Plastic forming method of draw-hole bolt

A processing method and a technology of parts, which are applied in the field of cold heading processing of parts with effective bottom holes, can solve the problems of small range of processing materials, affecting product quality, and products with burrs, and achieve material saving, excellent smooth quality, and simple procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

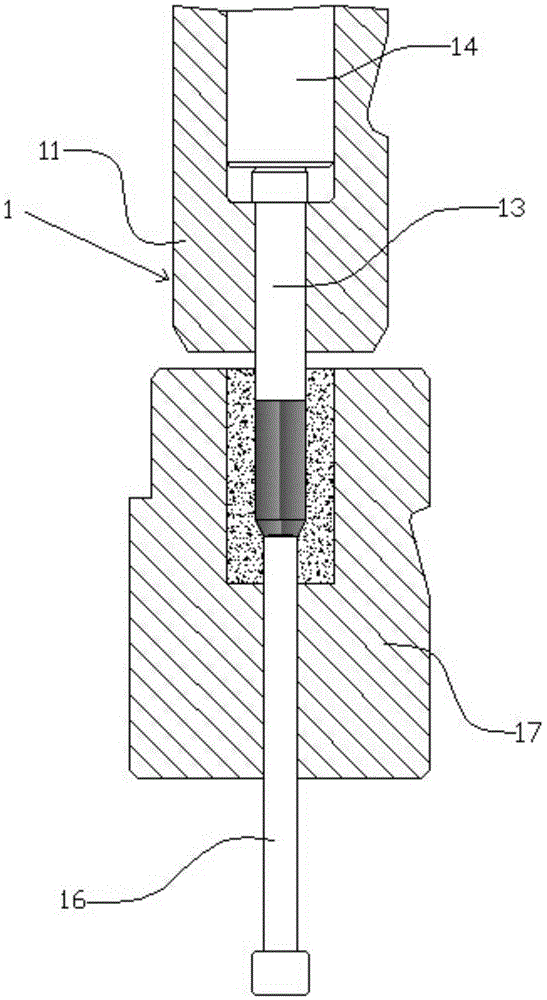

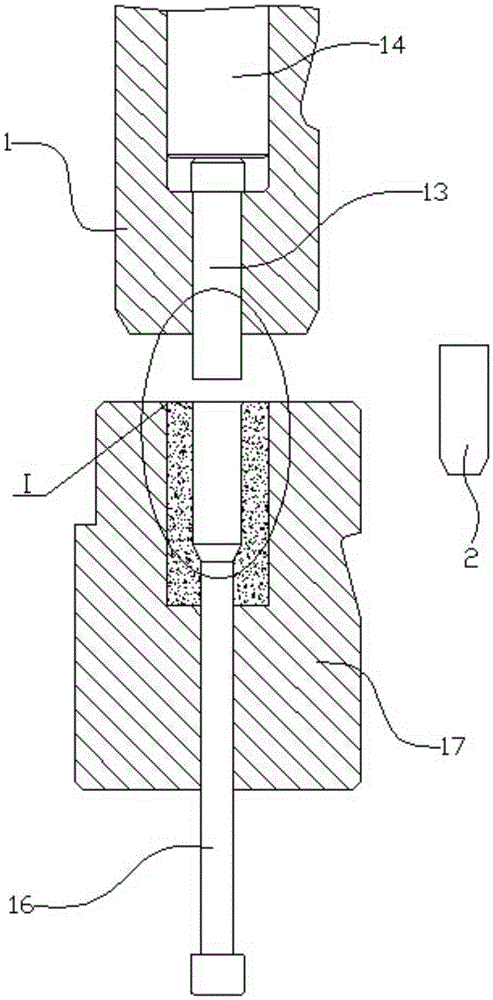

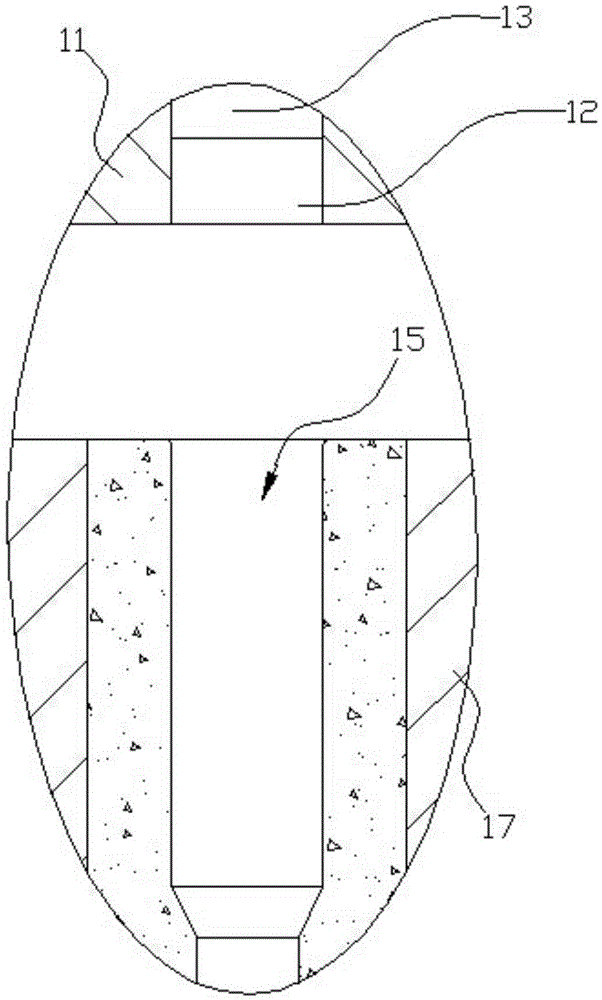

[0038] like Figure 1-16 As shown, the plastic forming method of the hole-absorbing bolt in this embodiment is carried out in the following steps:

[0039] Step 1: Extruding the part blank into the bottom mold through the first stamping die 1, forming a chamfer at the bottom of the blank, and obtaining the required size for the taper of the tail and the upsetting of the stem;

[0040] Step 2, extruding the part 2 of step 1 through the second stamping die 3 to obtain the upsetting of the part and drawing holes to reach the required size;

[0041] Step 3: Extrude and preform the head of part 2 in step 2 through the third stamping die 4. The part is then upset and further drilled to reach the required size to obtain the taper of the head and the upsetting of the rod and the evacuation depth. required size;

[0042] Step 4, using the fourth sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com