Shelling device aiming at Chinese chestnuts

A chestnut and scraper technology, which is applied in the field of chestnut shelling devices, can solve the problems of unreachable and excellent shelling effects, and achieve the effects of easy replacement, promotion of separation, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

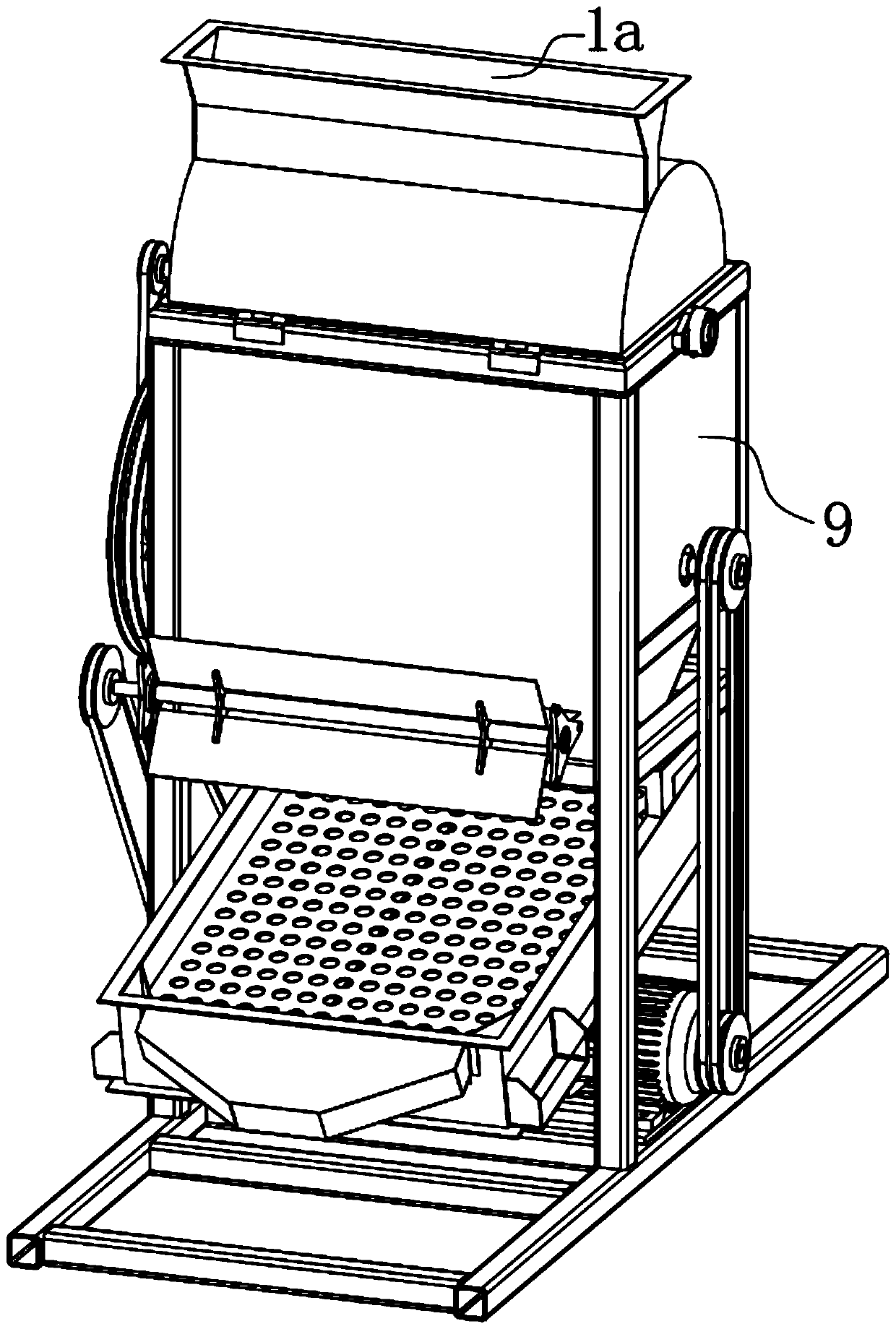

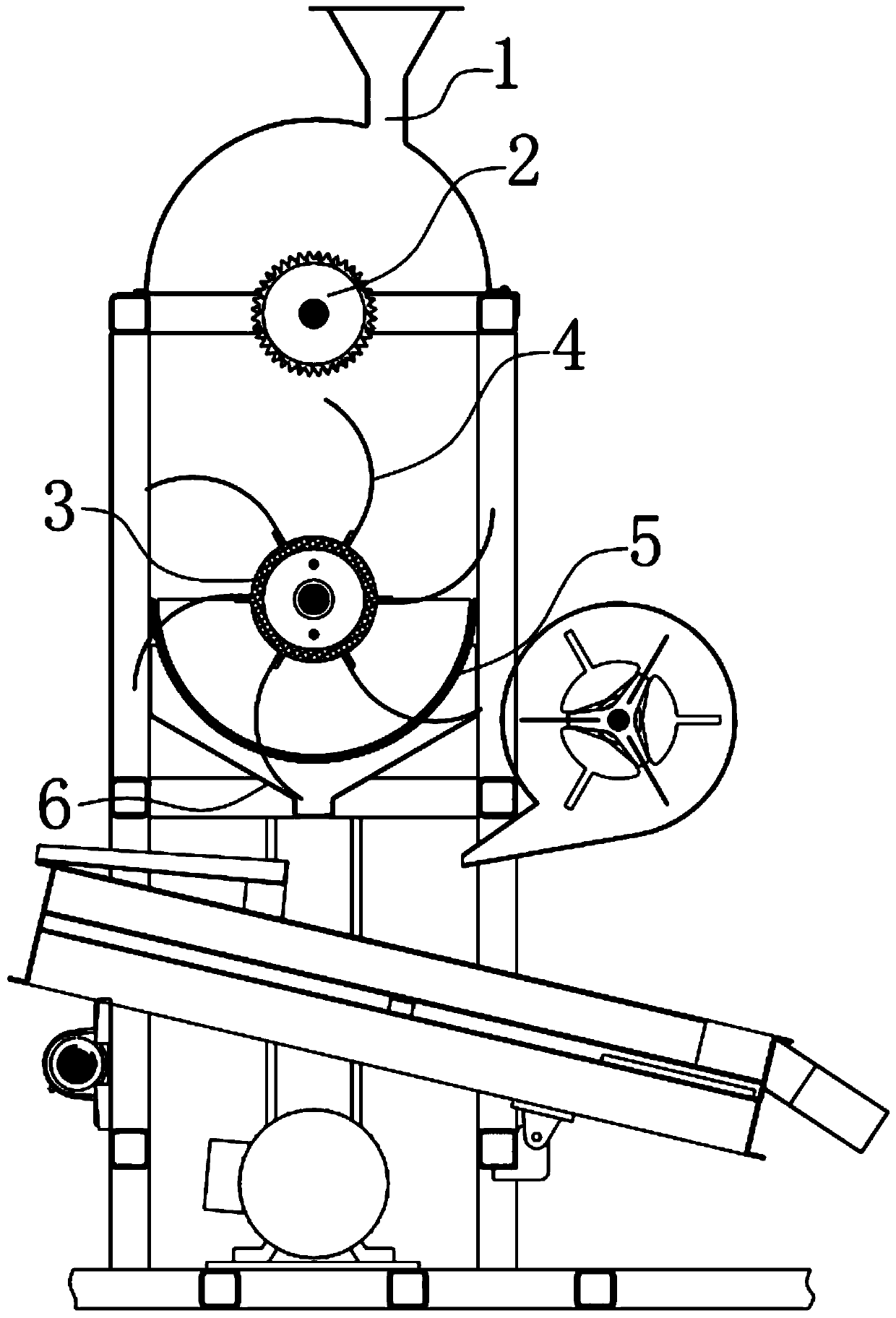

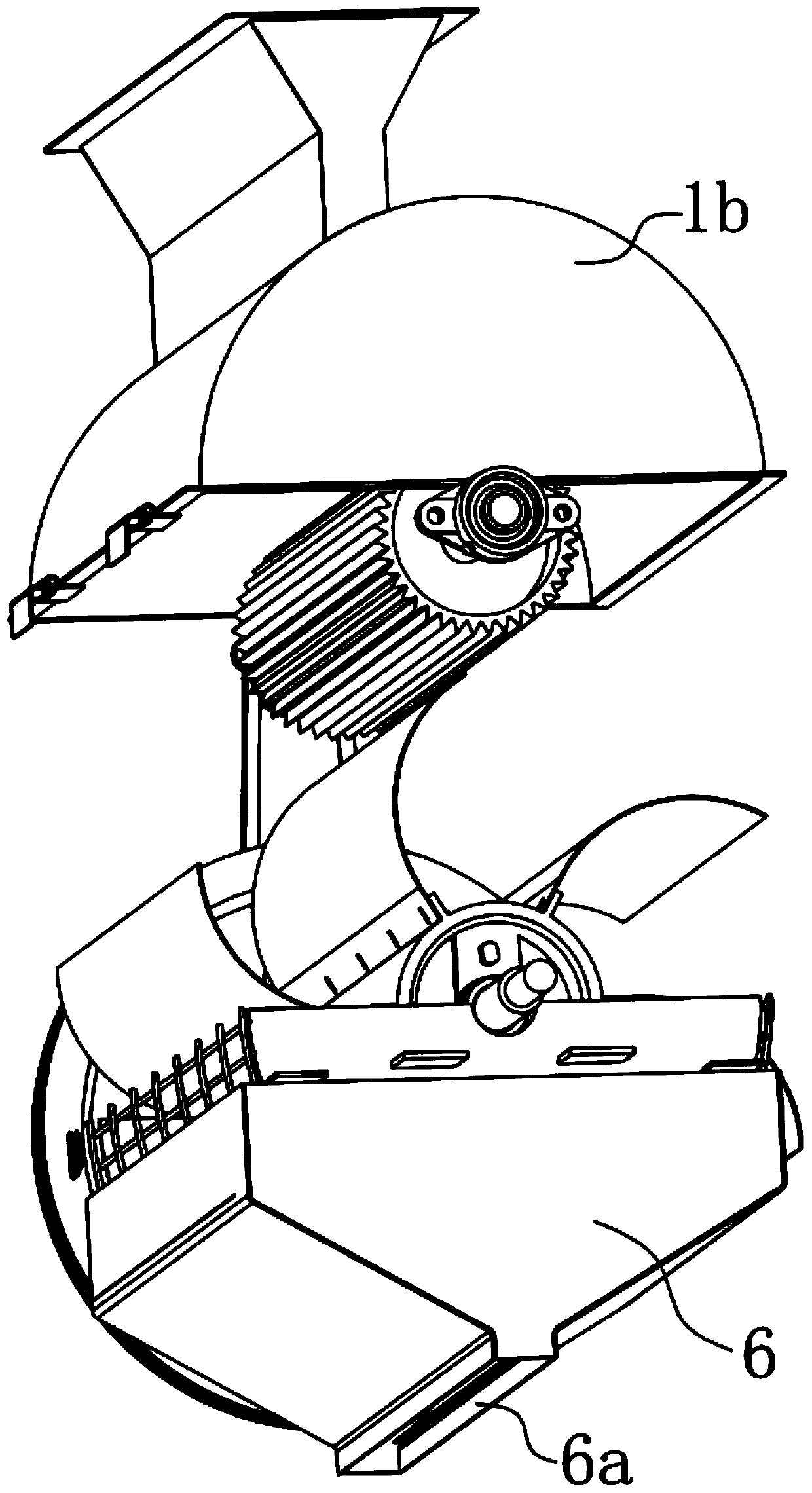

[0032] In order to achieve the purpose of the present invention, a kind of shelling device for chestnut comprises: extruding roller 2, is arranged horizontally, and the outer surface of extruding roller 2 is distributed with several ribs 2a parallel to its own axis; kneading roller The cylinder 3 is arranged in parallel directly under the extrusion roller 2, and the kneading roller 3 is equipped with several elastic scrapers 4; the cage grid 5 is arranged under the kneading roller 3, and the cage grid 5 has a curved grid , the curved grid has holes for chestnuts to pass through, and the axis of the curved grid coincides with the axis of the kneading roller 3 itself. When the scraper 4 is not under pressure, the radial distance between the curved grid and the kneading roller 3 is less than The radial distance between the top of the plate 4 and the kneading ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com