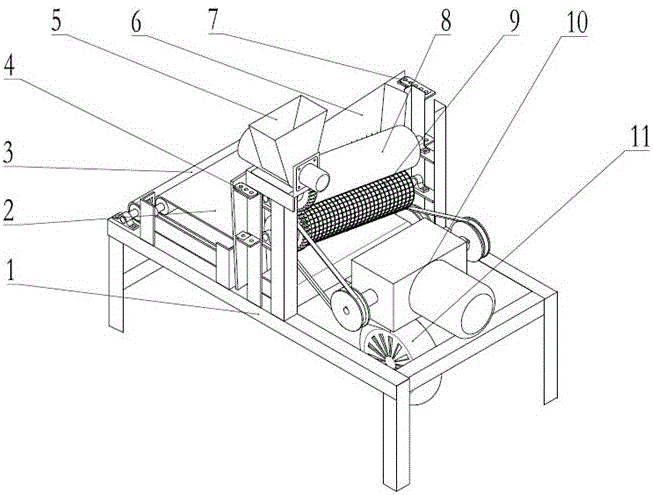

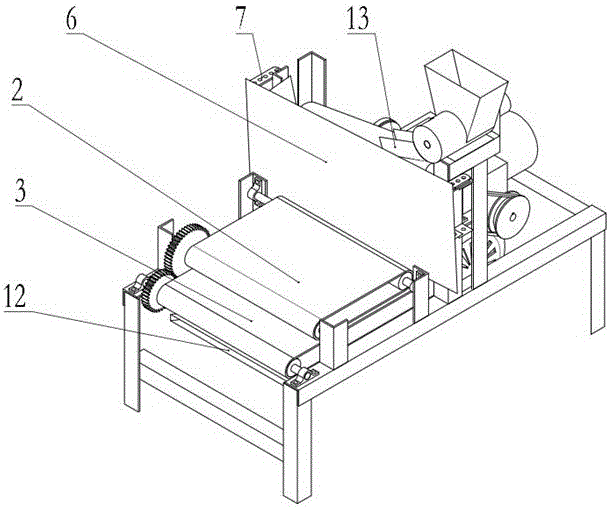

Self-adaptation grading unshelling integrated device for nuts

An adaptive and nutty technology, applied in the field of agricultural machinery, can solve the problems of large volume, damaged nuts, and high price, and achieve the effect of small overall volume, reduced cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

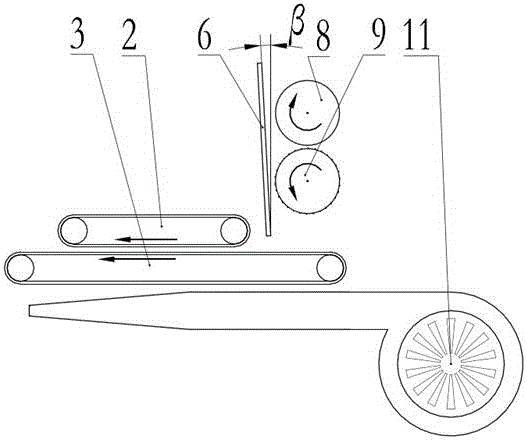

[0039]Taking hazelnut shelling as an example, put the hazelnuts in the feed hopper 15 of the feeding mechanism 5, and the screw conveyor 16 will discharge the hazelnuts with a certain initial speed into the gap between the grading roller 8 and the gap adjustment side plate 6, and the grading roller 8 rotates clockwise, and the hazelnuts will move down along the grading roller 8 under the drive of gravity and grading roller 8. At a gap suitable for the size of the hazelnuts, the hazelnuts will fall into the gap between the shell breaking roller 9 and the gap adjusting side plate 6 along the vertical extrusion blade on the gap adjusting side plate 6 to complete the grading of the hazelnuts before shelling.

[0040] The shell breaking roller 9 rotates counterclockwise, and the vertical extrusion blade on the clearance side plate 6 and the circumferential protrusion on the shell breaking roller 9 can hinder the hazelnut from sliding down along the shell breaking roller, and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com