Filtering device and lampblack purifier

A lampblack purifier and filter device technology, which is applied in the fields of lampblack removal, household heating, lighting and heating equipment, etc., can solve the problems of affecting the purification effect of lampblack purifiers and the inability to purify pretreated gas, achieving good purification effect and slowing down effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

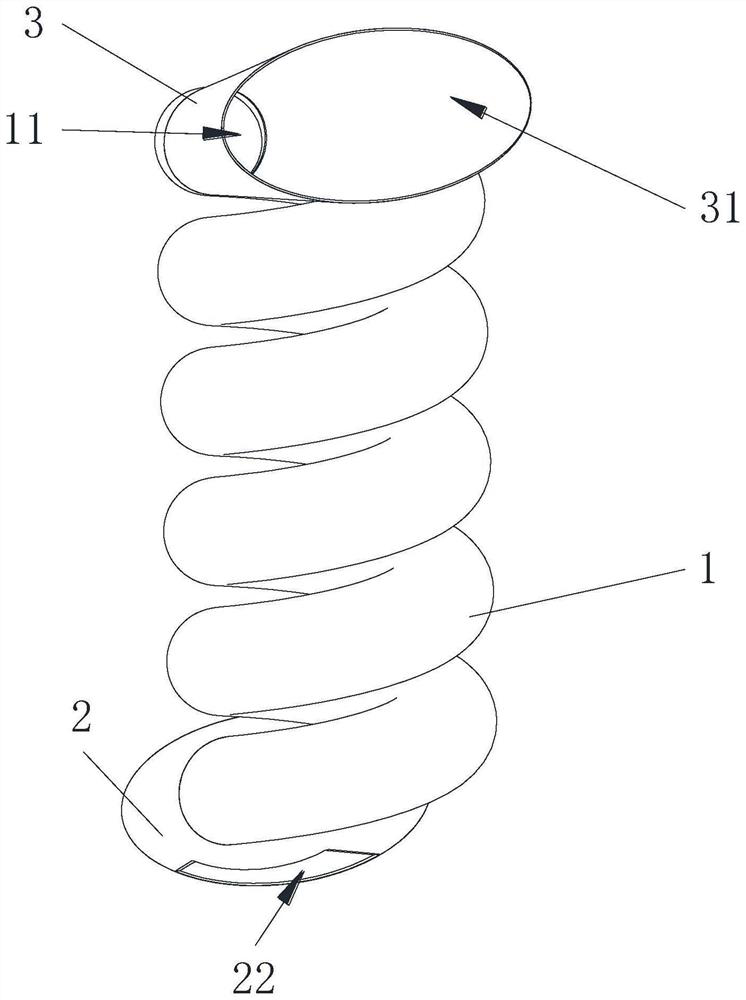

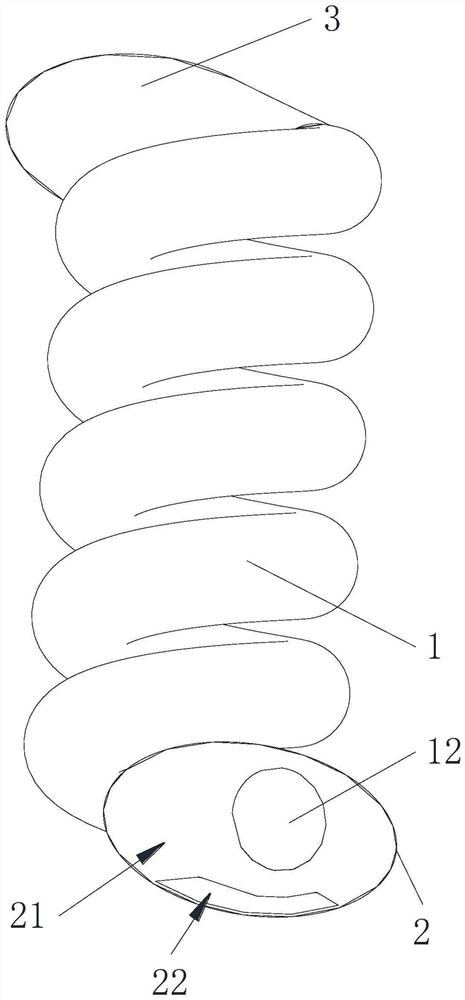

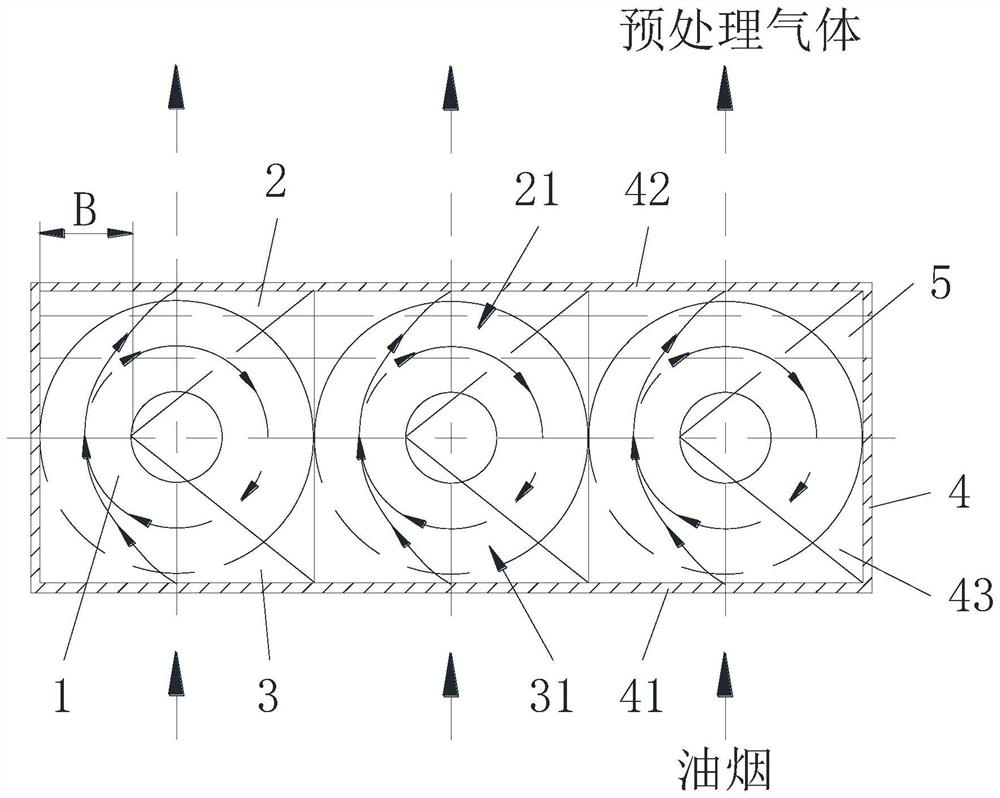

[0049] Such as figure 1 with figure 2 As shown, this embodiment provides a filter device, which is usually used in a fume purifier and is arranged upstream of the purifier body. The filter device plays a pre-filtering effect on the fume. The mechanism 1 includes an inlet 11 and an outlet 12 , the separation mechanism 1 can separate the oily fume entering from the inlet 11 , and the relatively clean pretreatment gas separated from the oily fume is discharged from the outlet 12 .

[0050] The separation mechanism 1 in the prior art usually adopts a mesh or honeycomb mechanical filter, which can filter large oil droplets and large particles in the oil fume. It reduces the resistance of the oil fume purifier by about 80%, increases the load of the fan, affects the overall purification efficiency of the oil fume purifier, and increases the frequency of maintenance and cleaning of the oil fume purifier.

[0051] In order to solve the above problems, such as figure 1 with figur...

Embodiment 2

[0086] This embodiment also provides an oil fume purifier, which includes a casing, a purifier body and the filter device in Embodiment 1. An air duct is opened on the cabinet, and the filter device and the purifier body are arranged in the air duct along the The flow direction of the oil fume is arranged, and the oil fume can pass through the filter device and the oil fume purifier in sequence through the external fan to form a clean gas and be discharged through the pipeline. The filter device can remove large particles of oil fume and particulate matter, and the purifier body can perform further secondary filtration on the pretreated gas filtered by the filter device, so as to achieve better oil fume filtering effect of the oil fume purifier.

[0087] The oil fume purifier in this embodiment can avoid the excessive flow rate of the pretreatment gas discharged from the outlet 12 by applying the filter device of the first embodiment, ensure that the pretreatment gas is fully p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com