Patents

Literature

70results about How to "Easy to remove the mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Motor stator core potting process

InactiveCN102280975AImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

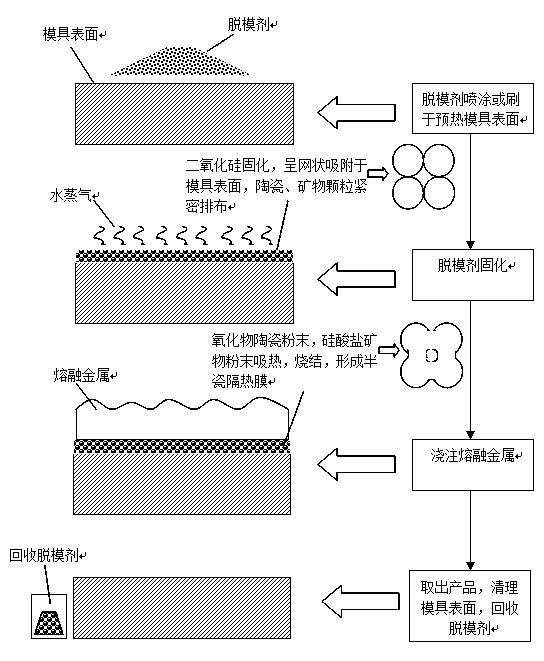

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Resin casting body processing die

The invention provides a resin casting body processing die, which is composed of two double-cross components, the double-cross components comprise a short beam and a through beam, the length of the short beam is more than two times of thickness of the prepared casting body and the width of the through beam, the spacing between the short beams is the length of the casting body and the width of the short beam, and the thickness of the through beam and the width of the prepared casting body. The resin casting body processing die is composed of two double-cross components, which enables flexible combination, convenient assembling and dismounting, and the die can be used for one-time moulding of resin casting body bending spline, a DMA test spline and other splines required to be tested.

Owner:HARBIN ENG UNIV

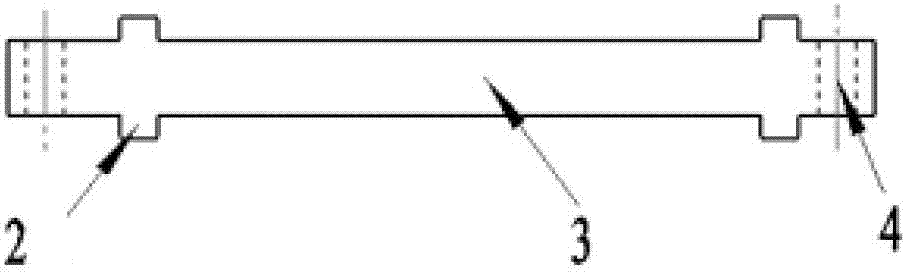

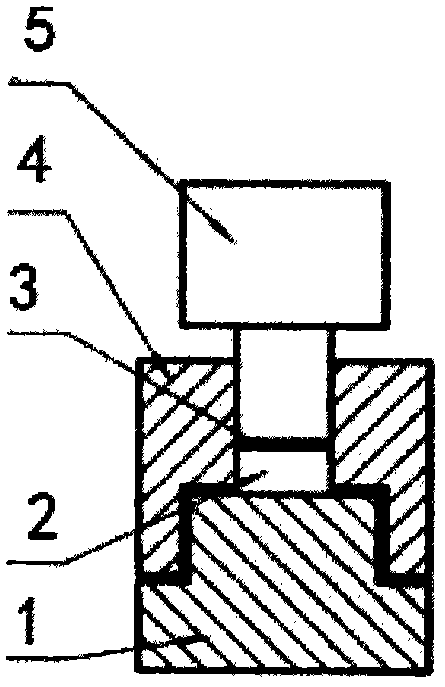

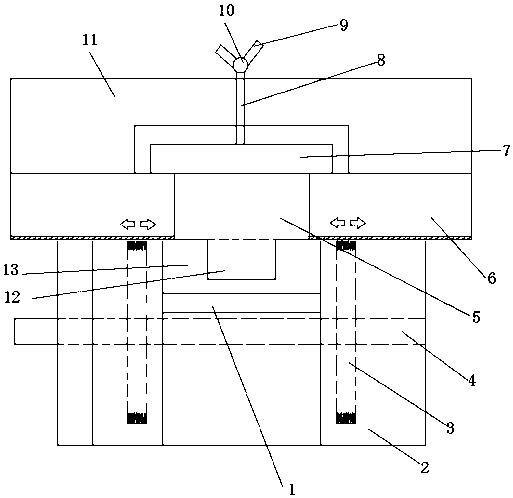

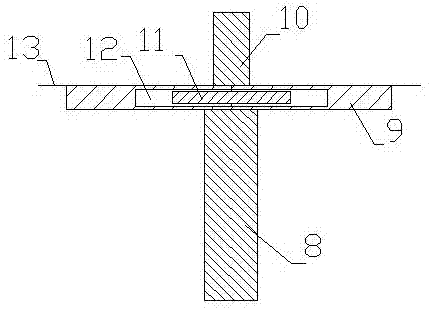

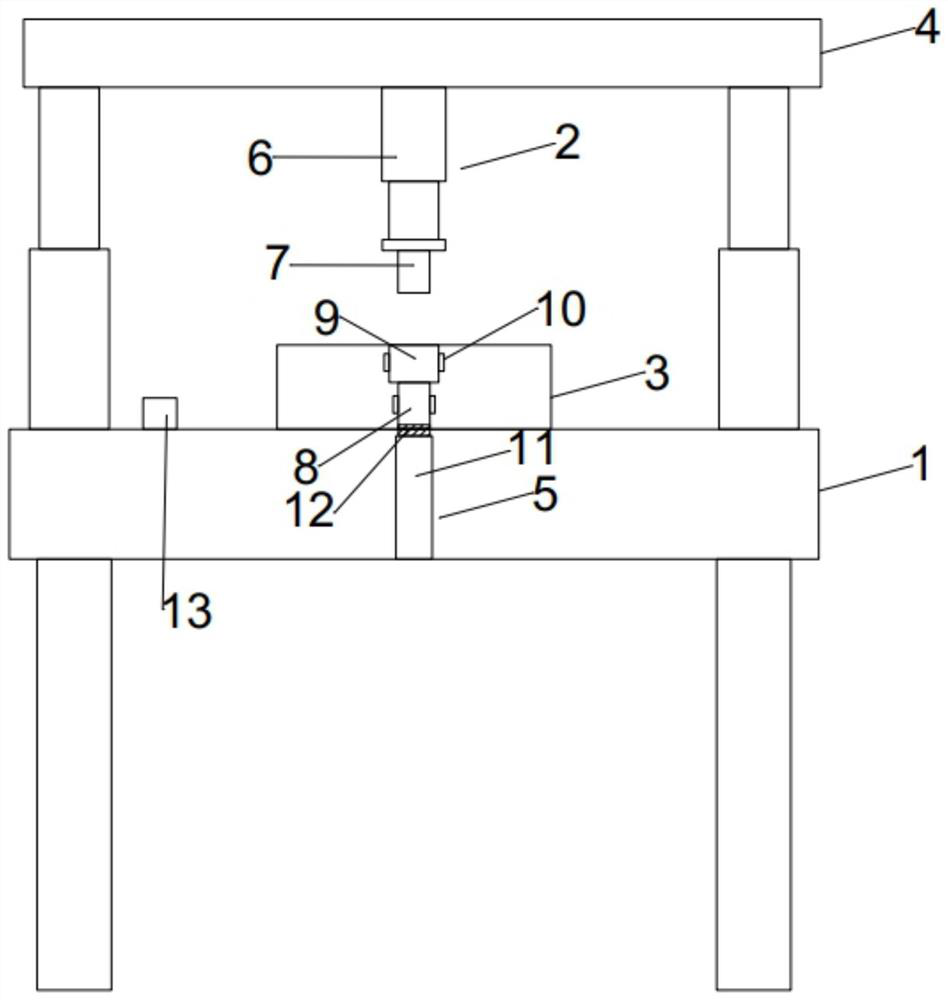

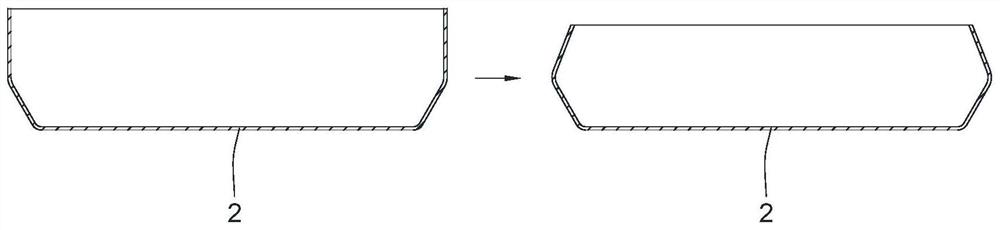

Plastic forming method of draw-hole bolt

ActiveCN105618665AEven by forceExtended service lifeBoltsForging/hammering/pressing machinesHead shapeMechanical engineering

The invention provides a plastic forming method of a draw-hole bolt and belongs to part cold heading methods. The plastic forming method comprises the steps that firstly, the tail taper and required dimension of a rod part are obtained by squeezing a part blank through a first stamping die (1); secondly, a bottom hole and the required dimension of the rod part are obtained by squeezing the part (2) in the first step through a second stamping die (3); thirdly, the head taper and the required dimension of upsetting depth and pumping depth of the rod part are obtained by squeezing the part (2) in the second step through a third stamping die (4); fourthly, the required dimension for flattening the head portion, drawing down the rod part and further hole drawing is obtained by squeezing the part (2) machined in the third step through a fourth stamping die (5); and fifthly, the head shape is obtained by squeezing the part (2) machined in the fourth step through a fifth stamping die (6). The plastic forming method of the draw-hole bolt has the advantages that the bottom hole is squeezed effectively, the procedures are simple, machining is convenient, the material utilization rate is high, and the service life of the dies is long.

Owner:丽水市知源科技有限公司

Infrared and/or ultraviolet sample wafer pressing die

InactiveCN106153411AEasy squeezeEasy to remove the moldPreparing sample for investigationUltravioletEngineering

The invention relates to an infrared and / or ultraviolet sample wafer pressing die. The infrared and / or ultraviolet sample wafer pressing die comprises a base with a circular boss and a framework connected with the base in a thread matched mode. A cylindrical hollow cavity is formed in the center of the framework in the axial direction, an internal thread is arranged on the inner wall of the cylindrical hollow cavity and connected with a cylinder pressing head through threads, and the other end of the pressing head is connected with a die sleeve. The center of the circular boss of the base is fixedly connected a cylindrical column platform matched with the pressing head to extrude powder into shapes. The column platform is connected with the internal thread of the cylindrical hollow cavity, and the column platform is provided with a forming ring for powder forming. According to the infrared and / or ultraviolet sample wafer pressing die, due to the fact that all connection is achieved through the threads, die discharging and releasing can be conducted conveniently; due to the fact that the column platform is provided with the forming ring for powder forming, power extrusion forming is convenient, and the powder can be placed into a transmission detector to be subjected to infrared and / or ultraviolet transmission detection conveniently after being taken out.

Owner:TIANJIN XIANNQUAN IND & TRADE DEV

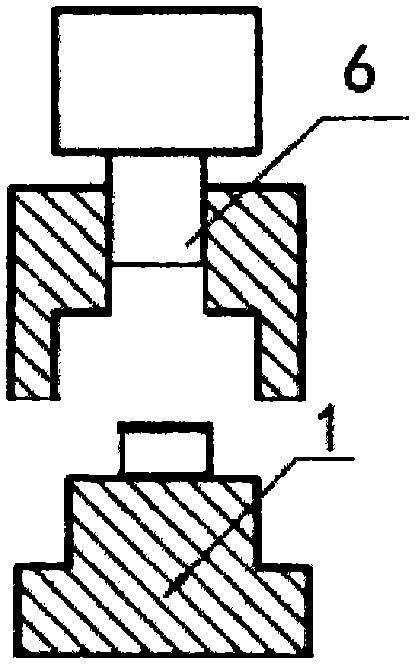

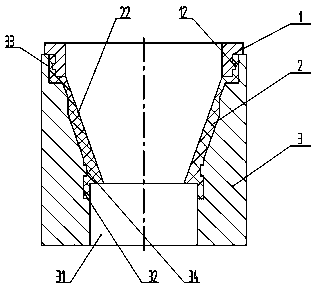

Plastic forming method of semi-hollow shaft pin

ActiveCN105750475AGuaranteed stabilityAvoid the phenomenon of mold collisionForging/hammering/pressing machinesEngine componentsPunchingMachining

The invention discloses a plastic forming method of a semi-hollow shaft pin. The plastic forming method comprises the following steps: step 1, extruding a part blank through a first punching die (1) to obtain needed sizes of a tail filleted corner, a bottom surface tapered hole and a rod part; step 2, extruding a part (2) in the step 1 through a second punching die (3), so as to obtain a needed size of a head pre-formed hole, carry out hole shrinkage and chamfering, and upset the rod part and a head to the needed sizes; step 3, extruding the part (2) in the step 2 through a third punching die (4) to obtain the needed size of the depth of a head hollow hole, and upset the head and the rod part to the needed sizes; and step 4, extruding the part (2) in the step 3 through a fourth punching die (5) to obtain a final size of the depth of the head hollow hole, and upset the head and the rod part to final sizes, so as to meet the shape and size requirements of a final product. The plastic forming method of the semi-hollow shaft pin, disclosed by the invention, is a part cold upsetting machining method which has the advantages of effective hole punching, stability of forming a product, simple procedures, convenience in machining, high material utilization rate and long service life of the die.

Owner:丽水市知源科技有限公司

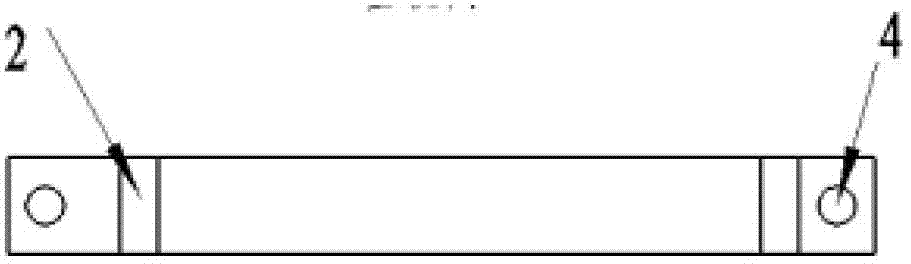

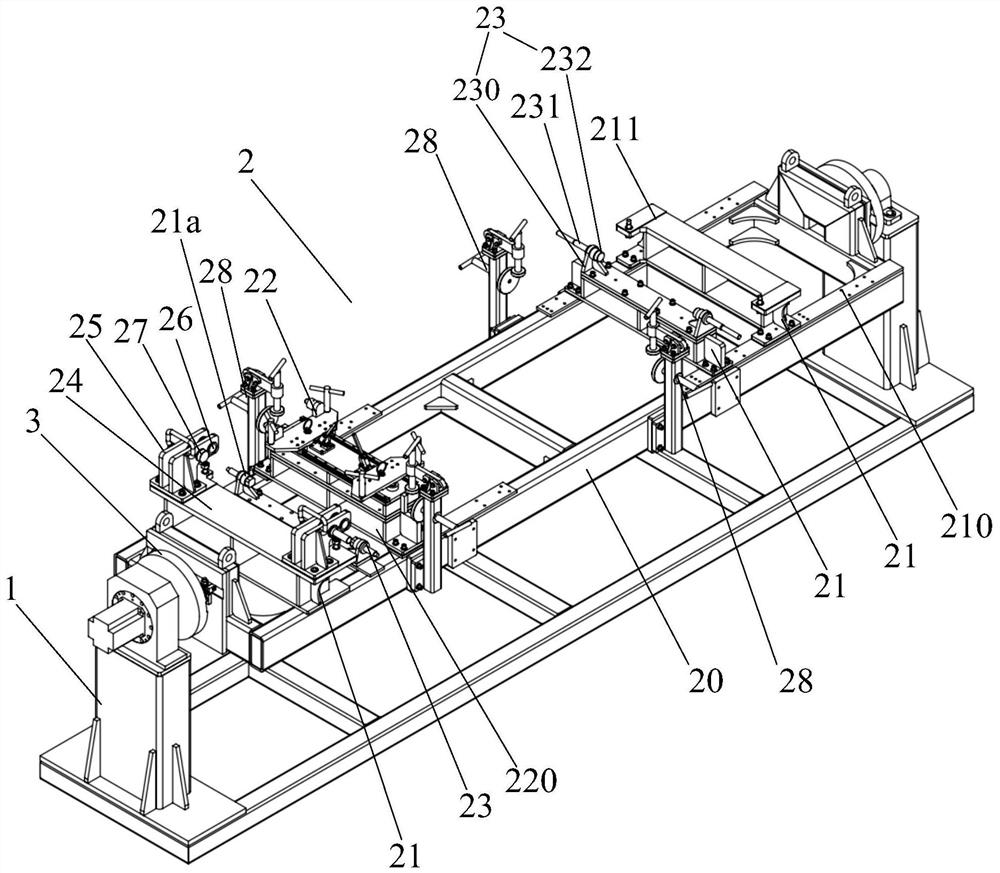

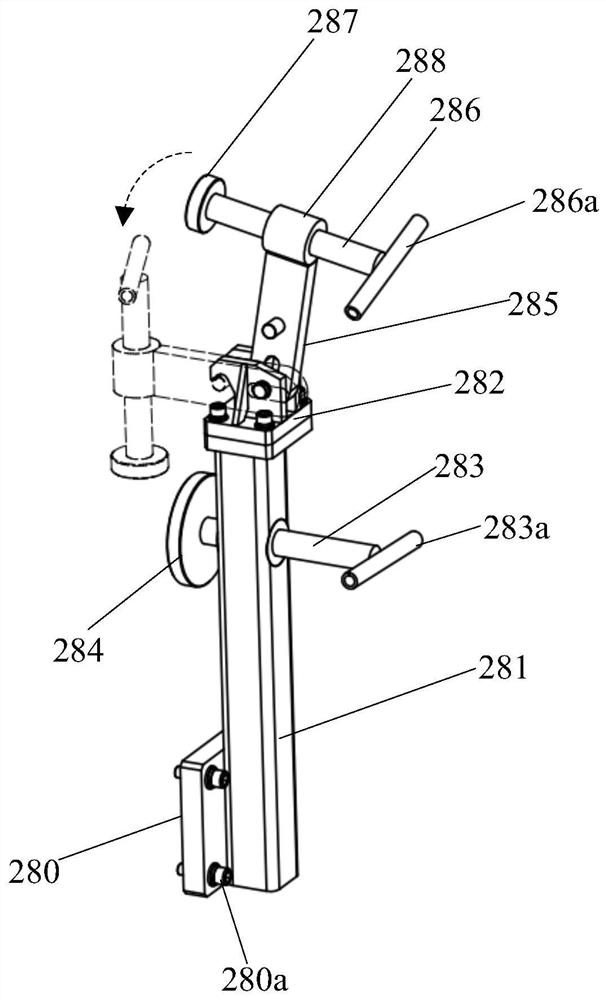

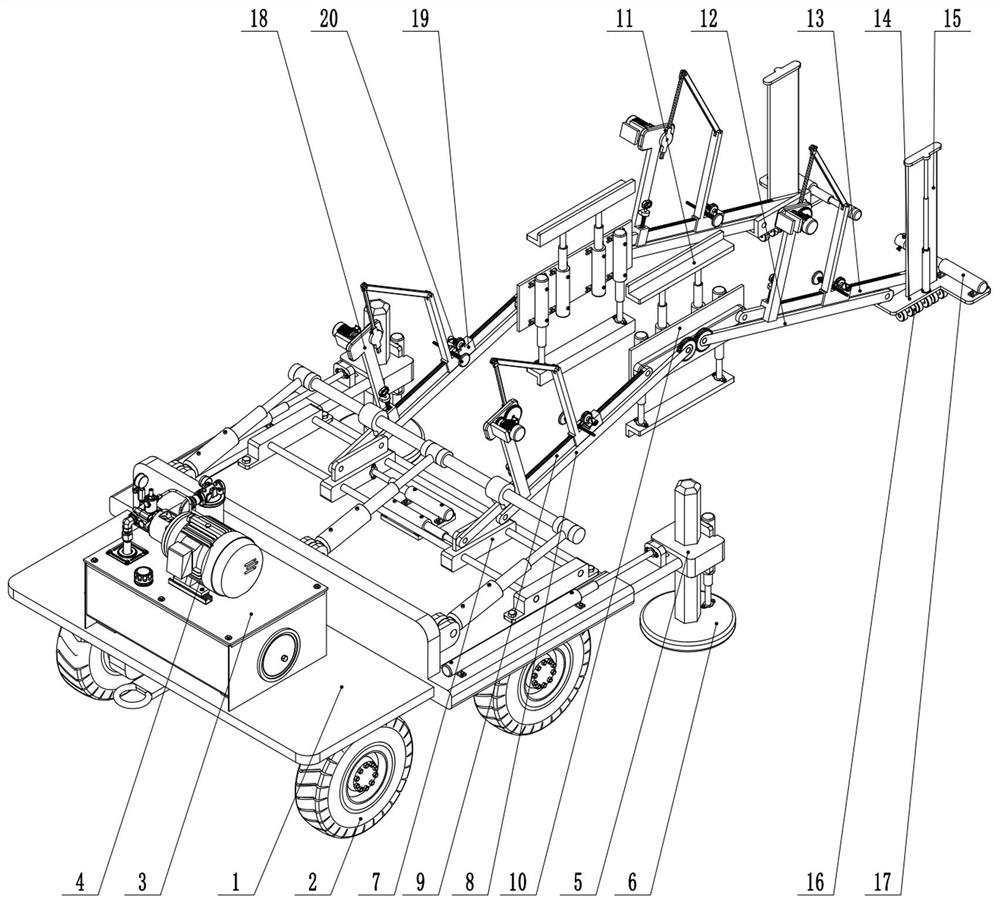

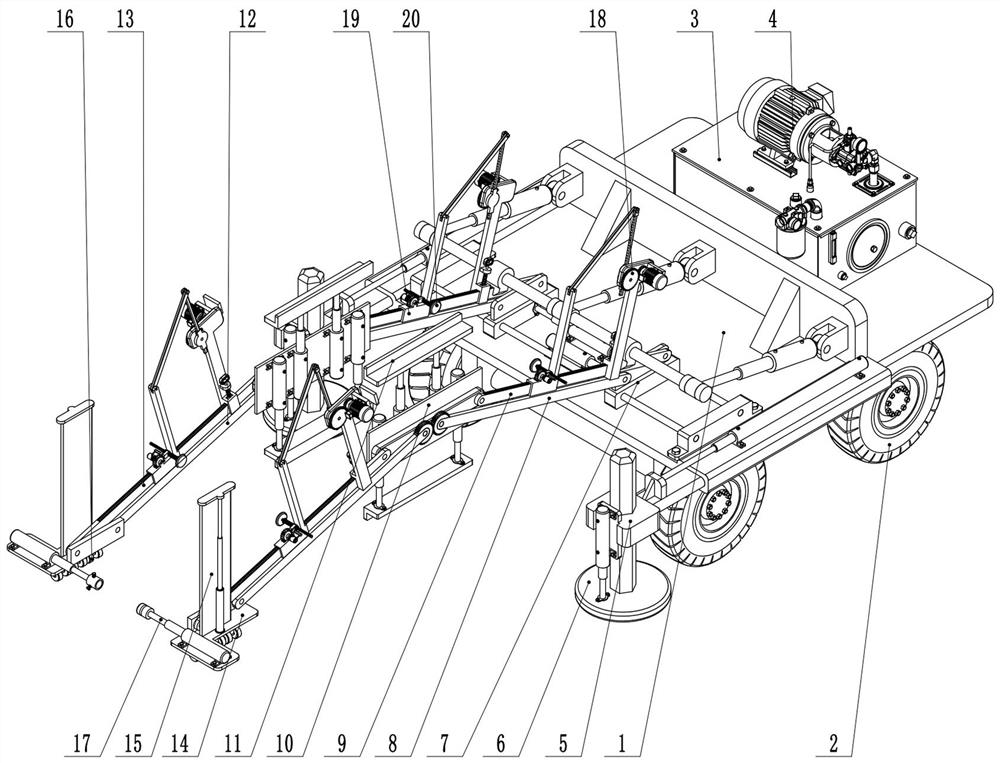

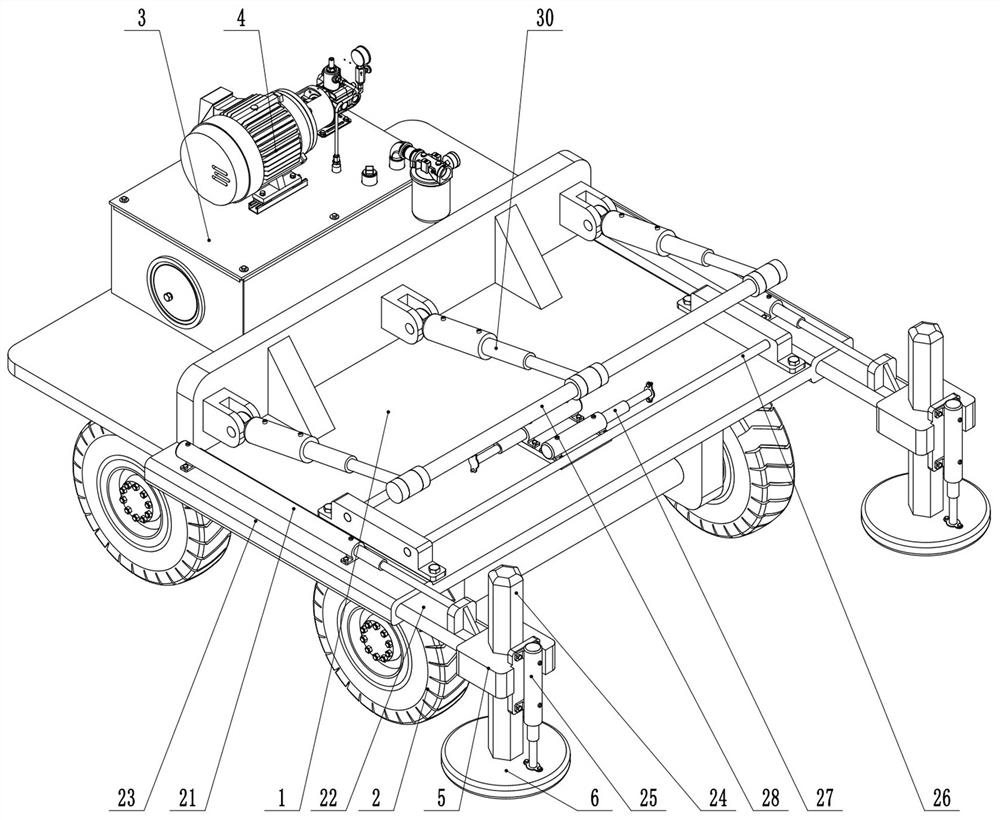

Flexible welding tool for main stand column structure of lifting cage and welding construction method

PendingCN112935687AFast solderingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding

The invention discloses a flexible welding tool for a main stand column structure of a lifting cage and a welding construction method. The flexible welding tool for the main stand column structure of the lifting cage comprises a welding positioner, tool quick-changing mechanisms and a tool platform used for clamping and fixing the main stand column structure of the lifting cage, wherein the tool quick-changing mechanisms are detachably arranged at the two ends of the tool platform correspondingly; the tool quick-changing mechanisms at the two ends of the tool platform are rotatably installed on the welding positioner, the two ends of a horizontal supporting bottom frame are rotatably installed on the welding positioner through the tool quick-changing mechanisms, and a plurality of detachable fixed positioning seats are transversely arranged on the upper surface of the edge of the horizontal supporting bottom frame at intervals; a plurality of movable clamping mechanisms which slide back and forth in the center direction of the horizontal supporting bottom frame are symmetrically arranged on the inner side of the edge of the horizontal supporting bottom frame, and first fixed clamping mechanisms are arranged at the two ends of the fixed positioning seats. According to the flexible welding tool for the main stand column structure of the lifting cage, the inner side direction, the outer side direction and the top of the main stand column structure of the lifting cage can be rapidly pressed and positioned, and overturning construction welding can be rapidly conducted.

Owner:GUANGXI CONSTR ENG GROUP CONSTR MACHINERY MFG

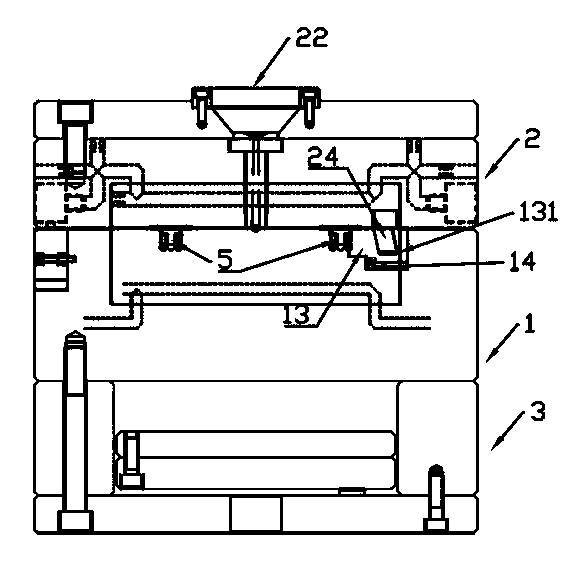

Stamping die capable of facilitating unloading

InactiveCN110899500AEasy to remove the moldPrecise positioningShaping toolsStripping-off devicesEngineeringStructural engineering

The invention belongs to the technical field of stamping die design and discloses a stamping die capable of facilitating unloading. The stamping die comprises a fixed base and an upper die holder; thetop surface of the fixed base is fixedly connected with the bottom of a lower die plate waste cutter; the top of the lower die plate waste cutter is fixedly connected with the bottom of a female diefixing plate; the top of the lower die plate waste cutter is fixedly connected with the bottom of a female die; a die shank is installed at the top of the upper die holder; and the upper die holder isfixedly connected with a male die fixing plate through positioning pins. According to the stamping die, with the positioning pins mounted, a male die and the die shank can be accurately positioned; with the lower die plate waste cutter adopted, the female die can be more accurate during blanking, and the situation that a material is stuck in the female die is avoided; with a stuck material unloading device adopted, a material plate which is attached to the male die can be unloaded conveniently.

Owner:王煜

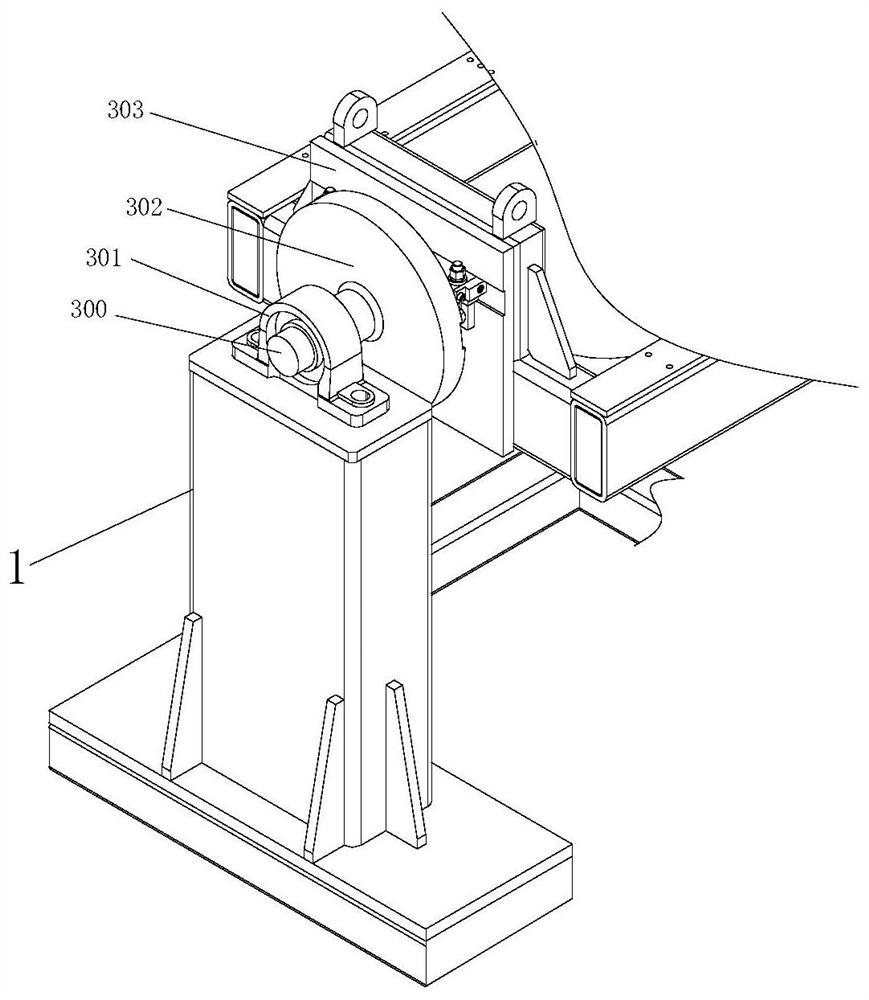

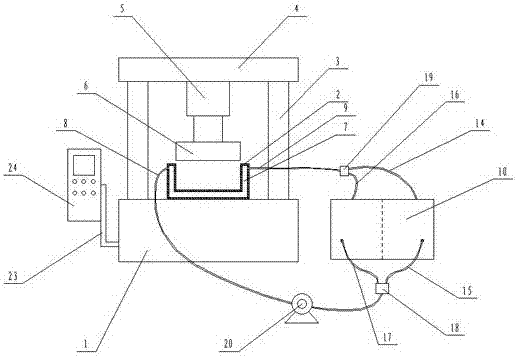

Automatic wire coiling machine

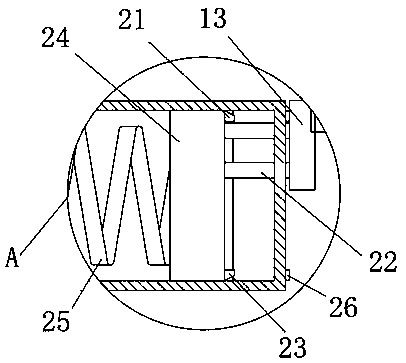

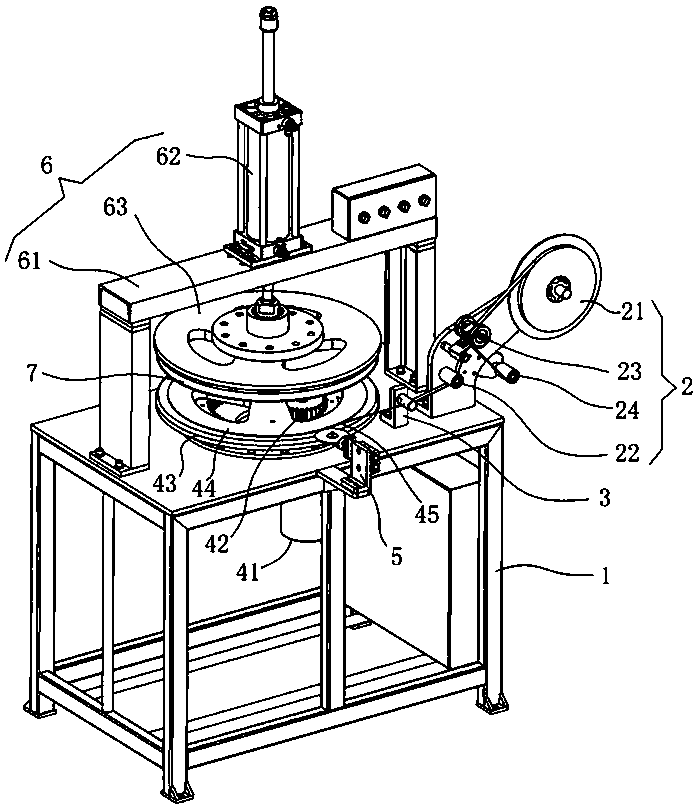

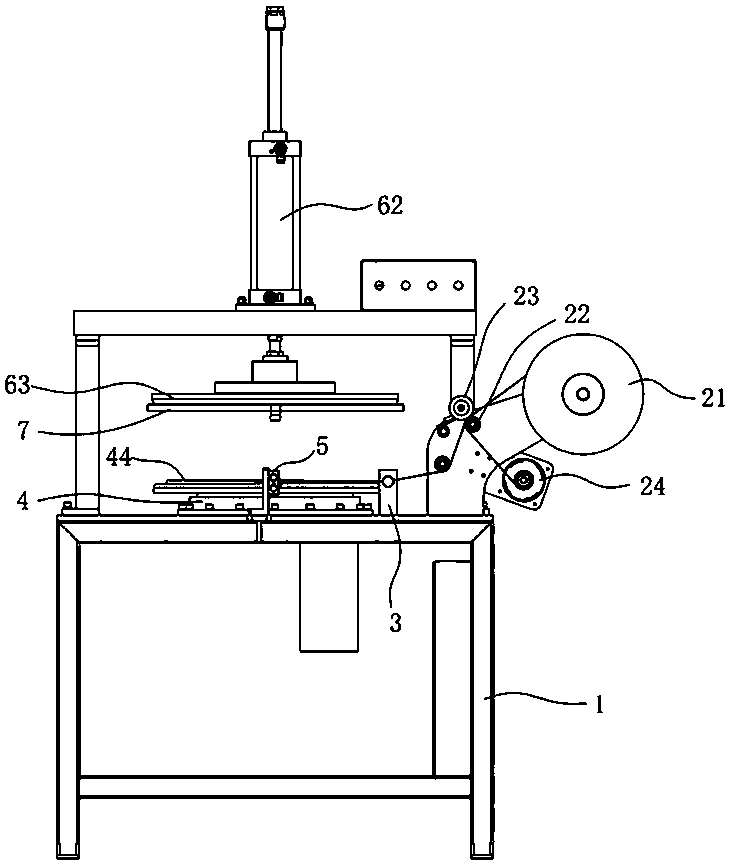

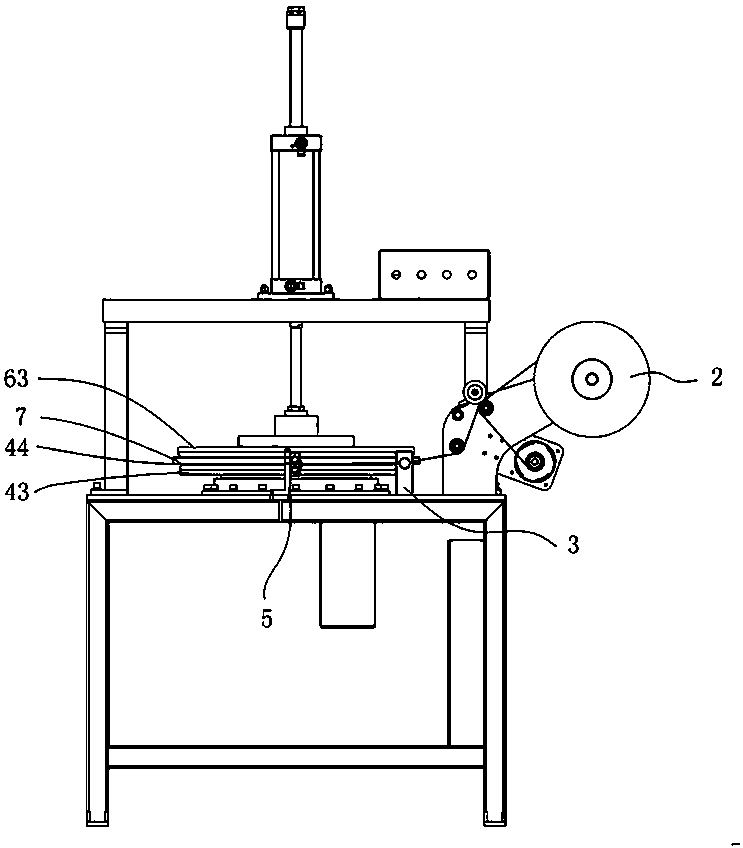

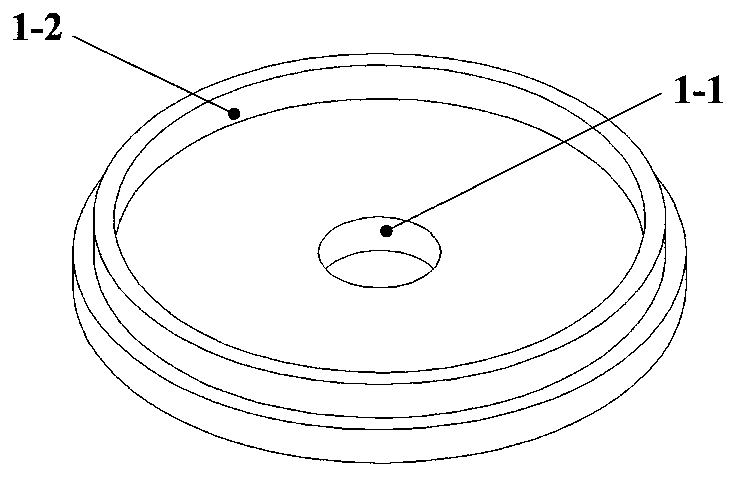

ActiveCN108726238AUniform thicknessImprove tightnessFilament handlingWebs handlingFiberCarbon fibers

The invention provides an automatic wire coiling machine. The automatic wire coiling machine comprises a rack, and an unwinding device, a wire guide device, a wire coiling main shaft device and a pressing device which are arranged on the rack, wherein the unwinding device comprises an unwinding disc for placing a pre-impregnated belt and a plurality of tensioning wheels; the wire guide device is arranged at one side of the unwinding device; a wire guide hole is formed in the wire guide device; the wire coiling main shaft device comprises a rotary motor and a driving disc which is controlled bythe rotary motor to rotate; the driving disc is provided with a round wire coiling jig; the pre-impregnated belt on the unwinding disc is dragged to the wire guide device through the tensioning wheels and passes through the wire guide hole to form a silk shape and then is wound on the round wire coiling jig; the pressing device comprises a bracket, a linear air cylinder and a pressing disc; the linear air cylinder is fixed on the bracket; the pressing disc and the linear air cylinder are coaxially connected; the pressing disc is located just above the round wire coiling jig. According to theautomatic wire coiling machine, carbon fiber pre-impregnated silks are uniformly and stably coiled on the round wire coiling jig, the tightness is good and the thickness is uniform, so that the strength of a product is ensured, and batch and standard production is realized.

Owner:XIAMEN HONGJI WEIYE INDAL

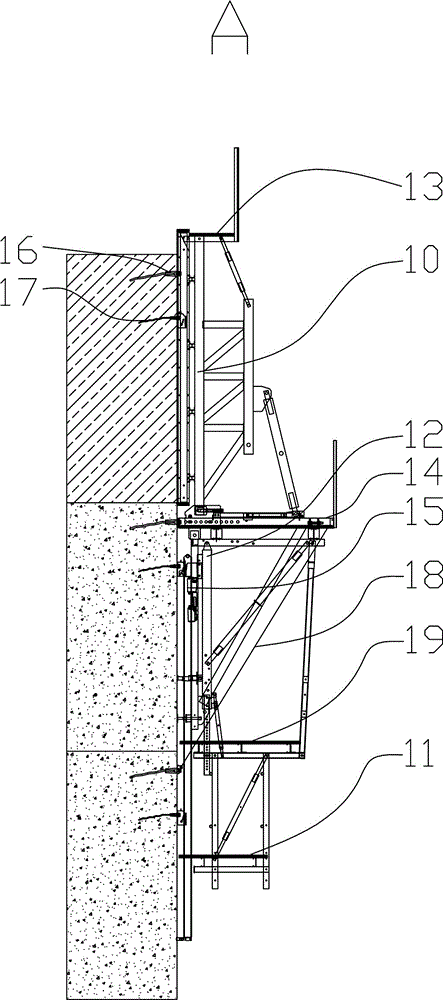

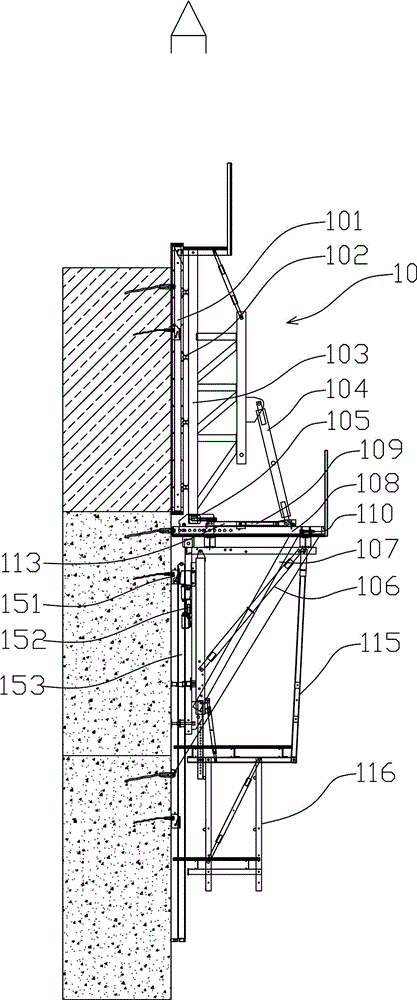

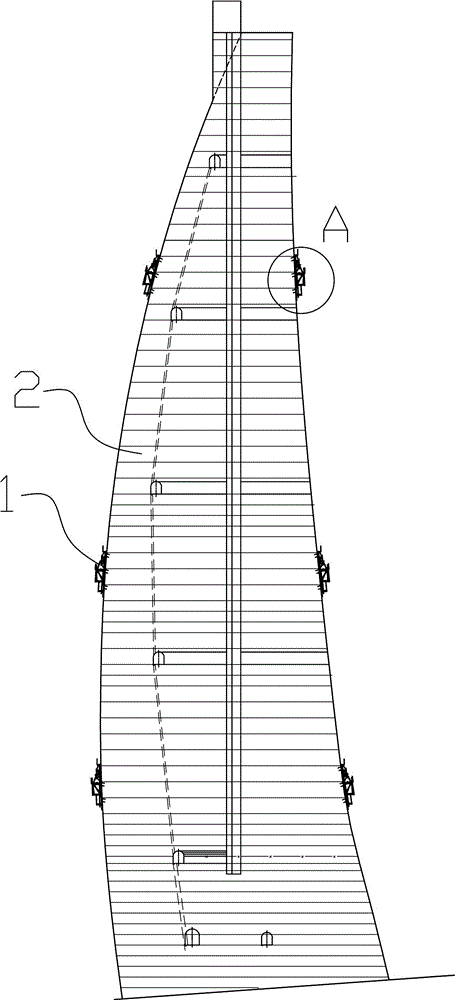

Hydraulic self-lifting cantilever heavy arch dam template work platform

ActiveCN106836146AEnsure construction safetyImprove construction efficiencyClimate change adaptationFoundation engineeringArchitectural engineeringArch dam

The invention provides a hydraulic self-lifting cantilever heavy arch dam template work platform. Multiple layers of platforms for construction are arranged at a self-climbing template system from top to bottom; each layer of platform is connected with the self-climbing template system through a platform leveling pull rod so as to be used for regulating the platform into a horizontal state. By using a structure of the platforms capable of being leveled, the corresponding horizontal state regulation of the work platform along with the incline of the an arch dam by the work platform of a self-lifting cantilever heavy arch dam template system can be ensured, so that construction personnel are always in a horizontal operation state; the relevant auxiliary construction equipment is always in the horizontal state, so that the construction efficiency is improved; the construction safety is ensured.

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

Plastic coating mold

The invention discloses a plastic coating mold. The plastic coating mold comprises a base provided with an caulking groove, wherein a pair of sliding blocks are arranged at the top of the base and areseparately arranged at the two sides of the caulking groove; a movable mold covers the top of the sliding blocks, and the movable mold, the sliding blocks and the embedded groove form a mold cavity;the sliding blocks are correspondingly driven by a screw rod in the base through rotating teeth; and an injection hole is connected to the mold cavity through the movable mold. An insert is fixed by the caulking groove, the size of the mold cavity is adjusted by the sliding blocks, and an outer space of a first firmware, namely, the size of an outer plastic coating is cooperatively adjusted by thesliding blocks and a moving block. Condensation is accelerated through a condenser tube. Various inserts are matched through the replaceable moving block and an embedded block. The injection hole isconnected with a plurality of plastic injection liquids to form a multi-layer and multi-material injection molded part through a directional valve. At the same time, demoulding and taking out parts are facilitated through opening and closing of the sliding blocks and the movable mold. The plastic coating mold is simple in structure, convenient to use, rich in functions and diversified in finishedproducts of injection molded parts, and has strong practicability and wide applicability.

Owner:JIANGSU BOYINGTE ELECTRONICS TECH CO LTD

Combined mold for extra-large casting and forging

The invention relates to a combined mold for an extra-large casting and forging, and belongs to the technical field of large casting molds. A main body is a wooden barrel with a regular shape; an additional part is a part for manufacturing the extra-large casting and forging in a required shape by using lost foam and is arranged on the main body barrel according to the shape of an extra-large workpiece to be cast and forged; the combined mold is arranged in a hollow box consisting of a left part and a right part; half of resin sand is poured outside a left side combined mold body in the box, and the combined mold is pulled out after the left side resin sand is molded; resin sand is poured outside a right side combined mold body in the box, and the combined mold is pulled out after the right side resin sand is molded, so that two shapes of the combined mold, which are mutually matched and consist of the resin sand are manufactured; and the two shapes of the combined mold are combined together. All parts of the combined mold can be freely disassembled and assembled, and are recycled, cost is saved, and efficiency is improved.

Owner:DALIAN JINHE CASTING

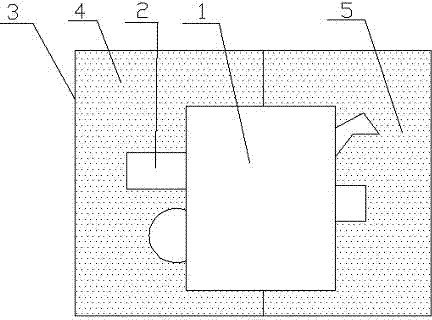

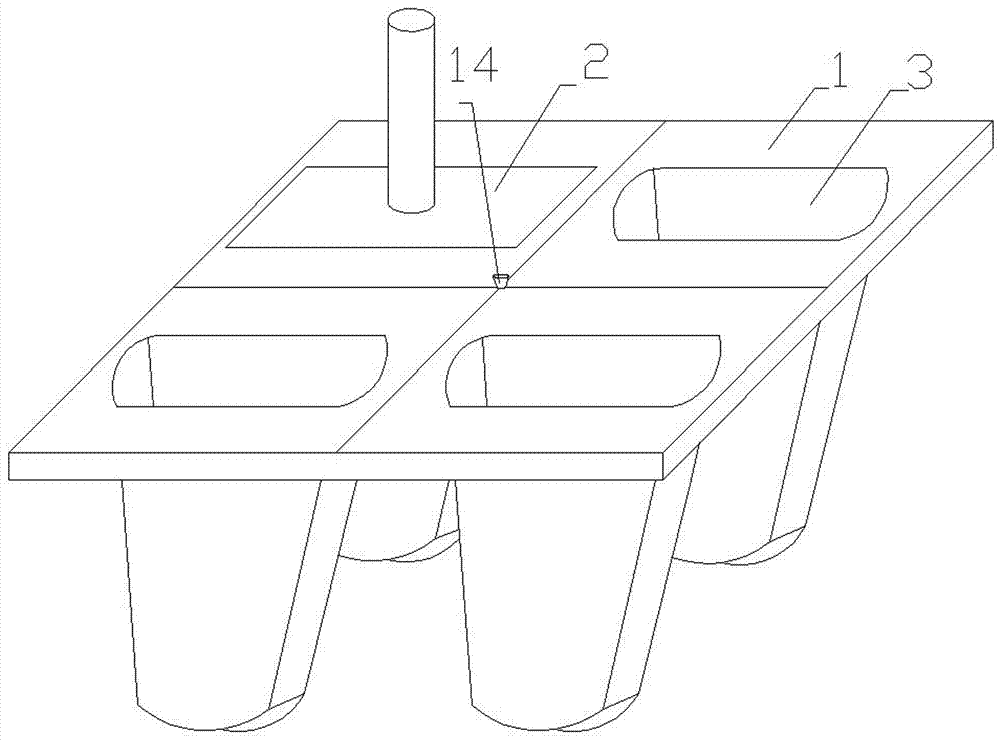

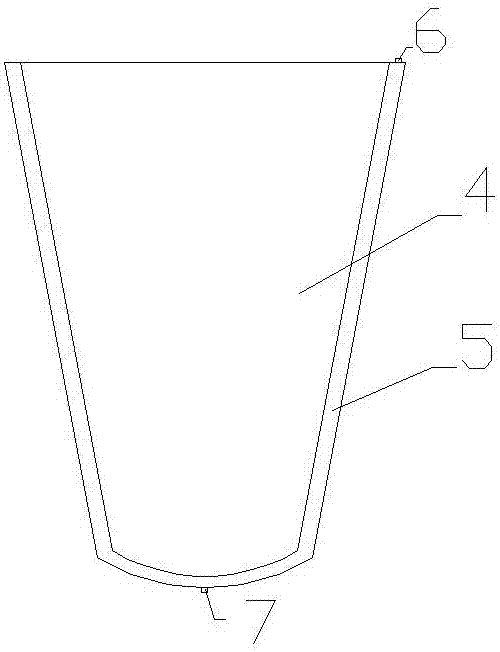

Domestic ice-lolly mold stripped conveniently

A household popsicle mold for easy demoulding, including a popsicle mold frame and a popsicle handle. The layer is a forming tank to hold the raw materials for making popsicles. The interlayer is a demoulding tank set outside the forming tank. The top of the demoulding tank is provided with a water injection port and the bottom is provided with a drain port; one end of the popsicle handle is a fixed end, The other end is the hand-held end. The middle part of the popsicle handle is provided with a support plate inserted into the notch of the forming groove. The side of the support plate connected to the hand-held end is provided with a limit plate that is pushed against the edge of the forming groove to close the forming groove. Inside the support plate is a cavity, and an elliptical turntable is provided in the cavity, openings are provided on both sides of the supporting plate, the hand-held end is connected to the turntable, and the turntable is rotated through the hand-held end to rotate the long axis end of the turntable from the opening. Push against the inner wall of the forming notch to expand the mouth of the forming notch. The invention has simple structure and obvious demoulding effect.

Owner:白娟娟

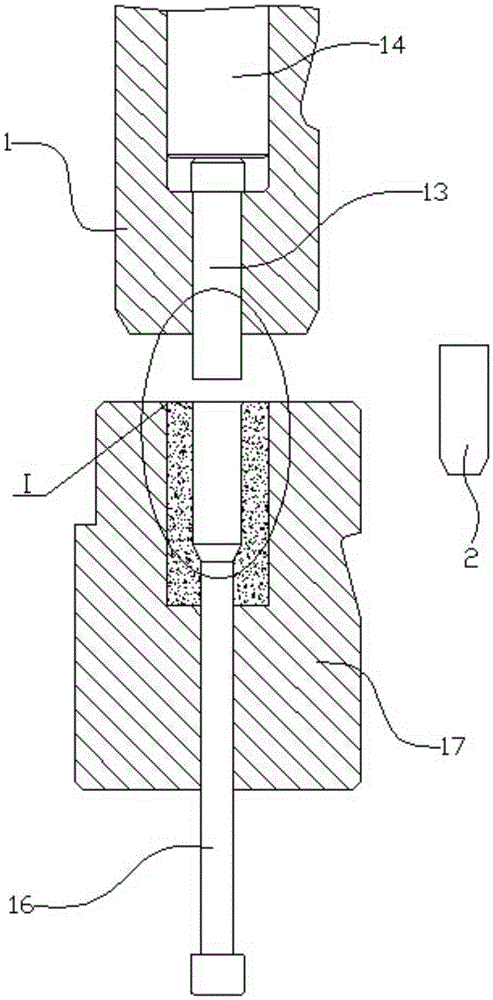

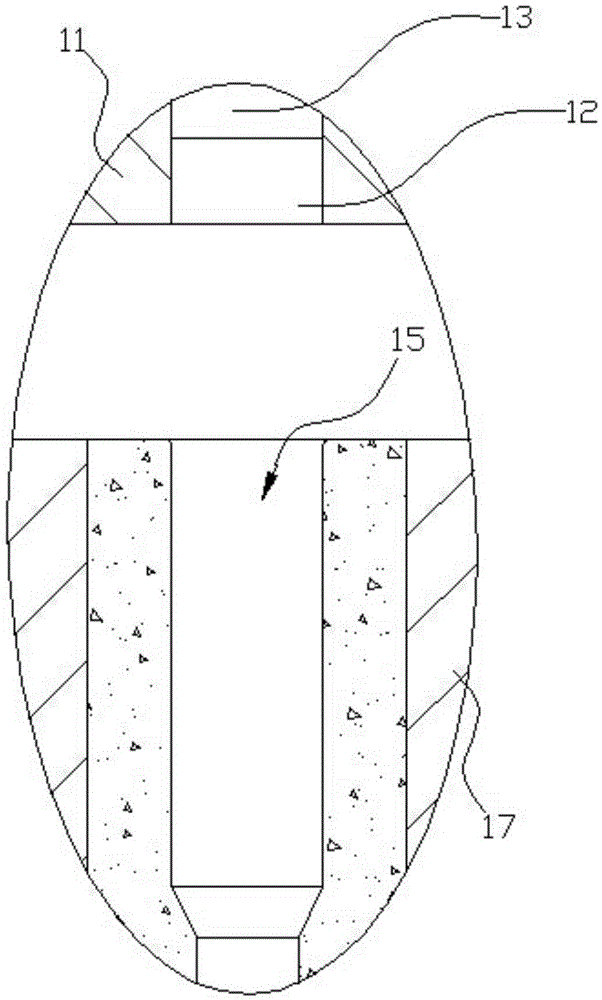

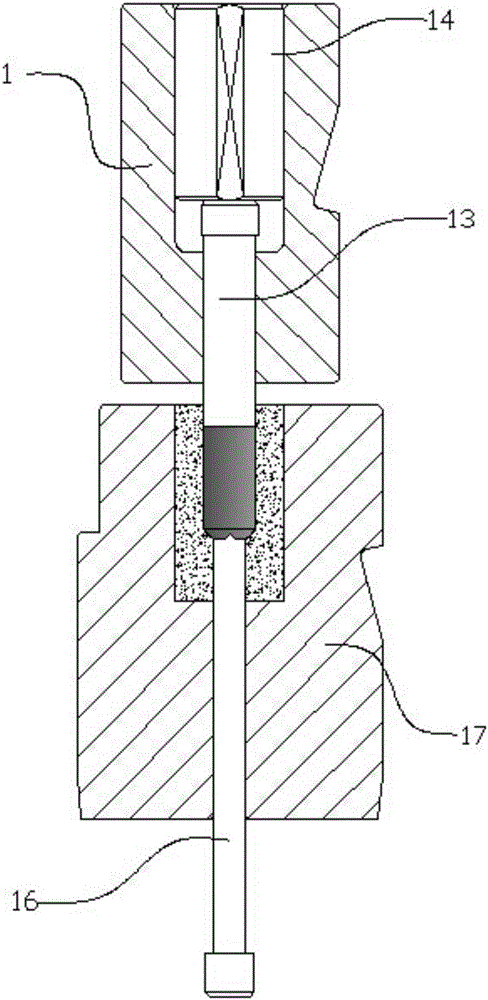

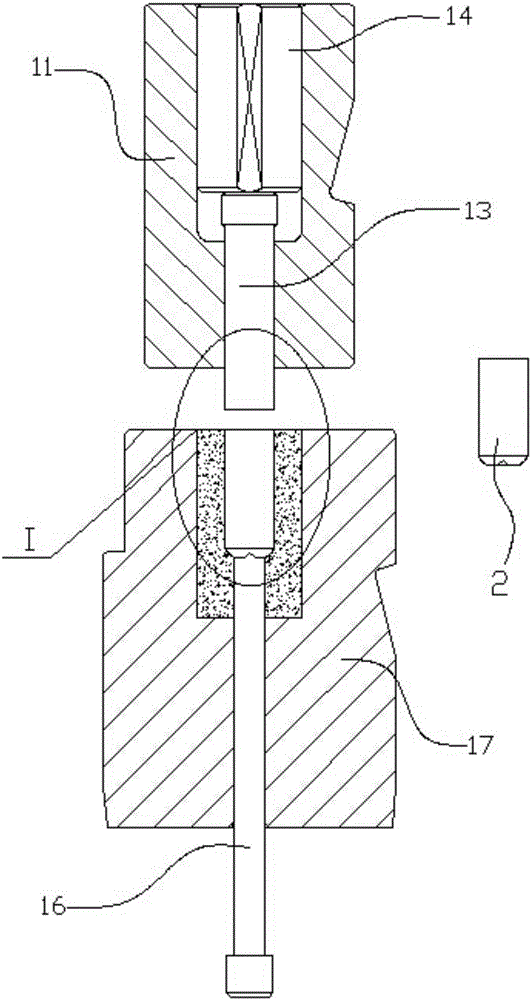

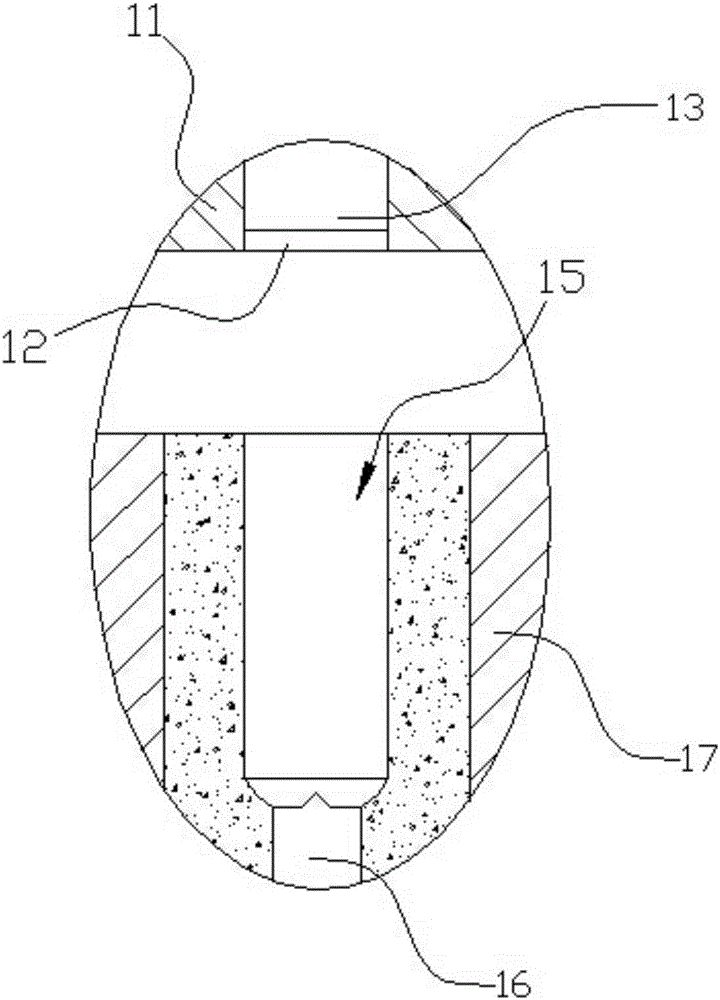

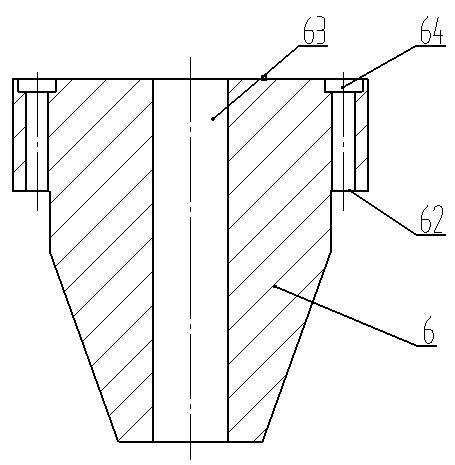

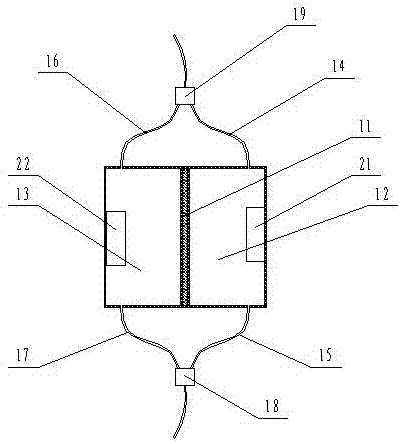

Solid motor nozzle blank assembly, production method thereof and mold for use

ActiveCN109047512ASolve the disadvantage of being easily ablatedExtended service lifeShaping toolsInternal combustion piston enginesEngineeringRoughcast

The invention relates to a solid motor nozzle blank assembly. The solid motor nozzle blank assembly is characterized in that the solid motor nozzle blank assembly is composed of a guide ring blank, aheat insulation body and a nozzle body blank; the outer surface of the heat insulation body is consistent with the inner surface of the nozzle body blank, and the diameter of the lower section of theinner surface of the heat insulation body is the same as that of a positioning step hole; the upper end of the heat insulation body is consistent with the outer surface of the guide ring blank, and the portion, between the end surface of the positioning step hole and the small end surface of the guide ring blank, of the inner surface of the heat insulation body is in a continuous and smooth trumpet shape from small to large; and the material of the heat insulation body is a high silica cloth / phenolic aldehyde combination, the forming pressure ranges from 20 MPa to 28 MPa, the materials are placed on an oil press equipped with upper and lower heating plates and is heated to 160-170 DEG C, the heat is preserved and the pressure is maintained for 8-10 minutes, and then a mold is removed. According to the solid motor nozzle blank assembly, the surface of a nozzle body is covered with a layer of heat insulation body with ablation resistance and good heat insulation performance, so that thedefect that the inner wall of a solid motor nozzle is likely to be ablated under the action of high temperature of tail gas is overcome, and the service life of the solid motor nozzle is prolonged.

Owner:FUJIAN ORDNANCE EQUIP

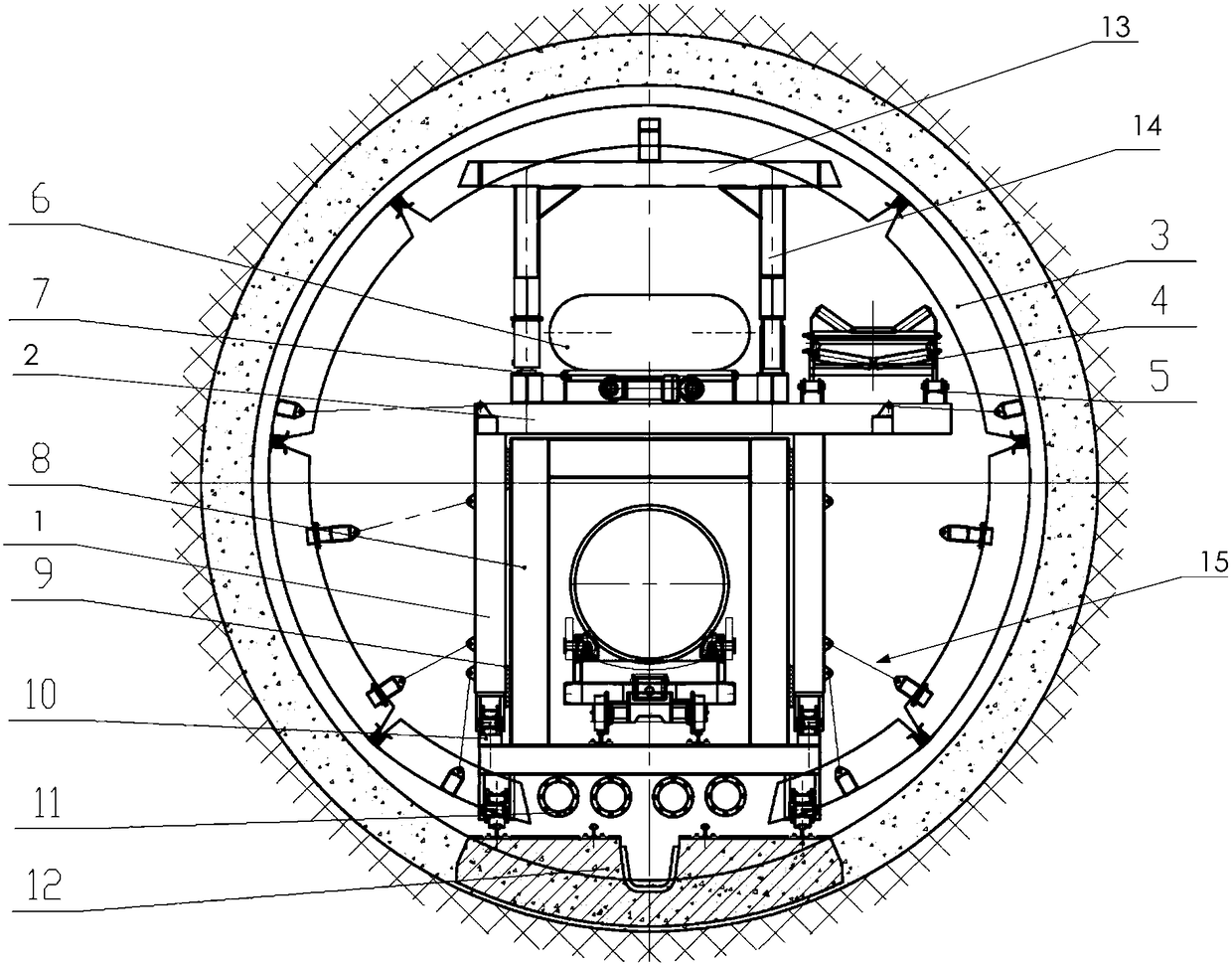

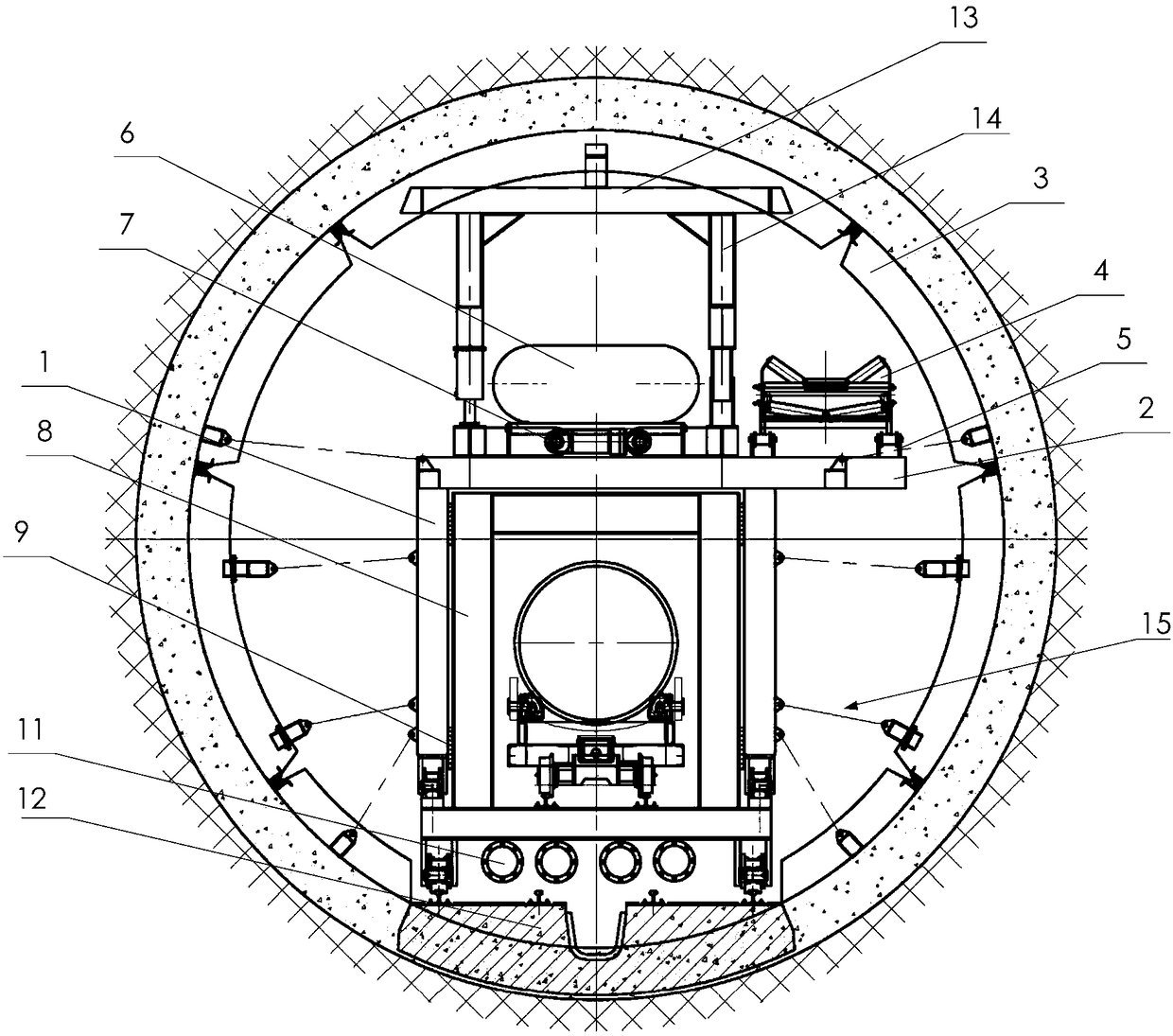

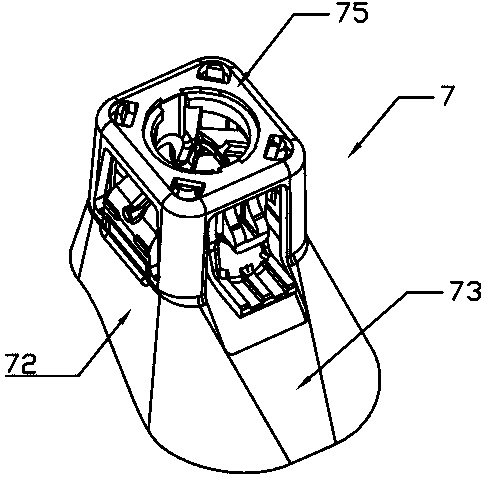

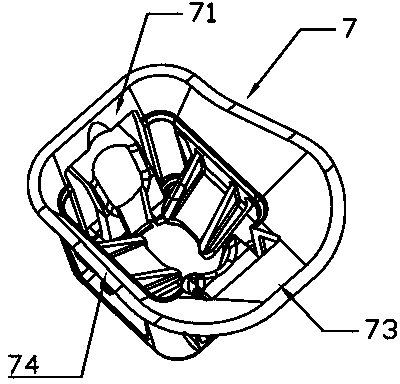

Back-matched simultaneous lining trolley and tunneling machine with same

PendingCN108166997AEffective protection and supportEasy to remove the moldUnderground chambersTunnel liningSlagEngineering

The invention discloses a back-matched simultaneous lining trolley. The trolley includes a trailer framework; a slidingly matched lining framework is arranged outside the trailer framework, and a walking bearing is arranged at the bottom of a tunnel of the lining framework; a model erecting device used for lining is connected to an outer support of the lining framework, and the lining framework isinternally provided with a ventilation assembly and a slag discharging and conveying assembly. The trailer framework provides a work space for a tunneling machine, the model erecting device is installed on the lining framework outside the trailer framework, and by using the lining framework to support the model erecting device, secondary lining construction is completed; by arranging the ventilation assembly and the slag discharging and conveying assembly which are matched with a tunneling device in the framework structure of the lining framework, the structures above can be effectively protected without influencing laying and support positions of the external model erecting device during construction, so that the situation is avoided that fixed tunnel ventilation pipes and a fixed continuous belt machine structure often need to be dismantled during the secondary lining construction and reassembled when the secondary lining construction is finished and tunneling needs to be continued.The invention also discloses the tunneling machine.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

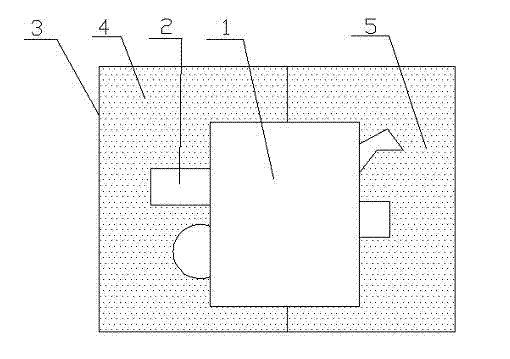

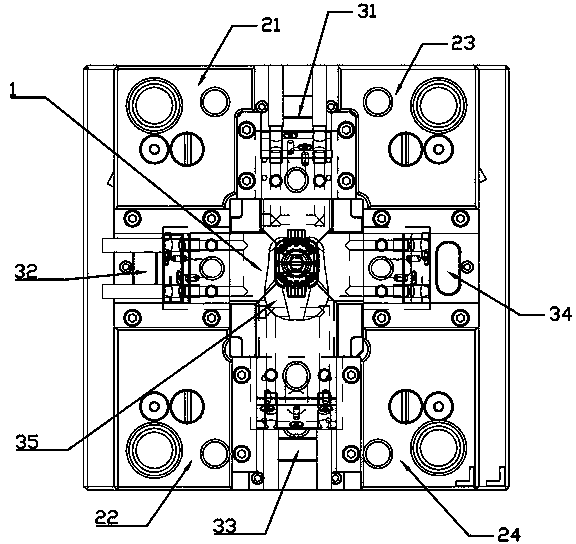

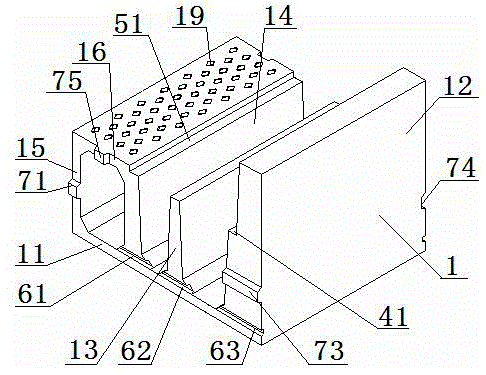

One-time injection molding die of multi-face irregular workpieces

ActiveCN103481454AEasy to remove the moldImprove accuracy and productivityEngineeringInjection moulding

The invention discloses a one-time injection molding die of multi-face irregular workpieces. The one-time injection molding die comprises an upper die base and a lower die base, particularly, the lower die base is provided with a lower die central fixing die holder, four fixing die holders and four sliding die holders, each sliding die holder is arranged between every two fixing die holders, all the die holders are in a nine-grid pattern layout, and the top of each sliding die holder is provided with a guide groove hole; the upper die base is provided with an upper die central fixing die holder and four driving guide rods having fixed inclination, the driving guide rods are connected in the guide groove holes in a sliding mode, the four sliding die holders slide inwards to gather together or slide outwards to extend in die opening-closing switching processes of the upper die base and the lower die base. According to the injection molding die, the three-dimensional multi-fact die opening mode is adopted, and an injection molding cavity of the multi-face irregular workpieces is constituted by the surface of the upper die central fixing die holder, the surface of the lower die central fixing die holder, and the molded surfaces of the four sliding die holders. Meanwhile, the sliding die holders further have die retreating displacement, die retreating of the workpieces is facilitated, accuracy and production efficiency of finished products are improved, and cost is low.

Owner:江苏朗佑精密部件制造有限公司

Refrigerator glass partition plate production forming mold facilitating mold withdrawing

Owner:滁州克莱帝玻璃科技有限公司

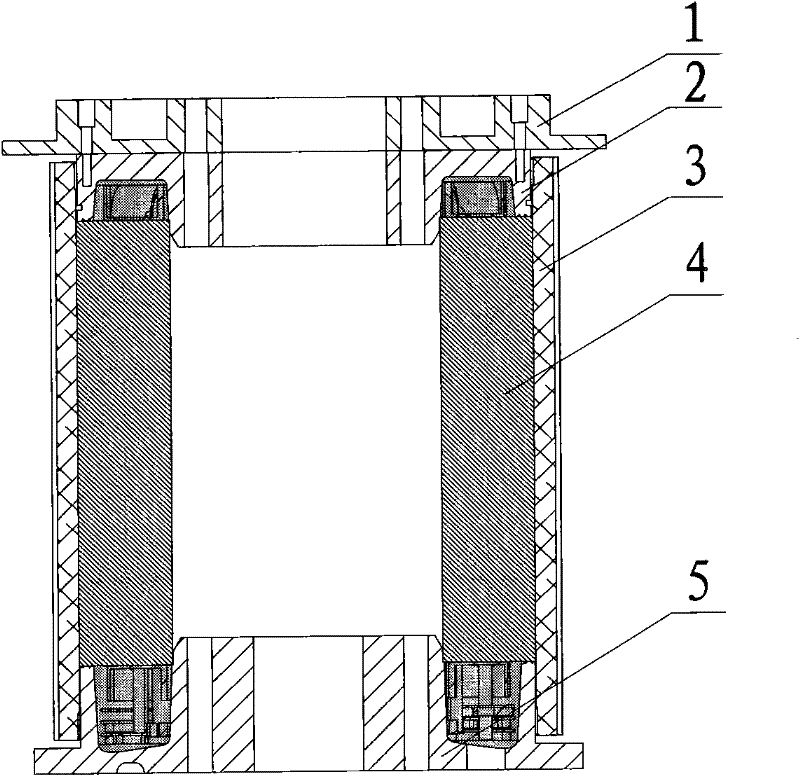

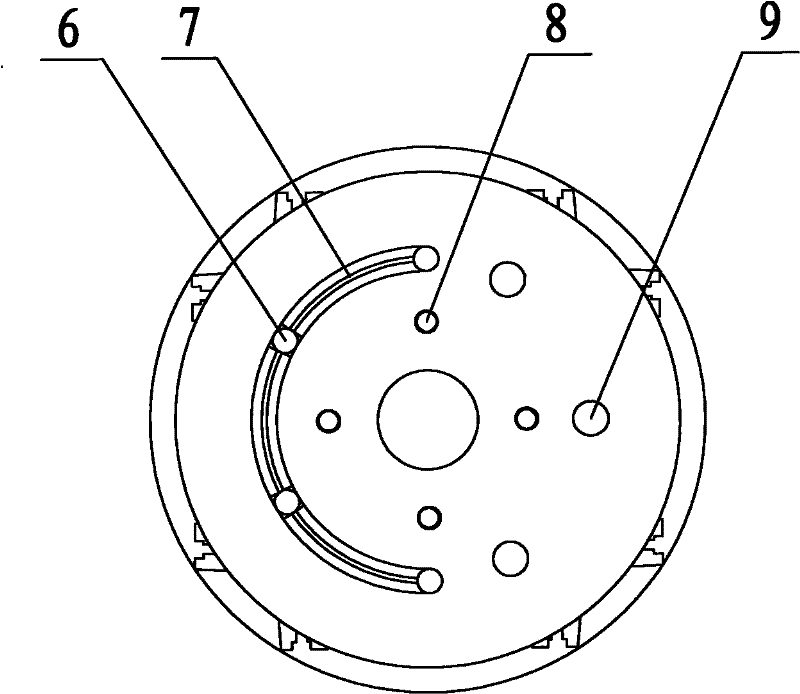

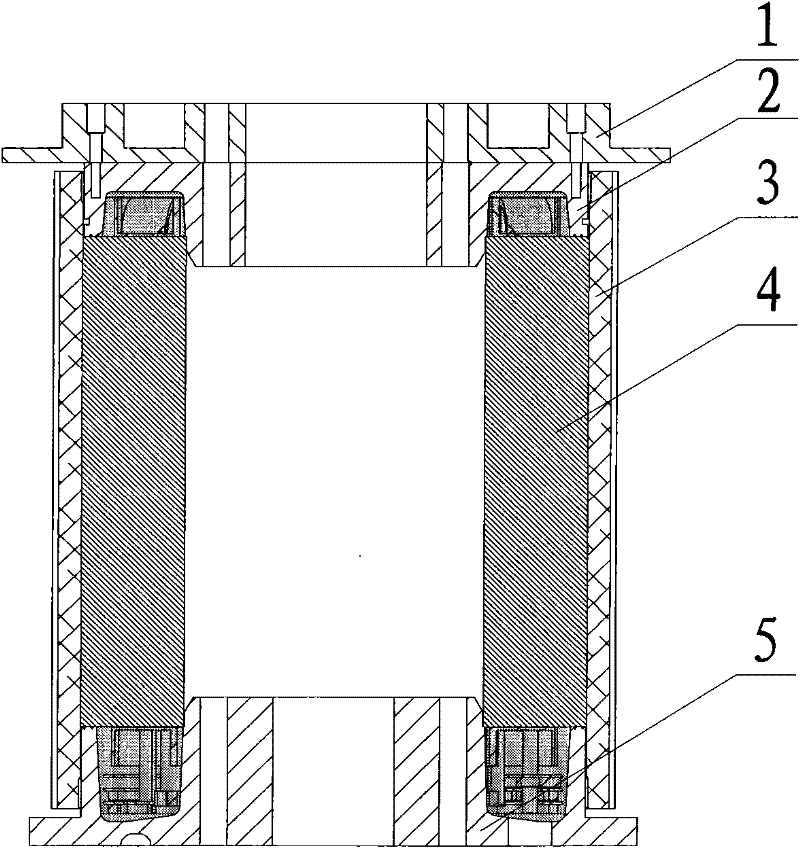

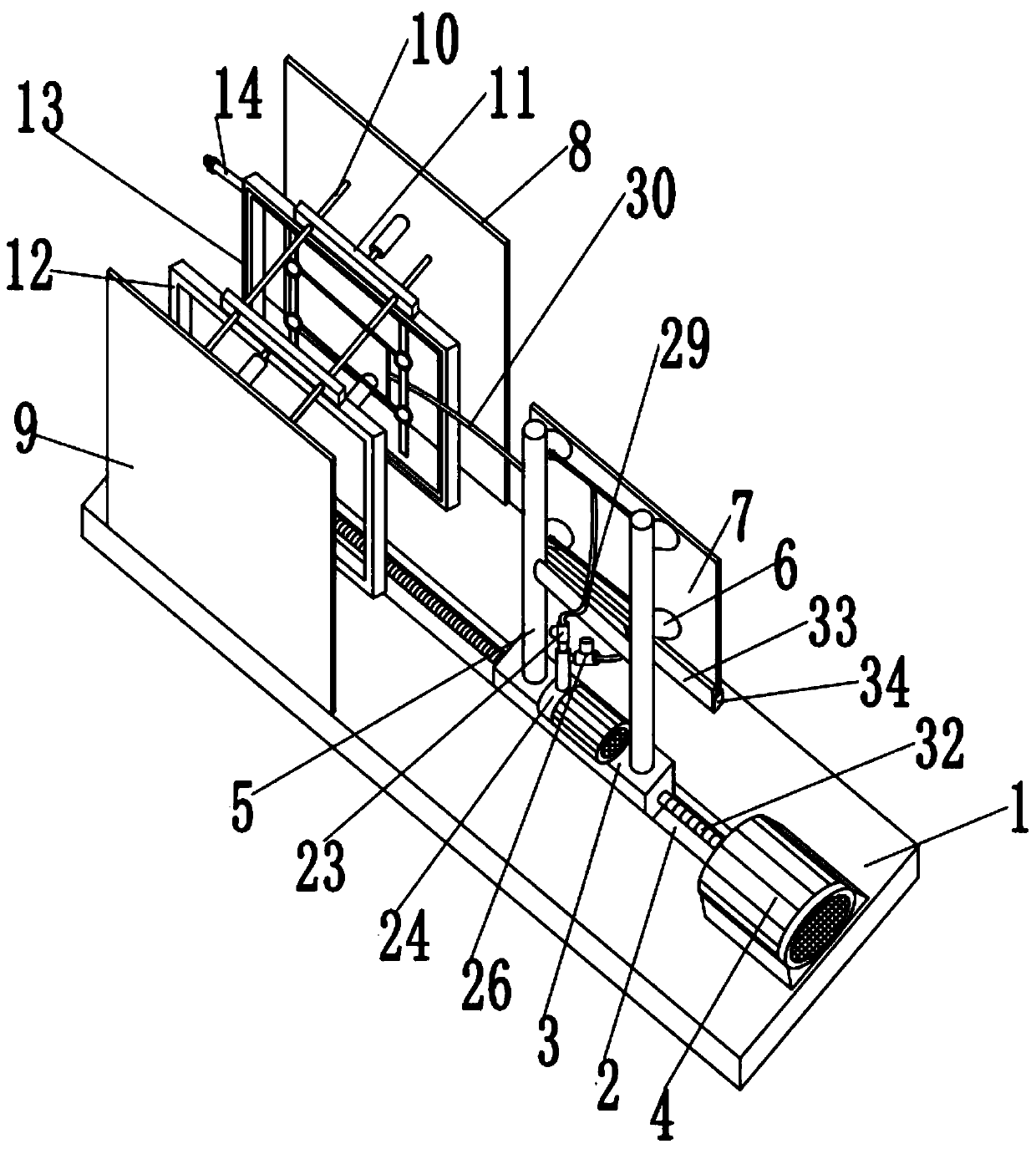

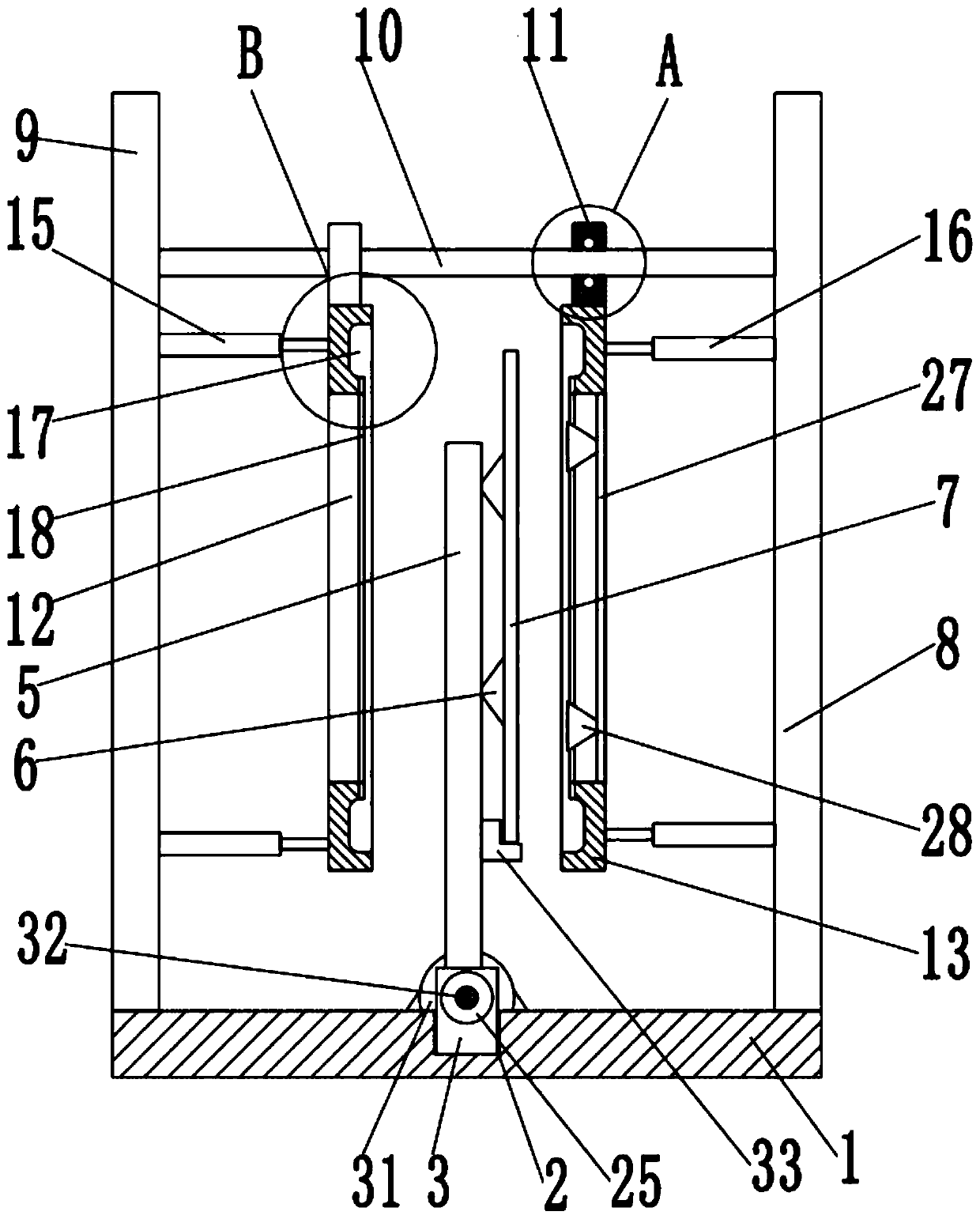

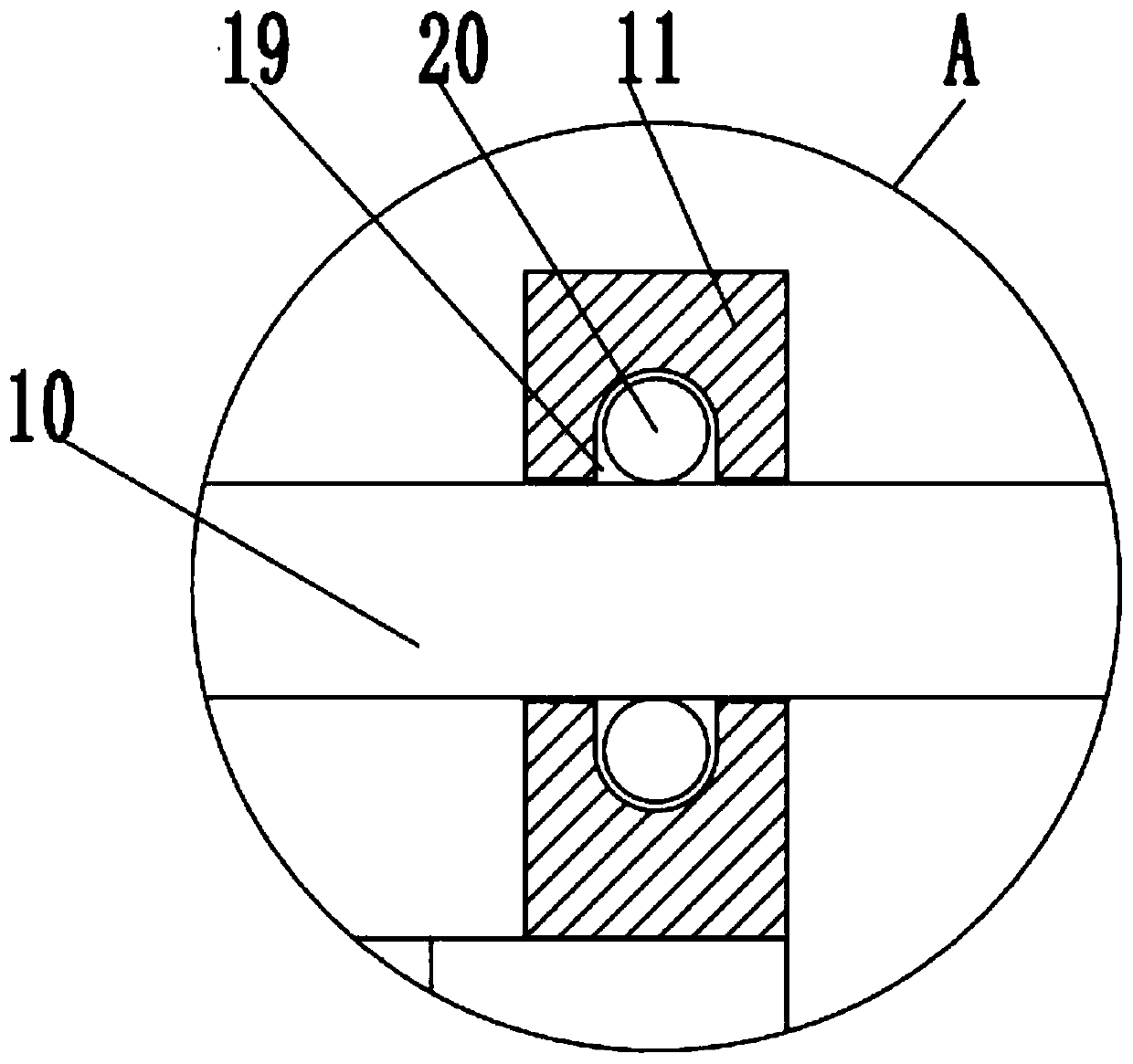

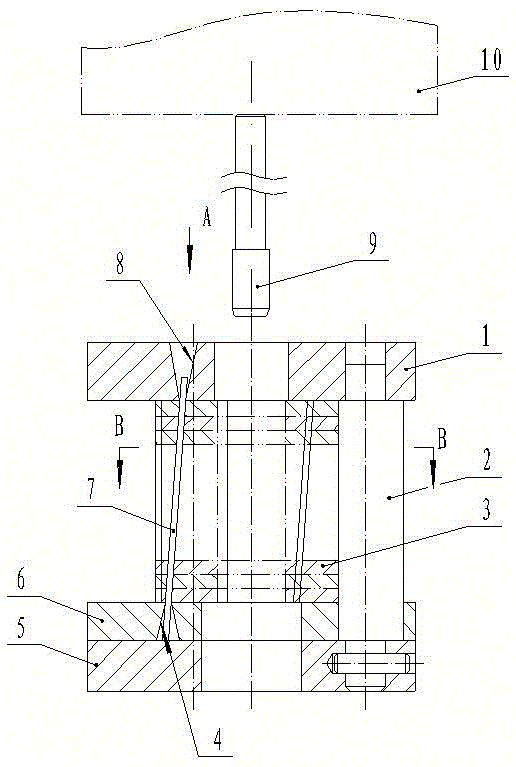

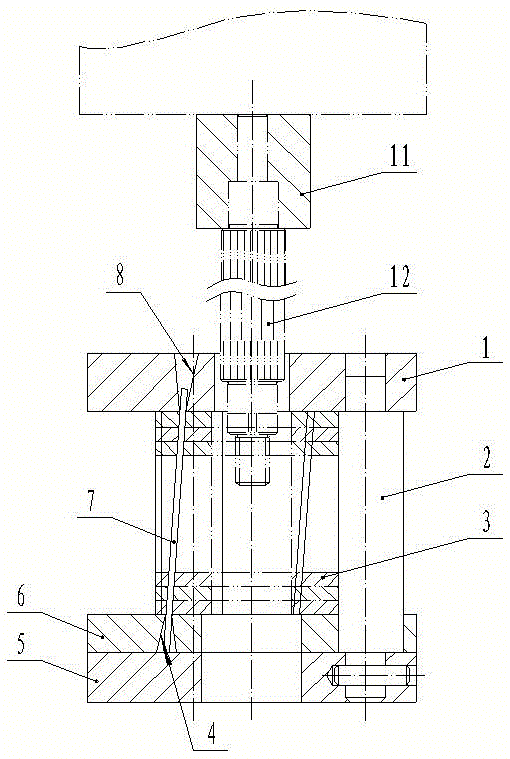

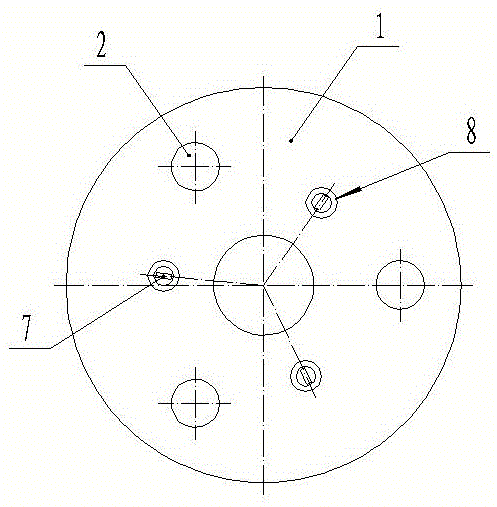

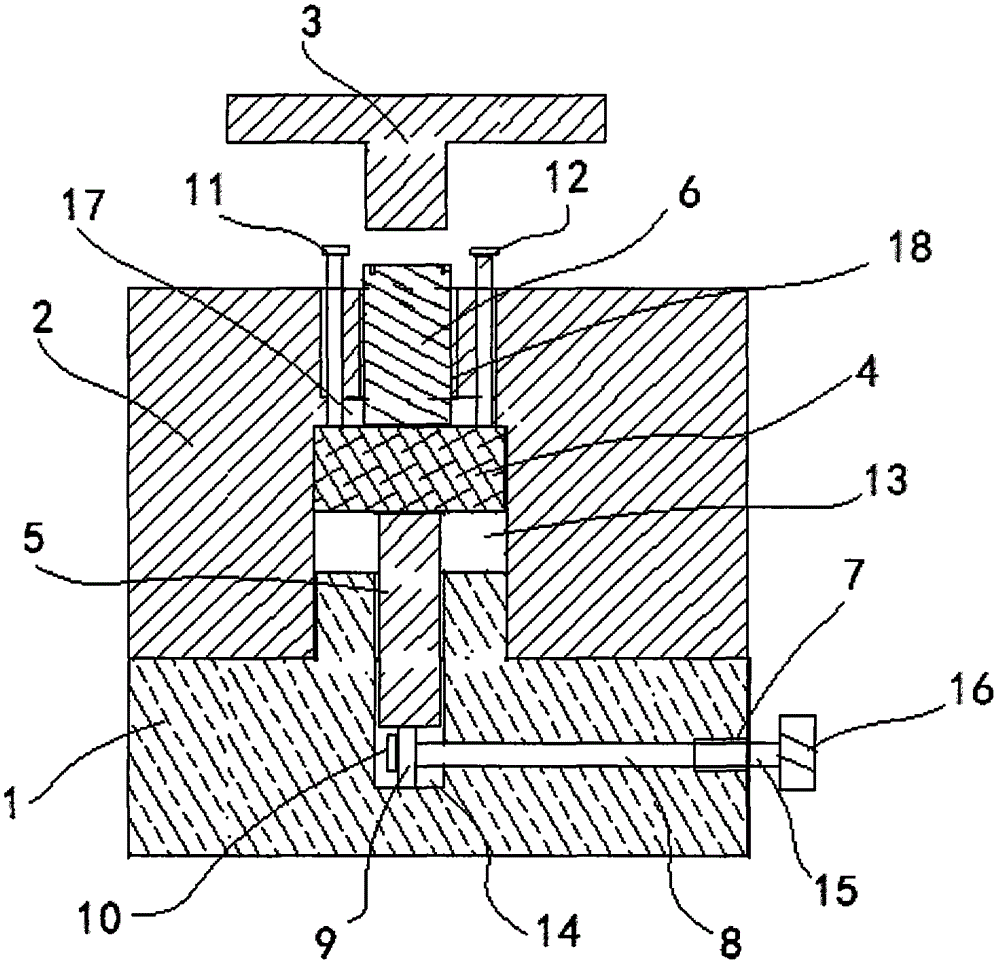

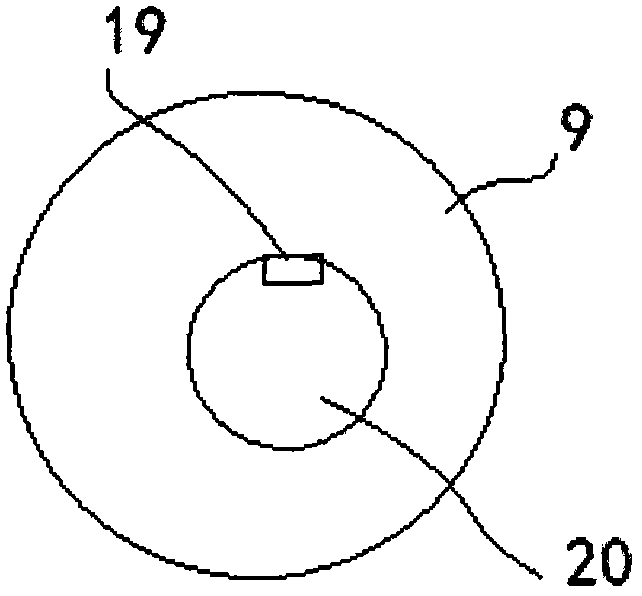

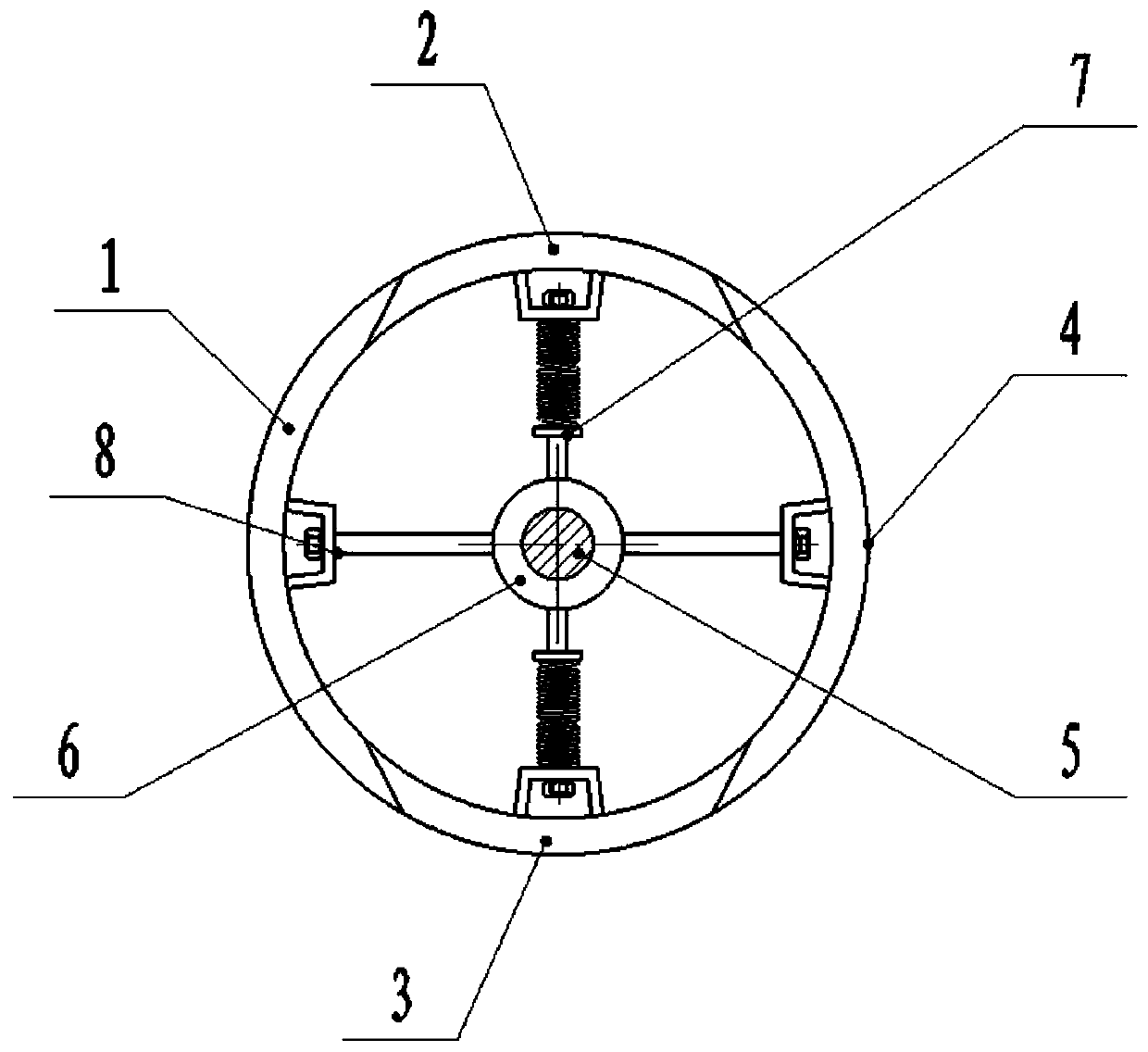

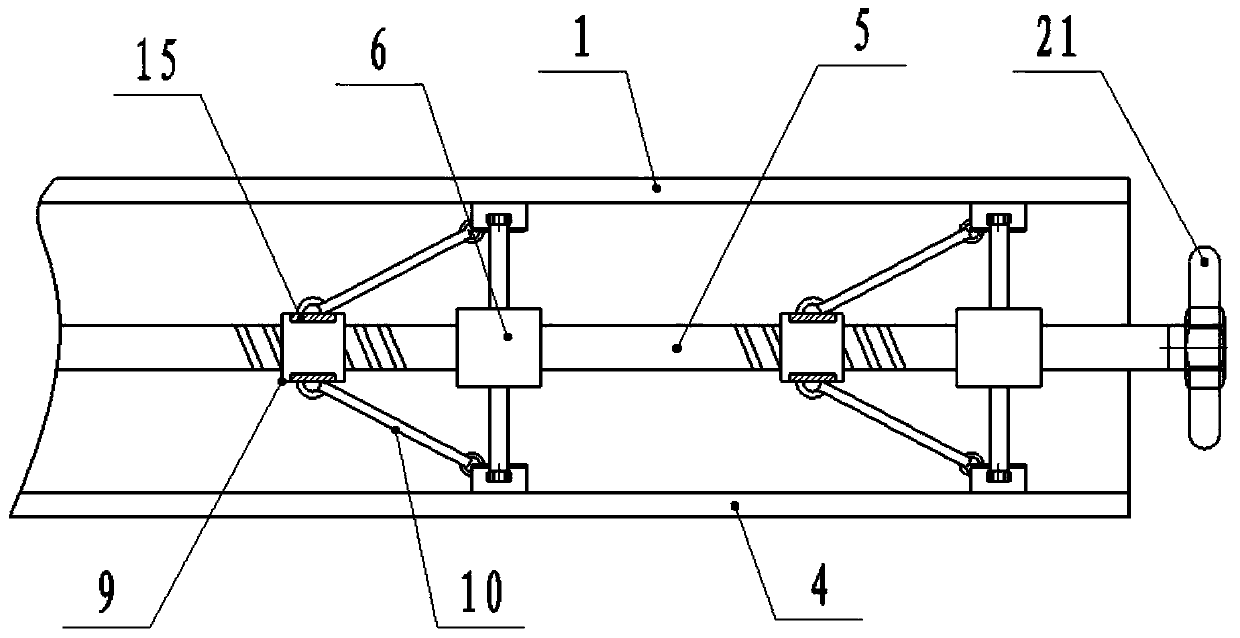

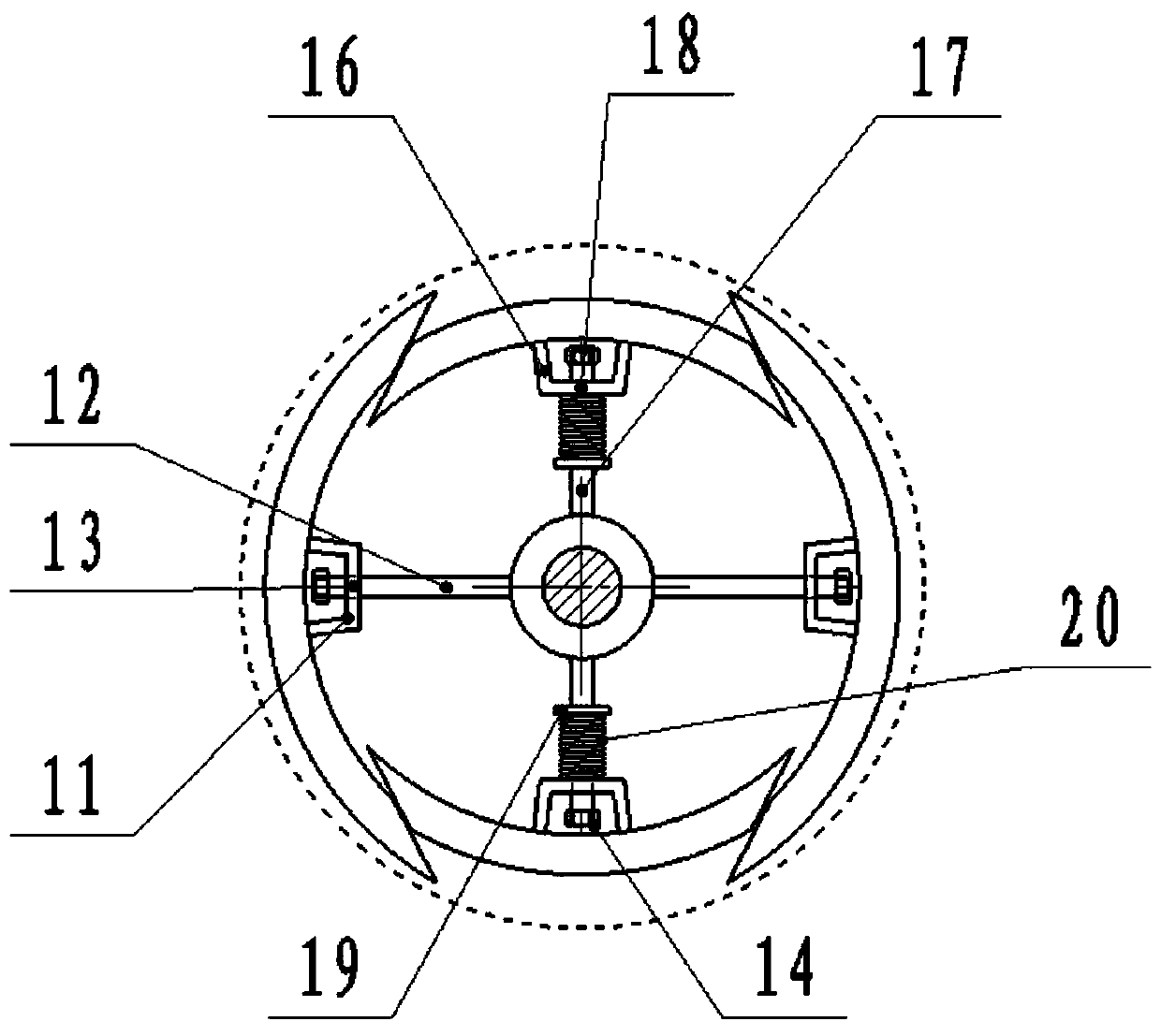

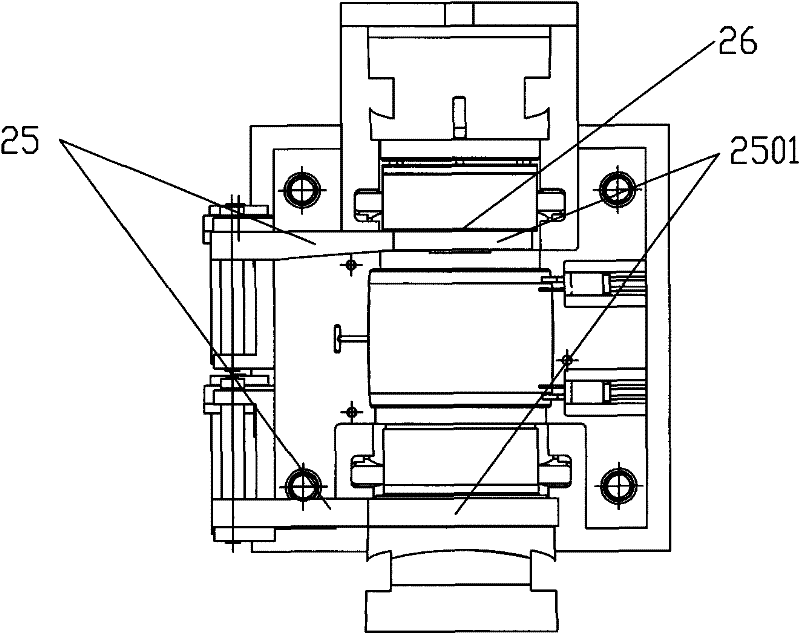

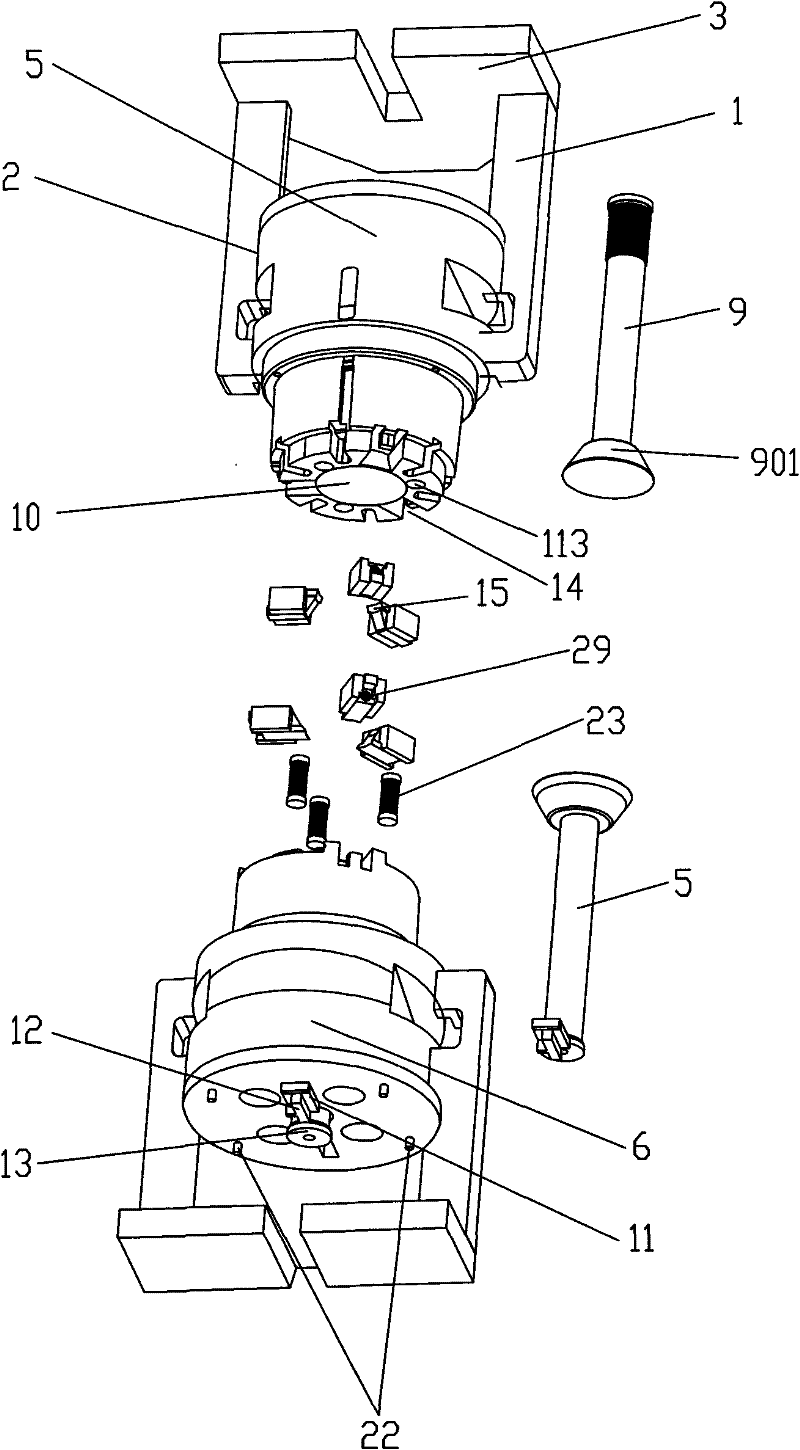

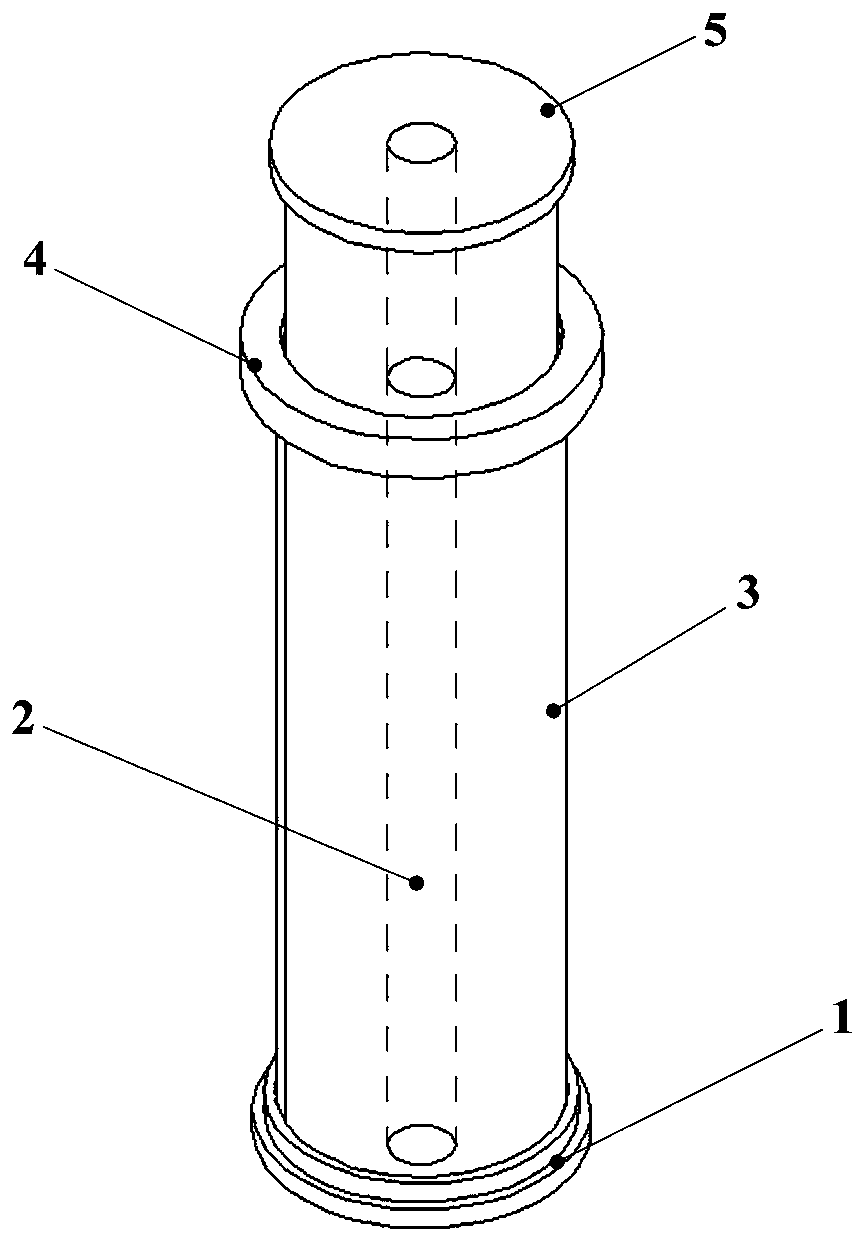

Pressing clamp for skew overlying rotor

ActiveCN105490469APrecise skew angleEasy to assembleManufacturing stator/rotor bodiesElectric machineEngineering

The invention discloses a pressing clamp for a skew overlying rotor, belongs to motor manufacturing fixtures, and aims to provide an overlying rotor assembly fixture which is good in assembly accuracy, simple in structure and convenient and efficient in demolding. The pressing clamp comprises a base, a pressing block and plug pins, wherein a base plate (6) and three positioning columns (2) are fixed on the base plate (5), and a pressing plate (1) is positioned on the positioning columns (2); three first horn holes (8) uniformly distributed by taking the center as the center of a circle are formed in the pressing plate (1), and three second horn holes (4) uniformly distributed by taking the center as the center of the circle are formed in the base plate (6); an angle is staggered between the first horn holes (8) and the corresponding second horn holes (4) by taking the center as the center of the circle; the plug pins (7) are inserted between the corresponding first horn holes (8) and second horn holes (4); and a pressing head (11) is arranged above the pressing plate (1). The pressing clamp has multiple functions in one object, and is an overlying rotor assembly clamp.

Owner:GUIYANG AVIATION MOTOR

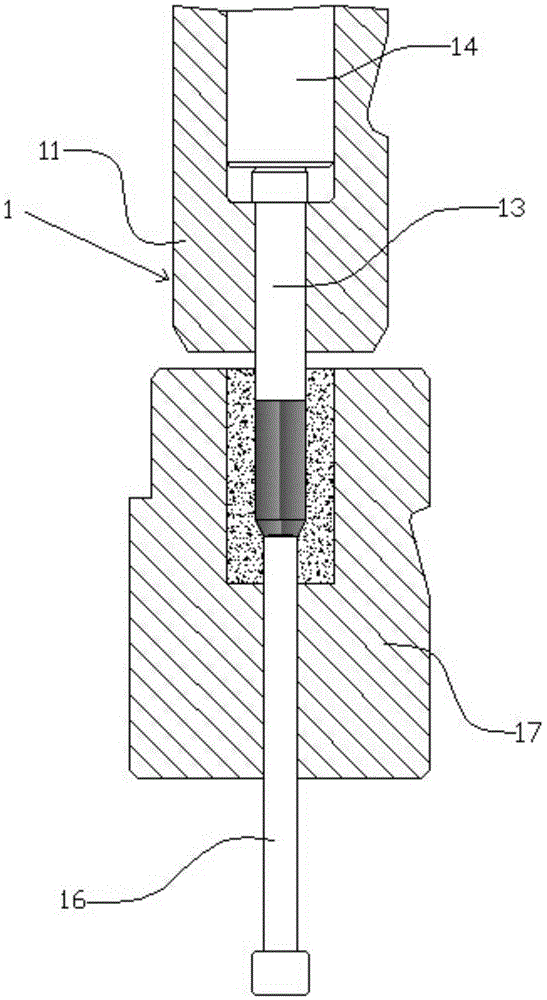

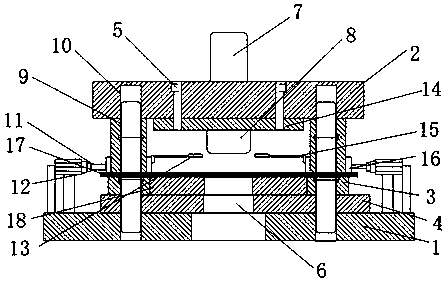

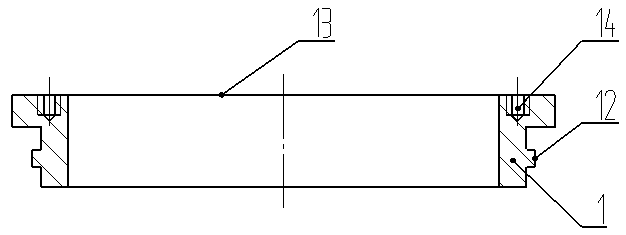

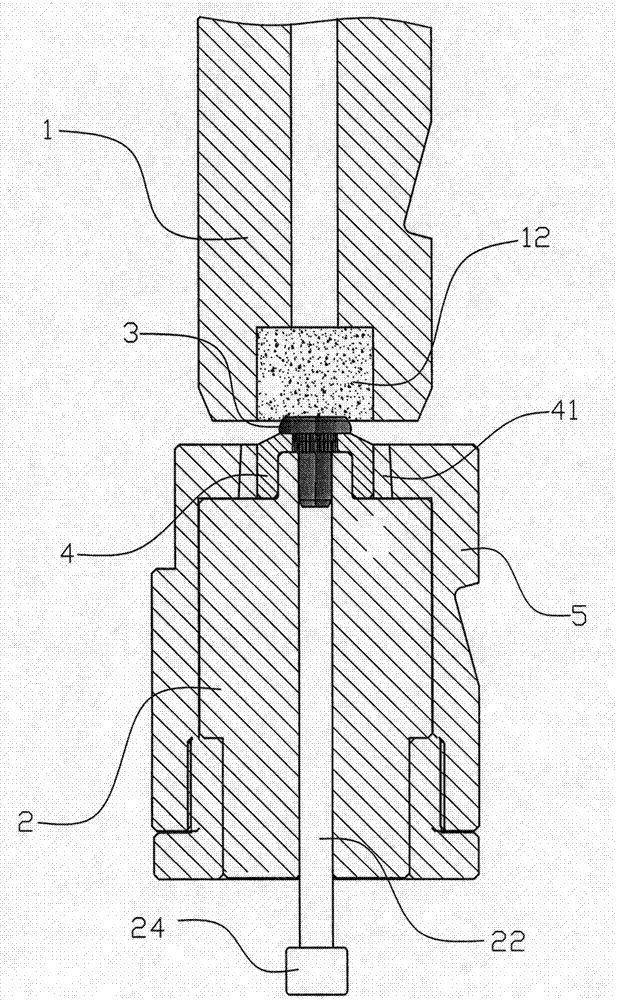

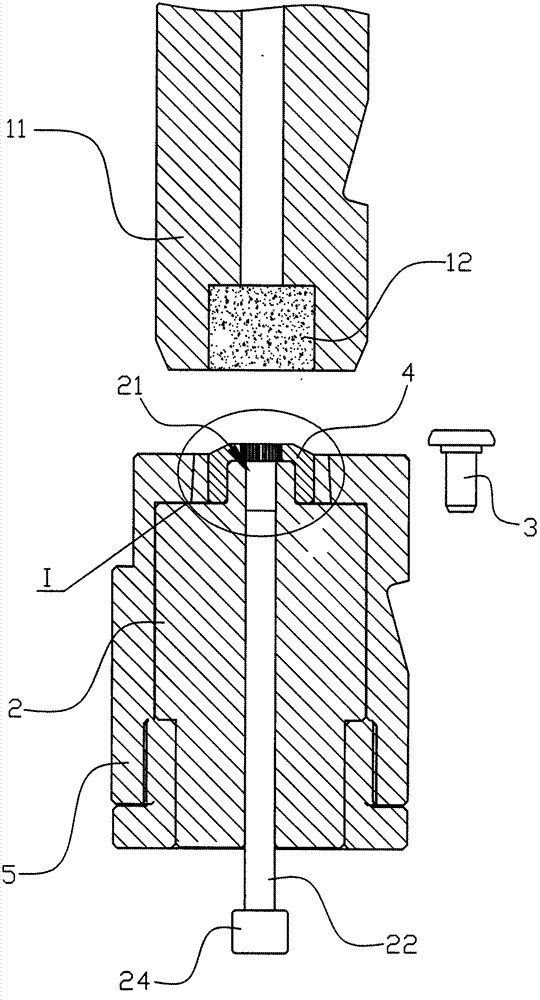

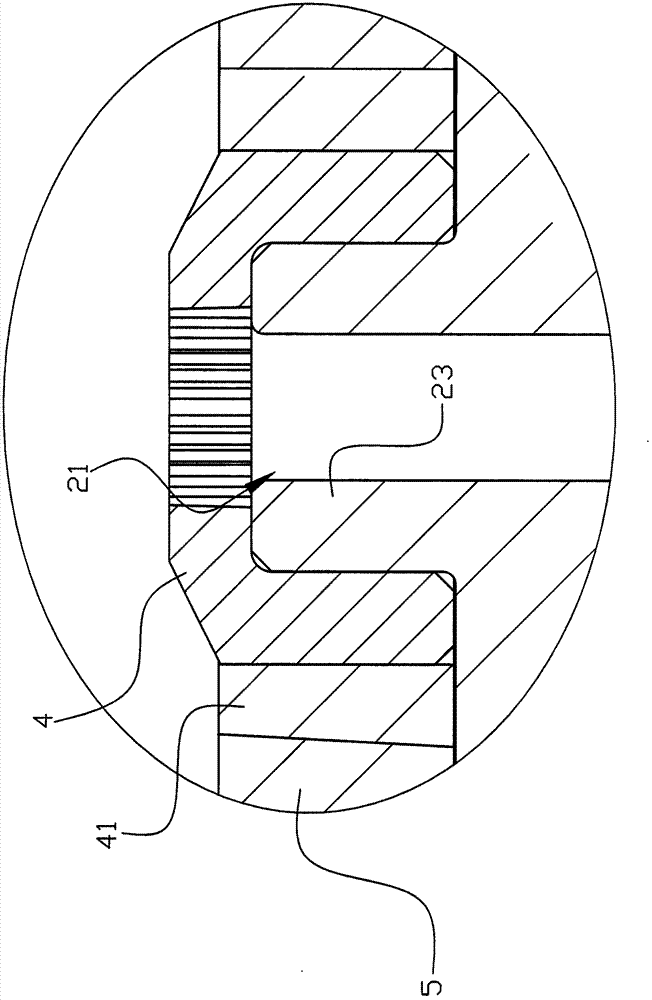

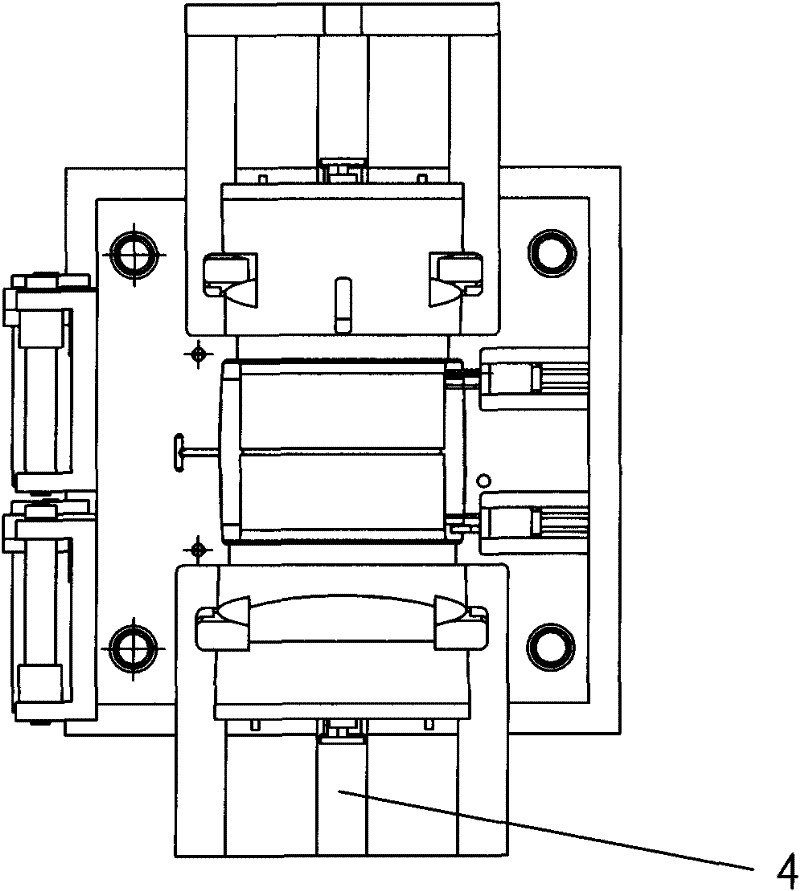

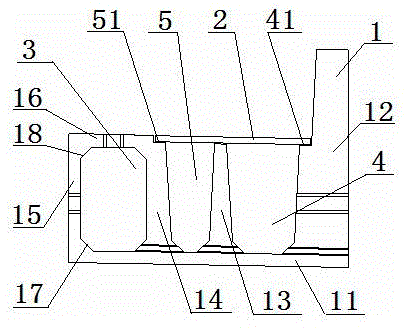

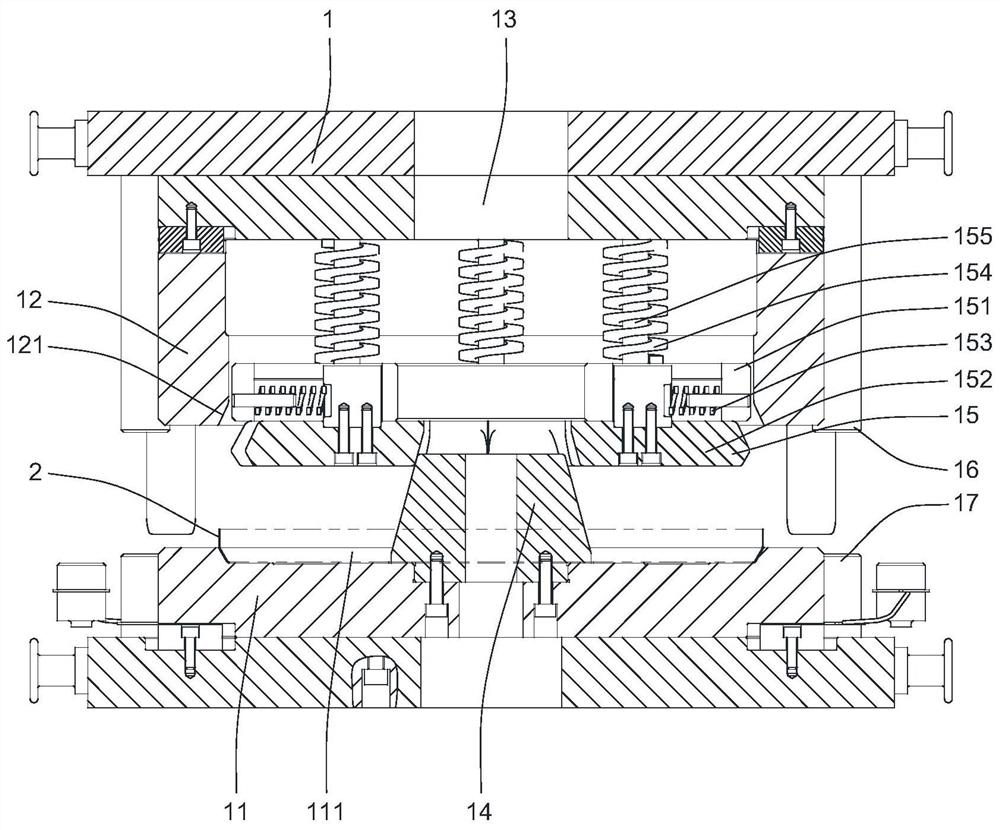

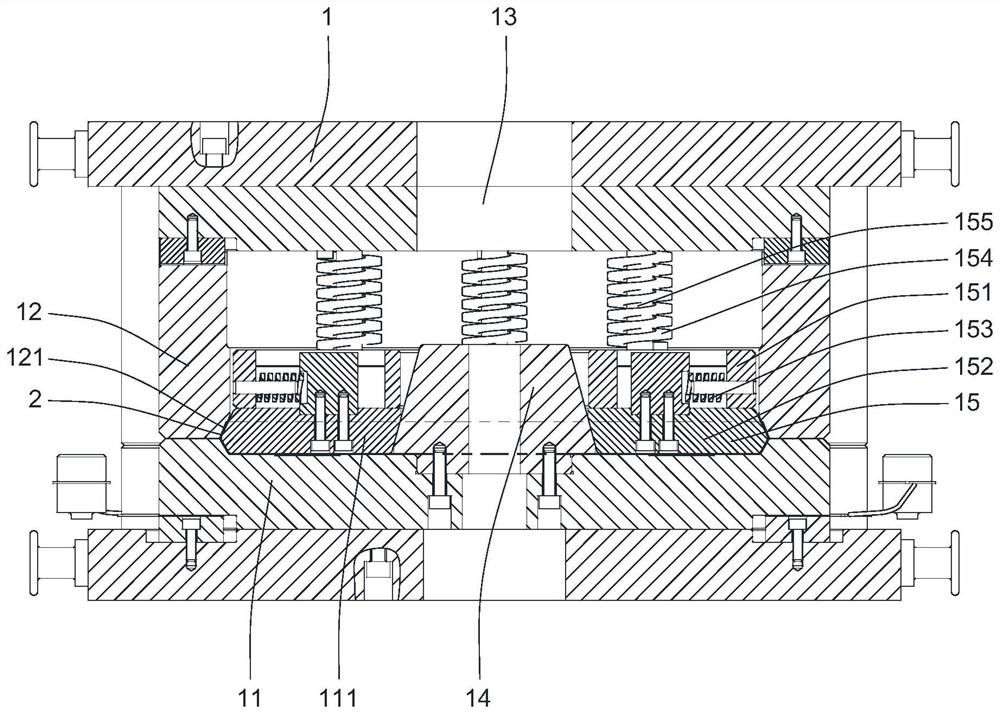

Part neck cold heading pattern cutting punching mold

ActiveCN104493042AAvoid horizontal displacementHigh speedForging/hammering/pressing machinesPunchingNeck parts

The invention provides a part neck cold heading pattern cutting punching mold, which comprises an upper mold (1) and a lower mold, wherein the upper mold (1) can vertically move relative to the lower mold, and comprises an upper mold case (11) and a punching block (12), a lower mold concave cavity (21) capable of containing parts processed is arranged in the lower mold, a through rod (22) is vertically arranged in the lower mold concave cavity (21), penetrates through the through hole of the lower mold in a way capable of vertically sliding and extends out of the bottom of the lower mold, a neck edge cutting mold (4) is arranged on the lower mold arranged outside the lower mold concave cavity (21), and when a processed part (3) is put into the lower mold concave cavity (21), the upper mold (1) downwards moves through being driven by a driving device and extrudes the top of the processed part (3), so that the processed part (3) downwards moves to enter the lower mold concave cavity (21), and the conical neck part is cut into a pattern tooth part by a neck edge cutting mold. The part neck cold heading pattern cutting punching mold has the advantages that the pattern teeth are formed in one step, the speed is high, the effect is good, the lower end of the part to be processed is in abutted contact with the through rod, the horizontal displacement of the part to be processed is avoided, the processing is more stable, and after the pattern tooth cutting is completed, the mold stripping is more convenient.

Owner:ZHOUSHAN 7412 FACTORY

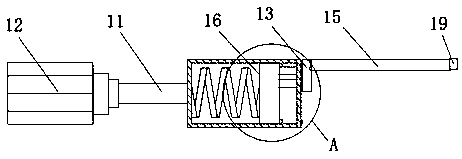

Powder slice pressing forming die capable of being disassembled conveniently

InactiveCN106142640AEasy squeezeEasy to remove the moldPreparing sample for investigationShaping pressMechanical engineeringExtrusion

The invention relates to a powder slice pressing forming die capable of being disassembled conveniently. The die comprises a base provided with a round boss, and a die frame connected with the base. The center of the die frame is coaxially provided with a first guide hole and a second guide hole which communicate with each other. A lifting seat making contact with the inner wall of the first guide hole slidably is installed in the first guide hole. A lower pressing head connected with the lifting seat is installed in the second guide hole. A lifting adjusting rod is connected to the bottom of the lifting seat, installed in a base guide hole and connected with an eccentric adjusting device. A matched upper pressing head is arranged above the lower pressing head. At least two lifting adjusting screws are arranged on the outer side of the second guide hole axially. According to the die, die disassembly and die release are convenient, powder extrusion core forming is convenient, and after the lower pressing head extends out of the guide holes, a formed slice can be taken out and put in a transmission detector to be subjected to transmission detection conveniently.

Owner:TIANJIN XIANNQUAN IND & TRADE DEV

A reducing die pipe device and diameter reducing method for easy casting and demolding

ActiveCN107035145BEasy to remove the moldSimple structureForms/shuttering/falseworksBridge erection/assemblyButt jointScrew thread

Owner:南京仁创模具科技有限公司

Automatic die input and output mechanism for thermosol pipe die

The invention discloses an automatic die input and output mechanism for a thermosol pipe die. A core of the die consists of an upper core and a lower core which are matched; the upper core is arranged in an upper cylinder sleeve; the lower core is arranged in a lower cylinder sleeve; the lower cylinder sleeve is provided with a salient matched with a drag hook arranged on the upper cylinder sleeve; both the upper core and the lower core are provided with a lock rod hole matched with a locking rod and a stop block slot; one end of a stop block arranged in the stop block slot is of an incline and is staggered with the incline of a locking block arranged at the head part of the locking rod; the other end of the stop block is matched with the grooves arranged on the upper cylinder sleeve and the lower cylinder sleeve; the side of the die is provided with a manipulator; the upper claw and the lower claw of the manipulator are matched with claw slots arranged on the upper cylinder sleeve and the lower cylinder sleeve. The automatic die input and output mechanism for thermosol pipe die has the characteristics of compact structure and high automation degree, so that the production efficiency is improved.

Owner:孙金军

Road and bridge steel formwork demolding device

InactiveCN113832861AImprove ease of useAchieve primary separationBridge erection/assemblyForm treatmentHydraulic pumpCaster angle

A road and bridge steel formwork demolding device comprises a main plate with wheels, a hydraulic pump and an oil tank are arranged at the top of the rear side of the main plate, a left stabilizing base and a right stabilizing base capable of adjusting the front-back position are arranged on the front side of the main plate, and a supporting foot capable of adjusting the vertical position is arranged on the front side of each stabilizing base; the front side of the main plate is provided with left and right demolding modules which can be relatively close to or far away from each other; a second supporting rod capable of adjusting the front-back inclination angle is arranged at the top of the demolding module; and a linkage plate capable of keeping horizontal is arranged at the tail end of the second supporting rod; a fourth supporting rod capable of relatively swinging along with swinging of the second supporting rod is arranged on the front side of the linkage plate, and a bottom plate capable of keeping horizontal is arranged at the tail end of the fourth supporting rod; and the linkage plate is provided with an upper demoldingplate and a lower demolding plate which can be relatively close to or far away from each other. According to the invention, the problems that the casting body is easy to damage and the existing equipment is difficult to adapt to different demolding occasions during demolding are effectively solved.

Owner:河南中州路桥建设有限公司

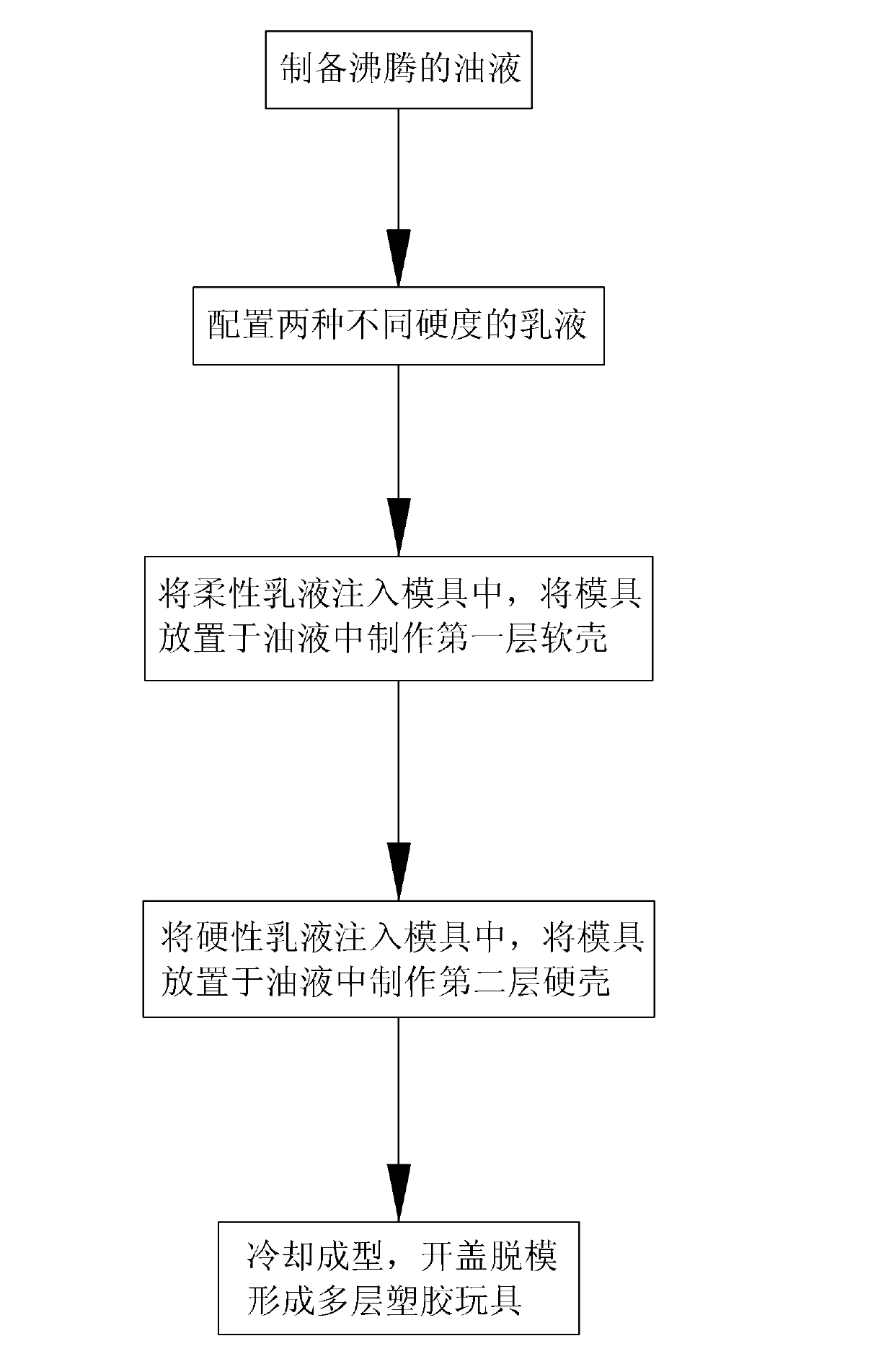

Manufacturing method of multilayered toy

The invention discloses a manufacturing method of a multilayered toy. The manufacturing method comprises the following steps: S1, preparing a certain amount of boiled oil; S2, preparing two types of plastic emulsions with different hardness; S3, fully filling a flexible emulsion into a mould and placing the mould into the boiled oil to manufacture and form a first layer of a soft shell; S4, fully filling a hard emulsion into the mould and placing the mould into the boiled oil to manufacture and form a second layer of a hard shell; and S5, cooling and molding the mould, and opening a cover and de-molding to form a plastic toy with soft outside and hard inside. According to the manufacturing method, the problem that the soft and hard degrees are not the same in a traditional multilayered toy manufacturing method is better solved and the toy can be closer to the touch feeling of a human skin, so that the quality of a product is better and better hand feeling and texture are brought to people.

Owner:李明灥

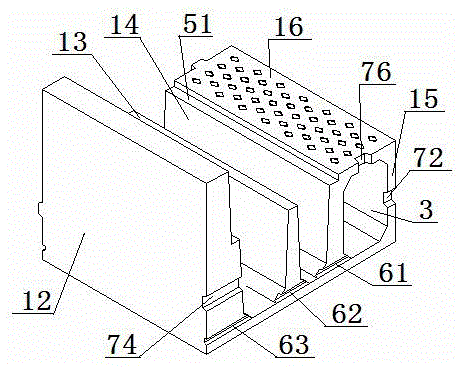

Assembly type cement prefabricated double-layer cable trench and manufacturing method thereof

ActiveCN105619597AUnified standardSmall size errorCable installations on groundCeramic shaping apparatusEngineeringCement

The invention provides an assembly type cement prefabricated double-layer cable trench and a manufacturing method thereof. The assembly type cement prefabricated double-layer cable trench comprises a trench base body and a cover plate. The cover plate is arranged on the trench base body. The trench base body is a concrete prefabricated piece. The trench base body comprises a trench bottom plate, a trench back wall, a first trench wall, a second trench wall, a trench face wall and a trench top plate. The bottom of the trench back wall, the bottom of the first trench wall, the bottom of the second trench wall and the bottom of the trench face wall are fixedly connected with the top face of the trench bottom plate. The top of the second trench wall and the top of the trench face wall are fixedly connected with the bottom of the trench top plate. A sealed cable groove is formed among the trench bottom plate, the second trench wall, the trench face wall and the trench top plate. A first cable duct is formed between the trench back wall and the first trench wall on the trench bottom plate. A second cable duct is formed between the first trench wall and the second trench wall on the trench bottom plate. By means of the design, the assembly type cement prefabricated double-layer cable trench is not only steady in structure, long in service life, but also simple in mounting and manufacturing method and high in practicability.

Owner:HUBEI ZHUANGZHI PETROCHEM EQUIP

Metal cold mold processing device for grinding roller production

InactiveCN112756451AEasy to remove the moldRegulatory useShaping toolsMetal working apparatusMechanical engineeringMold removal

The invention discloses a metal cold mold processing device for grinding roller production. The device comprises a cold mold processing table, a stamping upper mold, a lower mold, an adjusting support assembly and a protective demolding assembly, wherein the lower mold is arranged on the cold mold processing table, the adjusting support assembly is arranged on the cold mold processing table, the stamping upper mold is arranged on the adjusting support assembly, the stamping upper mold is located over the lower mold, the protective demolding assembly is arranged in the cold mold processing table, and the adjusting support assembly comprises an adjusting hydraulic rod and a supporting plate. The invention belongs to the technical field of cold mold processing, and particularly relates to the metal cold mold processing device for the grinding roller production, which is capable of conveniently demolding and collecting a casting, meanwhile conveniently protecting the lower mold, preventing abrasion and breakage and generating a self-protection effect through the arrangement of the protective demolding assembly, and meanwhile is capable of facilitating adjustment and being used for different castings through the arrangement of the adjusting support assembly. The metal cold mold machining device for grinding roller production is convenient to adjust and can be applied to different castings.

Owner:徐州兰岳企业管理服务有限公司

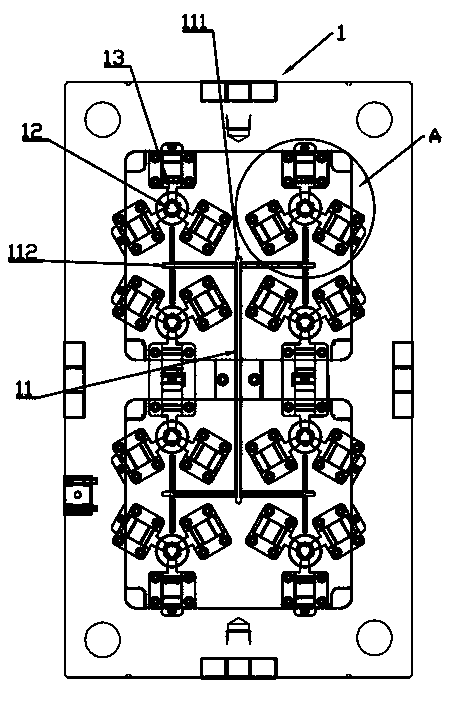

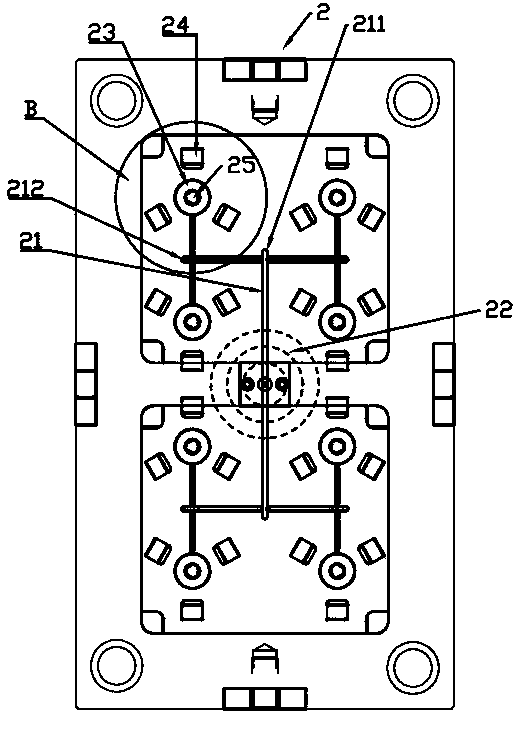

Injection mold easy to release

The invention discloses an injection mold easy to release. The injection mold comprises a bottom mold holder and a top mold holder. A plurality of bottom mold cores and injection sliding blocks with auxiliary mold cores are arranged on the bottom mold holder, top mold cores are arranged on the top mold holder, and a workpiece mold cavity is formed by the bottom mold cores, the top mold cores and the auxiliary mold cores in a spliced mode. Particularly, a guiding groove is formed in each injection sliding block, mold releasing supporting blocks are arranged on the top mold holder, the mold releasing supporting blocks are connected to the interior of the guiding grooves in a penetrating mode, in the mold opening and closing switching process, the injection sliding blocks are driven to slide outwards in an extending mode or slide inwards in a gathering mode with the bottom mold cores as centers, mold releasing centres are arranged on the top mold holder, and the mold releasing centres are driven to be stretched inside the mold cavity. By means of the injection mold, the design of combining the injection sliding blocks with the mold releasing centres is adopted, when the mold is released, the injection sliding blocks perform extending sliding to enable the auxiliary mold cores of the injection sliding blocks to be separated from an injection workpiece, primary mold releasing of the workpiece is conveniently carried out, then the workpiece is pushed out through the mold releasing centres, and mold releasing is completed. The injection production rate and the product pass percent are greatly improved, and meanwhile production cost is reduced.

Owner:SUZHOU INDAL PARK XIELI PLASTIC

Foamed plastic molding machine

The invention discloses a foam plastic molding machine, which comprises a workbench, on which a die is arranged, and multiple vertical support columns are arranged around the die, the top of the support pillars is provided with a mounting seat, and a mounting seat is provided on the mounting seat. There is a hydraulic lifting mechanism, the bottom of the hydraulic lifting mechanism is fixedly connected to the punch, a liquid storage chamber is provided between the inner wall and the outer wall of the die, and a liquid storage tank is provided on one side of the workbench, and a partition is arranged in the liquid storage tank. The plate and the partition divide the liquid storage tank into a heating chamber and a cooling chamber. The heating chamber is equipped with heating liquid, and the cooling chamber is equipped with cooling liquid. The liquid pipes are connected, and the heating liquid inlet pipe and the cooling liquid inlet pipe are connected with the die outlet pipe through a diverter three-way valve. The invention adds a heating and cooling system, and the prepared foamed plastic products have small particles, compact texture and high service strength, which can meet the market's requirements for the quality of foamed plastics.

Owner:句容市悠然包装制品有限公司

Fuel preparation mold for solid fuel ramjet

The invention discloses a fuel preparation mold for a solid fuel ramjet. The fuel preparation mold comprises a base, a hollow heating pipe, a cylinder body, a top clamping ring and a compression block; the cylinder body comprises two semi-cylindrical sections, and the two semi-cylindrical sections are connected through a clamping groove in a clearance fit mode; the base is connected to the hollowheating pipe through a stepped hole in an interference fit mode; the outer side surface of the lower end of the cylinder body is matched with the stepped inner circle of the base in an interference fit mode; the outer side surface of the top of the cylinder body is connected to the top clamping ring through the stepped hole in an interference fit mode; an inner hole of the compression block is matched with the outer side surface of the hollow heating pipe in a clearance fit mode; and the outer side surface of the compression block is connected to the inner side surface of the cylinder body ina clearance fit mode. The mold has the advantages that the design of the hollow heating pipe is adopted, so that internal and external heating balance of powdery solid fuel can be guaranteed to the maximum extent, and raw materials are saved; only the top clamping ring needs to be detached, so that cylinder body of the mold can be opened, and demolding can be realized; and the problem that demolding is difficult when the solid fuel prepared from different components is prepared can be solved, and the solid fuel with relatively good compactness for the test of the ramjet can be prepared quicklyat a low cost.

Owner:NANJING UNIV OF SCI & TECH

Thermal forming closing-in device

PendingCN114029405AEasy to remove the moldControlled Forming SpringbackShaping toolsEngine componentsEngineeringMechanical engineering

The invention discloses a thermal forming closing-in device which comprises a lower die provided with a workpiece mounting groove, an upper die provided with a closing-in inclined plane, a driving seat used for driving the upper die to press downwards and closing in a workpiece in the workpiece mounting groove, a conical guide block and an inner supporting mechanism used for abutting against the inner wall of the workpiece. The inner supporting mechanism comprises a connecting base used for being driven by the driving base to ascend and descend, a plurality of inner supporting blocks connected with the connecting base in a sliding mode and arranged around the conical guide block, and an elastic reset assembly used for pushing the inner supporting blocks to the conical guide block, and the inner supporting blocks are used for being pushed by the conical guide block to be in the state of abutting against the inner wall of the workpiece during descending. According to the thermal forming closing-in device, when the driving base drives the upper die to descend for closing in, the inner supporting mechanism can be synchronously driven to descend, the multiple inner supporting blocks are gradually opened through the guiding effect of the conical guiding block, the inner wall of a workpiece is automatically abutted against before the closing-in procedure, and the closing-in effect is guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com