Chestnut shell breaking method

A chestnut and shell breaking technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high chestnut shell breaking rate and low chestnut kernel breaking rate, so as to improve the shell breaking rate, reduce the breaking rate, and break the shell The effect of the compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

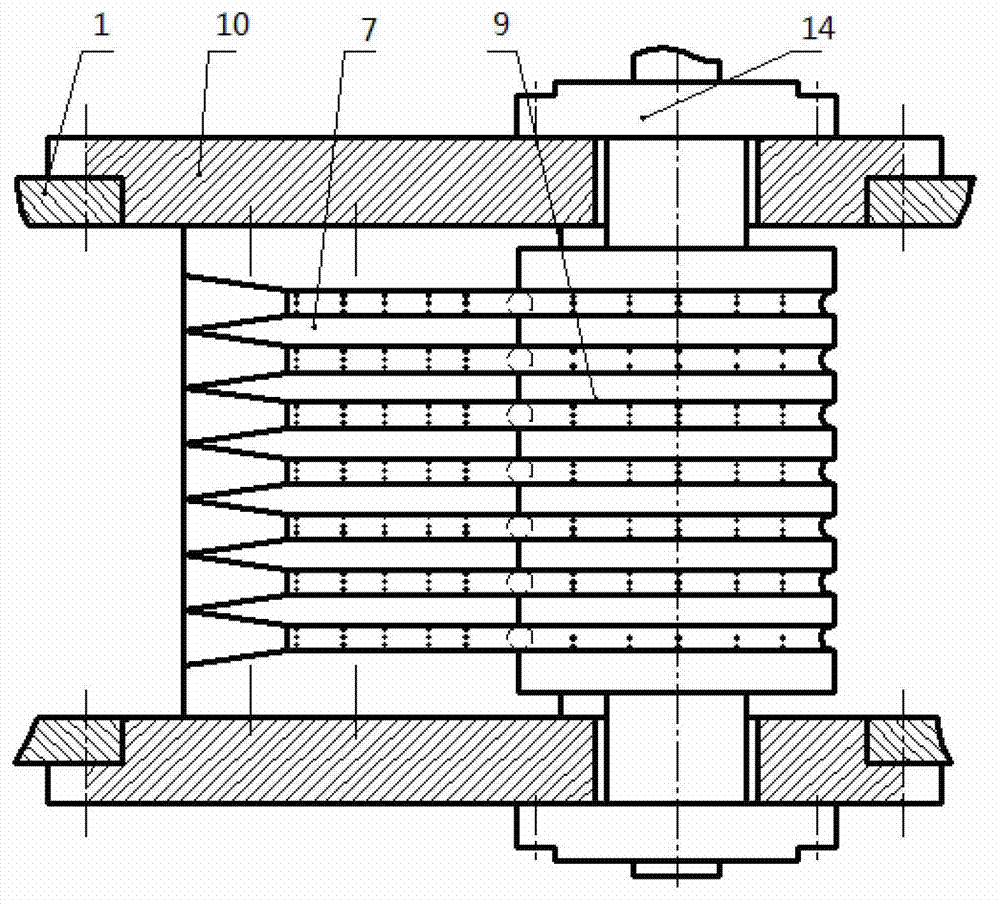

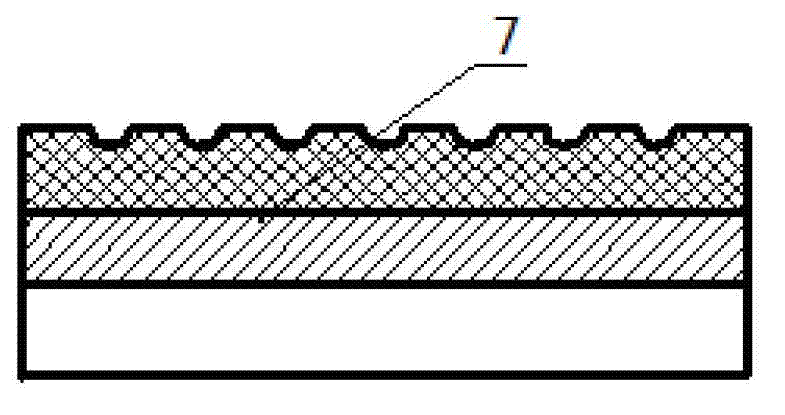

[0025] Chestnut shell breaking method, the chestnut is dried first, and then the dried hot chestnut is directly sent into the curved chestnut channel, and the chestnut is squeezed and kneaded through the elastic spines provided on the chestnut channel to achieve shell breaking.

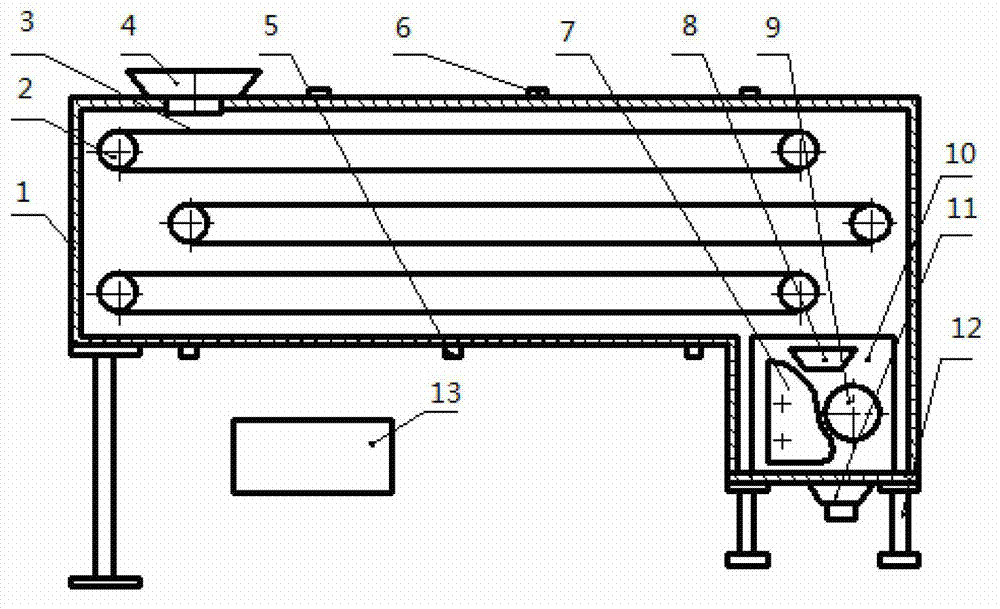

[0026] The schematic diagram of the overall structure of the chestnut shell breaking system adopted by the chestnut shell breaking method of the present invention is shown in FIG. figure 1 The process of chestnut drying is carried out in the airtight casing 1, multi-layer wire mesh conveyor belt 3 is set in the casing 1, the transmission direction of the upper and lower floor wire mesh conveyor belt 3 is opposite, and the starting end of the bottom floor wire mesh conveyor belt 3 It protrudes from the end of the upper wire mesh conveyor belt 3; chestnuts first en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com