Cam-type huller for extruding and breaking hulls of acorns

A hulling machine, cam-type technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low pertinence, high-efficiency shelling processing of difficult rubber fruit, rubber fruit shelling, classification, and screening. The machine is still blank, etc., to achieve the effect of high integrity rate, high shell breaking rate and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific structure and working process of the present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

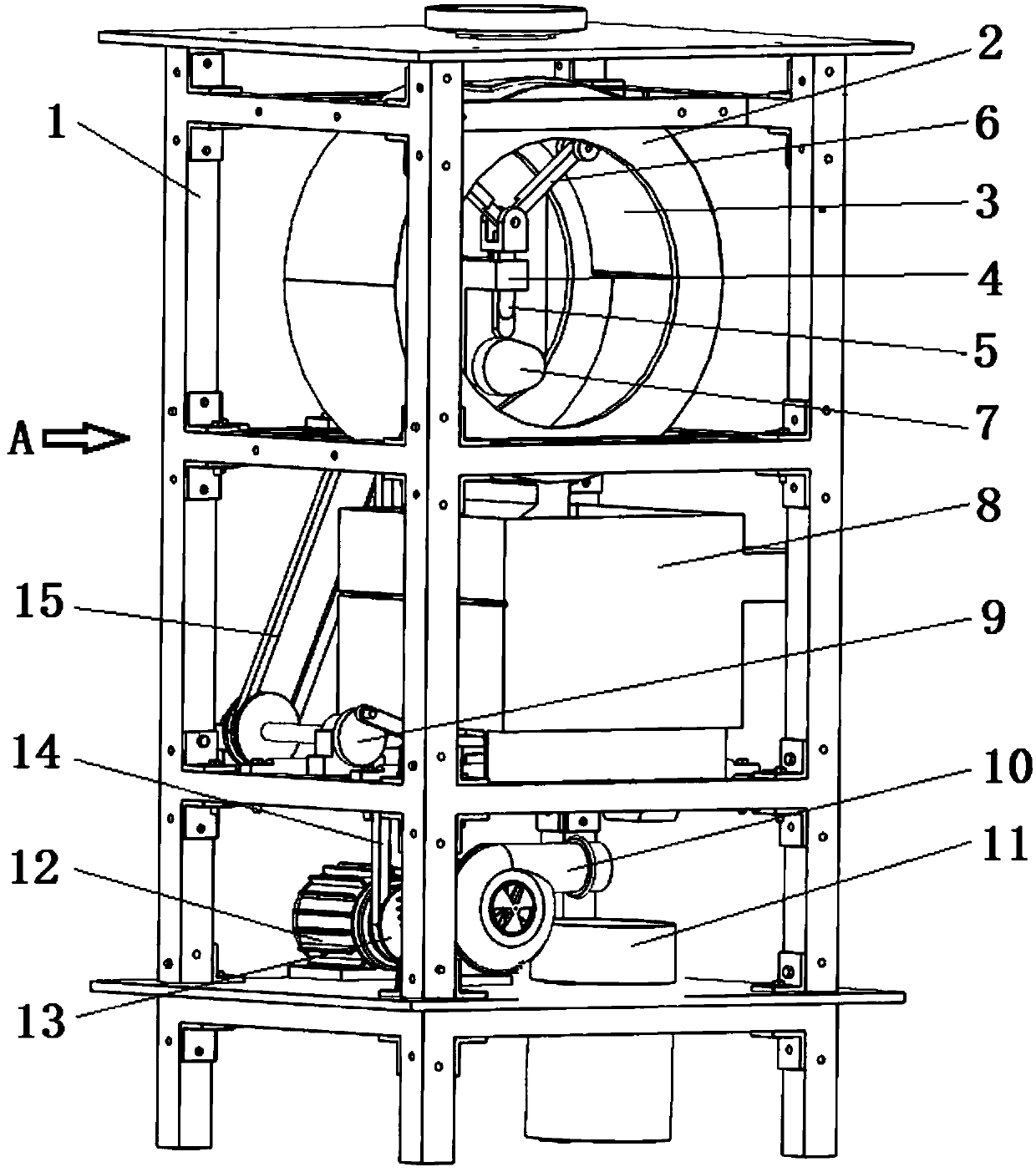

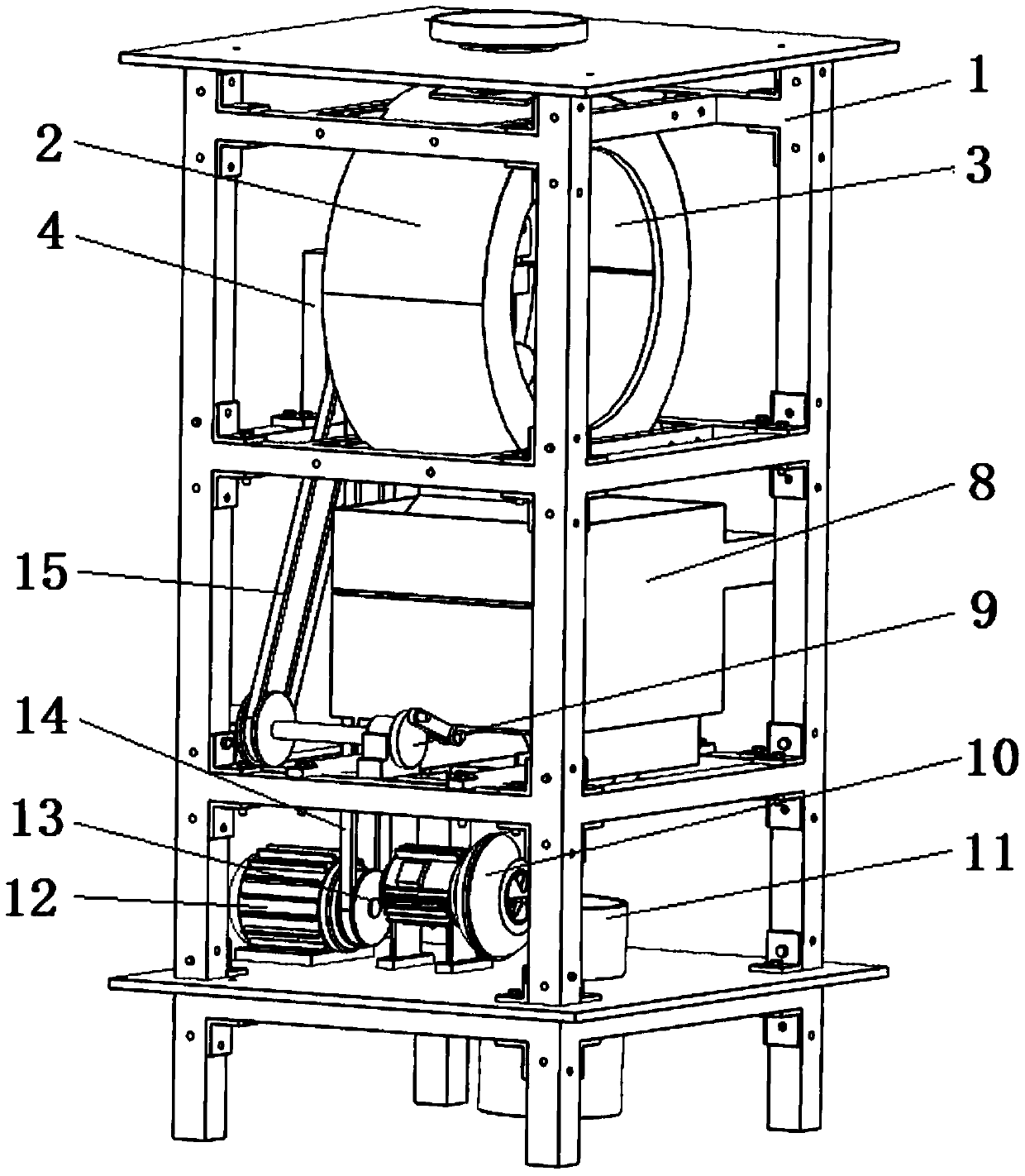

[0029] figure 1 It is a schematic diagram of the whole structure of the cam-type extruding shell breaking rubber fruit shelling machine, Figure 1A for figure 1 A schematic diagram of the structure. The cam-type extrusion shelling rubber fruit sheller is composed of a frame, an extrusion shelling device, a screening device, a winnowing and nut collection device, and a power and transmission device. The extrusion shelling device is installed on the upper layer of the frame. The screening device is installed on the lower floor of the frame, and the winnowing and nut collecting device is installed on the bottom plate of the frame.

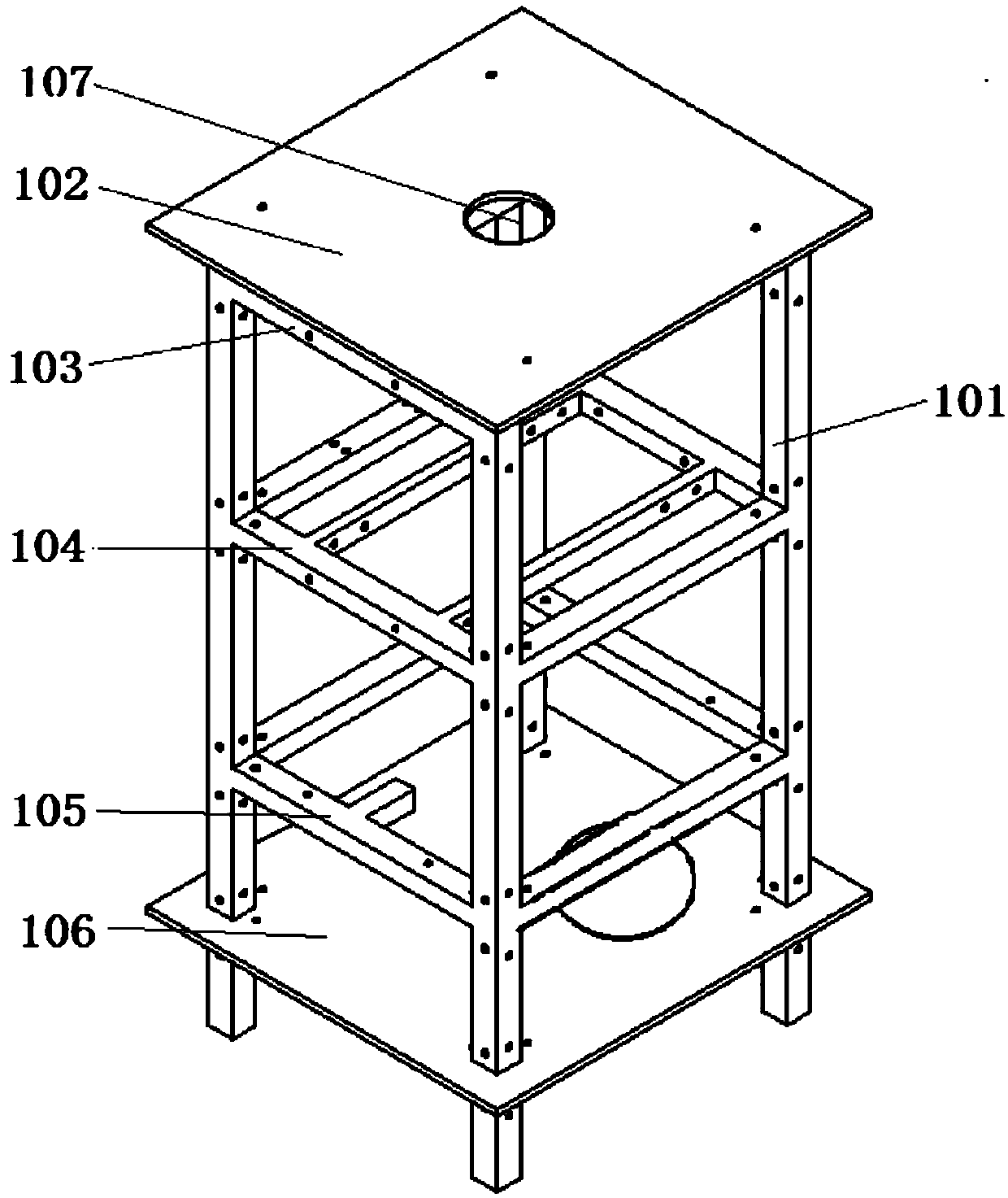

[0030] Such as figure 2 As shown in the frame structure diagram of the frame 1, the frame 1 is composed of 4 vertically arranged frame columns 101 and a horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com