Self-adapting-based walnut kneading type shell breaker

A self-adaptive, shell breaking machine technology, applied in the direction of shelling, application, pod removal, etc., can solve the problems of low broken kernel rate, small gap between shell and kernel, poor adaptability to walnut processing, etc., to achieve smooth operation and avoid accumulation jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

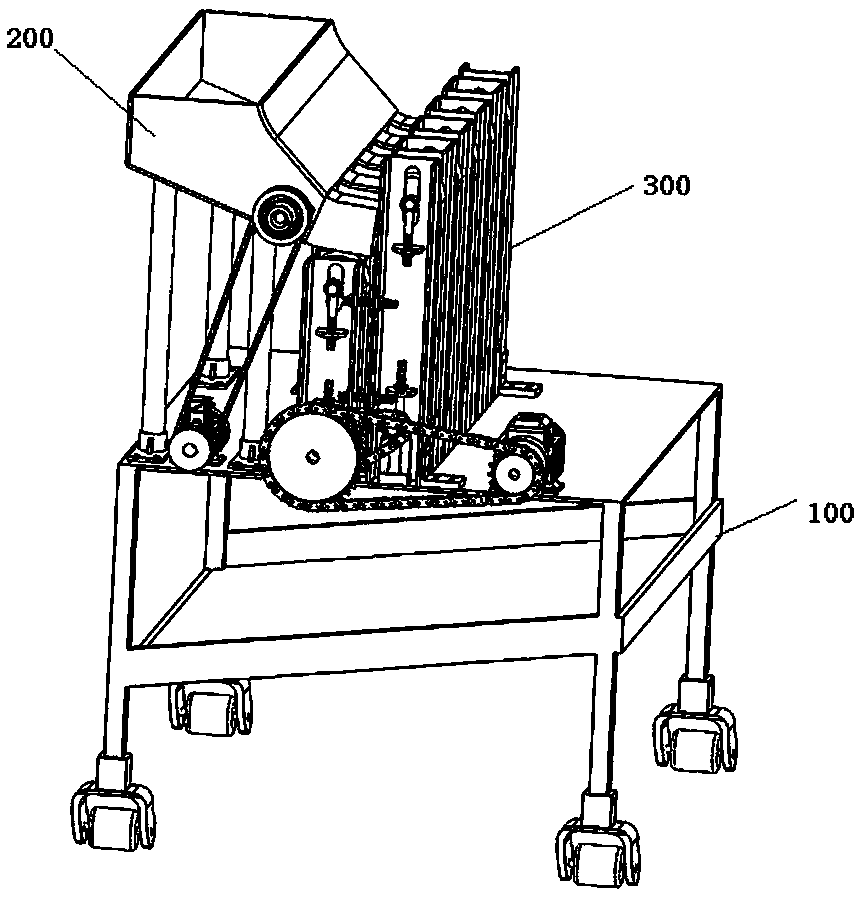

[0034] like figure 1 As shown, a walnut kneading type shell breaking machine based on self-adaptation is mainly composed of a frame 100, a feeding device 200 and a shell breaking device 300. The walnuts to be processed are put into the feeding device 200, and then the shell breaking Device 300 shell breaking process, the processed walnut shell kernels fall into the collection area at the bottom of the frame 100 to complete the shell breaking process of walnuts.

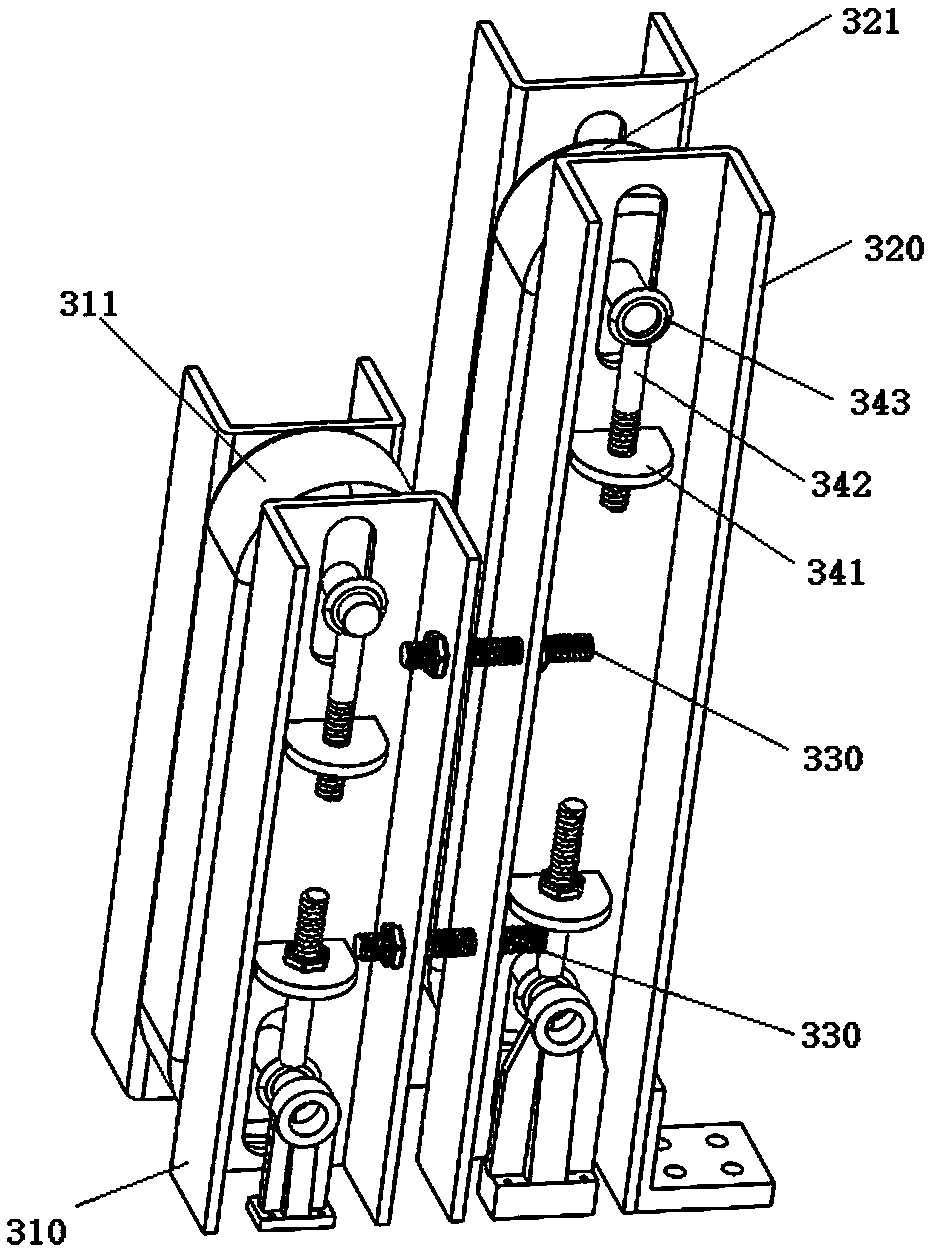

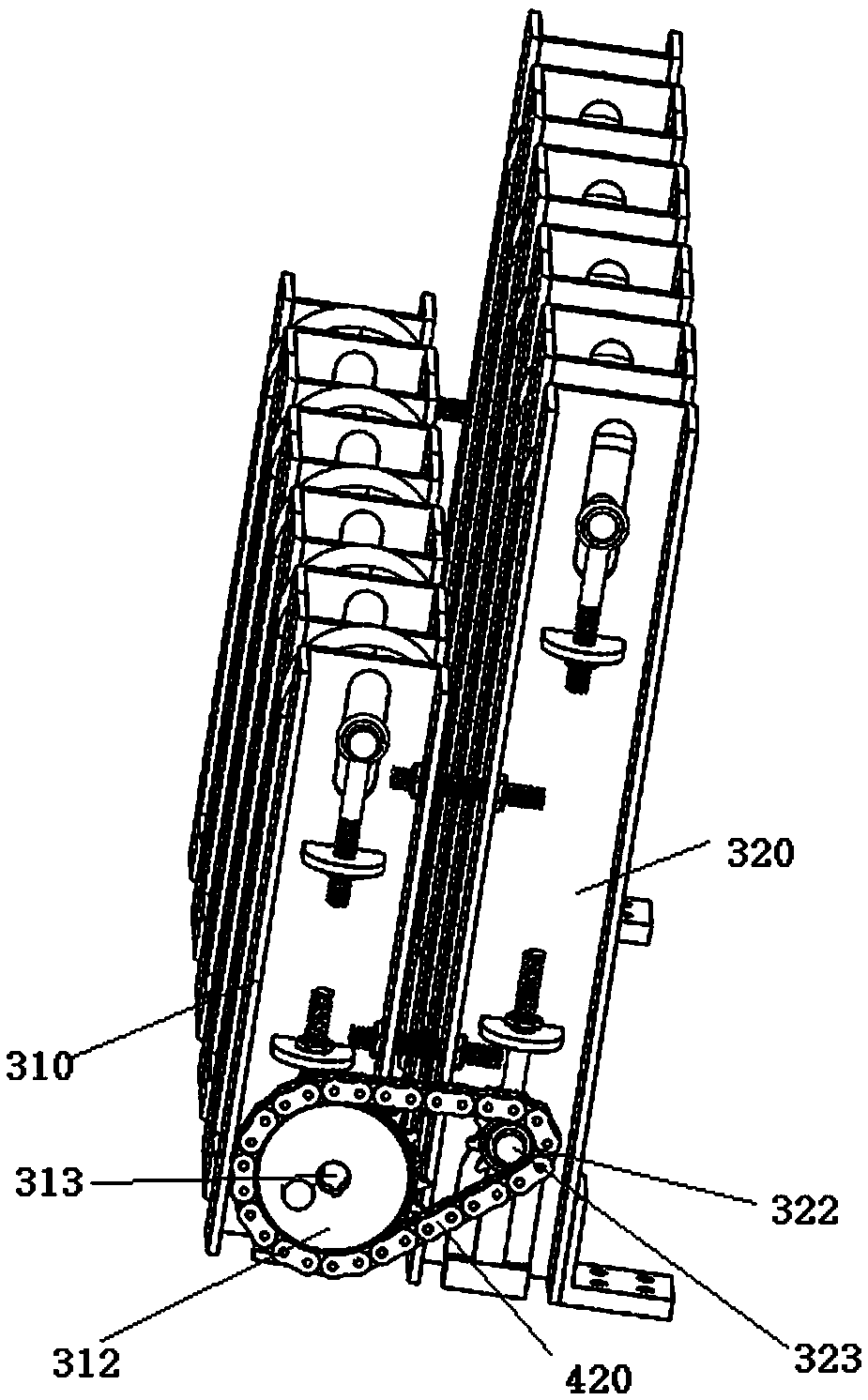

[0035] Wherein the cracking device 300 comprises a cracking mechanism; the structure of the cracking mechanism is as follows figure 2 As shown, it includes a first belt 311, a second belt 321 and an adjusting device. The first belt 311 is arranged obliquely to the second belt 321...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com