Diesel engine tail gas particulate matter water film adsorption purification device and method

A technology for exhaust particles and purification devices, which is applied to exhaust devices, mufflers, mechanical equipment, etc., can solve the problems of imperfect real-time autonomous regeneration, increased exhaust resistance, and reduced capture efficiency, and achieves continuity and uniformity. Good performance, slowing down the discharge speed and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

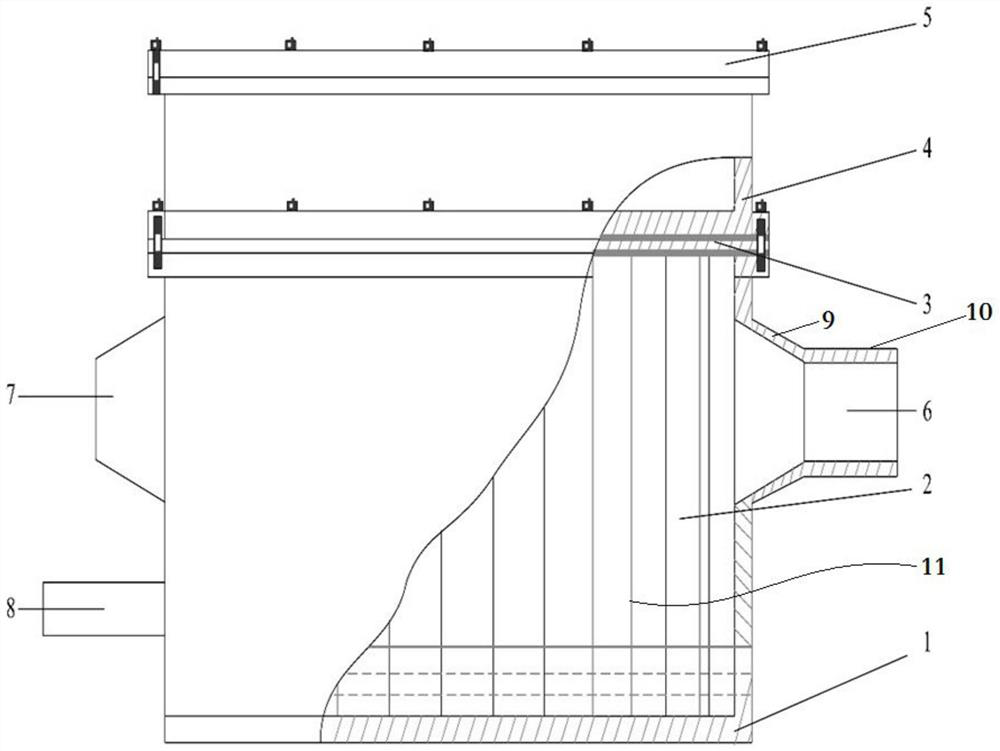

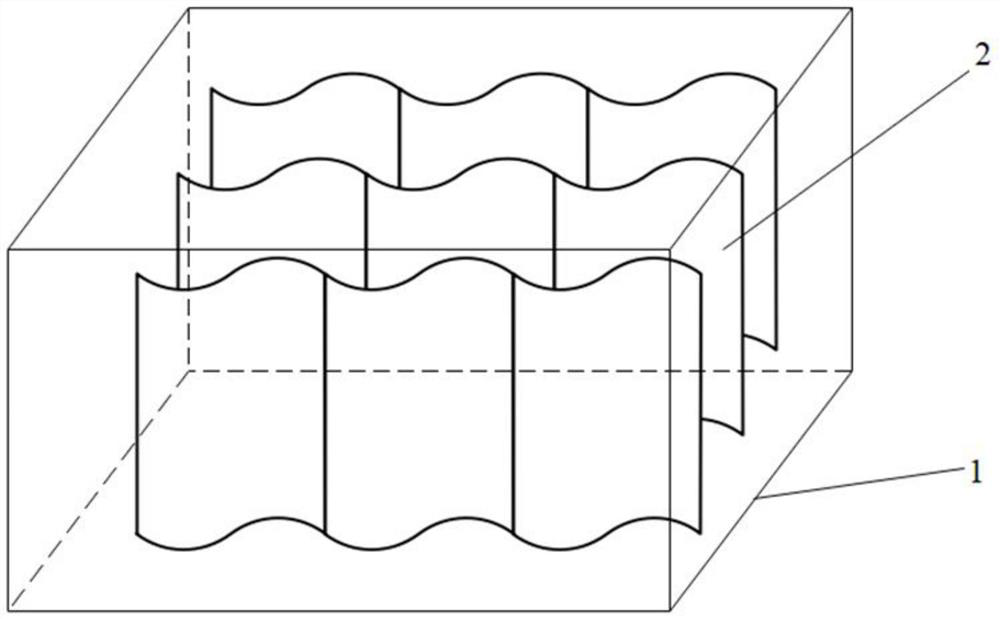

[0027] Such as figure 1 with figure 2 As shown, a diesel engine exhaust particulate matter water film adsorption and purification device includes a box body 1, a water tank 4 and an adsorption unit;

[0028] The upper end of the box body 1 is open, the middle part of the left side plate of the box body 1 is fixedly connected with an air outlet pipeline 7 communicating with its inner cavity, and the bottom of the left side plate of the box body 1 is fixedly connected with a drain pipe connected with its inner cavity Road 8, the middle part of the right side plate of the box body 1 is fixedly connected with the air inlet pipeline 6 communicating with its inner cavity; 1 continuously becomes smaller; the air intake pipeline 6 is composed of a reducing section 9 on the side close to the box body 1 and a fixed diameter section 10 on the side away from the box body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com