Assembly type cement prefabricated double-layer cable trench and manufacturing method thereof

A cable trench and assembled technology, which is applied in the field of assembled cement prefabricated double-layer cable trench and its manufacturing, can solve the problems of no development and adaptation, and achieve the effects of shortening the construction period, facilitating direct installation, and shortening the project period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

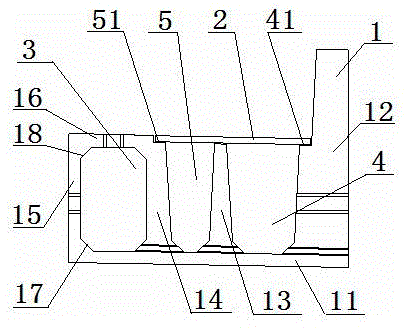

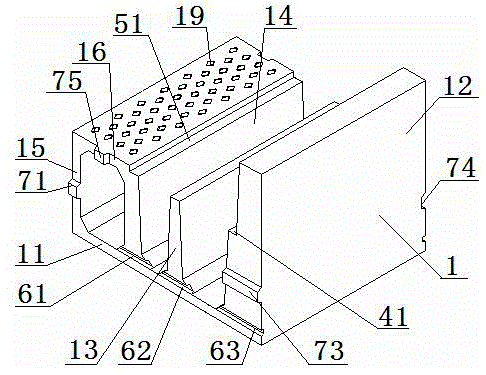

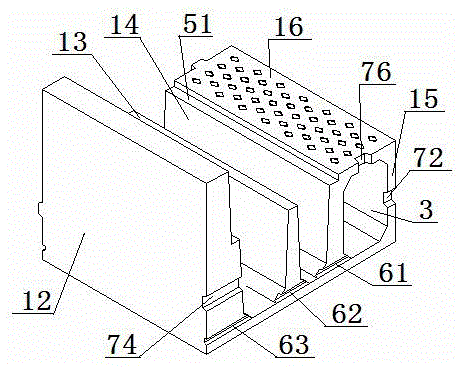

[0075] see Figure 1 to Figure 4, an assembled cement prefabricated double-layer cable trench, including a trench base 1 and a cover plate 2, the cover plate 2 is arranged on the trench base 1, and the trench base 1 is a concrete prefabricated part; the trench The groove base 1 comprises a groove bottom plate 11, a groove back wall 12, a first groove wall 13, a second groove wall 14, a groove face wall 15 and a groove top plate 16, the groove back wall 12, the first groove wall The bottoms of the groove wall 13, the second groove wall 14 and the groove wall 15 are all fixedly connected with the top surface of the groove bottom plate 11, and the tops of the second groove wall 14 and the groove wall 15 are connected with the groove The bottom of the top plate 16 is fixedly connected; a closed cable groove 3 is formed between the groove bottom plate 11, the second groove wall 14, the groove surface wall 15 and the groove top plate 16, and the groove on the groove bottom plate 11 ...

Embodiment 2

[0083] Embodiment 2 is basically the same as Embodiment 1 and its difference is:

[0084] The front tenon 71 , the rear tenon 73 and the upper tenon 75 are located on the same side of the groove base 1 .

Embodiment 3

[0086] Embodiment 3 is basically the same as Embodiment 1 and its difference is:

[0087] Described 3rd step: closing mold comprises the following steps:

[0088] a. Place the cage made of fine steel on the outer mold 81, the bottom of the cage is equipped with a cage bracket, after the placement is completed, there is no direct contact between the cage and the outer mold 81;

[0089] b. After placing the cage, close and lock the front formwork 82, rear formwork 83, convex formwork 84 and notch formwork 85, insert the mandrel 86 and adjust the mandrel 86 to make it tighter. At this time, the mold clamping is completed .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com