Solid motor nozzle blank assembly, production method thereof and mold for use

A solid motor and blank technology, which is used in machines/engines, rocket motor devices, forming tools, etc., can solve problems such as affecting performance and easy ablation of aluminum nozzles, extending service life and avoiding bonding processes. , the effect of easy filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the drawings. The enumerated embodiments can enable those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

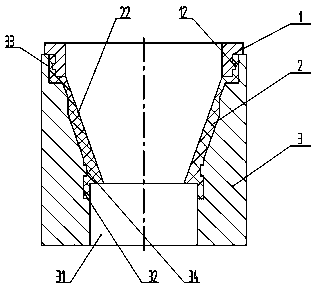

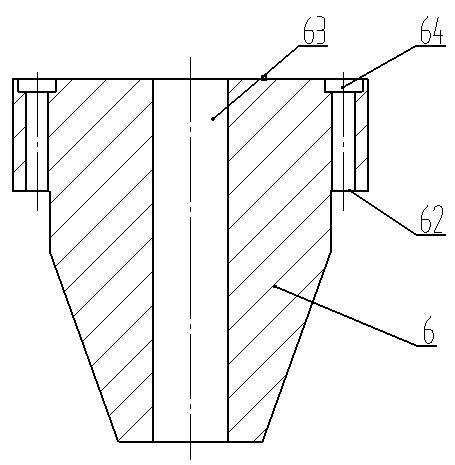

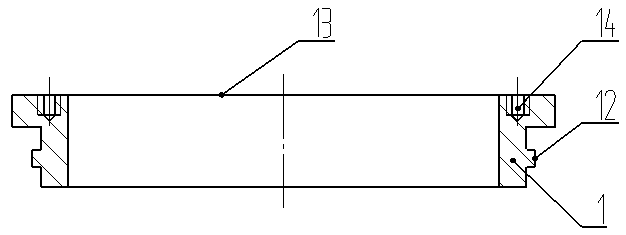

[0028] Such as figure 1As shown, a solid engine nozzle blank assembly is composed of a guide ring blank 1, a heat insulator 2, and a nozzle body blank 3. The nozzle body blank is cylindrical in shape and has a positioning step hole 31 at the lower end of the interior. On the top of the positioning step hole, there is a counterbore I32 which is larger than the positioning step hole, and there is a counterbore II33 at the upper end of the nozzle body blank. For rough, discontinuous surfaces, even undulating surfaces, the inner surface of the nozzle body blank from the end of the positioning step hole to the bottom of the counterbore Ⅱ33 is composed of multiple concentric axes, different taper cones and even different directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com