Injection mold easy to release

A technology for injection molds and ejection, applied in the field of injection molds, can solve problems such as ejection of molded products and high-efficiency production, and achieve the effects of reducing production costs, increasing injection molding production speed and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention improves the existing injection mold and creates an injection mold for special workpieces that is easy to withdraw from the mold. It adopts the design of the combination of injection sliders and ejector pins, which makes the injection molds easy to withdraw from the mold. , providing a practical technical solution for special workpiece ejection.

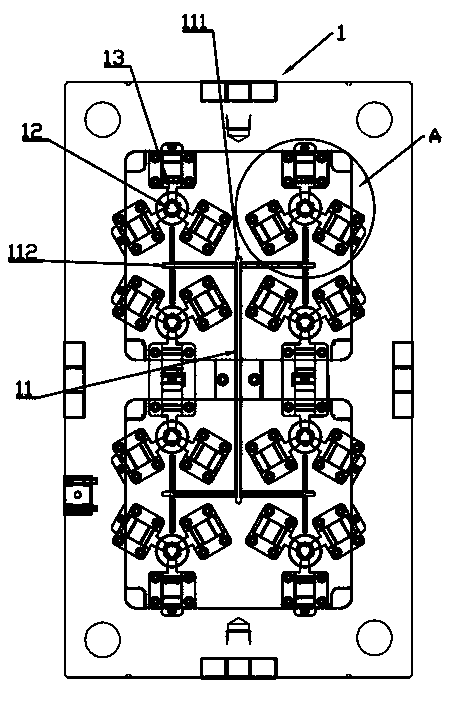

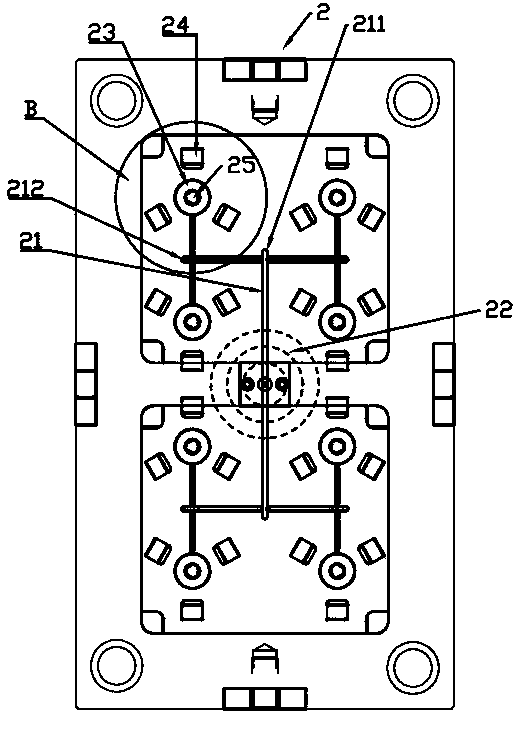

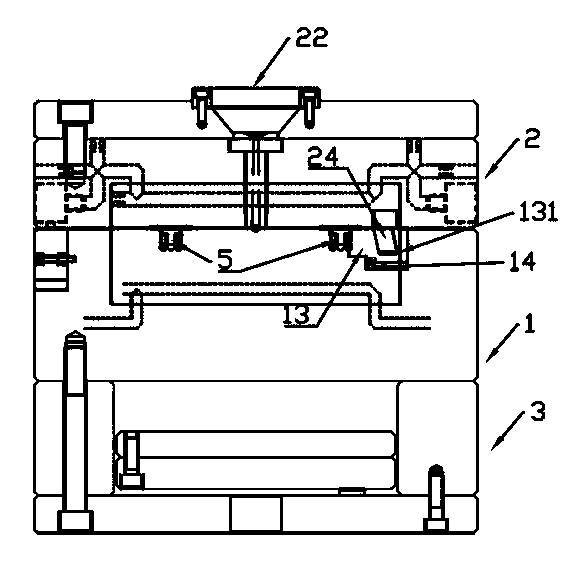

[0018] Such as Figure 1 to Figure 6 As shown, a kind of injection mold that is easy to withdraw from the mold includes a bottom mold base 1 and a top mold base 2, wherein the bottom mold base is provided with several bottom mold cores 12, and each bottom mold core 12 periphery is provided with a plurality of injection molding sliders 13 , the injection molding slider 13 is provided with a secondary mold core 132, and the top mold base 2 is provided with a number of top mold cores 23 matched with the bottom mold core 12, and the bottom mold core 12, the top mold core 23 and the secondary mold core 132 sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com