Conical-basket type shell breaking device used for walnut shell breaking machine

A shell breaking device and shell breaking machine technology, which is applied in the direction of shelling, application, pod removal, etc., can solve the problems of tough and hard shells that are difficult to peel off, reduce the added value of the walnut market, and consume manpower and time, so as to improve the cracking rate. Shell rate and work efficiency, simple structure, and the effect of reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

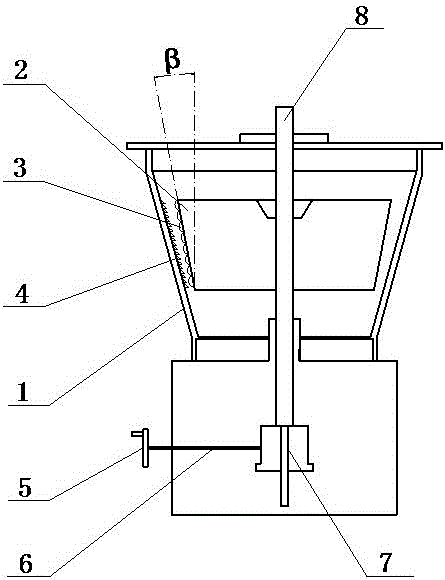

[0018] The shell cracking device for the cone basket type walnut shell cracker includes an outer shell 1, an inner shell 2, a protrusion 3, an inverted table 4, an adjustment handle 5, an adjustment screw 6, a worm gear 7 and a linkage shaft 8.

[0019] as attached figure 1 As shown, the inner broken shell 2 is arranged in the outer broken shell 1, the adjustment device is located below the inner broken shell 2, and the area corresponding to the outer wall of the inner broken shell 2 and the inner wall of the outer broken shell 1 forms a broken shell cavity. A protrusion 3 is provided on the outer wall of the inner broken shell 2, and an inverted platform 4 is arranged on the inner wall of the outer broken shell 1.

[0020] Wherein the adjusting device is composed of an adjusting handle 5, an adjusting screw 6, a worm gear device 7 and a linkage shaft 8.

[0021] One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com