Chestnut shell breaking system

A chestnut and shell breaking technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high shell breaking rate and low chestnut kernel breaking rate, etc., and achieve simple structure, reduce broken rate, and improve broken The effect of shell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

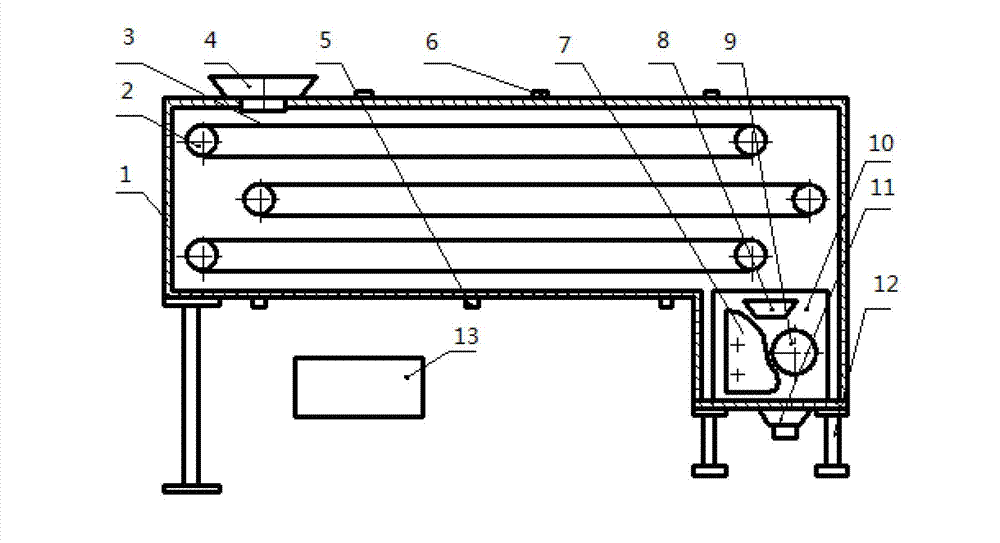

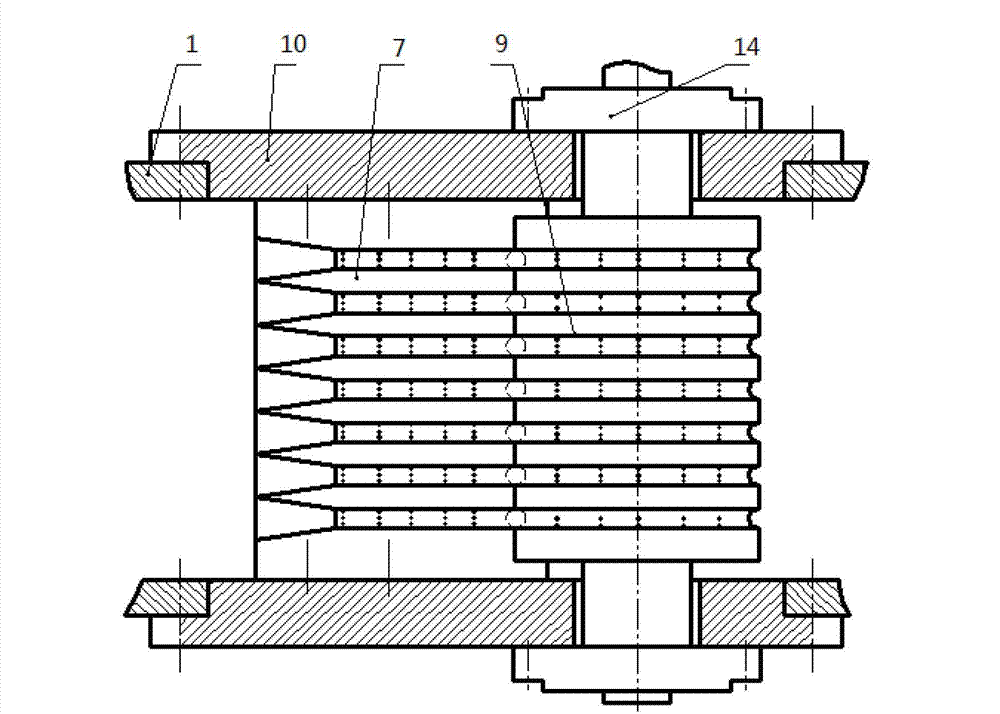

[0024] The chestnut shell breaking system includes a box body 1, a multi-layer wire mesh conveyor belt 3 arranged in the box body 1, and a shell breaking device. The box body 1 is provided with a feeder 4, a discharger 11, a hot air inlet 5, a wet The air extraction port 6 is controlled by a PLC controller 13; the shell breaking device is located below the bottom wire mesh conveyor belt 3, and the shell breaking device includes a shell breaking plate 7 and a shell breaking roller 9 arranged oppositely.

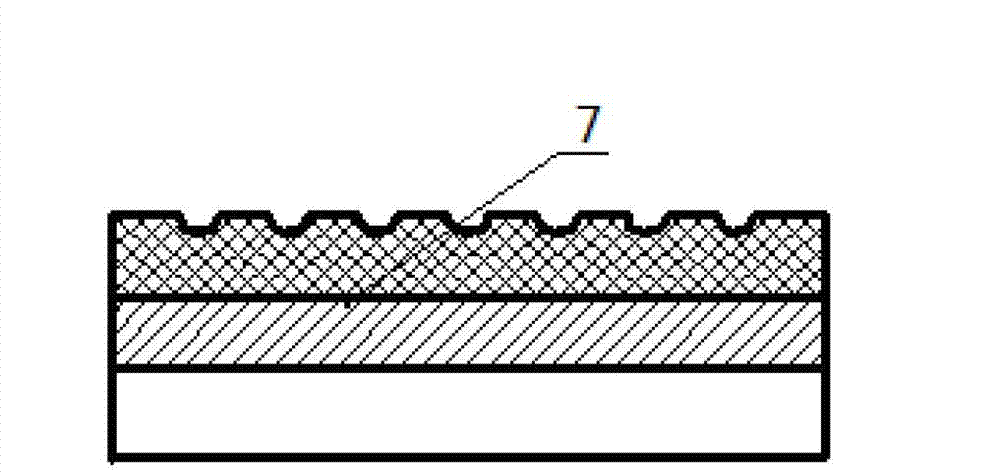

[0025] The plate surface of breaking shell plate 7 is arc, and the plate surface is provided with the arc channel from top to bottom, and arc channel is arc groove, and breaking shell roller 9 is provided with annular groove, and arc groove and The annular grooves are opposite to form a closed channel, and the elastic protrusions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com