Noise reducing device for reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., to achieve the effects of reducing discharge speed, reducing impact noise, and reducing bubble noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

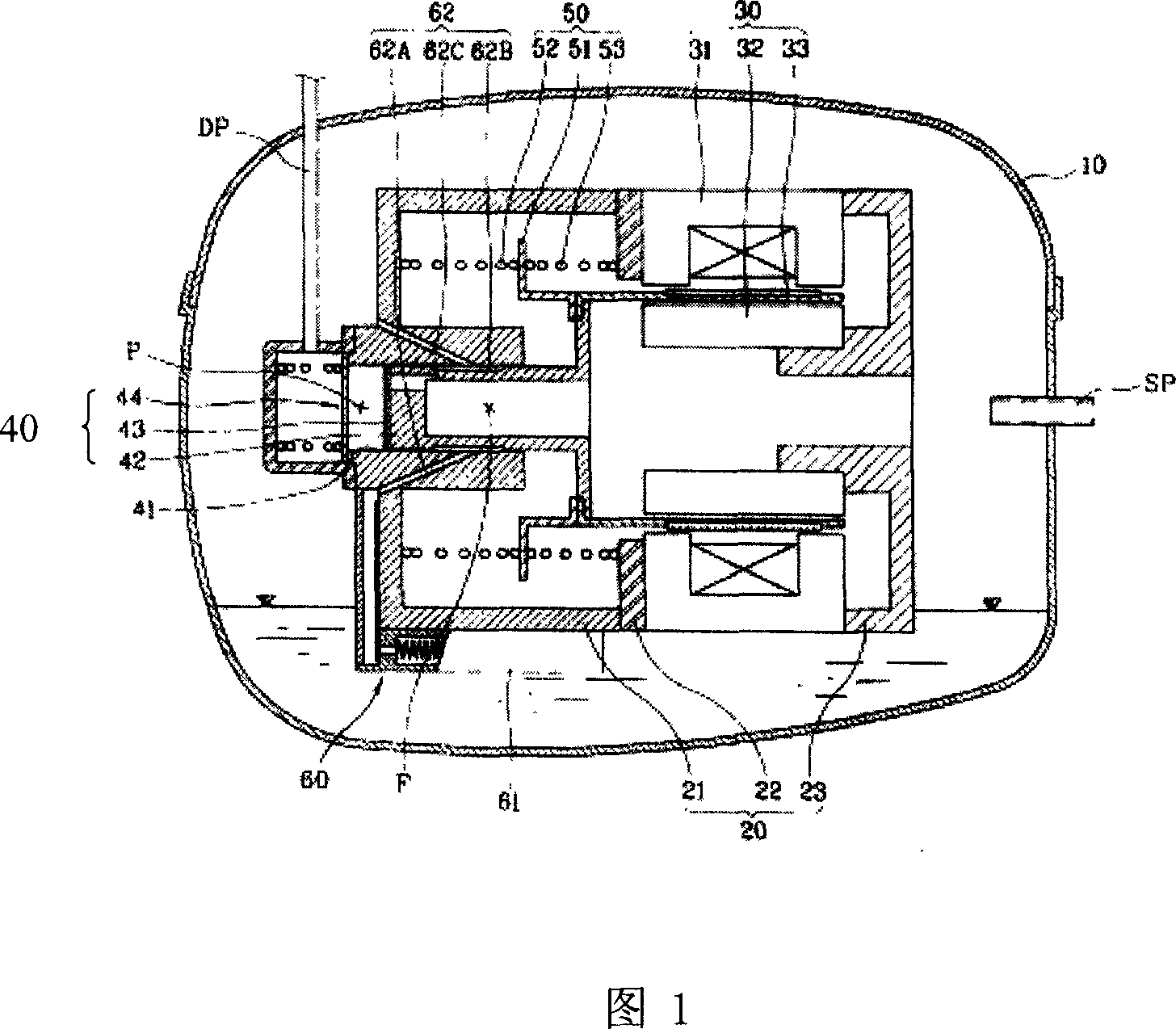

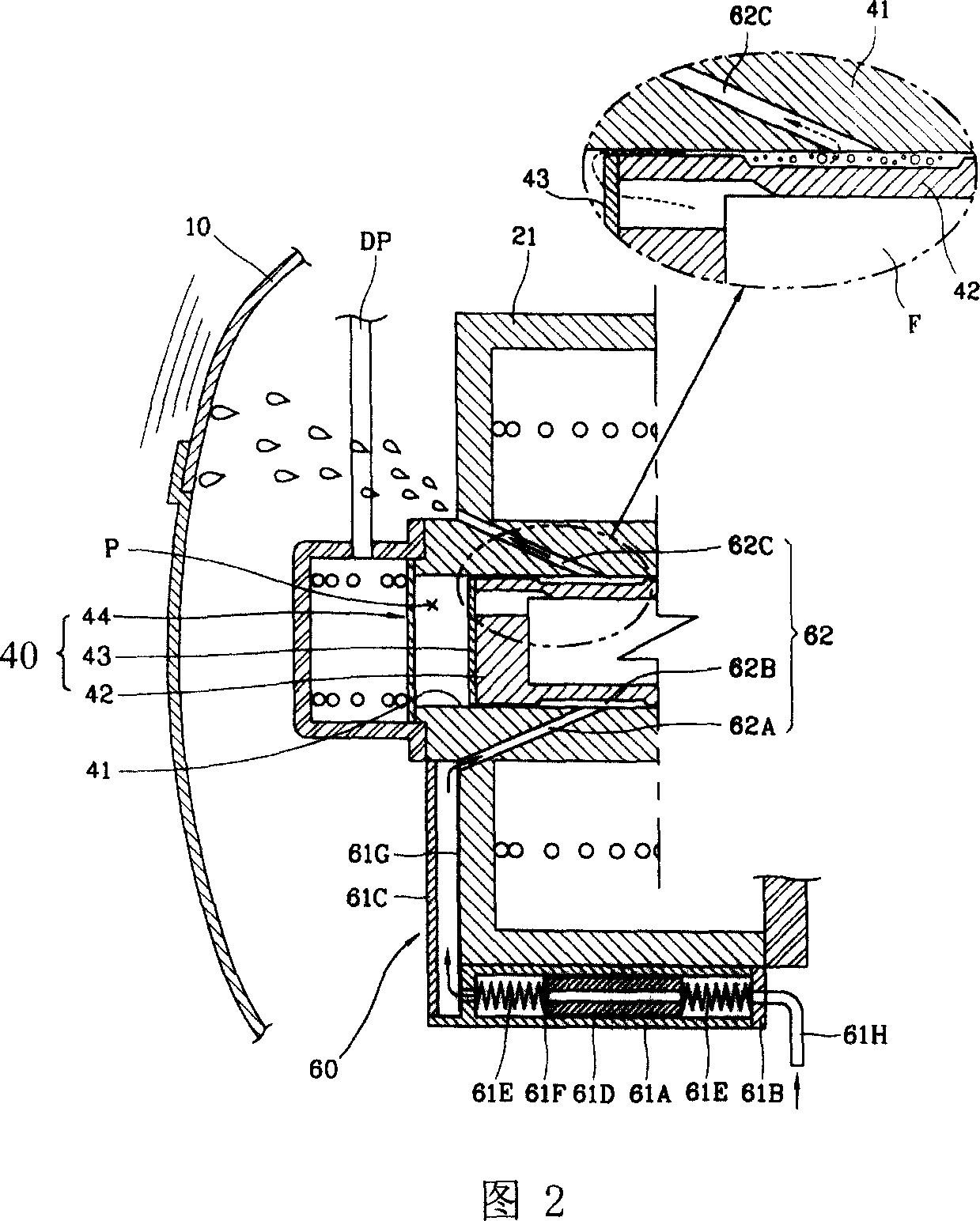

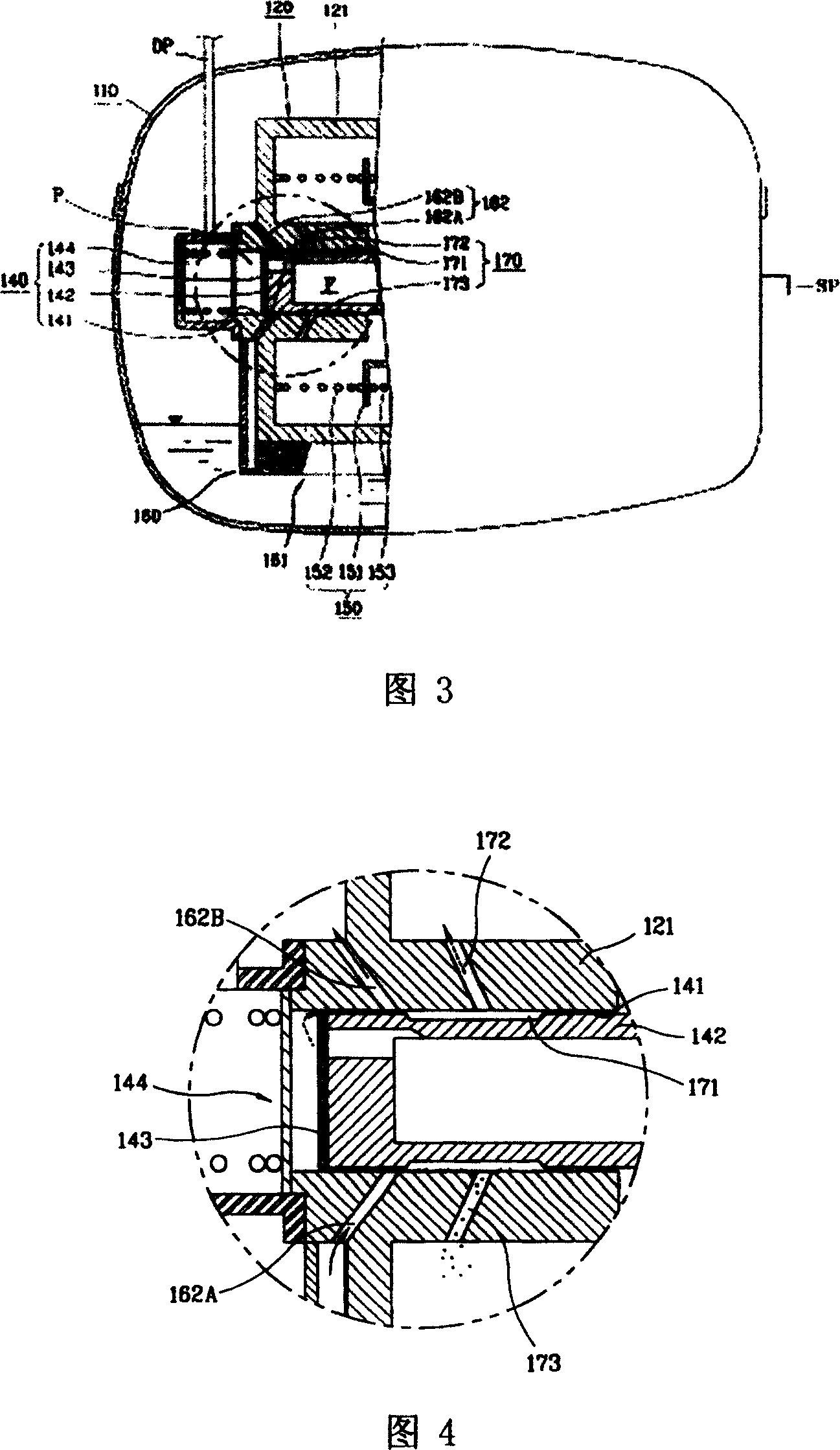

[0039] As shown in Figures 3, 4, 5 and 6, the reciprocating compressor using the noise reduction device of the reciprocating compressor of the present invention includes: a bracket assembly 120 elastically arranged in the shell 110, a bracket assembly fixed on the bracket assembly 120 The linear motor (not shown in the figure), the compression system 140 that compresses the refrigerant gas driven by the mover (not shown in the figure) of the linear motor, the spring system 150 that maintains the compression function of the compression system 140, and is installed on the bracket assembly 120 Lubricating oil supply system 160 that can supply the lubricating oil of the housing 110 to the sliding parts of the compression system 140 is set on the bracket assembly 120 at a certain distance from the lubricating oil supply system 160 and can leak out bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com