Walnut shell breaking machine

A shell breaking machine and walnut technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of reducing the added value of the walnut market, unclean shell breaking, and difficult to control the force of knocking, so as to improve the processing quality and Increase the export rate, increase the rate of broken shells and whole kernels, and realize the effect of mechanized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

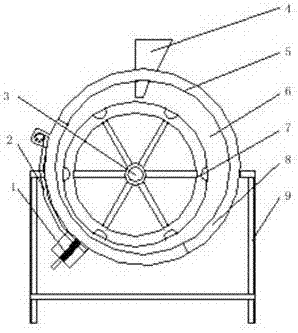

[0009] Such as figure 1 As shown, a walnut shell breaking machine includes an extruding device 1 and an extruding plate 2. The extruding device 1 is placed on the extruding plate 2, and the middle part of the extruding plate 2 is provided with a shaft 3, which is fixed on the machine. On the frame 9, the outer surface of the shaft 3 is uniformly divided into rollers 7, and the upper part of the extrusion plate 2 is provided with a feed port 4, and the feed port 4 is placed on the upper cover 5, and the lower part of the upper cover 5 is provided with an end cover 6 , love the lower part of the 6 is provided with a lower cover 8.

[0010] The stiffness of the extruding device 1 is 15.5 N / mm.

[0011] It works as follows:

[0012] When working, the walnut falls into the groove of the roller 7 through the feed port 4, and with the rotation of the roller 7, the extrusion plate 2 squeezes and breaks the walnut; the walnut shell breaking extrusion stroke and the extrusion spring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com