Hydraulic self-lifting cantilever heavy arch dam template work platform

A working platform and formwork technology, applied in arch dams, dams, infrastructure projects, etc., can solve problems such as the influence of shape changes, achieve reliable fixation and suspension, facilitate mold withdrawal and mold closing, and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

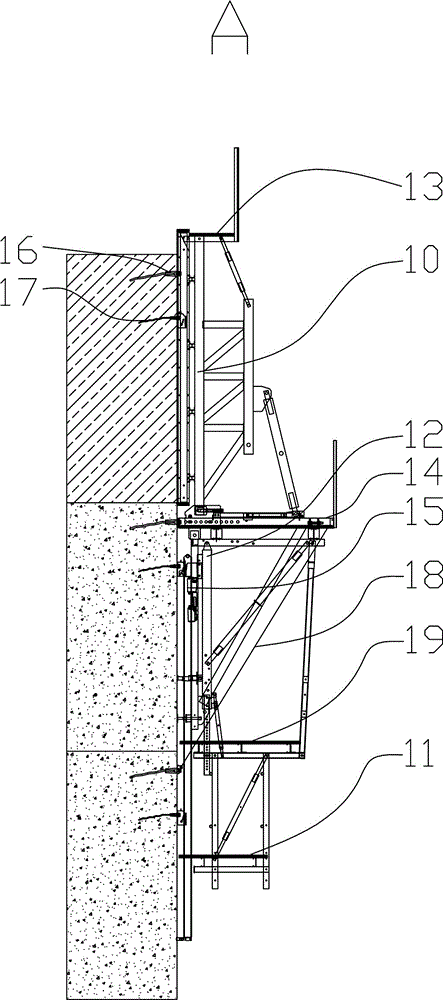

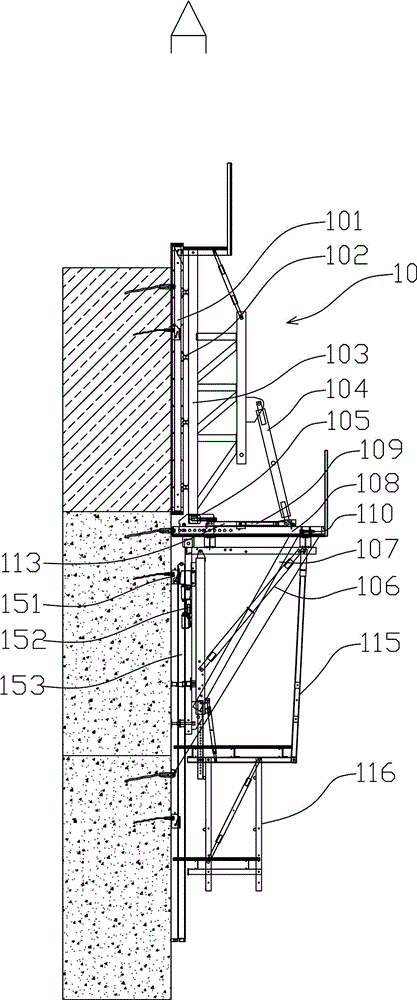

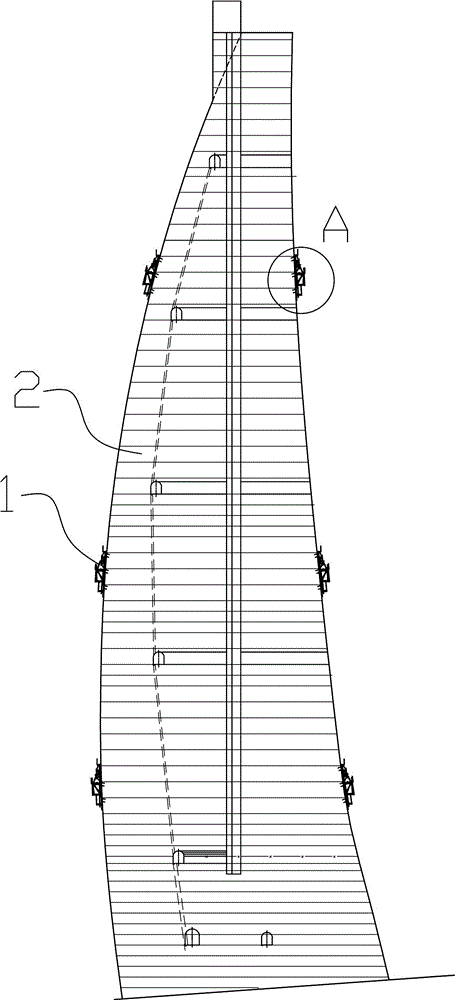

[0048] Such as Figure 1-11 Among them, a hydraulic self-elevating cantilever heavy-duty arch dam formwork platform, the self-climbing formwork system is provided with multi-layer platforms for construction from top to bottom, and each layer of platforms is connected to the self-climbing formwork system through platform leveling rods 106 , to level the platform. Due to this structure, during the construction process, it is convenient to keep the platform in a horizontal state all the time, so that construction equipment can be placed conveniently, construction operations can be facilitated, and construction safety can be ensured.

[0049] The preferred solution is as figure 1 , 2 In the self-climbing formwork system, the first platform 13, the second platform 14, the third platform 19 and the fourth platform 11 are arranged sequentially from top to bottom;

[0050] The first platform 13 is located on the top of the formwork device 10; it is used for pouring and formwork co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com