Production line used for magnesia carbon brick products and technology thereof

A production line, magnesia carbon brick technology, applied in the field of pneumatic conveying, lifting conveying, can solve the problems of low measurement accuracy, easy material leakage in the hopper, failure to meet environmental protection requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] Specific embodiments of the present invention will be described below.

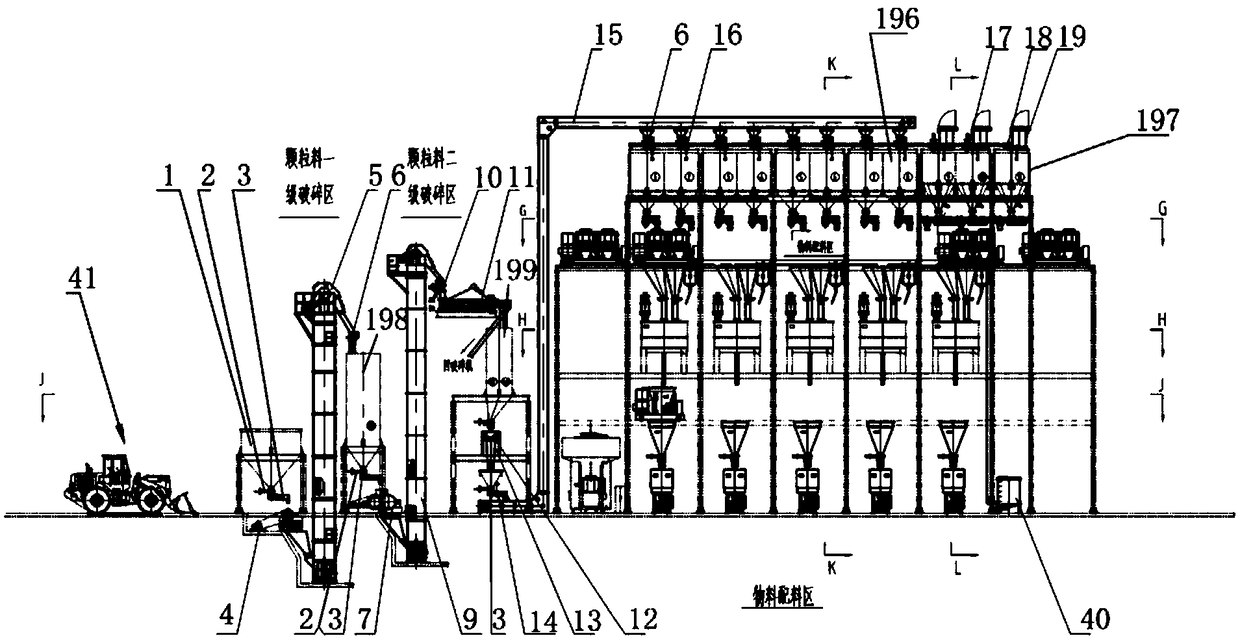

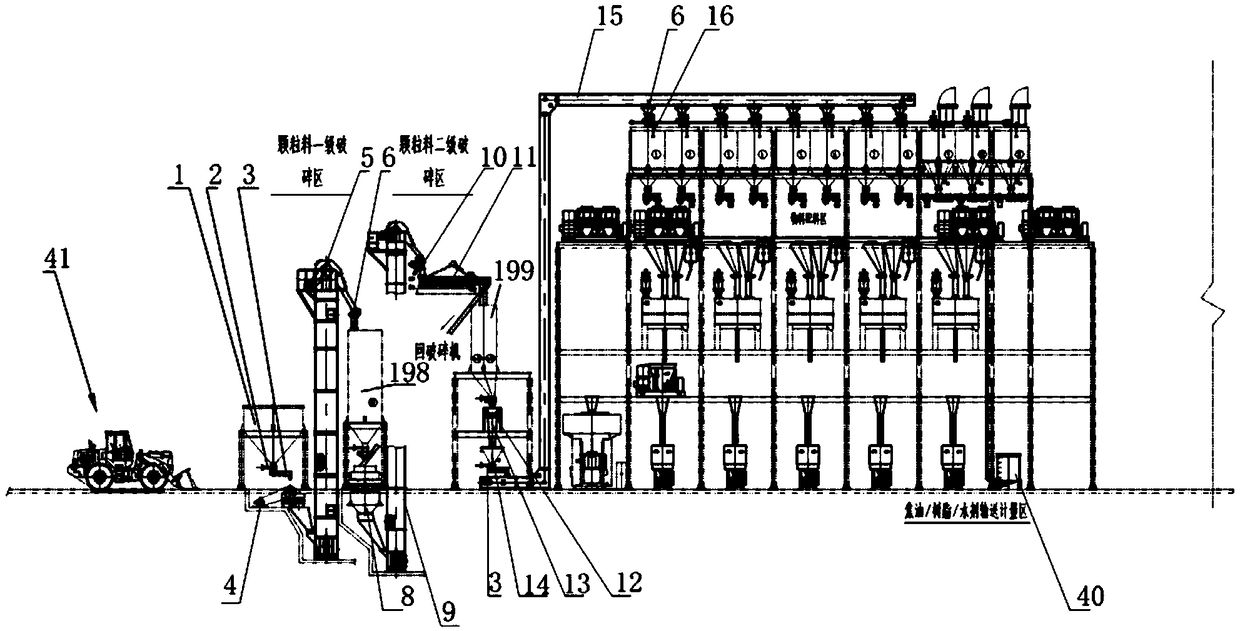

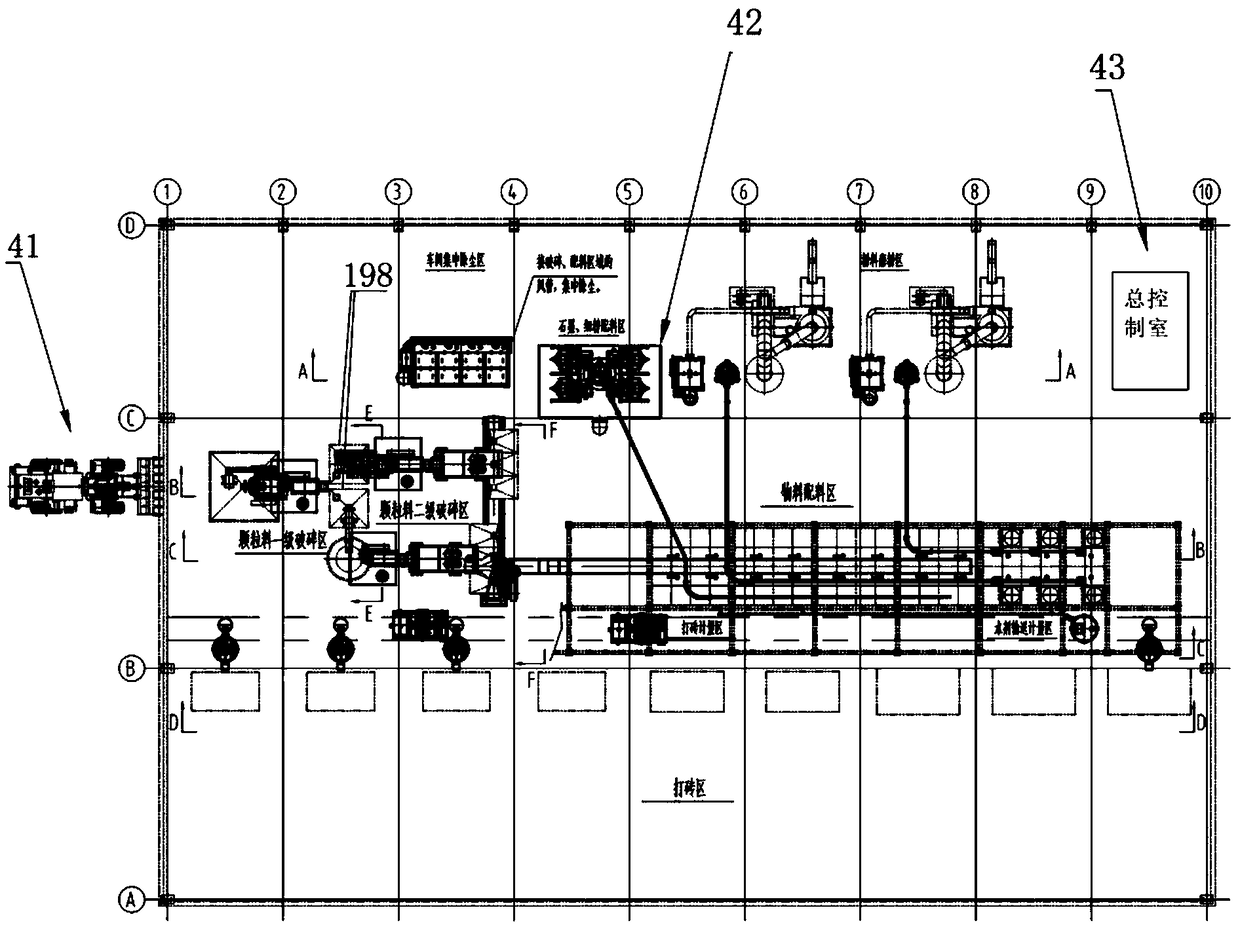

[0097] like figure 1 , figure 2 and image 3 As shown, the magnesia-carbon brick automatic conveying and batching system of the present invention includes a granular material crushing unit for granular material processing, multiple groups of powder material grinding units for powder material processing, and graphite for graphite and fine powder batching. Or the automatic batching of fine powder and the delivery system 42 after batching, and the liquid material delivery metering unit 40 used for liquid material processing, also includes the material batching unit for batching broken granular materials and ground powder materials, for receiving Material batching unit, automatic batching of graphite or fine powder and conveying system 42 after batching, material mixing unit of liquid material delivery metering unit 40 and brick-breaking metering unit for receiving mixed materials, material batching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com