Dual-directional extrusion-type hull breaking equipment for walnuts

A kind of shell breaking equipment and two-way extrusion technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems that affect the appearance and price, the price is expensive, and affect the shell breaking rate, so as to achieve good shell breaking effect and work High efficiency and the effect of improving the shell breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

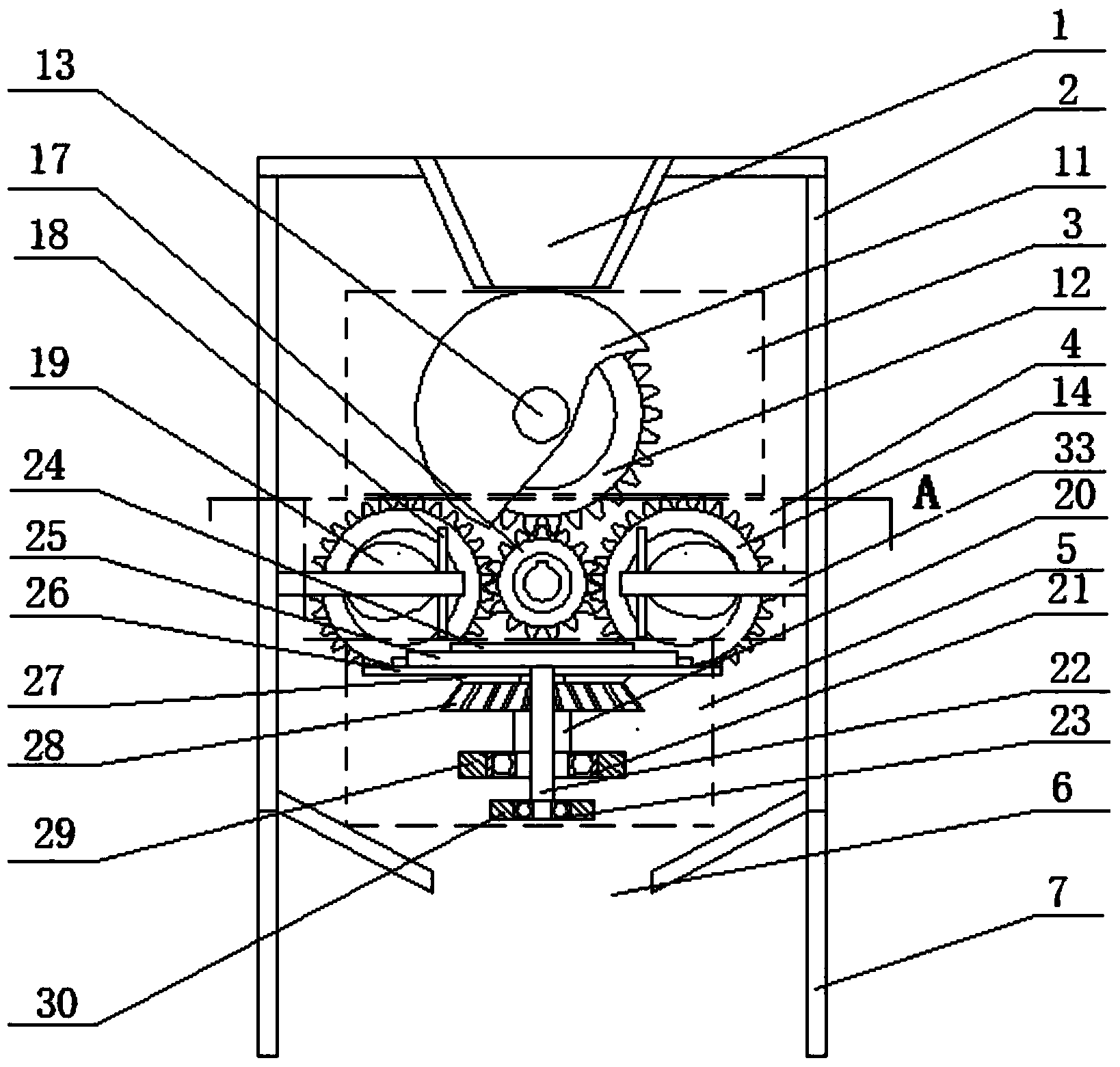

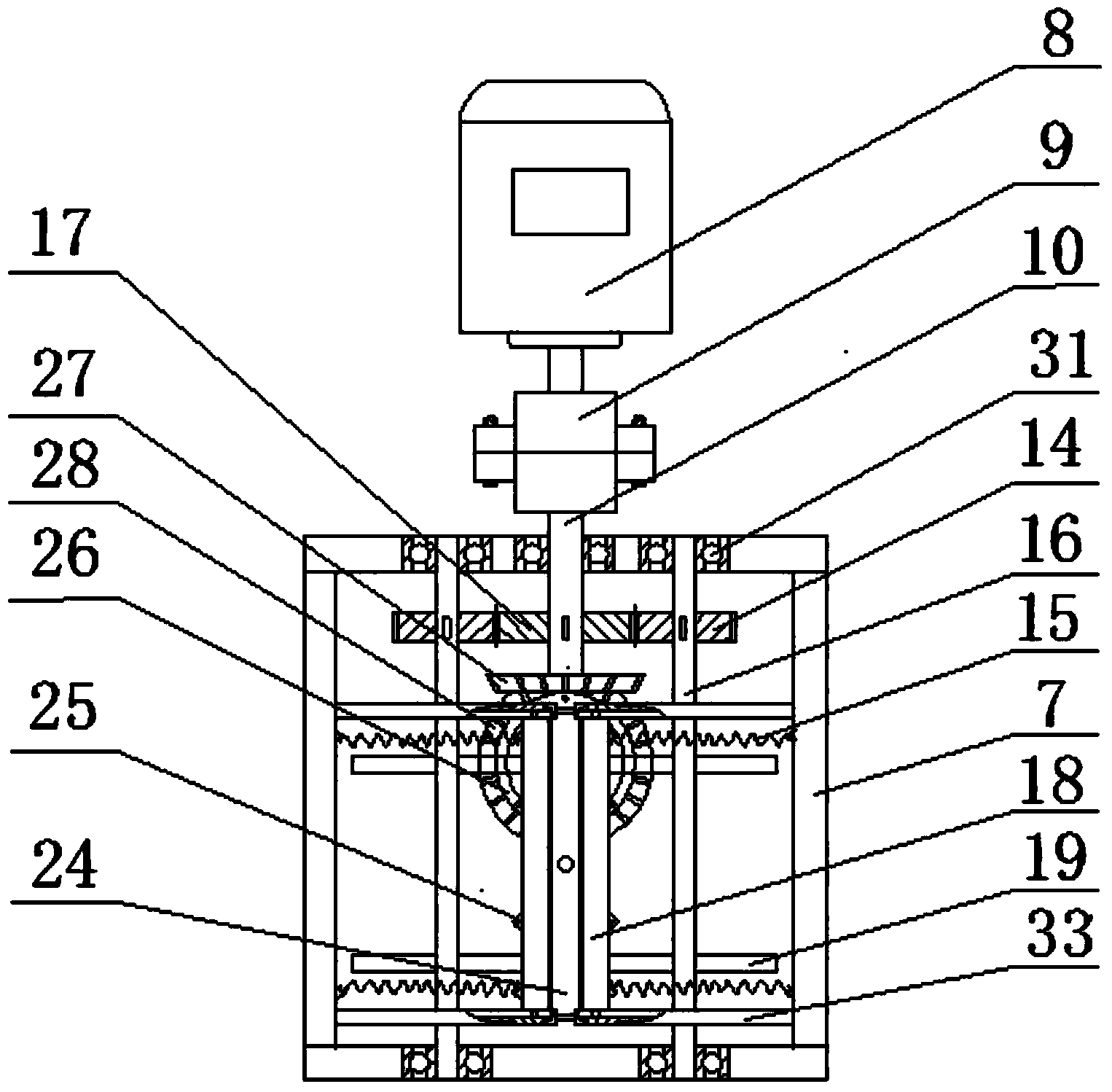

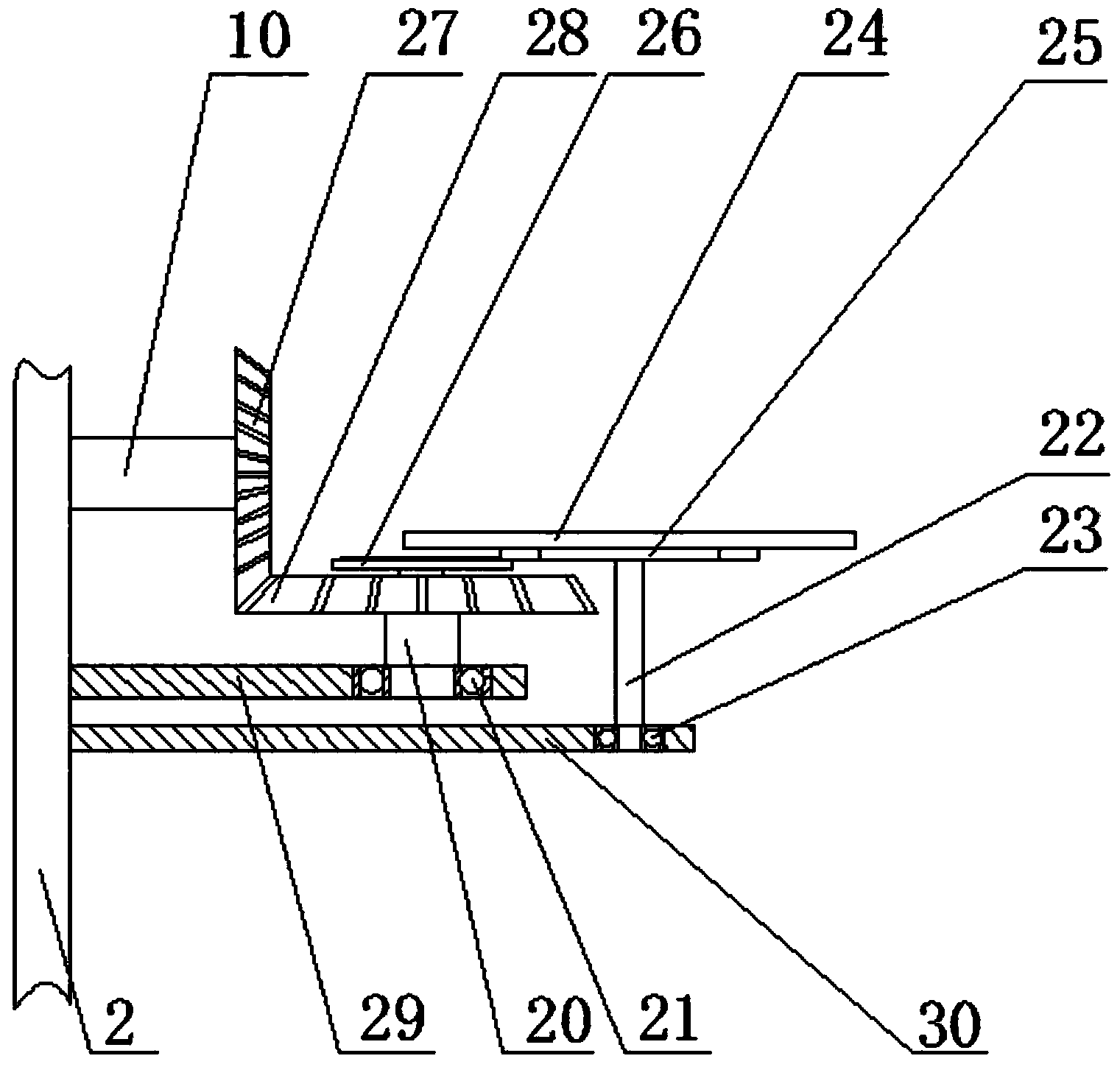

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026]The present invention is a two-way extruding type walnut shell breaking equipment, comprising a box body 2 and a frame 7, the box body 2 is welded on the frame 7, and the top surface of the box body 2 is provided with a The feed port 1, the bottom surface of the box body 2 is provided with an outwardly protruding discharge port 6, and the box body 2 is sequentially provided with a feeding device 3, an extrusion device 4 and a supporting device 5 from top to bottom, The feeding device 3 is located directly below the feeding port 1 and communicates with the feeding port 1, the extruding device 4 is located directly below the feeding device 3 and communicates with the feeding device 3, and the supporting device 5 is located in the extruding device 4 directly below, connected with the extruding device 4, the walnuts that fall into the feeding device 3 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com