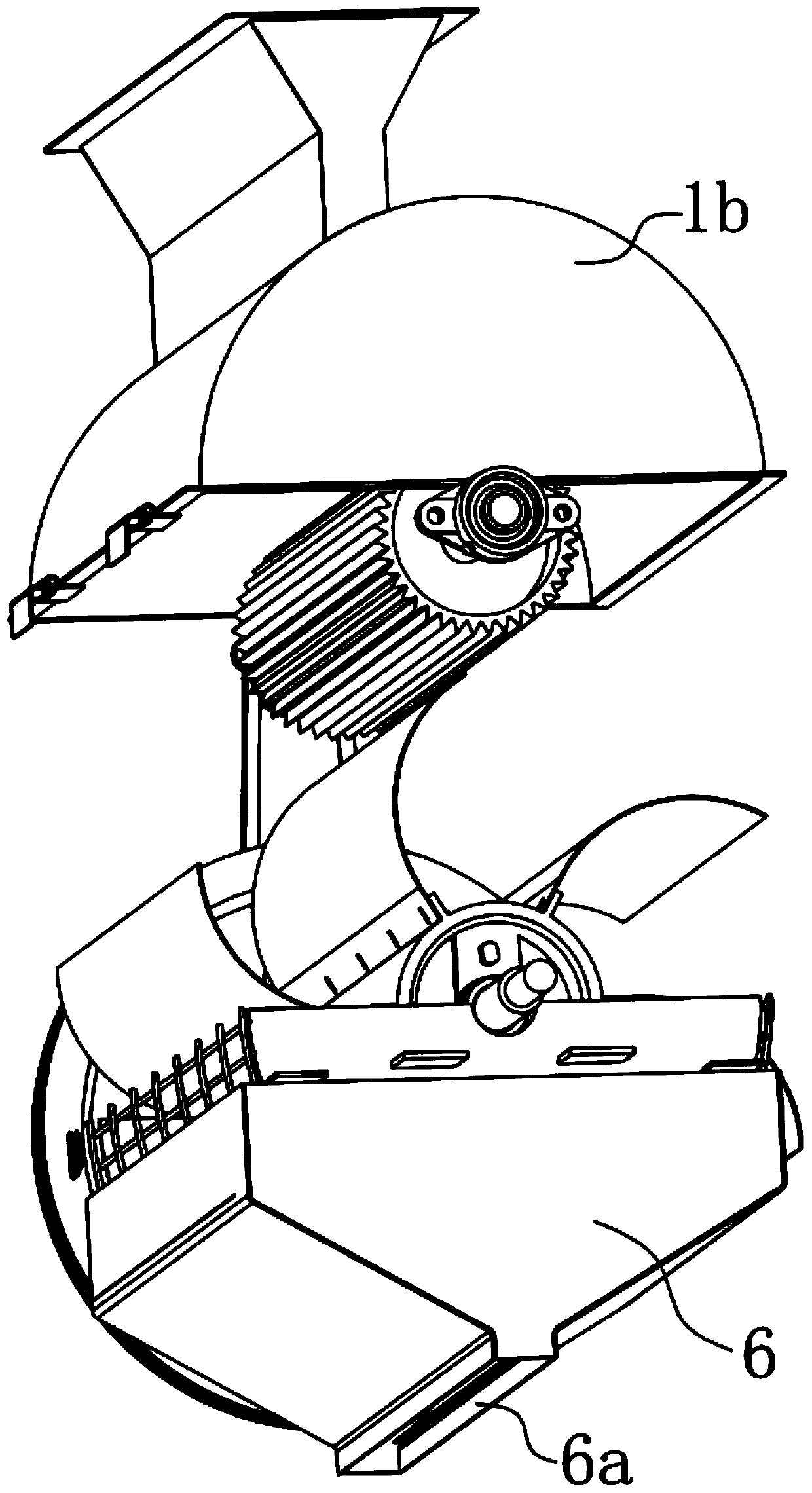

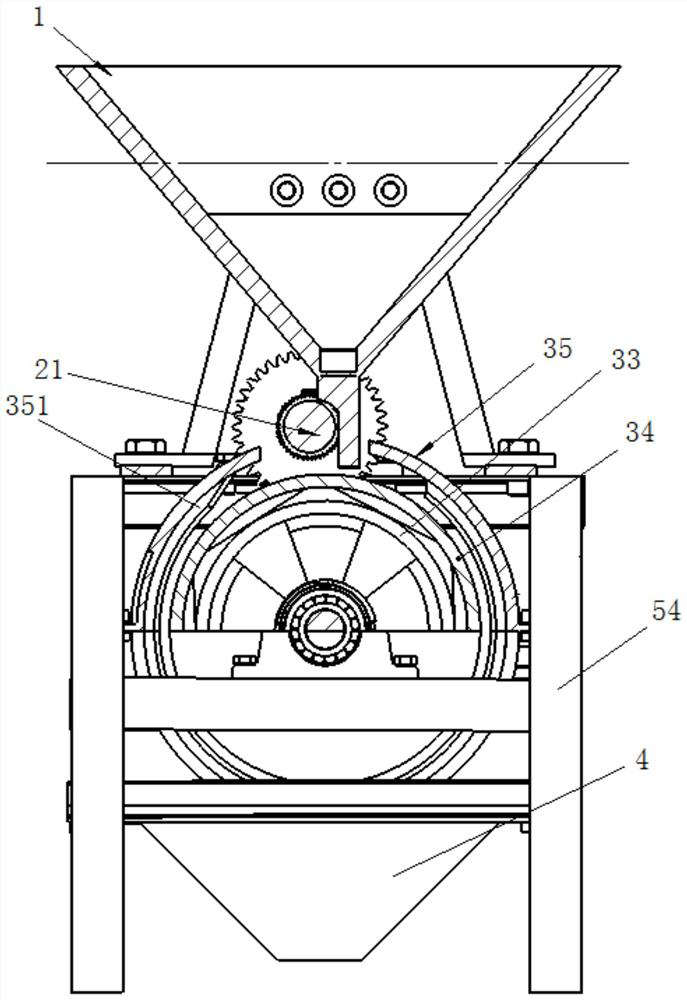

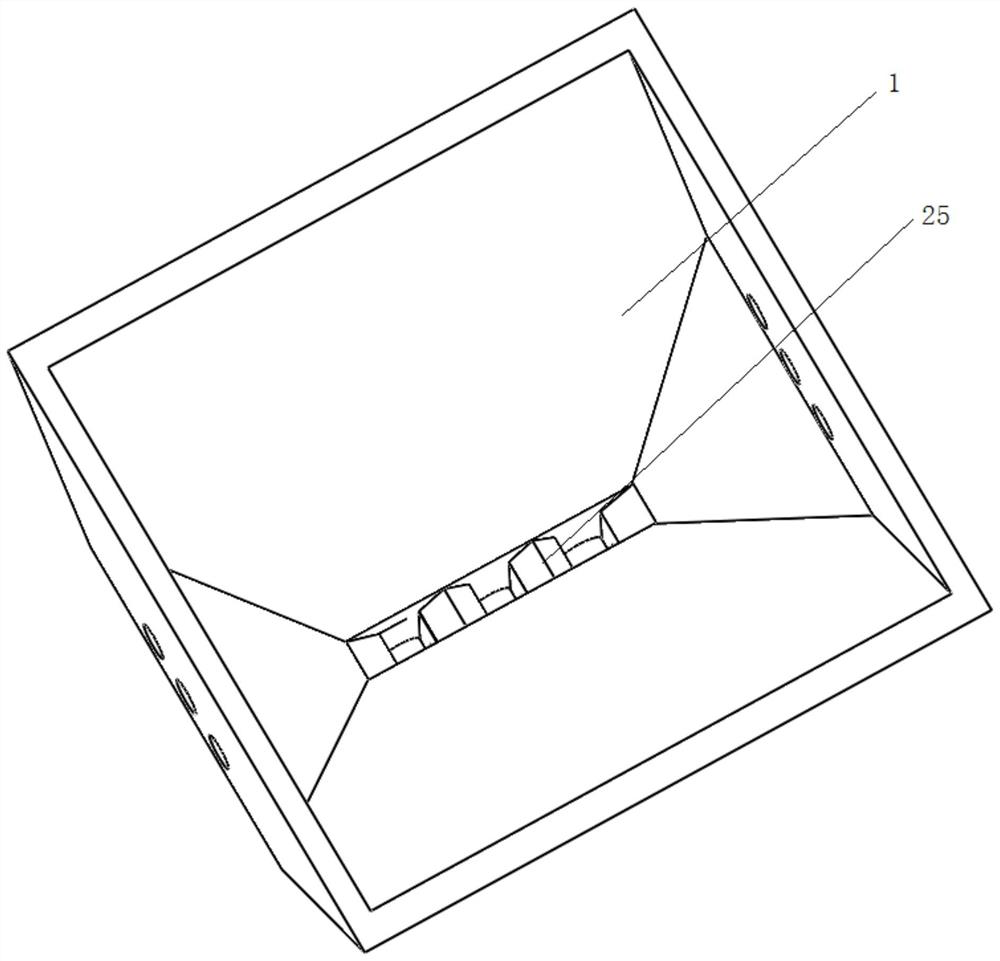

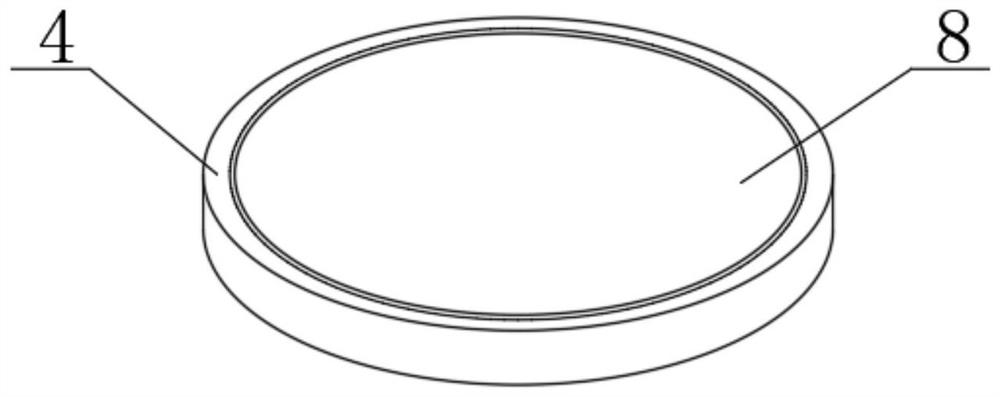

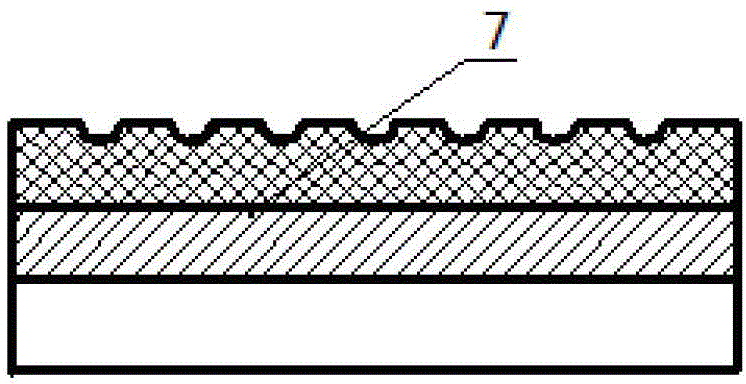

Conical-basket type shell breaking device used for walnut shell breaking machine

The invention belongs to the technical field of walnut shell breaking equipment, and particularly relates to a conical-basket type shell breaking device used for a walnut shell breaking machine. The conical-basket type shell breaking device is composed of an outer shell breaking body (1), an inner shell breaking body (2) and an adjusting device. The inner shell breaking body (2) is arranged inside the outer shell breaking body (1), and the adjusting device is located below the inner shell breaking body (2). The shell breaking device is characterized in that a shell breaking cavity is formed in the region, corresponding to the inner wall of the outer shell breaking body (1), of the outer wall of the inner shell breaking body (2), protrusions (3) are arranged on the outer wall of the inner shell breaking body (2), and an inverted table (4) is arranged on the inner wall of the outer shell breaking body (1). The adjusting device is composed of an adjusting handle (5), an adjusting screw rod (6), a worm and gear device (7) and a linkage shaft (8). The inclination angle beta of the inner shell breaking body (2) ranges from 3 degrees to 10 degrees. The shell breaking device has the advantages of being simple in structure and high in practicability, increasing the shell breaking rate, improving working efficiency and reducing the damage rate of walnut kernels.

Owner:方慧发

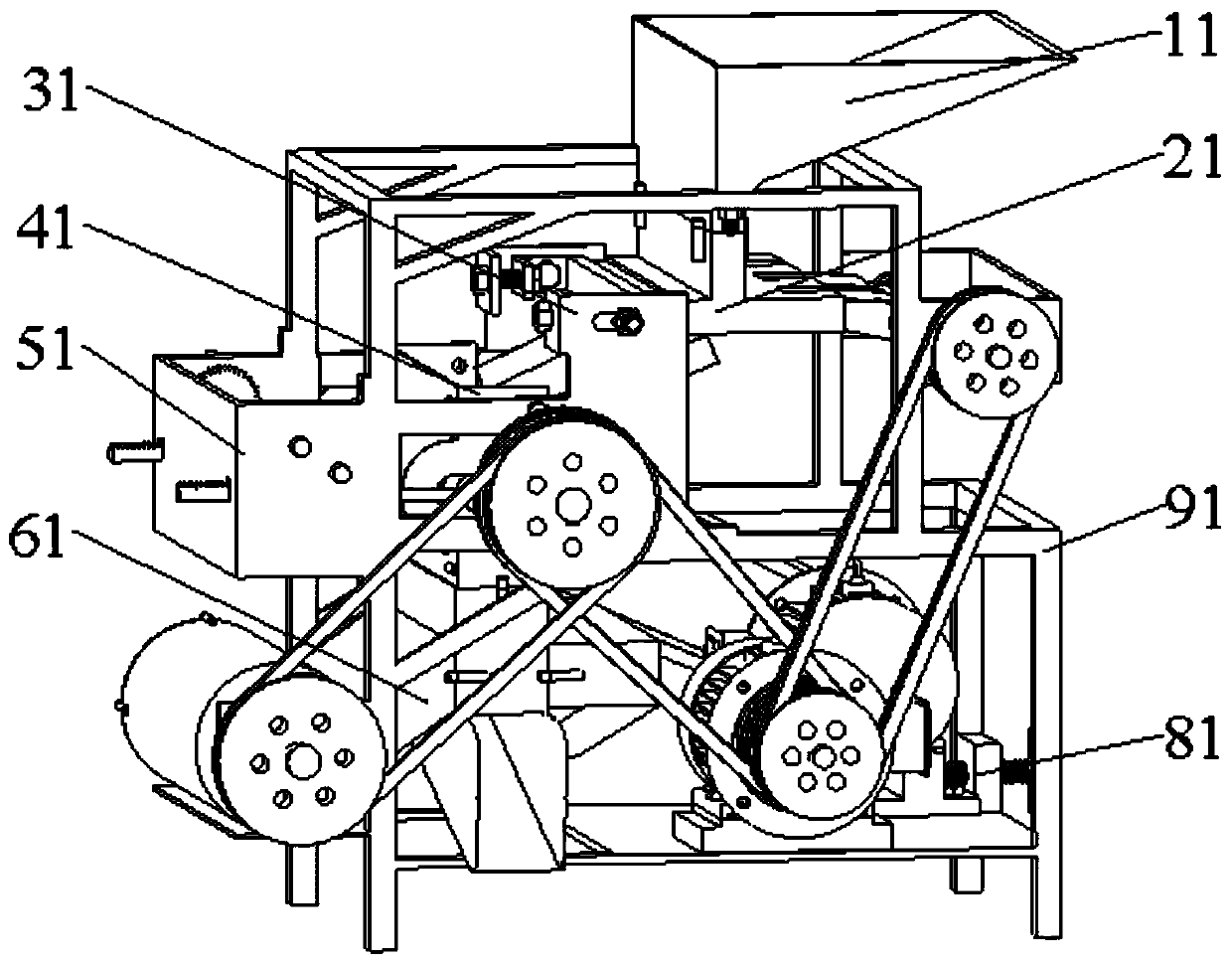

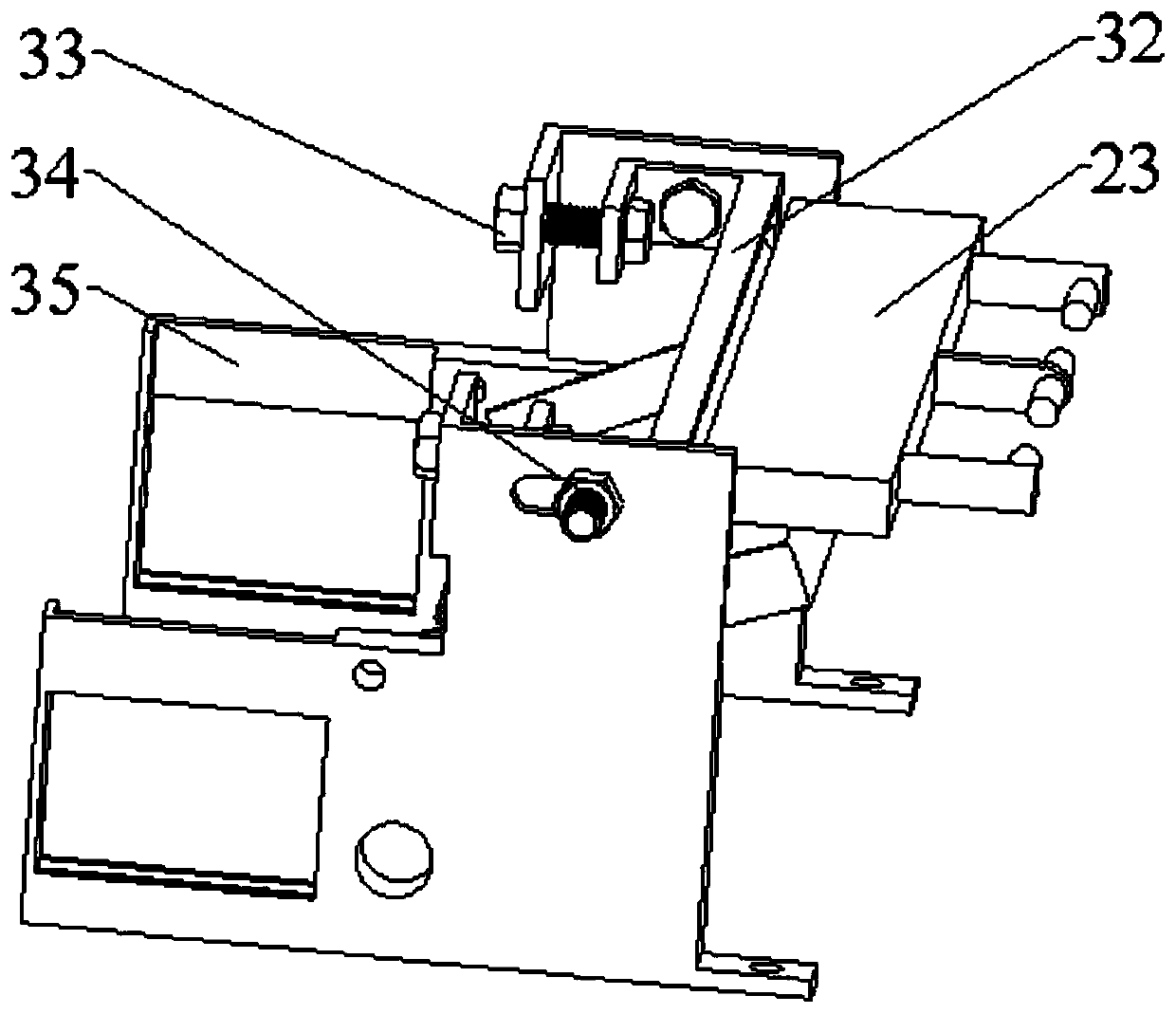

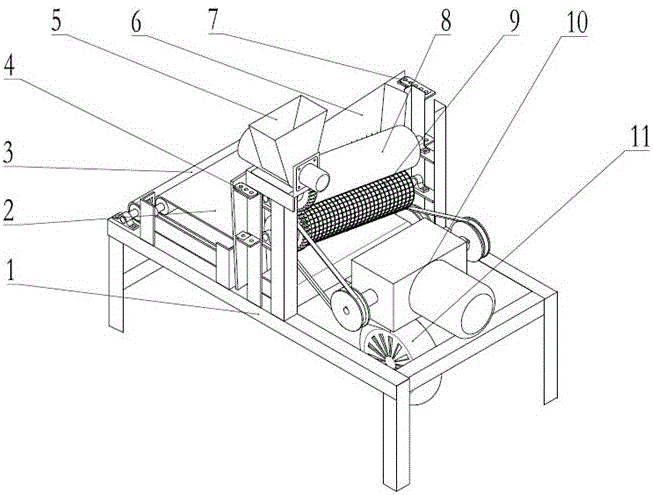

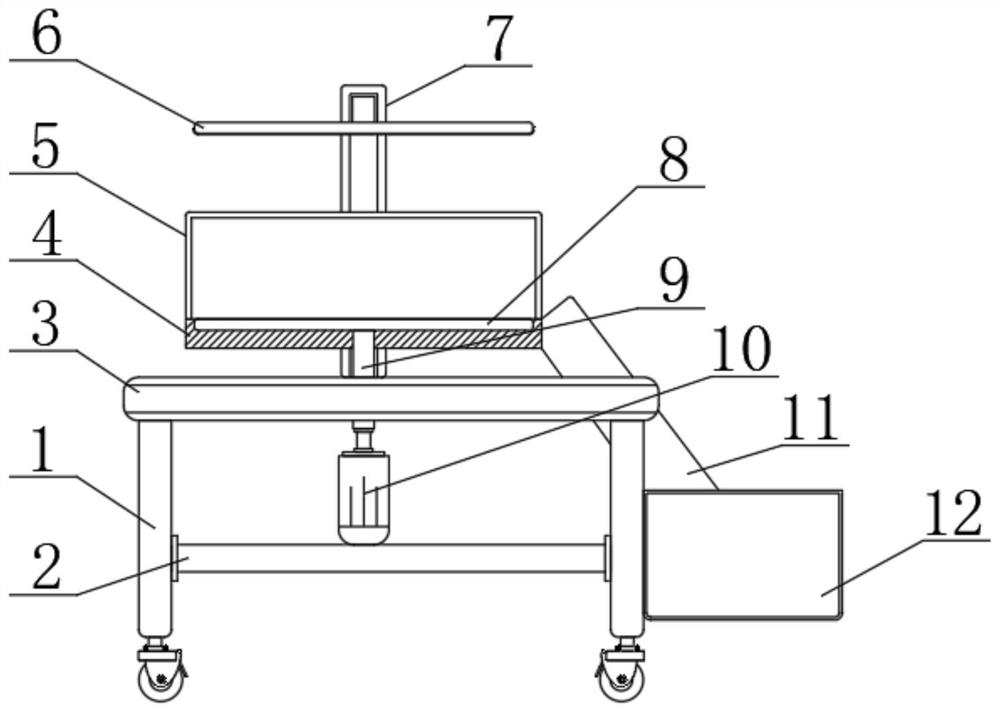

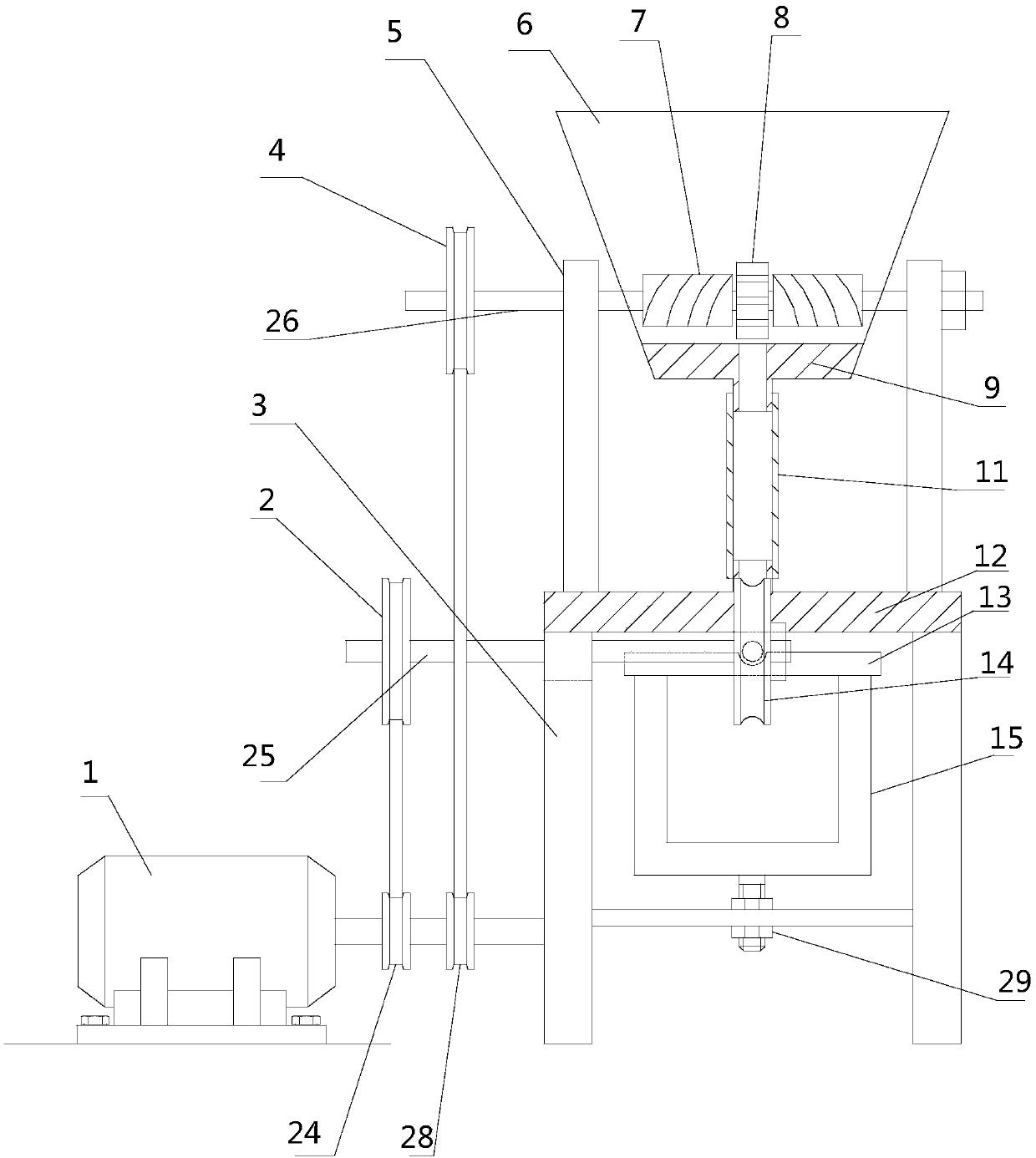

Adjustable impact roller press-type hevea brasiliensis fruit shell-breaking machine and use method thereof

ActiveCN111329078AImprove completenessEasy to separateGas current separationHuskingAgricultural engineeringStructural engineering

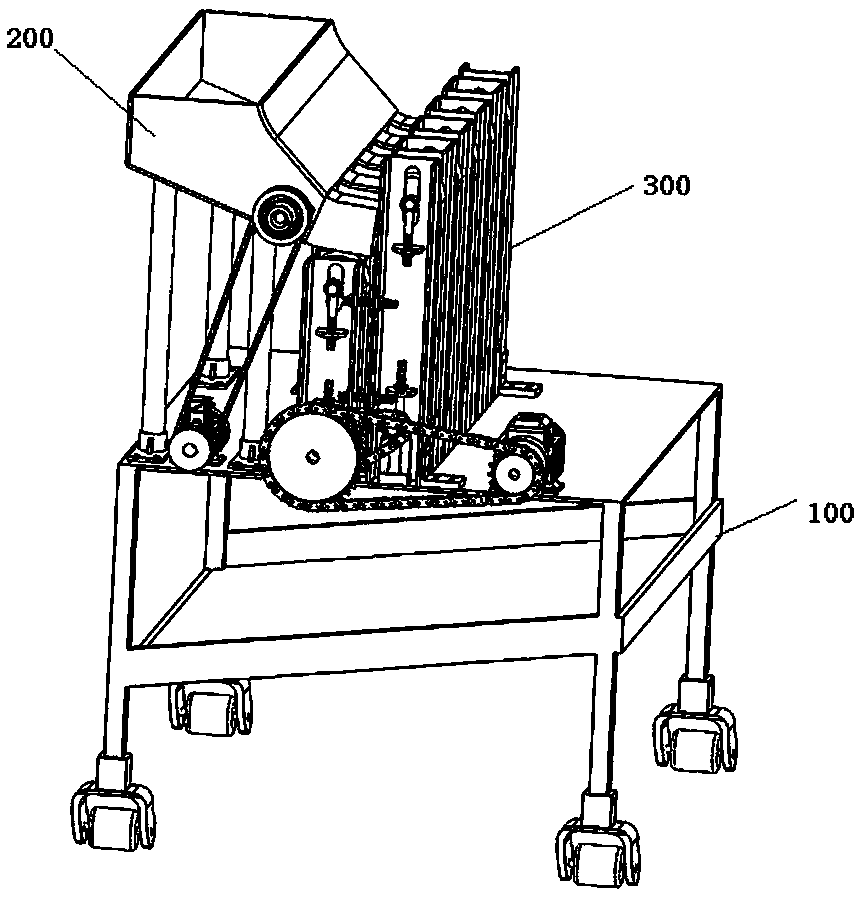

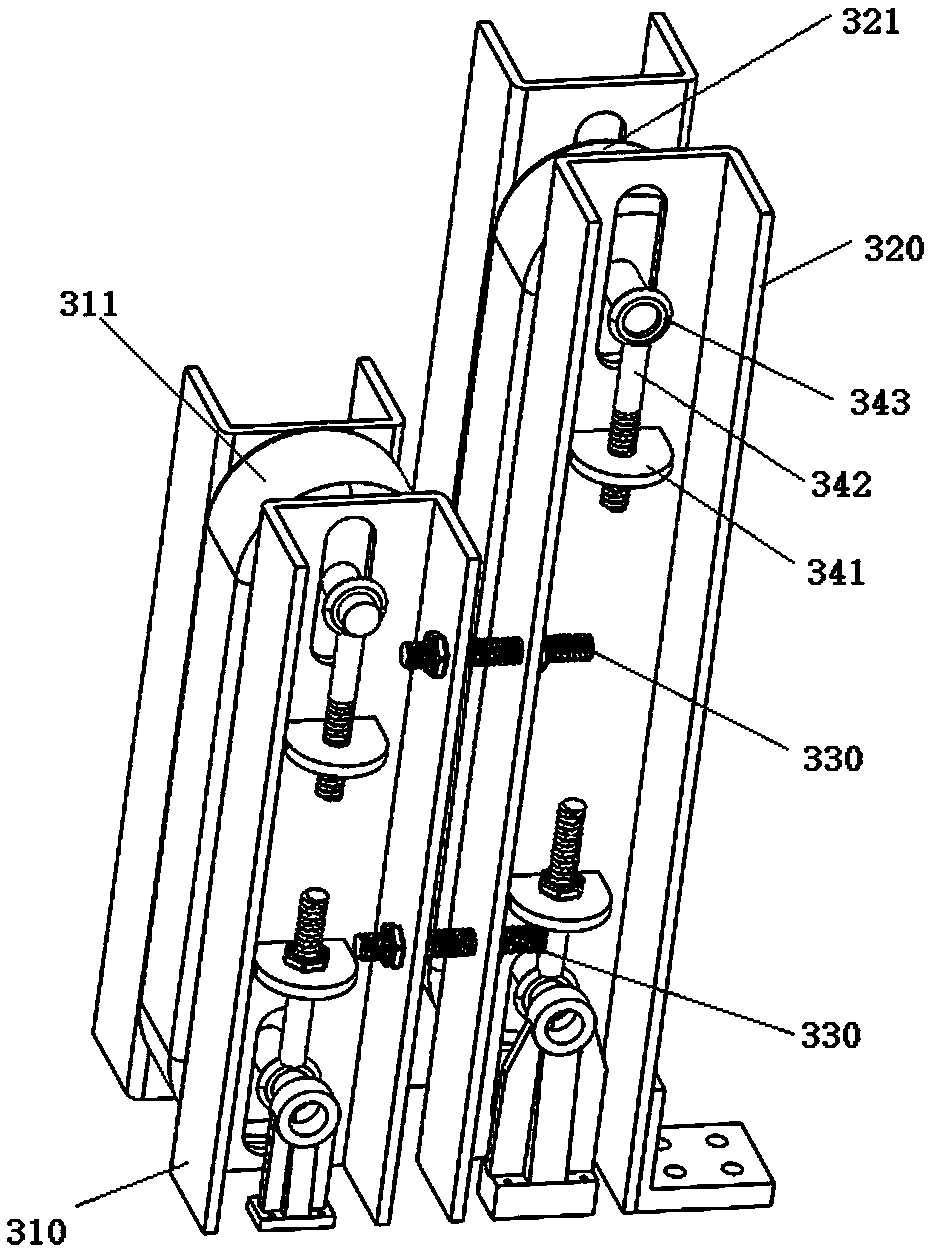

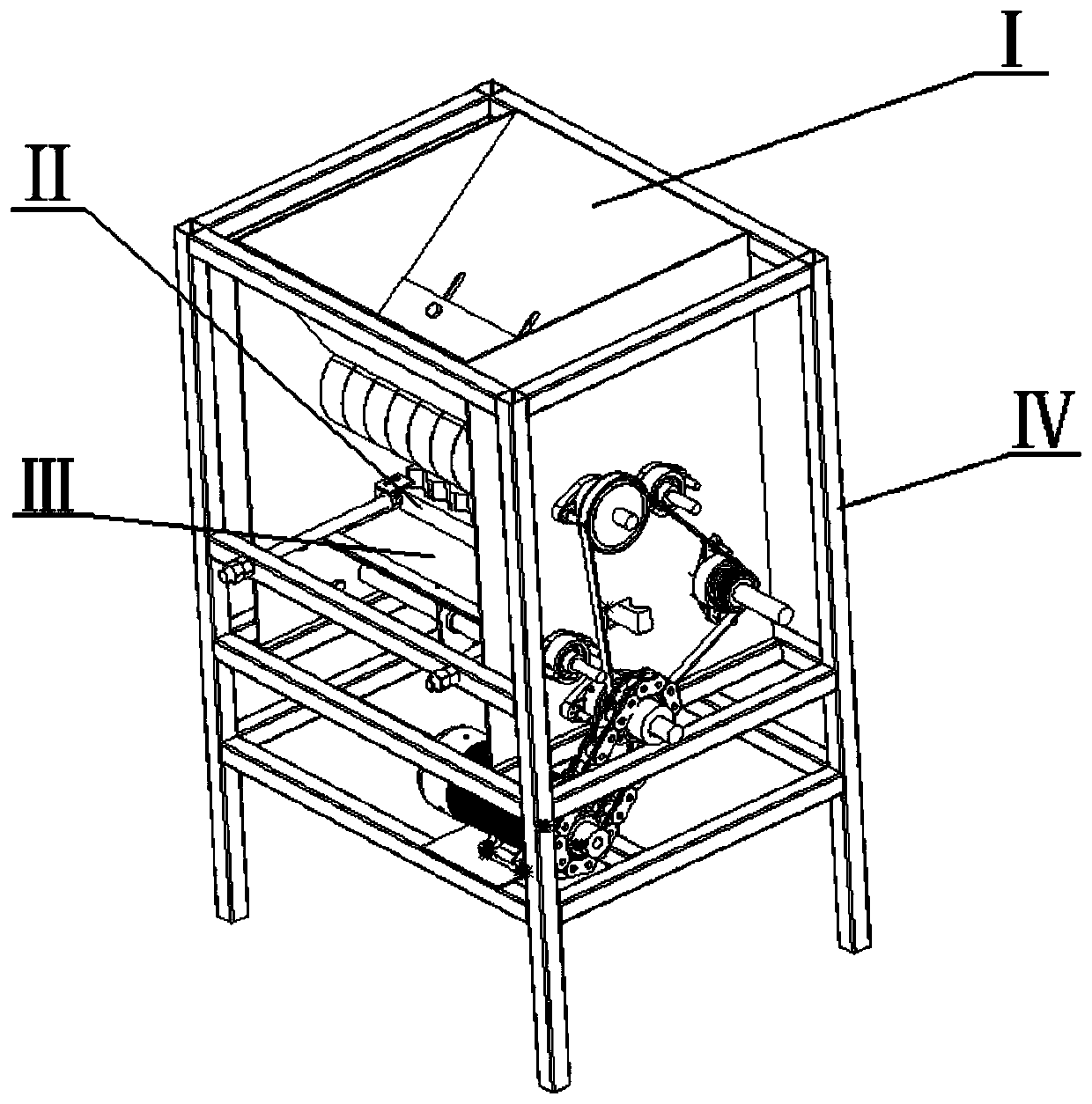

The invention discloses an adjustable impact roller press-type hevea brasiliensis fruit shell-breaking machine and a use method. The shell-breaking machine comprises feeding apparatus, crank impact apparatus, impact plate adjustment apparatus, double-roller extrusion apparatus, roller distance adjustment apparatus, wind screening apparatus, power transmission apparatus, motor adjustment apparatusand a machine frame, wherein the feeding apparatus, the crank impact apparatus, the double-roller extrusion apparatus and the wind screening apparatus are fixedly arranged on the machine frame from top to bottom. The shell-breaking machine adopts an impact shell-breaking manner with an adjustable strength and a double-roller extrusion breaking manner with an adjustable spacing to perform compoundshell-breaking of hevea brasiliensis fruits, the shell-breaking machine has a high shell-breaking rate, and a kernel integrity rate after shell-breaking is high. The shell-breaking machine adopts blower blowing to realize separation of the shell and kernel, the separation effect of the hevea brasiliensis fruit shell and kernel is improved, and the purity of the kernel is improved.

Owner:HAINAN UNIVERSITY

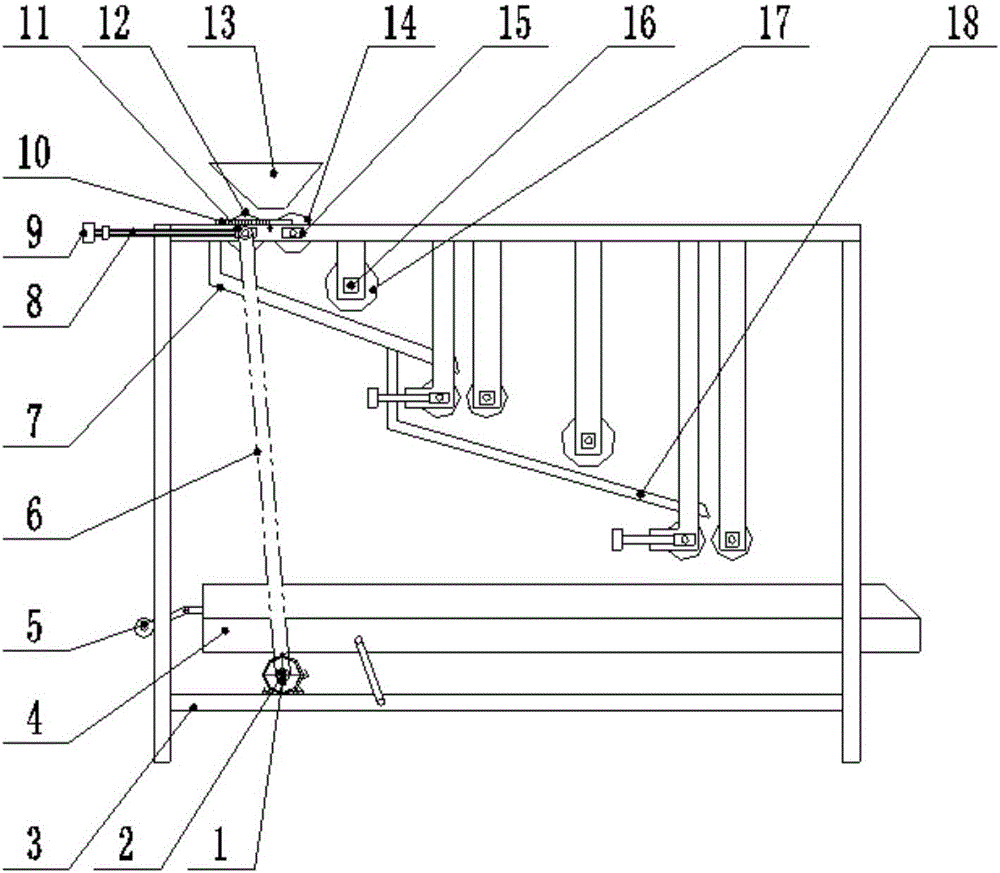

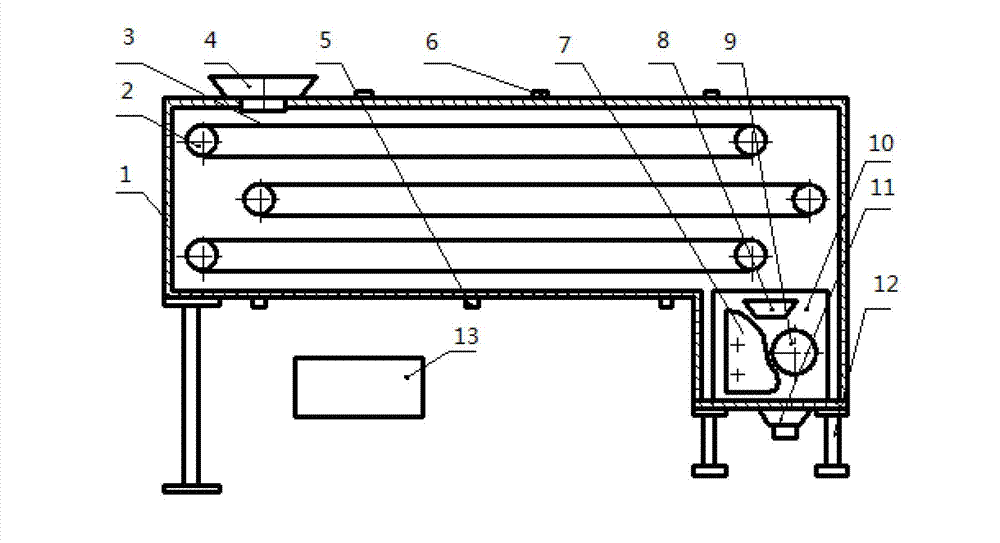

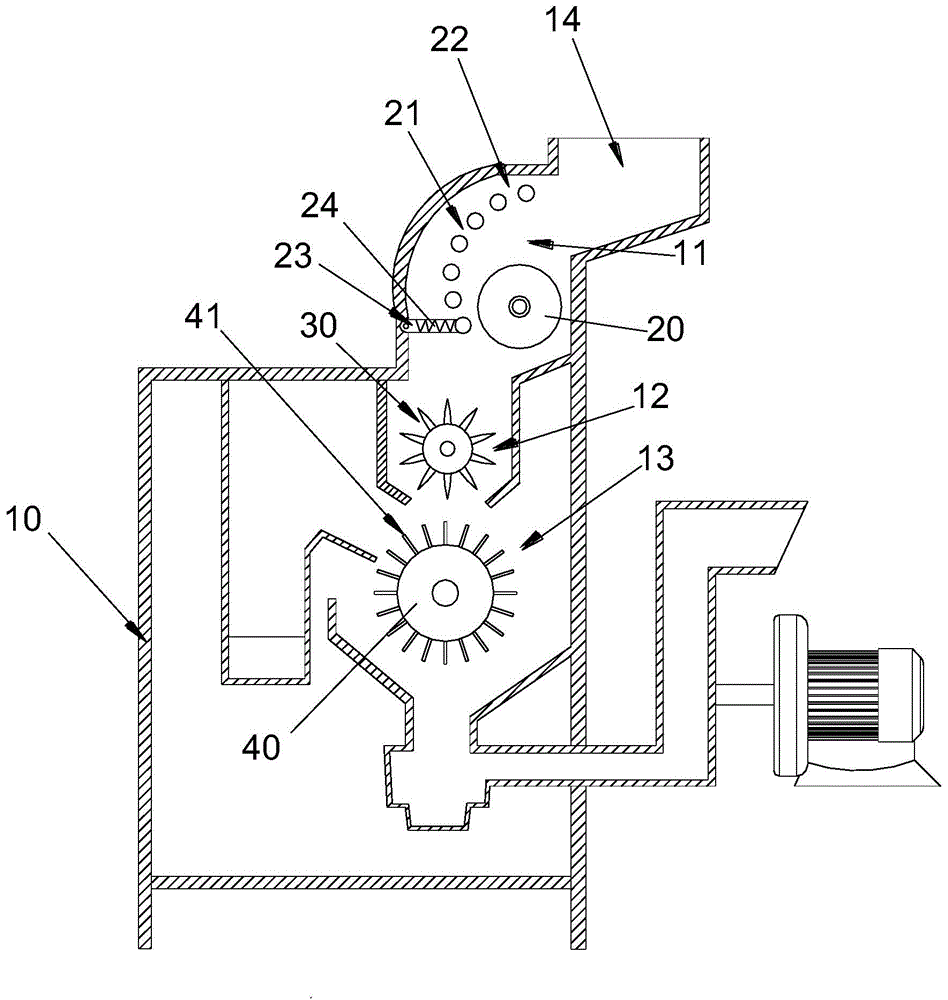

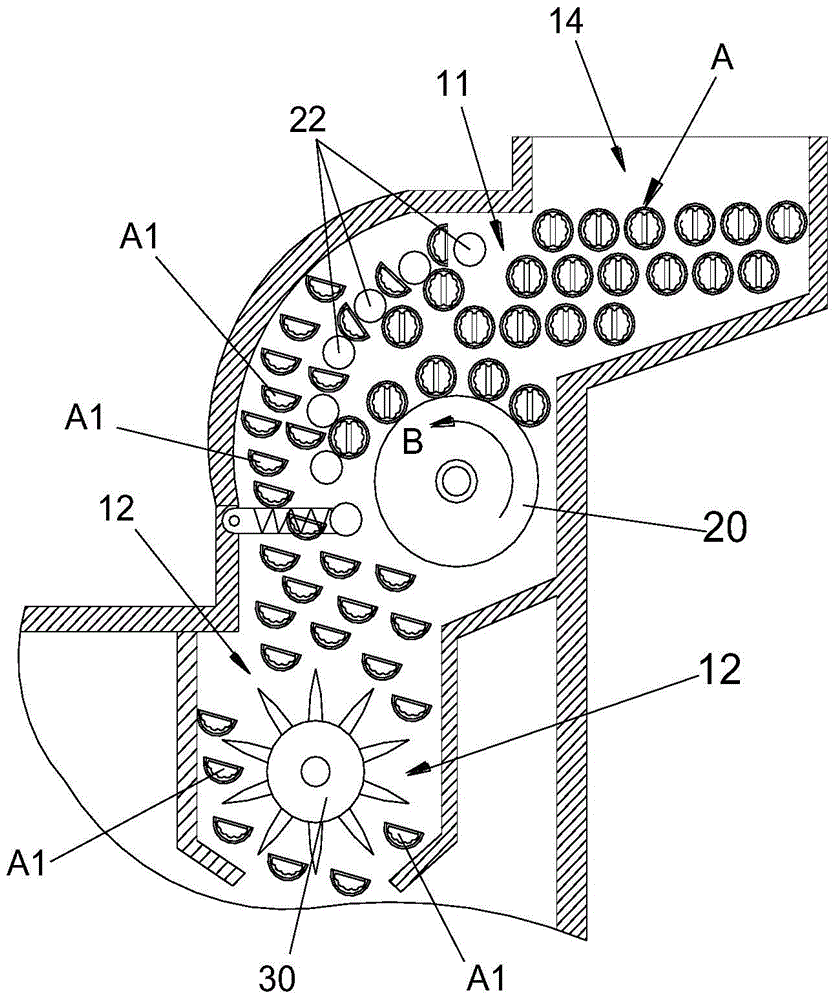

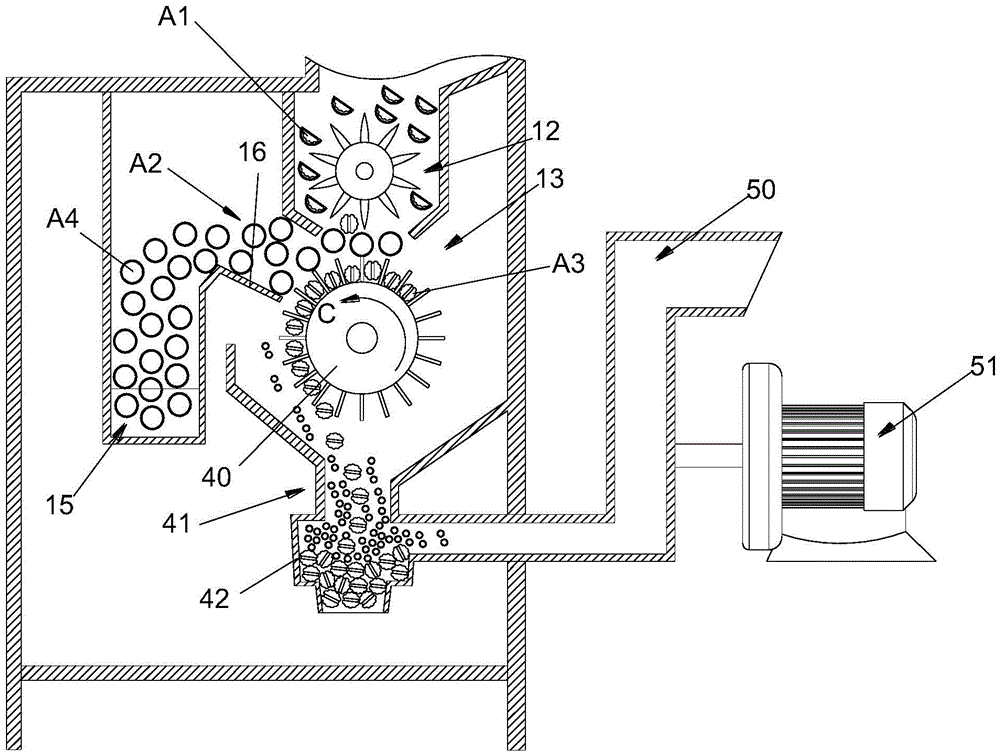

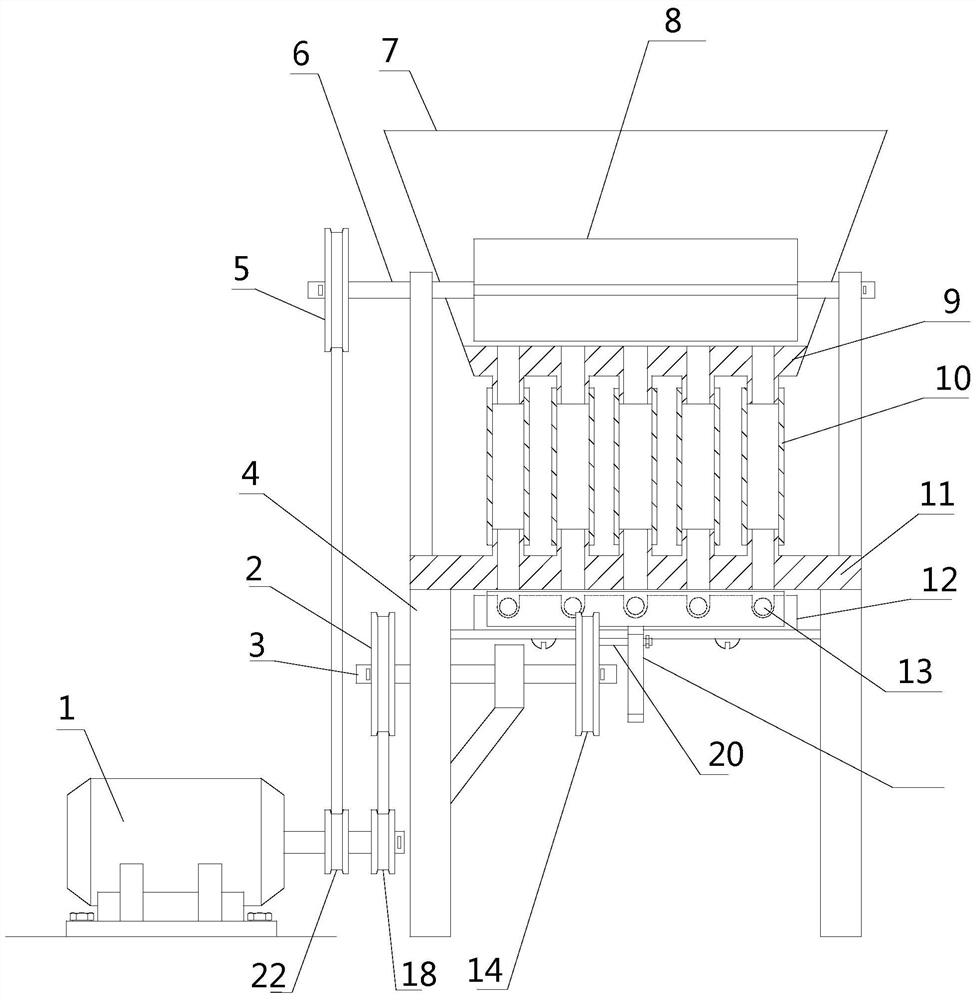

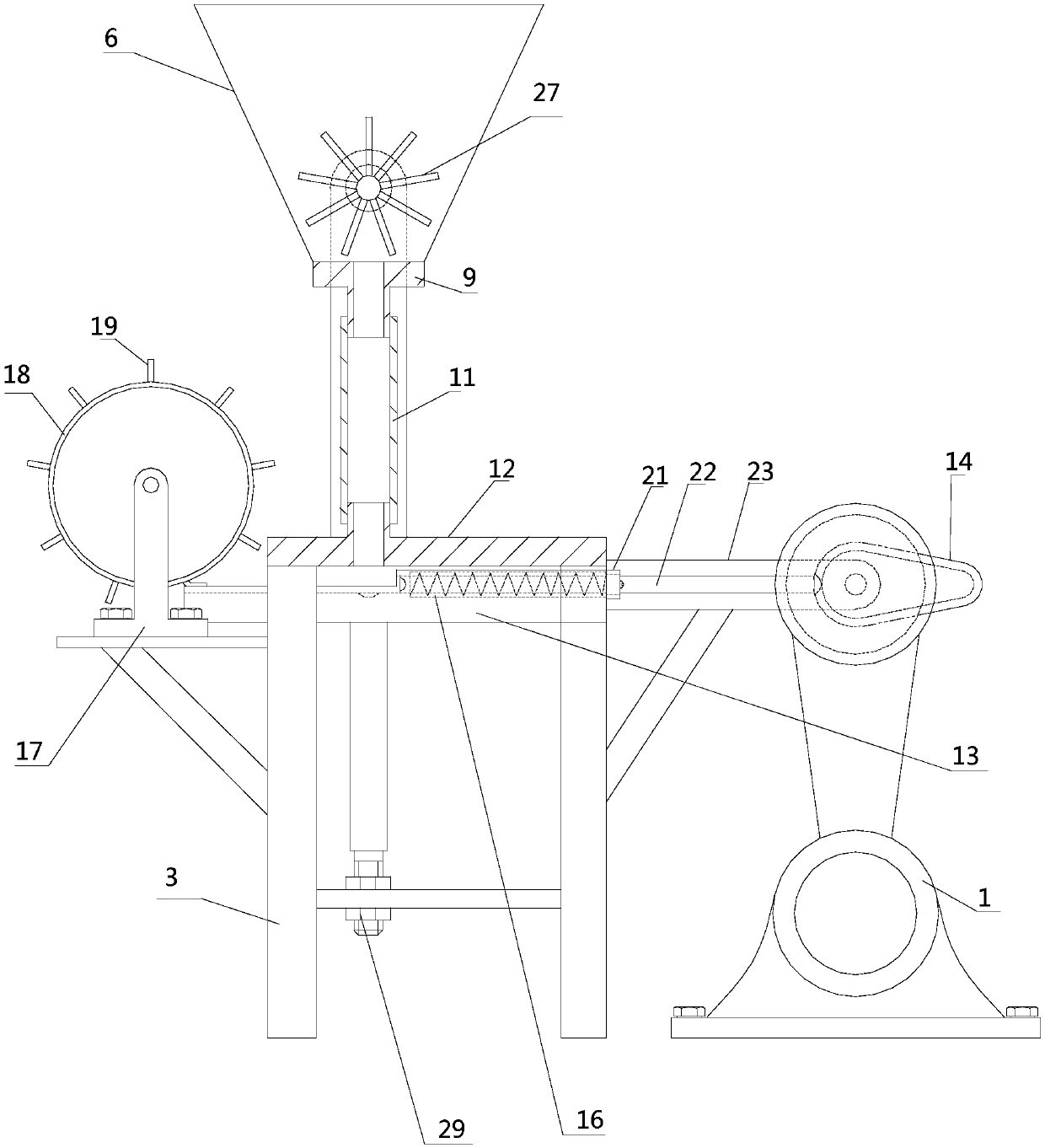

High-efficiency multifunctional badam shell crusher

ActiveCN105707911AImprove shell breaking rateAvoid secondary crushingHuskingHullingGear wheelAgricultural engineering

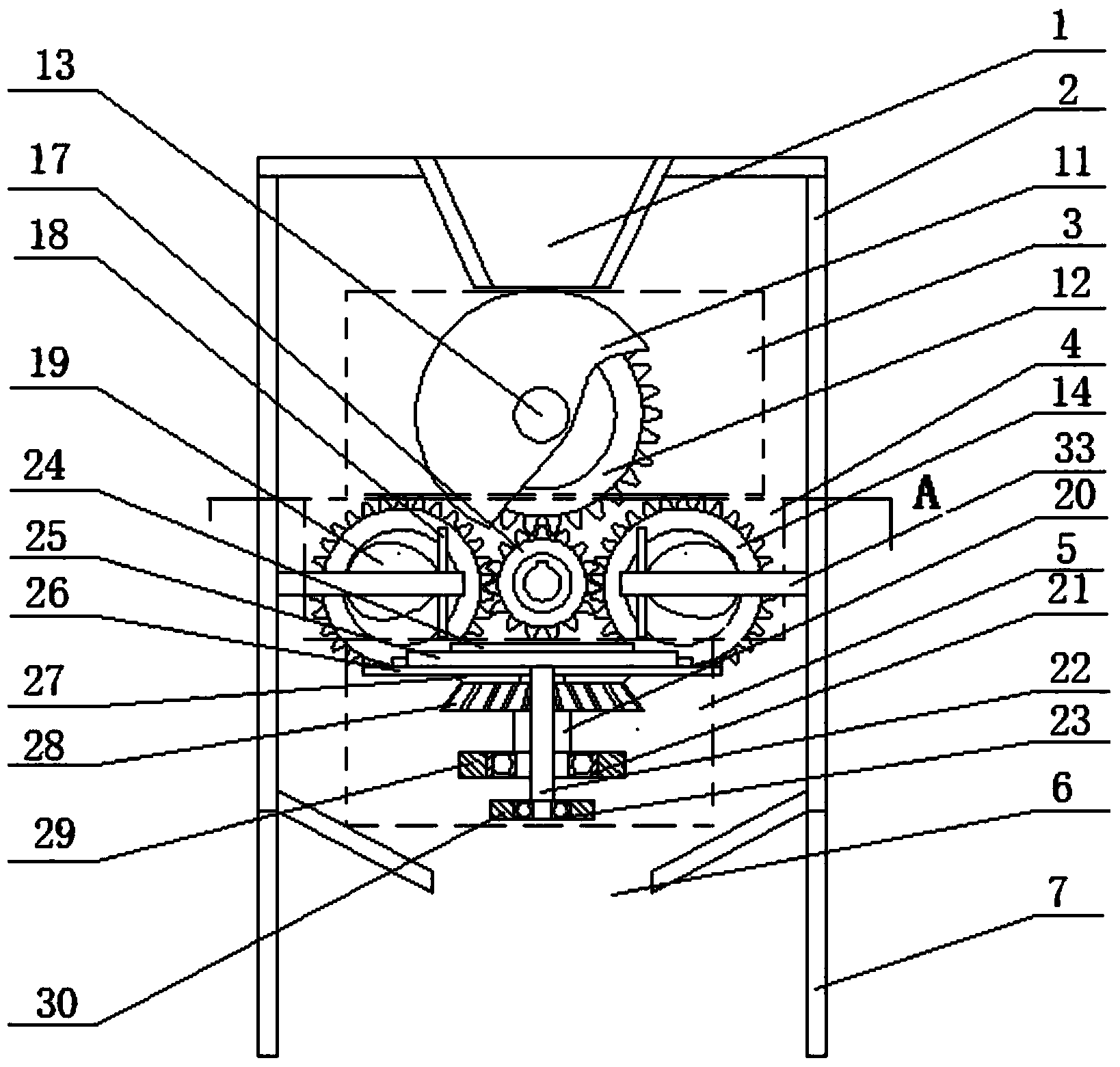

The invention relates to a high-efficiency multifunctional badam shell crusher. The high-efficiency multifunctional badam shell crusher comprises an electromotor, a motor chain wheel, a frame, a vibrating screen, a crank mechanism, a first separating frame, a screw rod, a handle, a scaleplate, a sliding bearing, a shell-crushing driving roll, a feeding hole, a shell-crushing driven roll, a bearing, a cleaning roll shaft, a cleaning roll, a second separating frame, a gear, a shell-crushing roll shaft, a first chain wheel, a second chain, a second chain wheel, a synchronous chain wheel, a third chain, a third chain wheel, a shell-crushing roll driving shaft, a fourth chain wheel, a fifth chain wheel, a sixth chain wheel, a seventh chain wheel, a grid screen, a shell discharging hole and a kernel discharging hole. The high-efficiency multifunctional badam shell crusher disclosed by the invention has the following beneficial effects: 1, the shell crushing rate is high; 2, the integrity rate of kernels is increased; 3, the high-efficiency multifunctional badam shell crusher is simple in structure and easy to manufacture; 4, the shell crushing speed and the working efficiency are high, and the problems of a nut shell crusher that a shell crushing clearance cannot be adjusted conveniently and a clearance between shell crushing rolls is not uniform are solved.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

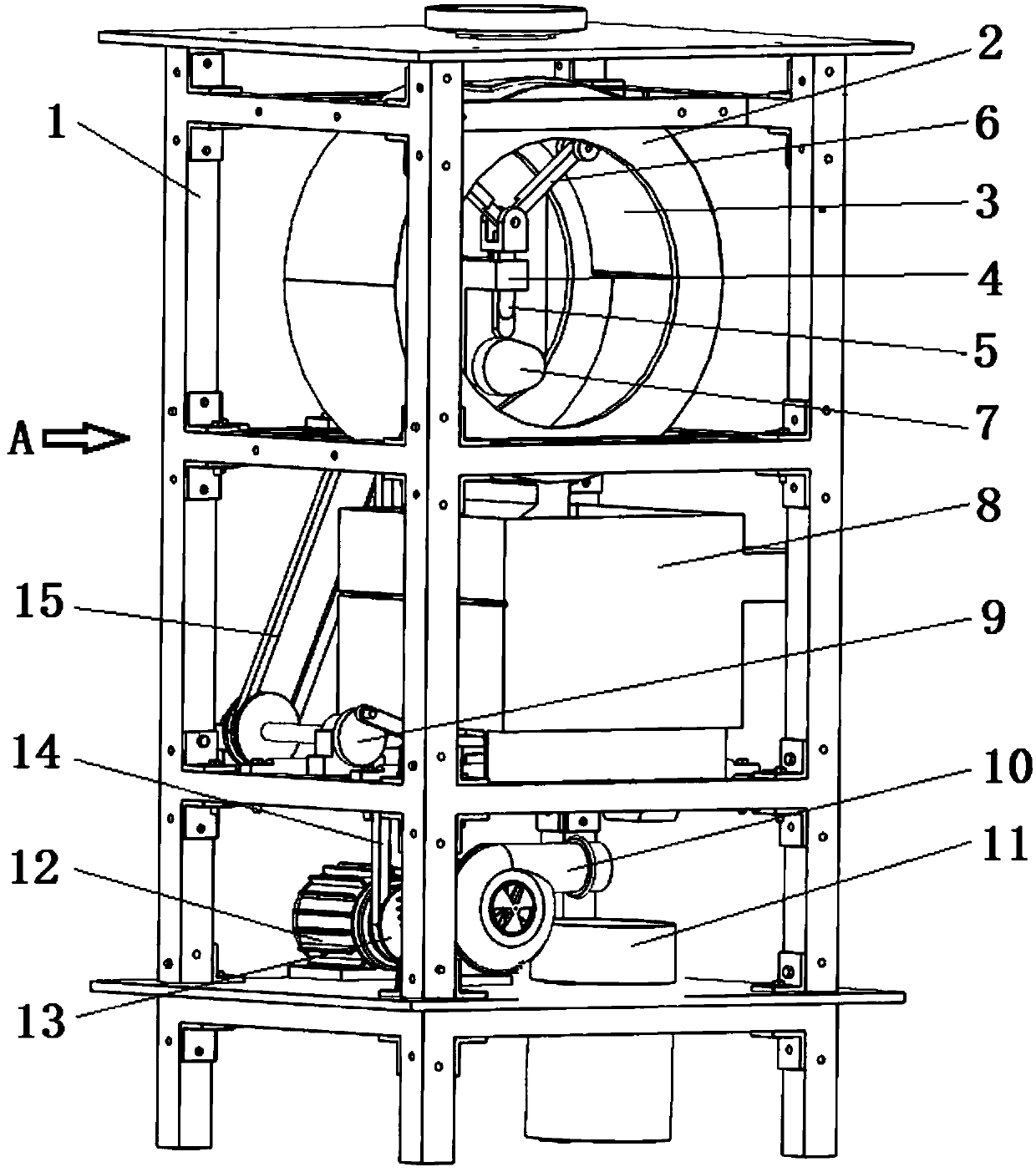

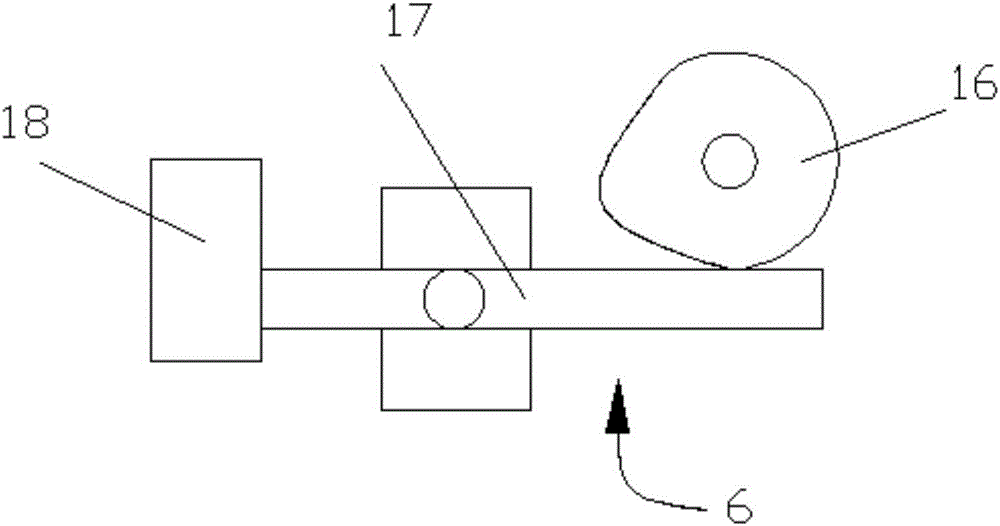

Cam-type huller for extruding and breaking hulls of acorns

InactiveCN108669575AExtrusion to break the shellImprove completenessHuskingHullingEconomic benefitsEngineering

The inVention belongs to the technical field of forest product processing machinery and relates to a cam-type huller for extruding and breaking hulls of acorns. The cam-type huller for extruding and breaking the hulls of the acorns completes the steps of extruding and breaking the hulls of the acorns, screening the hulls and kernels after the hulls of the acorns are broken, conducting winnowing for remoVing debris on the kernels and collecting the kernels through a hull extrusion and breaking deVice, a screening deVice, a winnowing deVice and a kernel collecting deVice respectiVely. A cam mechanism is utilized to driVe an arc-shaped extrusion plate assembly to reciprocate up and down, the spacing between the arc-shaped extrusion plate and a circular extrusion plate is changed periodically,extrusion and breakage of the acorns are achieVed, the structure of the huller is simple, the hull breakage rate is high, and the integrality of the kernels after the hulls are broken is high. The kernels and the hulls are separated from each other in the screening deVice and the winnowing deVice after the hulls are broken. The economic benefits of processing and comprehensiVe utilization of theacorns are increased, and the huller is applicable to enterprises engaging in comprehensiVe utilization of the acorns.

Owner:HAINAN UNIVERSITY

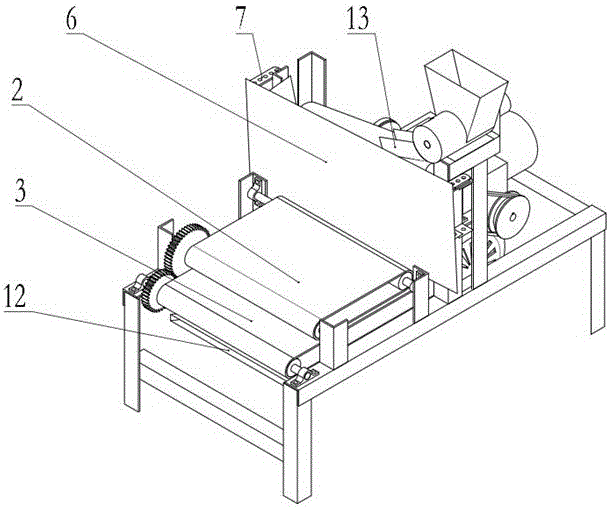

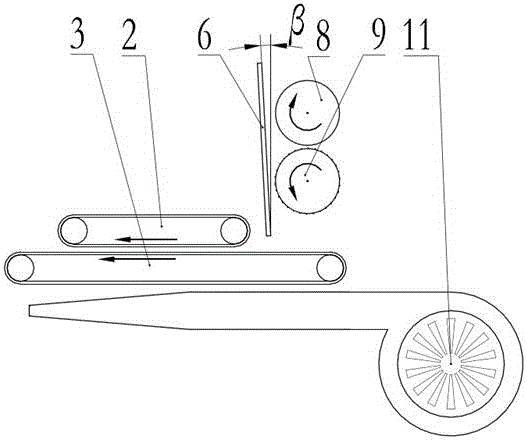

Self-adapting-based walnut kneading type shell breaker

The invention discloses a self-adapting-based walnut kneading type shell breaker, and relates to the technical field of walnut shell breaking. The self-adapting-based walnut kneading type shell breaker comprises a shell breaking device, wherein the shell breaking device comprises a shell breaking mechanism; the shell breaking mechanism comprises a first belt, a second belt and an adjusting device;the first belt is inclined to the second belt; a wedge-shaped shell breaking channel is formed between the first belt and the second belt; the speed of the first belt is different from that of the second belt; and the adjusting device is used for adjusting the distance and the inclination angle between the first belt and the second belt. The invention aims to overcome the defects in the prior art, and provides the self-adapting-based walnut kneading type shell breaker. Shearing force and extrusion force which are periodic are provided to walnuts between the two belts through the two belts atdifferent speeds so as to break shells of the walnuts, the distance and inclination angle between the two belts are adjustable to adapt to the walnuts in different sizes and different types, and the requirements of high shell breaking rate and low kernel breaking rate are met simultaneously.

Owner:SHIHEZI UNIVERSITY

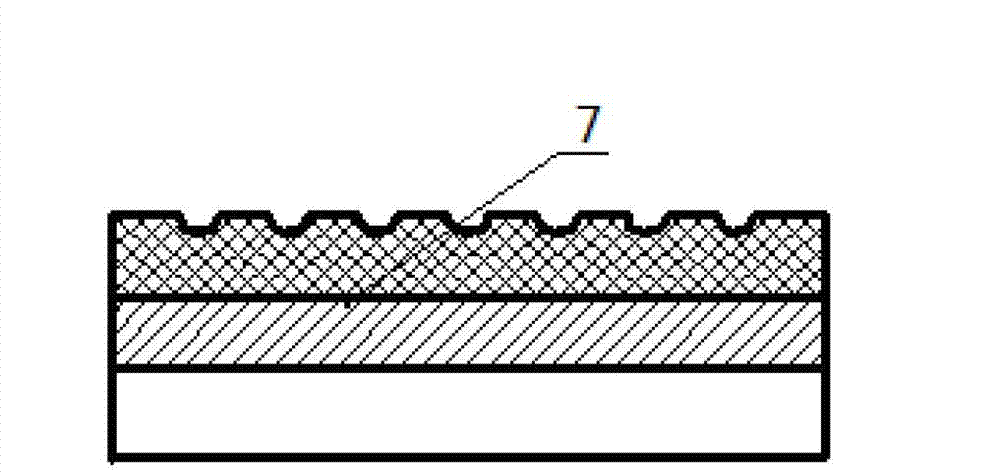

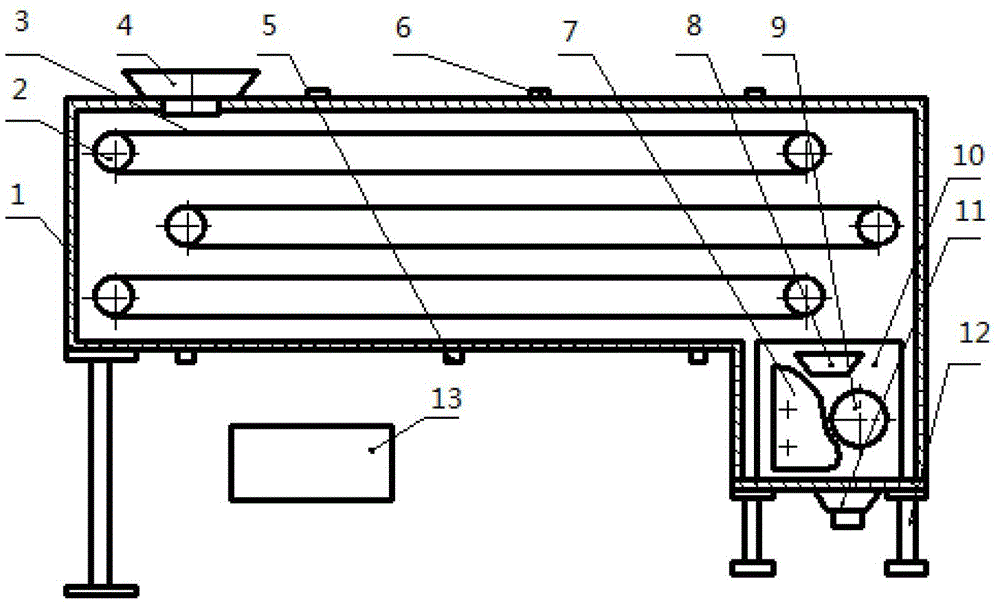

Chestnut shell breaking system

InactiveCN103082381AImprove shell breaking rateReduce breakage rateHuskingHullingEngineeringMechanical engineering

The invention provides a chestnut shell breaking system which comprises a box body, silk screen conveyer belts and a shell breaking device, wherein the silk screen conveyer belts and the shell breaking device are placed inside the box body. A feeder and a dampness extraction opening are placed on the box body; a discharging device and a hot air inlet are placed on the lower portion of the box body; the shell breaking device is placed below the lower end of the silk screen conveyer belts, and comprises a shell breaking channel, wherein the shell breaking channel is composed of a shell breaking plate and a shell breaking roller; and elastic protruding stabs are placed on the shell breaking channel. A plurality of silk screen conveyer belt layers are placed on the shell breaking device, and in the chestnut conveying process, the hot air inlet and the dampness extraction opening continuously convey hot air and extract damp and hot air and the chestnuts are completely dried, then the chestnuts immediately enter the shell breaking channel and the shell of the chestnuts are broken, and therefore shell breaking rates of the chestnuts are effectively improved. Meanwhile because the shell breaking channel is of an arch-shaped channel and is made of elastic materials to break the shells, breaking rates of peeled chestnuts are effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

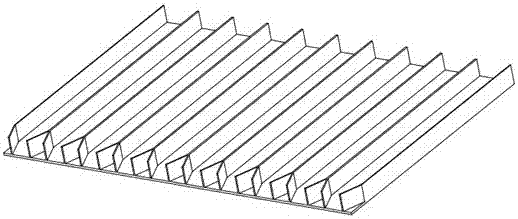

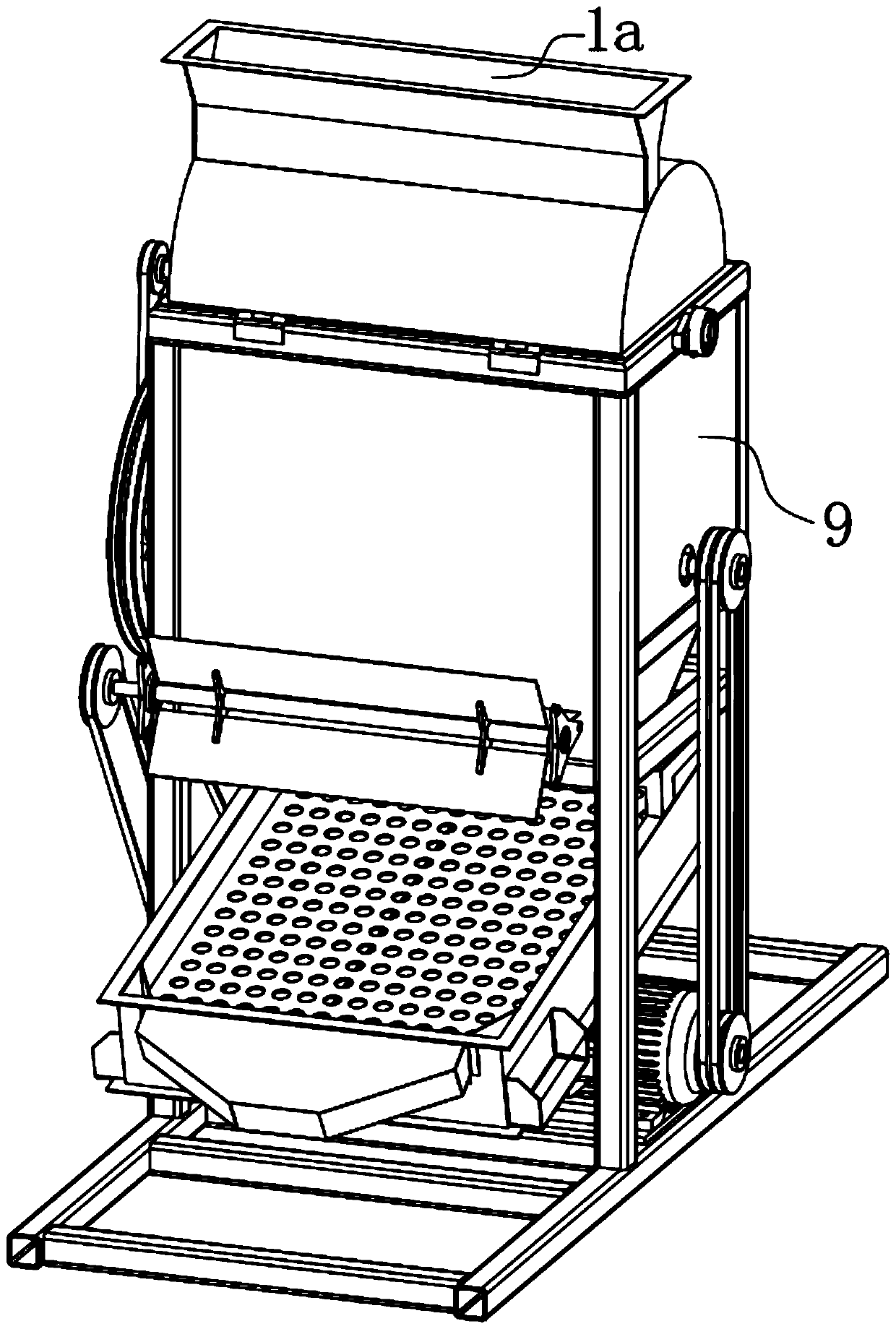

Self-adaptation grading unshelling integrated device for nuts

The invention discloses a self-adaptation grading unshelling integrated device for nuts. The self-adaptation grading unshelling integrated device comprises an upper differential speed belt, a lower differential speed belt, a front adjustment hinge, gap adjustment side plates, a rear adjustment hinge, a grading roller, an unshelling roller, an air blower and an air duct. The grading roller is located above the unshelling roller and is parallel with the unshelling roller, a certain inclination angle is formed, the gap adjustment side plates are located on the side face of the grading roller and the side face of the unshelling roller, the lower differential speed belt and the upper differential speed belt are arranged in parallel, a certain distance is formed between the two belts, and the air blower and the air duct are located below the lower differential speed belt. The functions of nut grading and unshelling and shell and nutlet separating under the action of rubbing are first integrated on the same device; during grading and unshelling, the self-adaptation grading unshelling integrated device can select suitable positions for the nuts according to the sizes of the nuts for grading and unshelling, and therefore the damage rate of nutlets during unshelling is greatly decreased. The self-adaptation grading unshelling integrated device has the advantages of being convenient to use, small in size and low in energy consumption and damage rate of the nutlets.

Owner:ZHEJIANG UNIV

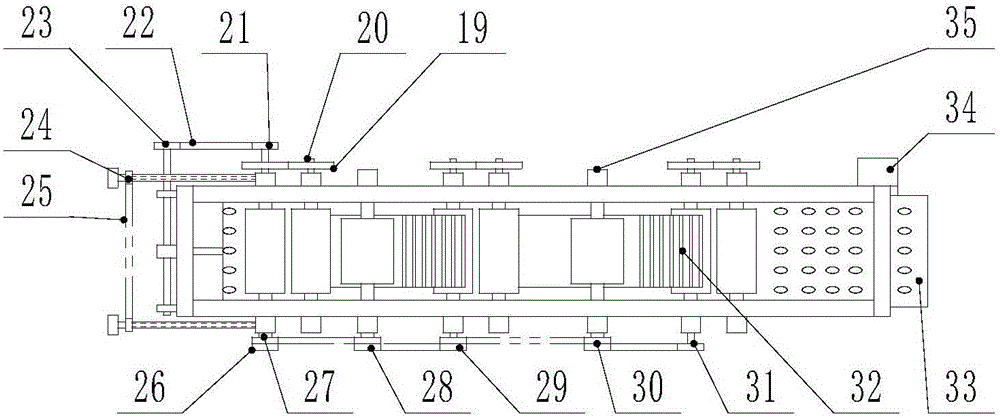

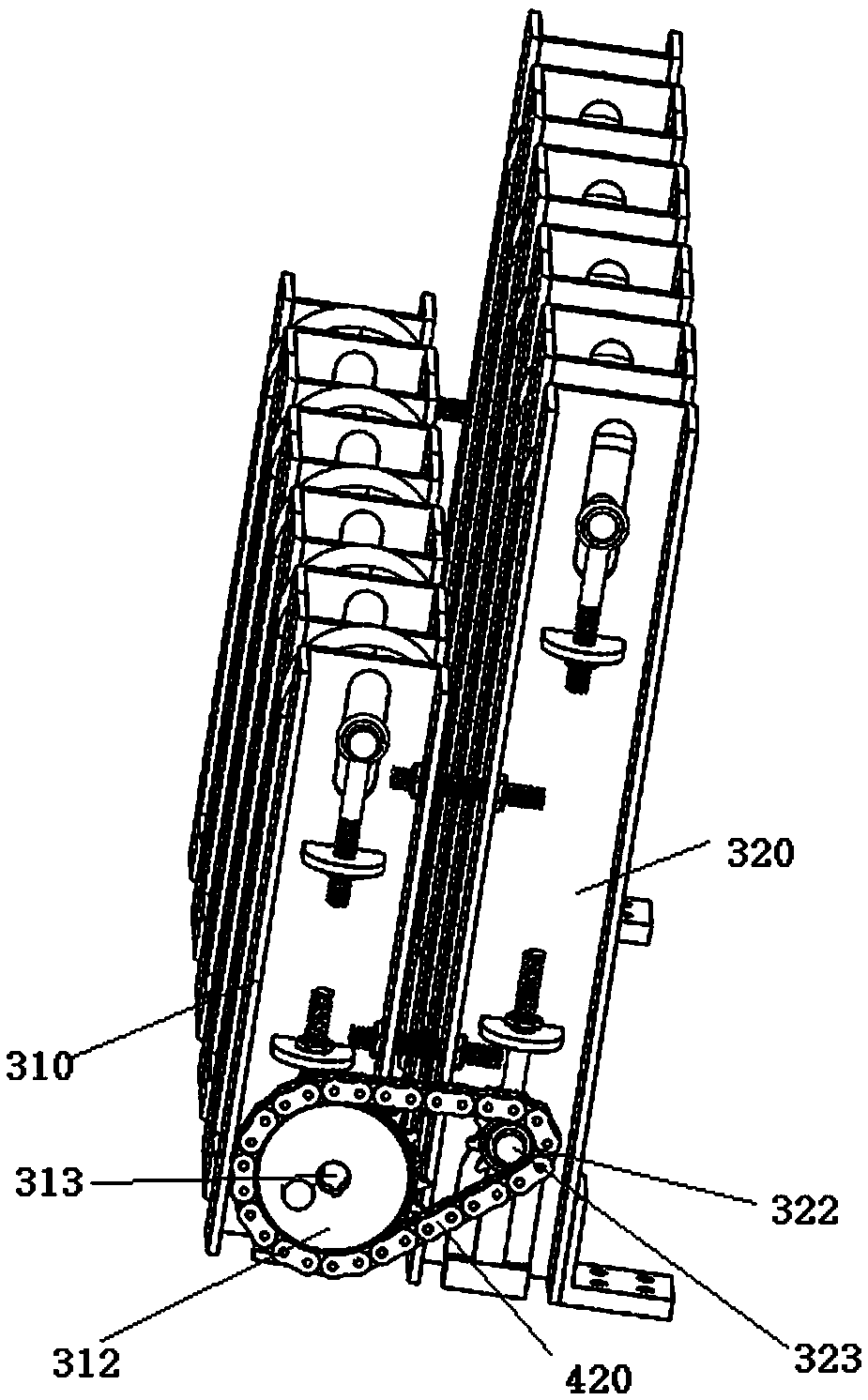

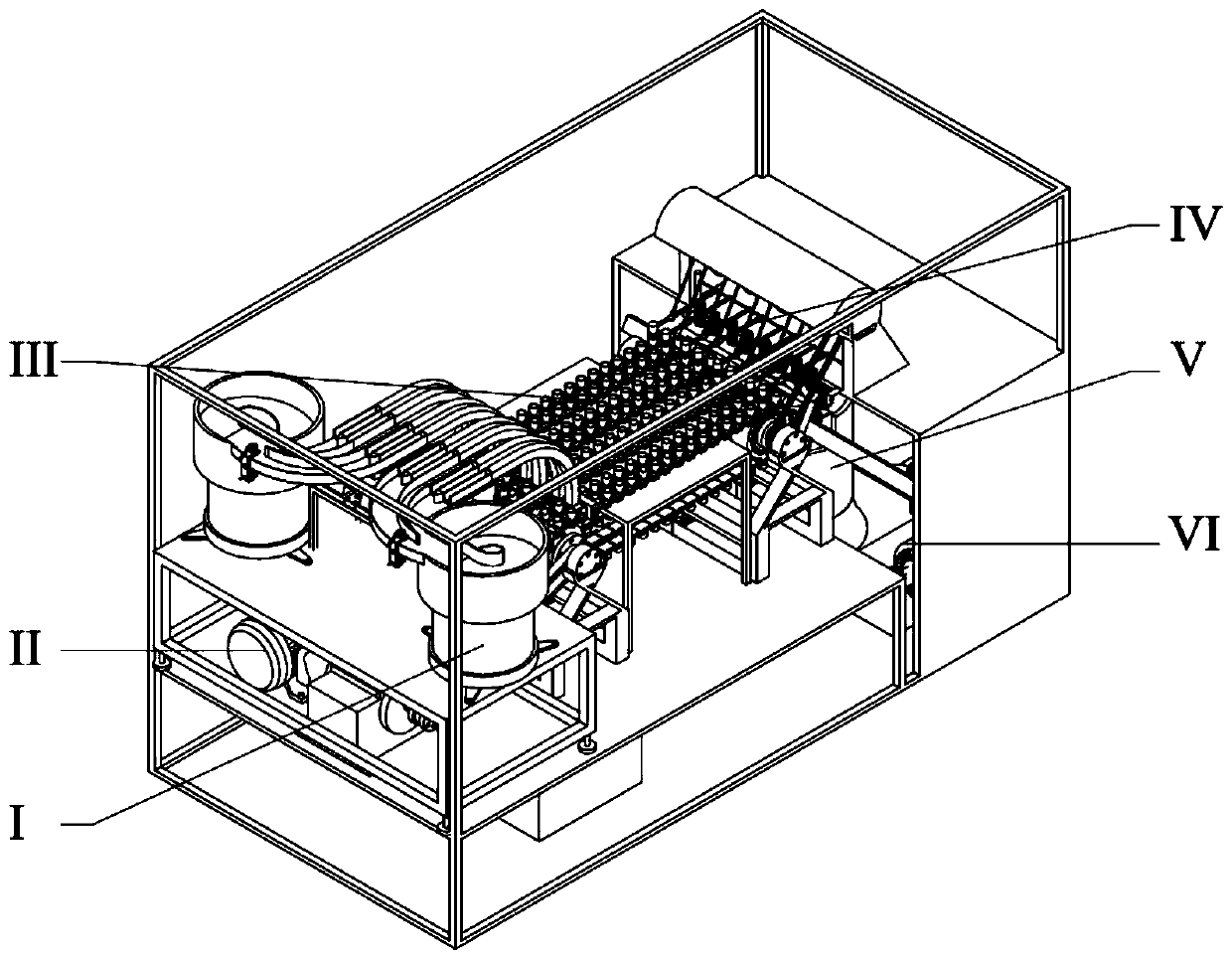

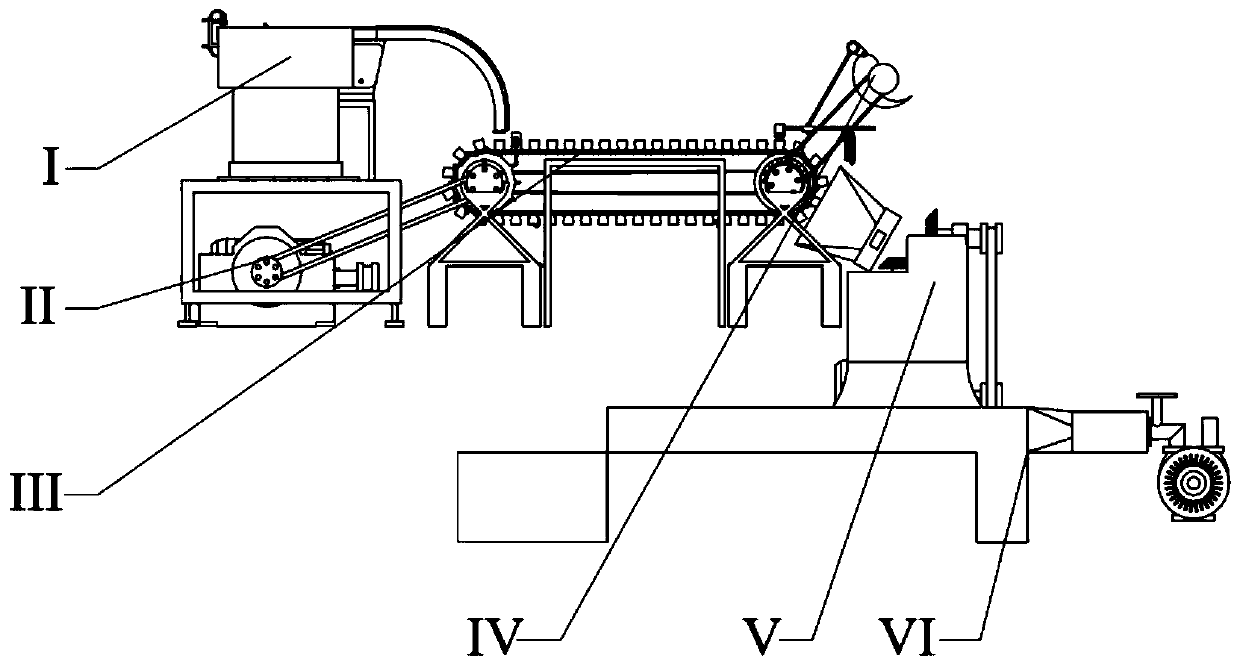

Indent self-positioning long-diameter striking type shell breaking and whole kernel taking equipment and method for high-exposed-kernel walnuts

InactiveCN111567817AImprove shell breaking rateStrong controllabilityHuskingHullingEngineeringMechanical engineering

The invention provides indent self-positioning long-diameter striking type shell breaking and whole kernel taking equipment and method for high-exposed-kernel walnuts. The equipment comprises a feeding positioning device used for discharging the walnuts in a long-diameter posture, a chain plate feeding device used for fixing the discharged long-diameter walnuts through indents and conveying the walnuts to a primary shell breaking device, the primary shell breaking device used for simulating manual knocking type shell breaking to realize a shell breaking action, a secondary shell breaking device that comprises a spiral slideway, and a shell and kernel separation device for separating shells and kernels by utilizing air pressure power generated by pressure difference, wherein the spiral slideway can rotate, so that the walnuts treated with the primary shell breaking device roll downwards along the spiral slideway under the action of gravity.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Technique for separating hemp seed and husk kernel

The invention relates to a separation process of hemp seeds, shells and kernels, in particular to a separation process of hemp seeds, shells and kernels. The invention includes breaking shells, screening and separating shells and kernels, and the steps are divided into: A. removing impurities and grading; B. controlling moisture; C. breaking shells with double-toothed rollers; D. separating shells and kernels with vibrating sieves; E. Separation of shell and kernel with a non-net inclined vibrating screen; F. Packing separately. The separation process of the present invention can make the hemp seed have a shell content rate≤5%, a kernel content rate in the shell≤3%, and a total yield of more than 97%, so as to improve the sensory perception, internal quality, and economical quality of further deep-processed products. effect played a positive role.

Owner:PUER JIANYUAN GREASE

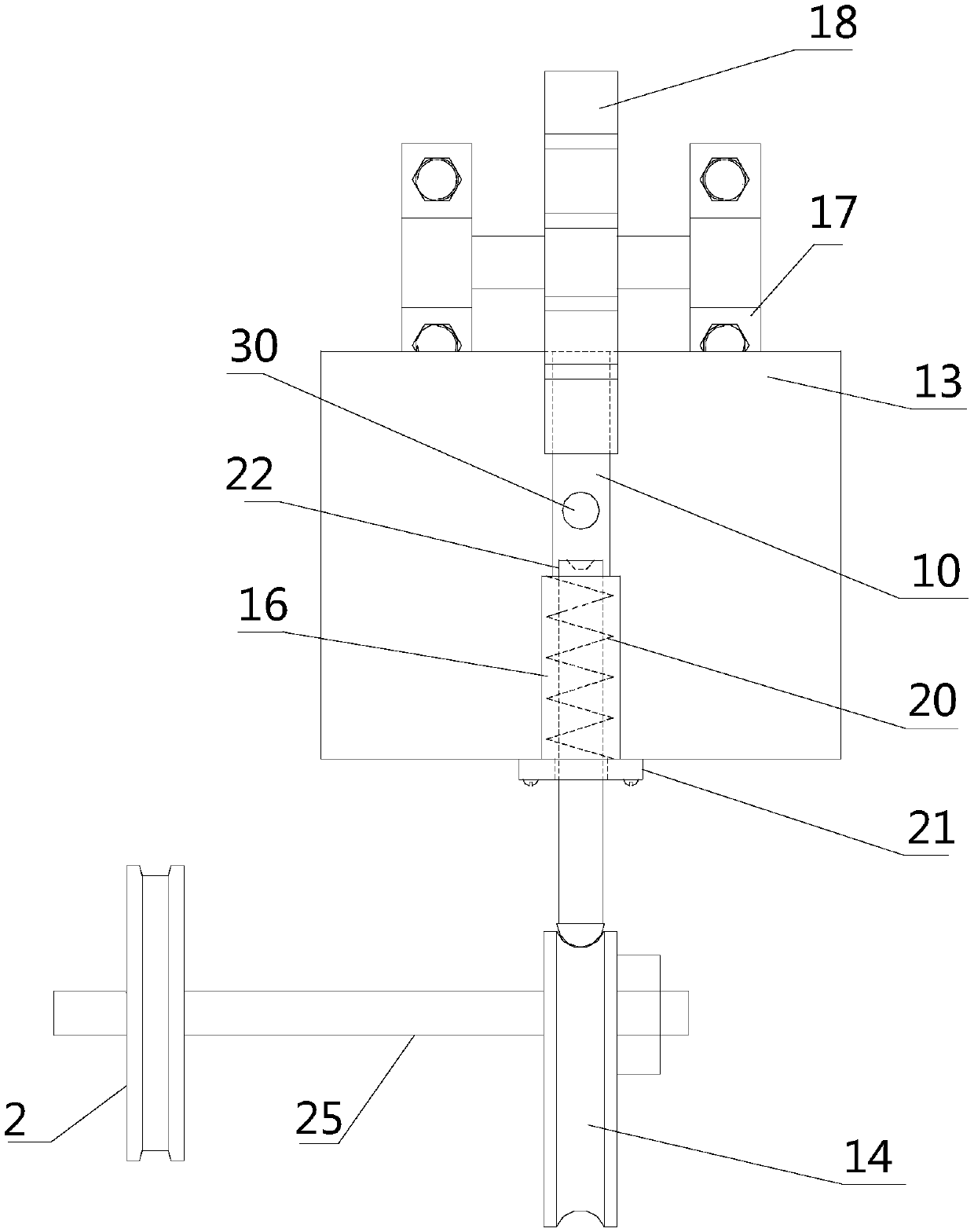

Gordon euryale seed shell breaking device

ActiveCN107136523AHigh degree of automationHigh breaking efficiencyHuskingHullingAgricultural engineering

The invention discloses a gordon euryale seed shell breaking device. The gordon euryale seed shell breaking device comprises a machine frame, a hopper, a seed cleaning machine, an upper seed taking plate, a lower seed taking plate, a working table, a seed pushing machine and a blocking block, wherein the seed cleaning machine is arranged in the hopper; the upper seed taking plate is arranged at the bottom of the hopper; a plurality of upper through holes are formed in the upper seed taking plate; a plurality of lower through holes corresponding to the upper through holes in a one-to-one manner are formed in the lower seed taking plate; each upper through hole is connected with the corresponding lower through hole through a seed taking pipe; a plurality of long grooves corresponding to the lower through holes are formed in the upper end surface of the working table; a pit is formed in the bottom of each long groove; a plurality of push rods of the seed pushing machine are driven by a first driving mechanism to move back and forth along the corresponding long grooves, so that gordon euryale seed granules in the corresponding pit are pushed backwards to the blocking block; and the shell breaking operation of the gordon euryale seed granules is realized under the extruding of the push rods and the blocking block. Compared with the prior art, the gordon euryale seed shell breaking device disclosed by the invention has the following advantages that mechanized shell breaking of the gordon euryale seed granules can be realized; and the requirements for shell breaking quality and technology of the gordon euryale seed granules are met.

Owner:CHUZHOU UNIV

Full-automatic mechanical walnut shell opening machine

The invention relates to a full-automatic mechanical walnut shell opening machine. The full-automatic mechanical walnut shell opening machine is characterized by comprising a machine frame, a feedinghopper, a hard brush roller, guiding rollers, sequencing slideways, a mechanical automatic shell opening device, a material storing box and the like, wherein the mechanical automatic shell opening device comprises an electric cylinder, a cutting saw blade, a walnut fixture, an air cylinder and the like; a signal is transmitted to a PLC by a sensor; and the PLC is used for controlling a motor, theair cylinder and the electric cylinder to be mutually coordinated for providing power for the machine. According to the full-automatic mechanical walnut shell opening machine disclosed by the invention, automatically processing walnuts is realized through the control of the PLC; pretreatment of shell opening of walnut shells is performed, and the surface stress of the walnuts is released, so thatin the process of shell breaking and kernel taking, the shell breaking rate and perfect kernel rate of the walnuts are improved, and the situation that when being processed, a food of walnuts with shells is tasty is also convenient to realize; and through the adoption of the full-automatic mechanical walnut shell opening machine, the walnuts can be automatically processed, so that human resourcesare greatly saved, the accuracy and the controllability are high, and processing the walnuts in batch can be realized.

Owner:SHIHEZI UNIVERSITY

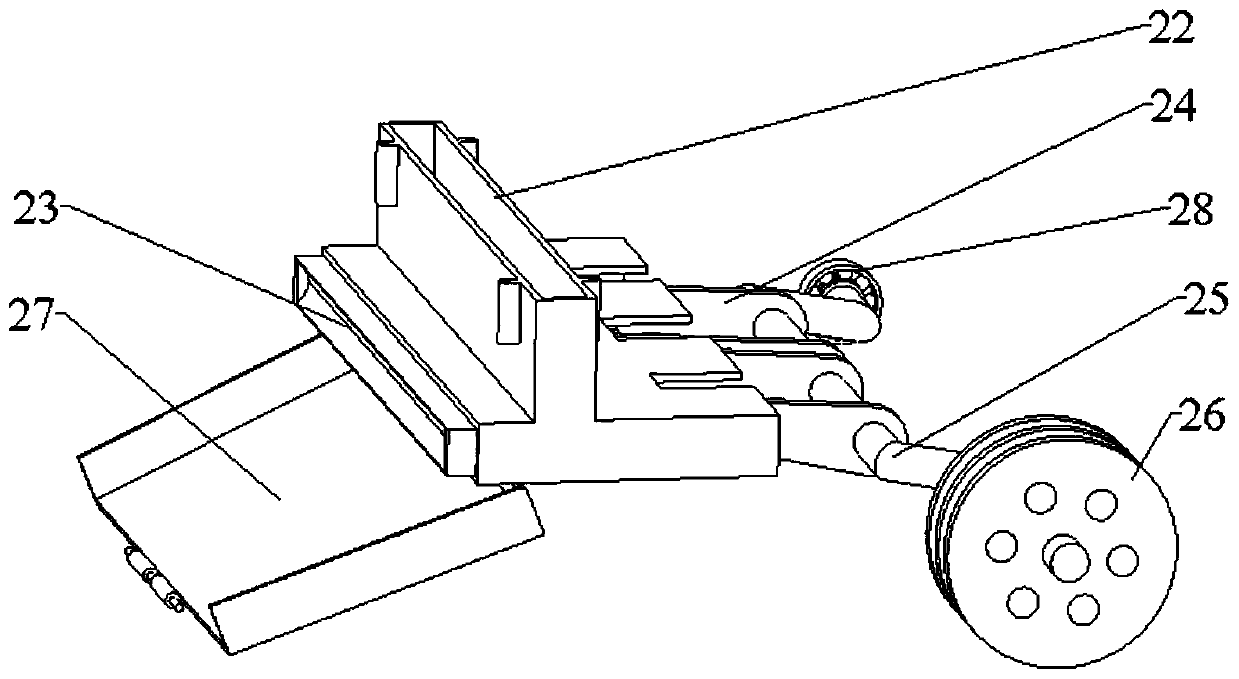

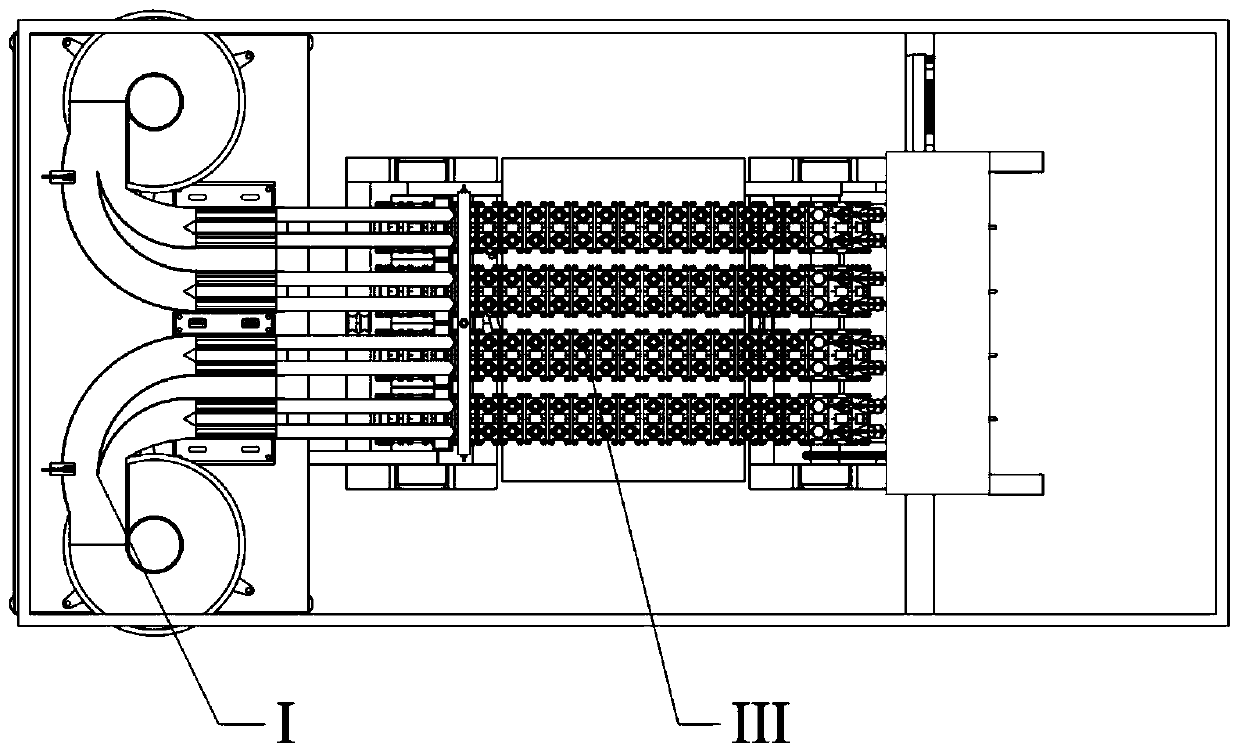

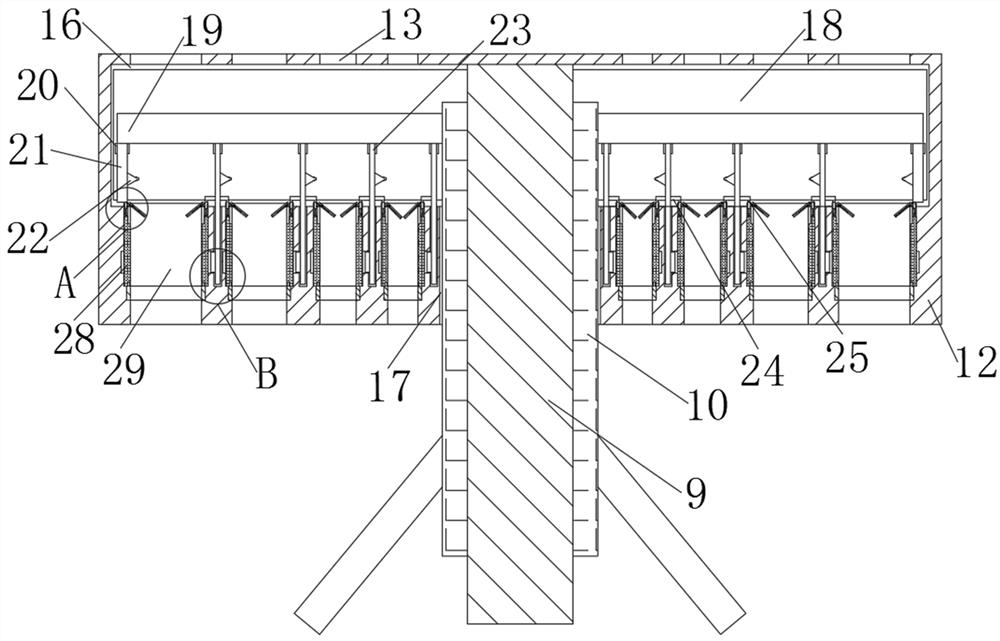

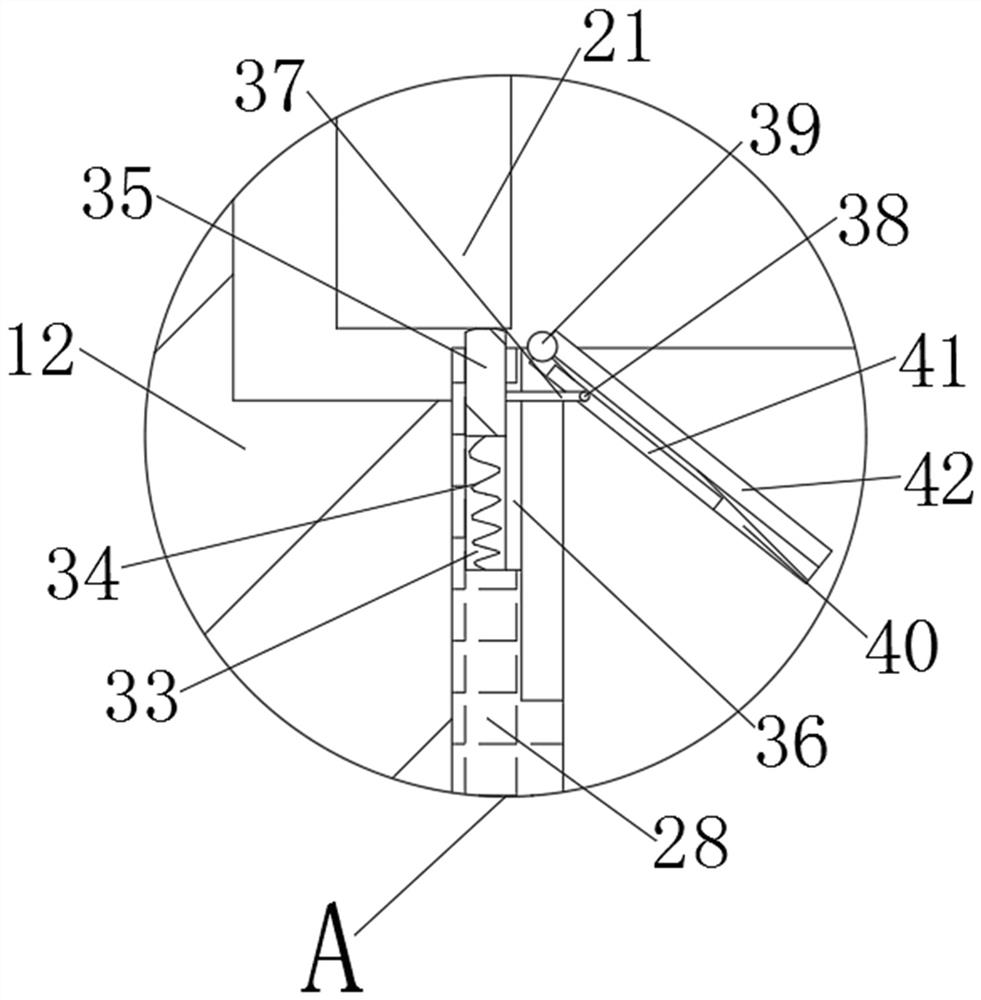

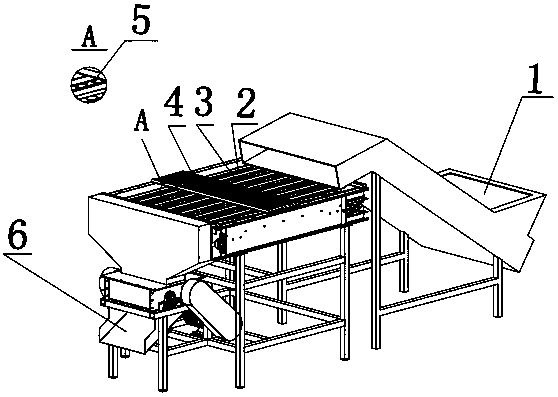

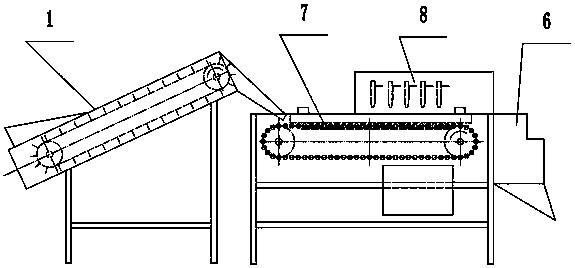

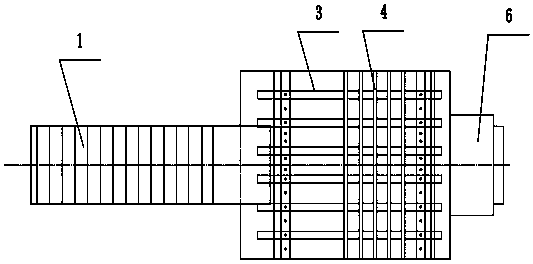

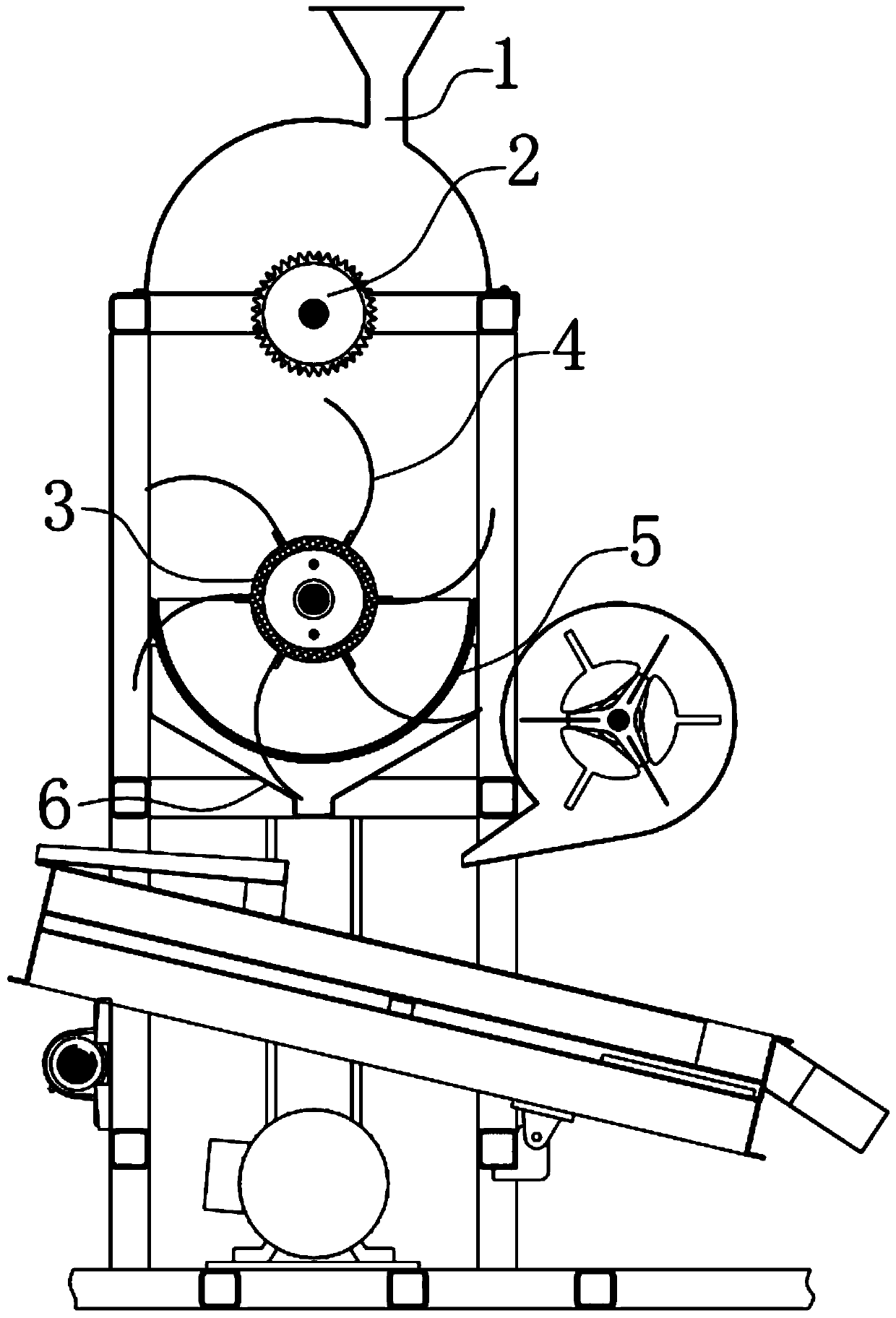

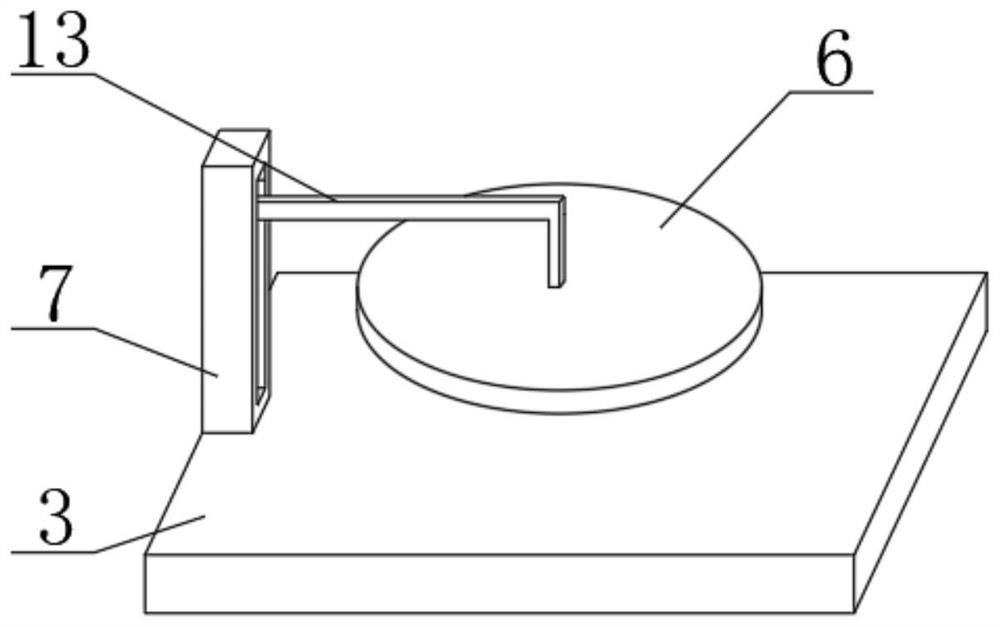

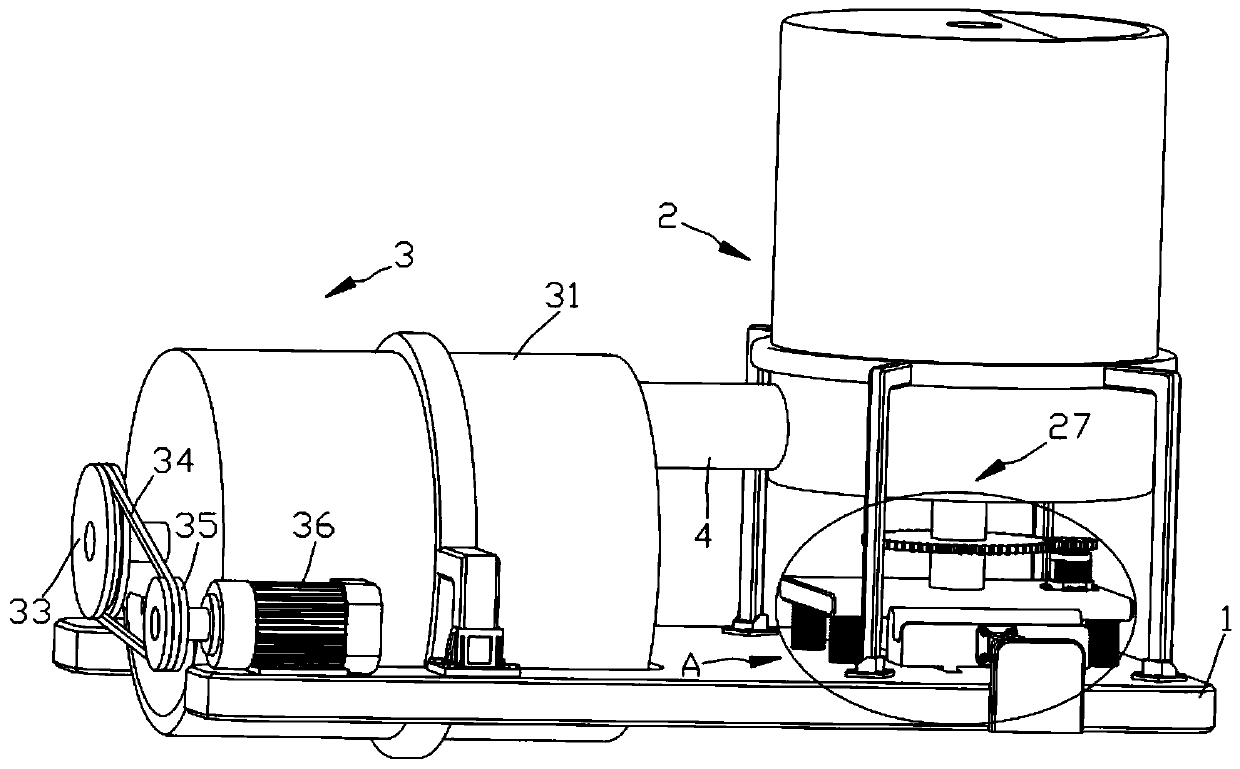

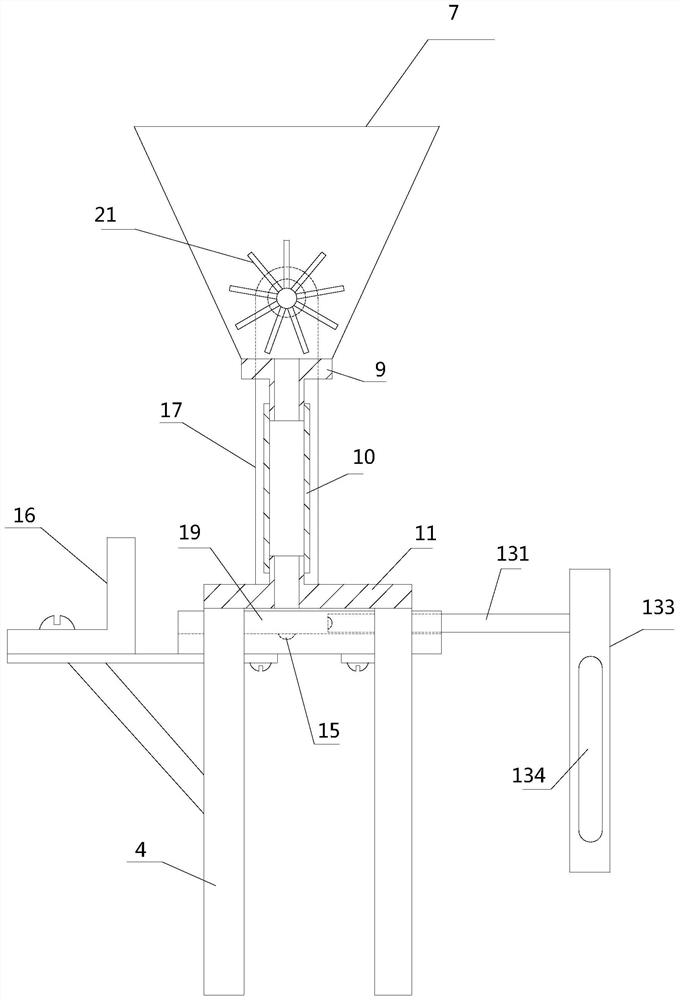

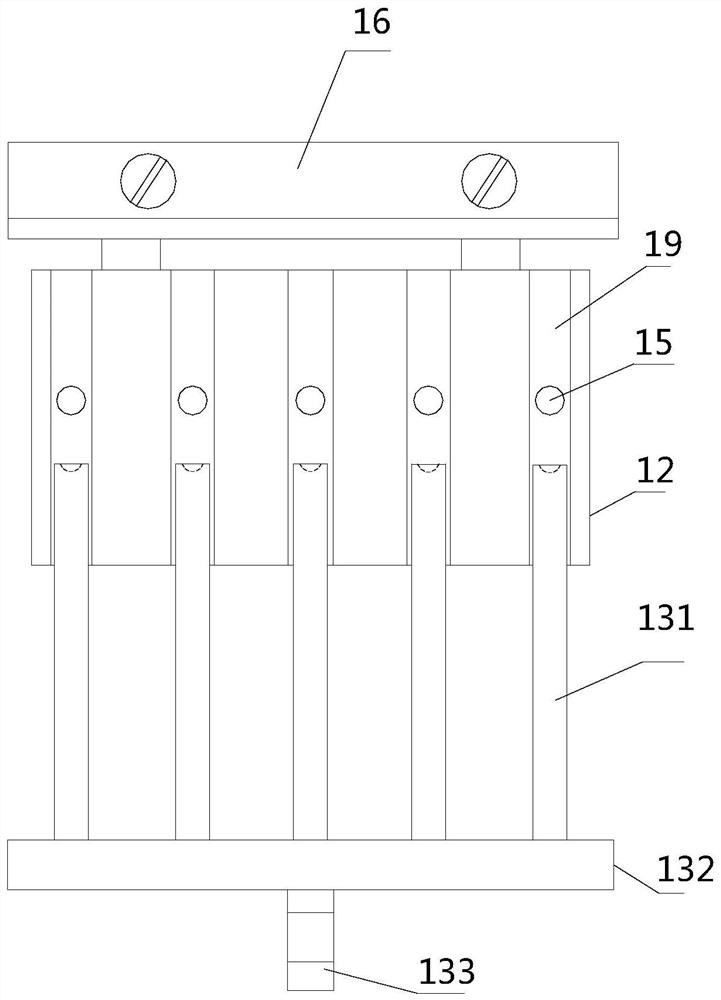

Cam roller type walnut horizontal-squeezing shell-breaking system

InactiveCN110710692APrecise feedingImprove delivery rateHuskingHullingWalnut NutReciprocating motion

The invention discloses a cam roller type walnut horizontal-squeezing shell-breaking system. According to the technical scheme, the cam roller type walnut horizontal-squeezing shell-breaking system comprises a feeding device, a shell-breaking device and a falling device which are fixed to a rack, the feeding device is arranged above the shell-breaking device, and the falling device is arranged below the shell-breaking device; the feeding device comprises a feeding box, an intermittent feeding roller is arranged in the feeding box, a feeding baffle is mounted on one side of the intermittent feeding roller, an adjustable feeding scraper mechanism is mounted on the other side of the intermittent feeding roller, and feeding grooves spaced by 180 degrees are formed in the intermittent feeding roller; and the shell-breaking device comprises a squeezing box, a movable tooth-shaped squeezing plate and a fixed tooth-shaped squeezing plate are relatively mounted in the squeezing box, a squeezingcam is mounted on the side, away from the fixed tooth-shaped squeezing plate, of the movable tooth-shaped squeezing plate, and the movable tooth-shaped squeezing plate and the fixed tooth-shaped squeezing plate are each provided with a plurality of tooth gaps. Walnuts pass through the feeding device and then fall into the gaps of the movable tooth-shaped squeezing plate and the fixed tooth-shapedsqueezing plate, and the squeezing cam drives the movable tooth-shaped squeezing plate to conduct periodic reciprocating motion to be in synchronous fit with the fixed tooth-shaped squeezing plate toconduct squeezing shell-breaking on the walnuts.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

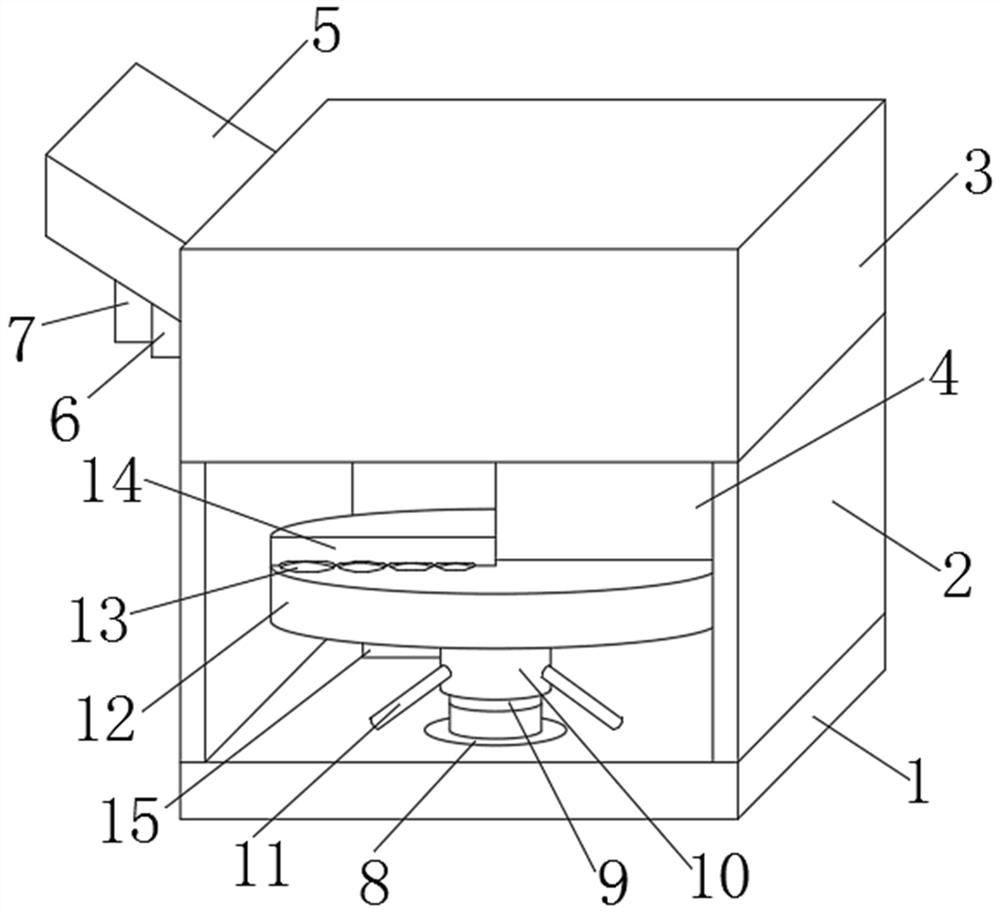

Gordon euryale seed shelling device for agricultural production and use method thereof

InactiveCN113383969AFor continuous placementImprove shelling efficiencyHuskingHullingAgricultural scienceHusk

The invention relates to a gordon euryale seed shelling device for agricultural production and a use method thereof. The gordon euryale seed shelling device comprises a base; vertical plates are fixed to the two sides of the upper surface of the base; a servo motor is embedded in the center of the base; a connecting column is fixed to the top end of the output end of the servo motor, and the connecting column is sleeved with a sleeve; a supporting rod is fixed to the side face of the sleeve; the other end of the supporting rod is fixed to the upper surface of the base; a rotating disc is fixed to the upper end of the connecting column; a cavity is formed in the rotating disc; a through hole is formed in the center of the lower portion of the cavity; and a plurality of rotating pipes are arranged on the lower surface of the cavity. The gordon euryale seed shelling device has the beneficial effects that gordon euryale seeds can be conveniently and continuously placed, the number of shells broken at a time is greatly increased, the gordon euryale seed shell removing efficiency is improved, and the gordon euryale seeds are prevented from slipping in the shell breaking process, so that shell breaking can be continuously carried out, shells are completely broken, the gordon euryale seed shell breaking rate is increased, and the working intensity is reduced.

Owner:王爱义

Laser-type walnut shell-slitting machine

The present invention relates to a laser-type walnut shell-slitting machine. The laser-type walnut shell-slitting machine is characterized in that the laser-type walnut shell-slitting machine consistsof a material charging device, a roller sorting device, a laser slitting device and a material discharging device. Walnuts are uniformly sorted after being sent to the roller sorting device by a walnut hoister, the walnuts are successively slit by two laser probes installed on a hanging beam when the walnuts are under the laser probes, which fully guarantees that walnut shells are effectively slit with good slitting quality. The invention aims to: release the surface stress of the walnut shells, ensure the shell breaking rate and the whole kernel rate of the walnuts in the subsequent processof industrialized shell breaking and kernel removing and make the unshelled walnut food easy to be tasty in processing; the laser-type walnut shell-slitting machine can reduce the contact energy lossof mechanical slitting and improve the degree of automation and controllability, thus achieving the purpose of precisely controlling the slitting quality; and the laser-type walnut shell-slitting machine has advantages of batch slitting, high slitting efficiency, etc.

Owner:SHIHEZI UNIVERSITY

Walnut shell crushing machine high in shell crushing rate

PendingCN106617139AHigh breaking efficiencySatisfy the needs of breaking the shellHuskingHullingEngineering

The invention relates to the technical field of shell crushing machines, in particular to a walnut shell crushing machine high in shell crushing rate. The walnut shell crushing machine comprises a machine body, a feeding hopper is arranged on the machine body, a discharging hole is formed in one side of the bottom of the machine body, a crushing channel is arranged in the machine body in an inclined mode, one end of the crushing channel is connected with the feeding hopper, and the other end of the crushing channel is arranged at the discharging hole. The size of the cross section of the crushing channel is decreased progressively in the direction from the feeding hopper to the discharging hole, walnuts pass through the crushing channel, the shells of bigger walnuts can be crushed, and then the shells are crushed by degrees according to the size. In this way, the shell crushing requirements for walnuts in different sizes can be met, the phenomenon that walnut kernels are crushed due to an undersize gap cannot occur, crushing teeth are mutually matched with a shell crushing tank, so that the shell crushing efficiency is high.

Owner:方会云

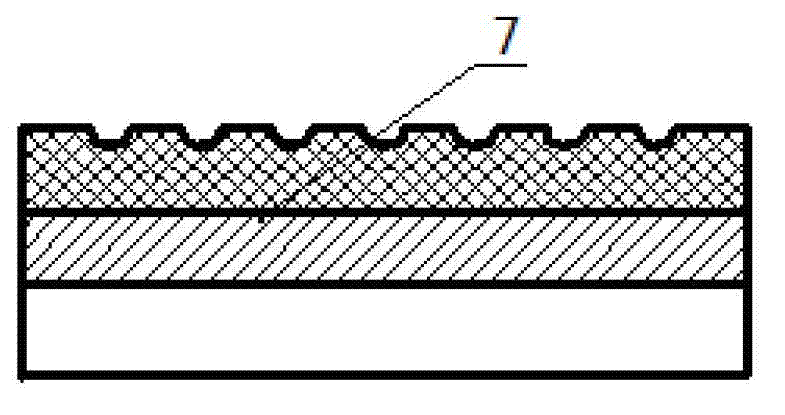

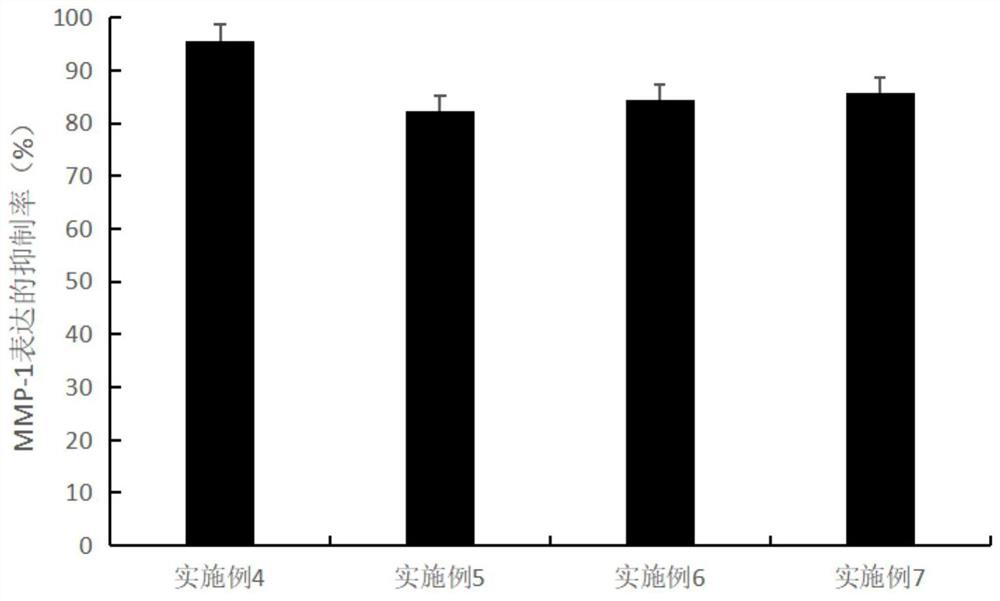

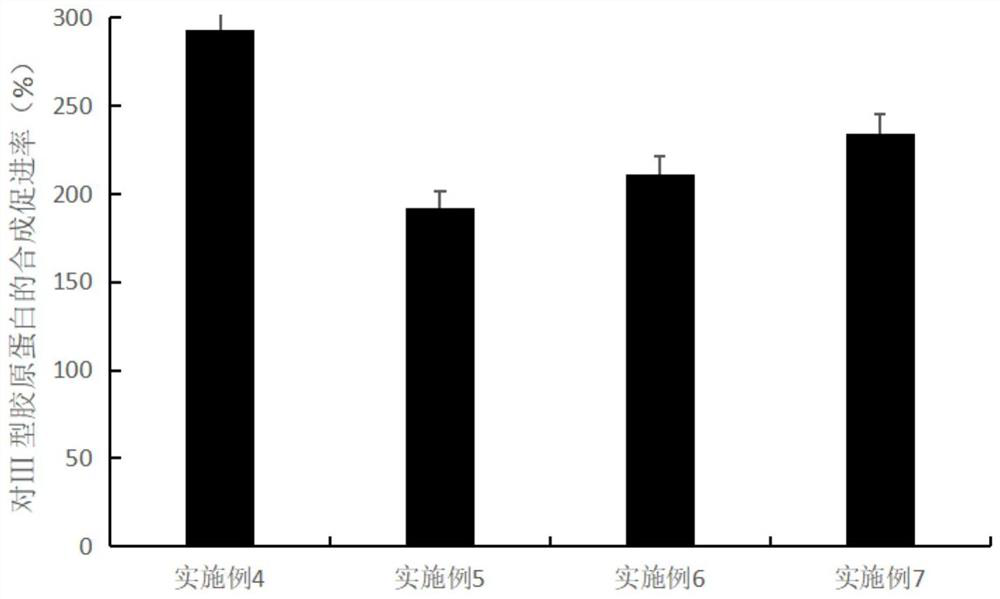

Cosmetic composition, cosmetic and preparation method of cosmetic

InactiveCN111821217AIrritant Broad SpectrumInhibitory activityCosmetic preparationsAntipyreticPolymer scienceAllergy

The invention provides a cosmetic composition. The cosmetic composition is prepared from the following raw materials: plant essential oil microspheres containing polyglycerol fatty acid ester, kojic acid, arbutin, 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, 2-(2'-hydroxy-3', 5'-di-tert-phenyl)-5-benzotriazole chloride, a transdermal absorption enhancer, polyoxyethylene lauryl ether and sorbitanmonolaurate. The invention also provides a cosmetic and a preparation method thereof. The preparation method is simple, plant essential oil active substances in the prepared cosmetic are protected bythe microspheres and rubbed and broken when being used, the activity of the active substances is protected from being damaged, and the cosmetic has the effects of resisting bacteria, diminishing inflammation, resisting allergy, removing acnes and the like, is good in use effect and has a wide application prospect.

Owner:深圳名仕堂贸易有限公司

Shell breaking device for conical basket type walnut shell breaking machine

The invention belongs to the technical field of walnut shell breaking equipment and particularly relates to a shell breaking device for a conical basket type walnut shell breaking machine. The shell breaking device is composed of an outer shell breaking body (1), an inner shell breaking body (2) and an adjusting device, wherein the inner shell breaking body (2) is arranged in the outer shell breaking body (1), and the adjusting device is positioned below the inner shell breaking body (2). The shell breaking device is characterized in that a shell breaking cavity is formed in a region where theouter wall of the inner shell breaking body (2) corresponds to the inner wall of the outer shell breaking body (1), the outer wall of the inner shell breaking body (2) is provided with a bulge (3), and the inner wall of the outer shell breaking body (1) is provided with an inverted stand (4); the adjusting device is composed of an adjusting handle (5), an adjusting screw rod (6), a worm and geardevice (7) and a universal driving shaft (8); and the inclination angle beta of the inner shell breaking body (2) is 3-10 degrees. The shell breaking device provided by the invention has the beneficial effects of simple structure and high practicability, improves the shell breaking rate and the working efficiency, and reduces the breakage rate of walnut kernels.

Owner:谢燕燕

Shelling device aiming at Chinese chestnuts

PendingCN110140976ASlow down dischargeIncrease the number of agitationsHuskingHullingEngineeringMechanical engineering

The invention discloses a shelling device aiming at Chinese chestnuts. The device comprises: an extrusion roller which is horizontally arranged, wherein a plurality of convex ribs which are parallel to the axis of the convex ribs are distributed on the outer surface of the extrusion roller; a kneading and rubbing roller which is arranged under the extruding roller in parallel, wherein the kneadingand rubbing roller is provided with a plurality of elastic scraping plates; a cage grid which is arranged below the kneading and rubbing roller, wherein the cage grid is provided with a curved-surface grid, the curved-surface grid is provided with a hole through which Chinese chestnuts pass, the self axis of the curved-surface grid is superposed with the self axis of the kneading and rubbing roller, and the radial distance between the curved-surface grid and the kneading and rubbing roller is smaller than the radial distance between the top of the scraping plates and the kneading and rubbingroller when the scraping plates are not pressed; and a shell which is used for wrapping the extrusion roller, the kneading and rubbing roller and the cage grid, wherein the top of the shell is provided with a feed hopper, the bottom of the shell is provided with a discharge hopper, and a gap exists between the cage grid and the discharge hopper. The extrusion roller and the kneading and rubbing roller are provided with rotating driving power. The device is combined with an extrusion method and a kneading and rubbing method to remove shells, the chestnuts are fully stirred, and the shelling effect is uniform.

Owner:NANTONG INST OF TECH

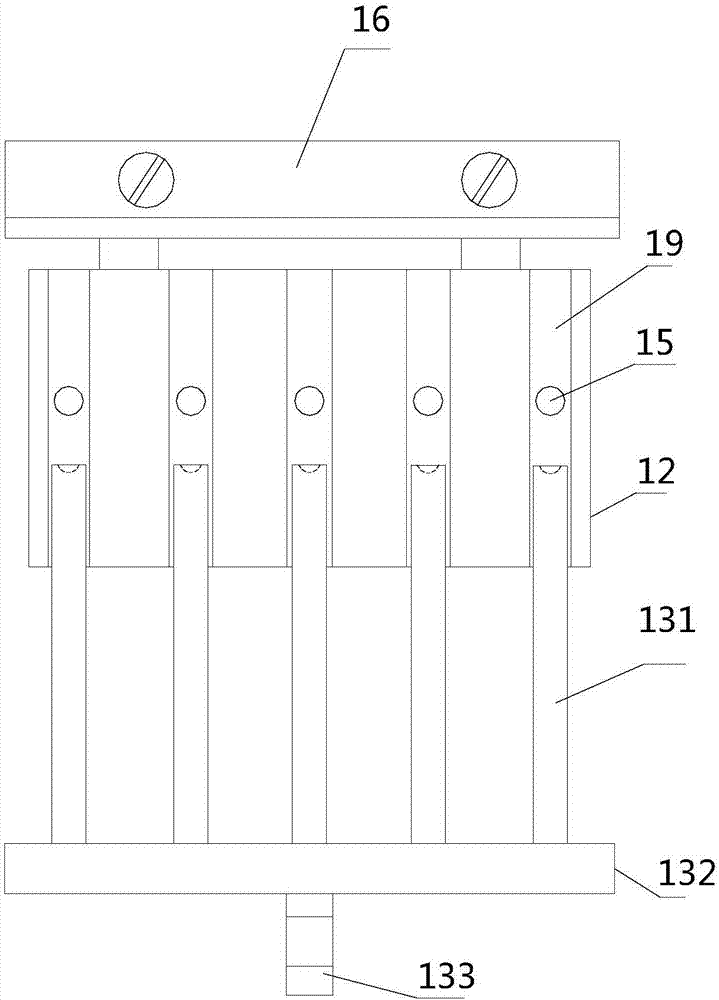

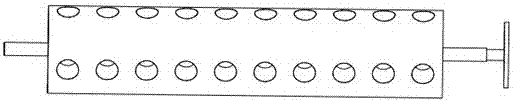

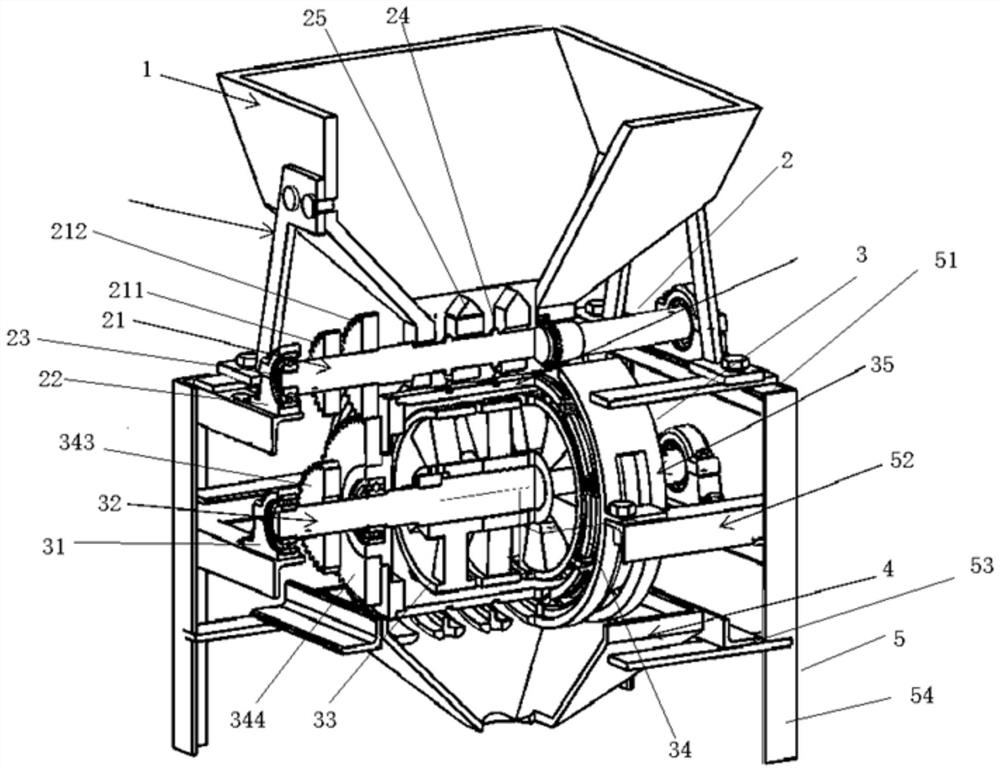

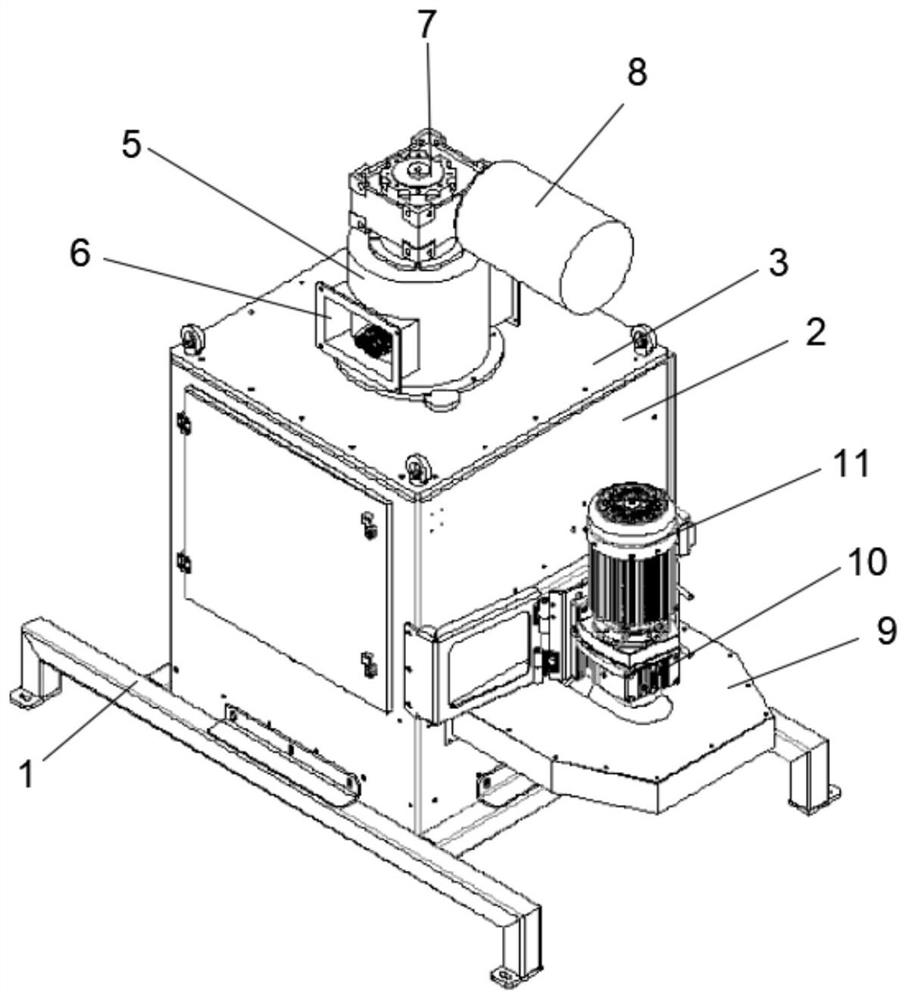

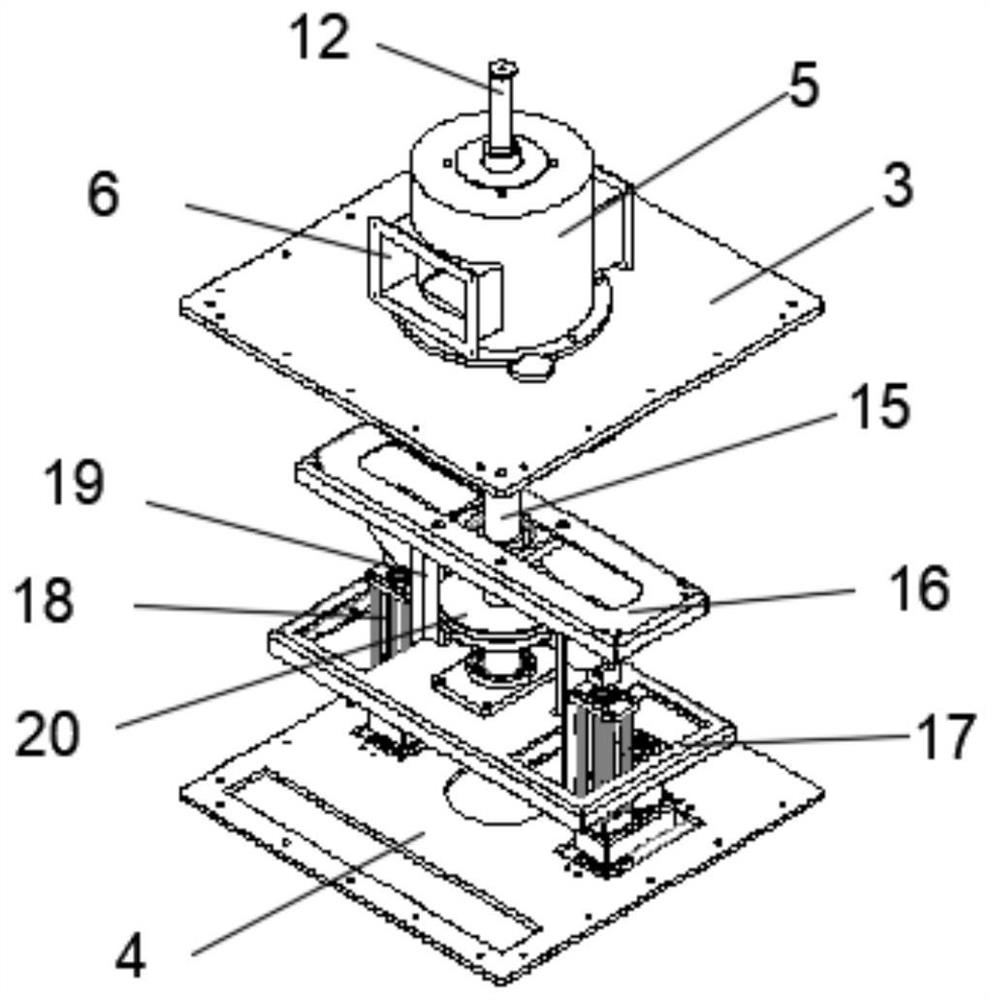

Multi-grain gordon euryale seed shell breaking device

PendingCN112293753AReduce manual labor intensityImprove shell breaking rate and breaking speedHuskingHullingHorticultureElectric machinery

The invention discloses a novel gordon euryale seed shell breaking device. After a power supply is switched on and a motor is started, the motor transmits power to a synchronous gear through a synchronous belt to drive a cutting roller and a cutter shaft to rotate forwards, and at the moment, gordon euryale seeds in a hopper are guided into a shape hole by a guide sheet in the hopper under the action of gravity; the gordon euryale seeds are cut in the rotating state of the cutting roller; the cut gordon euryale seeds fall into indents in an indent roller, and at the moment, the indent roller rotates reversely under the action of a pair of straight-tooth gears and enters a fixed cutter plate under the driving of the indent roller, and the gordon euryale seeds roll in the direction of a fixed cutter under the action of extrusion force and the indent roller, and a 30-degree screwer exerts axial force on the gordon euryale seeds while the gordon euryale seeds roll, so that shells of the gordon euryale seeds are broken. According to the novel gordon euryale seed shell breaking device, mechanical shell breaking of gordon euryale seeds is achieved, the labor intensity of workers is greatly reduced, and meanwhile the production efficiency is improved.

Owner:SICHUAN AGRI UNIV

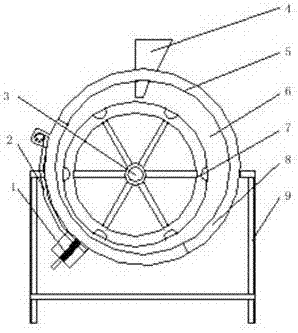

Walnut shell breaking machine

InactiveCN107495397AImprove processing qualityIncrease export rateHuskingHullingWalnut NutEngineering

A walnut shelling machine, comprising an extruding device and an extruding plate, the extruding device is placed on the extruding plate, a shaft is arranged in the middle of the extruding plate, the shaft is fixed on the frame, and the outer surface of the shaft is evenly divided Roller, the upper part of the extrusion plate is provided with a feeding port, the feeding port is placed on the upper cover, the lower part of the upper cover is provided with an end cover, and the lower part is provided with a lower cover; the advantages of the present invention are: The advantages are: simple structure, realizing mechanized processing, liberating productivity, improving efficiency, improving walnut processing quality and export rate, improving shell breaking rate and whole kernel rate, and good shell breaking performance.

Owner:李颂

A kind of rotating and striking walnut shell breaking equipment

Owner:TARIM UNIV

Chestnut Shelling System

InactiveCN103082381BImprove shell breaking rateReduce breakage rateHuskingHullingEngineeringMechanical engineering

The invention provides a chestnut shell breaking system which comprises a box body, silk screen conveyer belts and a shell breaking device, wherein the silk screen conveyer belts and the shell breaking device are placed inside the box body. A feeder and a dampness extraction opening are placed on the box body; a discharging device and a hot air inlet are placed on the lower portion of the box body; the shell breaking device is placed below the lower end of the silk screen conveyer belts, and comprises a shell breaking channel, wherein the shell breaking channel is composed of a shell breaking plate and a shell breaking roller; and elastic protruding stabs are placed on the shell breaking channel. A plurality of silk screen conveyer belt layers are placed on the shell breaking device, and in the chestnut conveying process, the hot air inlet and the dampness extraction opening continuously convey hot air and extract damp and hot air and the chestnuts are completely dried, then the chestnuts immediately enter the shell breaking channel and the shell of the chestnuts are broken, and therefore shell breaking rates of the chestnuts are effectively improved. Meanwhile because the shell breaking channel is of an arch-shaped channel and is made of elastic materials to break the shells, breaking rates of peeled chestnuts are effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Walnut shelling machine

ActiveCN104172438BImprove shell breaking rateImprove completenessHuskingHullingQuality levelAgricultural engineering

The patent of the present invention provides a walnut shelling machine, relates to the technical field of processing agricultural products, and is applied in the processing of walnut products. The walnut kernel shelling machine disclosed in the patent of the present invention includes a casing, a shell breaking roller, a grid screen, a prying roller, a groove wheel and a shell kernel separation groove, and the casing includes, sequentially arranged from top to bottom. Crushing chamber, prying chamber and separation chamber. It solves the problems of high cost, low efficiency, and low quality grade of processed walnut kernels in the existing technology of breaking shells and extracting kernels in my country. It can be seen that, with the walnut kernel shelling machine of the patent of the present invention, the operation is simple and convenient, the efficiency is high, and the quality of the walnut kernel has been improved.

Owner:广西诚杨食品有限公司

A device for cracking walnut shells

ActiveCN108835646BImprove shell breaking rateReduce processingHuskingHullingWalnut NutVertical plane

The invention provides a walnut shell breaking device. The walnut shell breaking device comprises a bottom plate, a shell breaking mechanism, a shell removing mechanism and an air pressure conveying mechanism. The shell removing mechanism is communicated with the shell breaking mechanism through the air pressure conveying mechanism. The shell breaking mechanism comprises a shell breaking box, supporting plates I, supporting plates II, a rotary shaft, grinding plates I, grinding plates II and driving mechanism, the shell breaking box is mounted on the bottom plate, the two supporting plates I and the two supporting plates II are fixedly mounted in the shell breaking box, the rotary shaft is movably mounted in the shell breaking box and penetrates through the supporting plates I and the supporting plates II, the rotary shaft is fixedly sleeved with the two grinding plates I and the two grinding plates II, and the driving mechanism is in transmission connection with the rotary shaft. Thedriving mechanism drives the rotary shaft to rotate and vertically move, and then shell breaking is achieved. Due to the fact the rotary shaft moves on the horizontal plane and the vertical plane, theshell breaking rate is increased. The distance between the supporting plates and the grinding plates is gradually reduced, and therefore the walnut shell breaking device adapts to materials of different sizes for shell breaking; shells are separated from pulp through the shell removing mechanism.

Owner:安徽亮中亮食品有限公司

A device for cracking gorgon seeds

ActiveCN107136523BBreaking the shell to achieveImprove the efficiency of breaking upHuskingHullingEngineeringMechanical engineering

The invention discloses a Gorgon fruit shell breaking device, which comprises a frame, a hopper, a seed cleaner, an upper seed removal board, a lower seed removal board, a workbench, a seed pusher and a stopper, and a seed cleaner is arranged in the hopper. The bottom of the hopper is provided with an upper seed plate, and the upper seed plate is provided with a plurality of upper through holes; the lower seed plate is provided with a plurality of lower through holes corresponding to the plurality of upper through holes. , Each upper through hole is connected to the corresponding lower through hole through a seed tube; the upper end of the workbench has a plurality of long slots corresponding to the lower through holes, and a pit is arranged at the bottom of the long slot , through the first driving mechanism, the plurality of ejector rods of the seed pusher are driven to move back and forth along the long groove, thereby pushing the Gorgon seeds in the pit back to the stopper, and the ejector rod and the stopper are squeezed to realize Shelling of Gorgon seeds. Compared with the prior art, the present invention has the following advantages: it can realize the mechanized cracking of the gorgon seeds, and meets the quality and technical requirements for the cracking of the gorgon seeds.

Owner:CHUZHOU UNIV

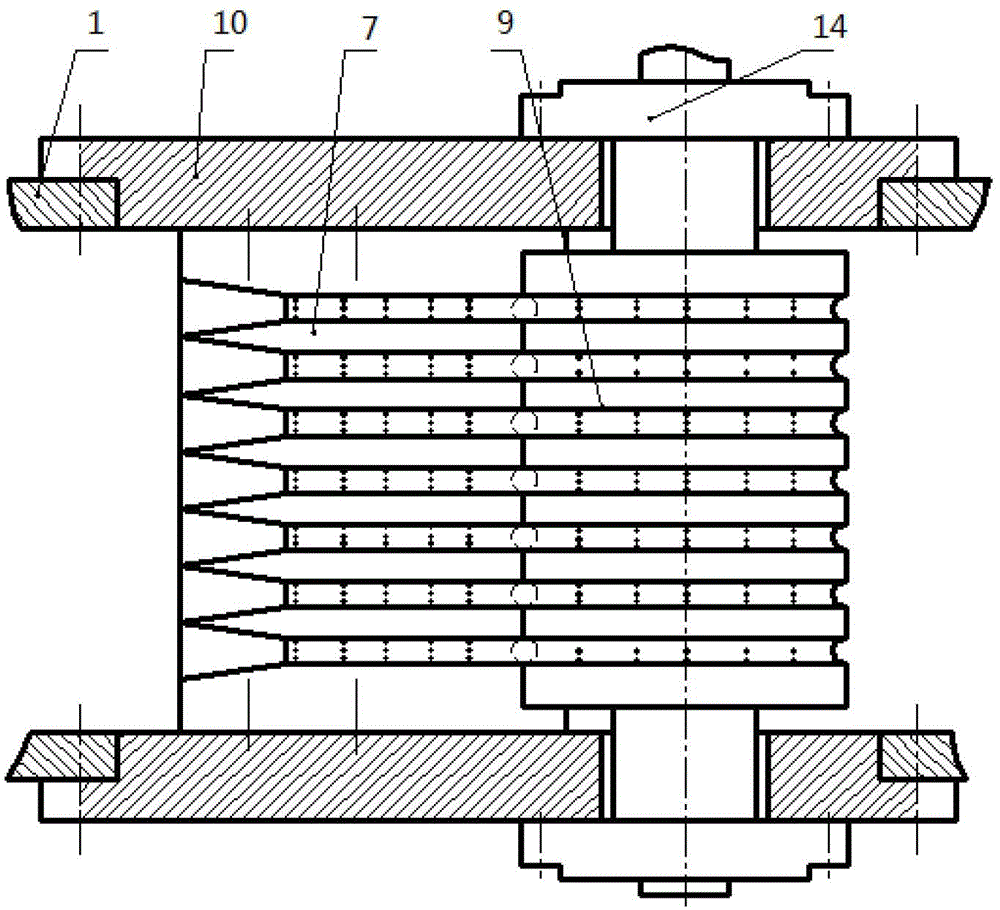

Shell stripping equipment self-adaptive to nut size

PendingCN113303479AImprove shell breaking rateRealize crushing and peelingHuskingHullingWalnut NutSpherical bearing

The invention discloses shell stripping equipment self-adaptive to nut size. The shell stripping equipment comprises a bottom frame and a box body, the box body is arranged on the bottom frame, the top and the bottom of the box body are fixedly connected with an upper top cover and a lower bottom cover correspondingly, a feeding barrel is fixedly connected to the center of the top of the upper top cover, and an upper transmission shaft is arranged in the feeding barrel in a penetrating mode; the upper transmission shaft is rotationally connected with the feeding cylinder and the upper top cover through bearings, an upper grinding disc is fixedly connected to the bottom of the upper transmission shaft, the upper grinding disc and the upper transmission shaft are coaxially arranged, supporting seats are arranged in the box body in parallel, and the supporting seats are fixedly connected with the inner side wall of the box body; the central position of the support seats is movably connected with a lower transmission shaft through a spherical bearing. The shell stripping equipment can be applied to the industry, meanwhile, the upper grinding disc and the lower grinding disc can be adjusted according to walnuts of different sizes, the shell breaking rate of the walnuts and the yield of finished products are increased, the production efficiency is greatly improved, and the labor intensity of workers is reduced.

Owner:合肥中安智能视觉科技有限公司

A squeeze wheel type gorgon shell cracking device

ActiveCN107048429BImprove the efficiency of breaking upRealize automatic single seed extractionHuskingHullingEngineeringCam

The invention discloses an extruding wheel-type shell-breaking device for Gorgon fruit. The device comprises a frame, a hopper, a grain stirring mechanism, an upper seed taking board, a seed taking pipe, a lower seed taking board, a workbench, a seed pushing mechanism and an extruding wheel. The hopper is internally provided with the grain stirring mechanism. The bottom of the hopper is provided with the upper seed taking board, in which an upper through hole is arranged. A lower through hole corresponding to the upper through hole is arranged in the lower seed taking board. The upper through hole is connected with the lower through hole through the seed taking pipe (11). Due to the fact that seeds for Gorgon fruit directly fall into a pit of a long trough from the lower through hole, a cam is driven to rotate through a first driving mechanism so that a top rod is driven to move along a circular hole channel and the long trough back and forth; therefore, seeds for Gorgon fruit located in the pit can be pushed backwards to the extruding wheel so that seeds for Gorgon fruit can be for extrusion and shell breakage through rotation of the extruding wheel. Compared with the prior art, the extruding wheel-type shell-breaking device for Gorgon fruit has the following advantages: shells of seeds for Gorgon fruit can be mechanically broken so that the requirement for quality and technology of seeds for Gorgon fruit is met.

Owner:CHUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com