Road and bridge steel formwork demolding device

A technology of steel formwork and mold removal, which is applied in the direction of bridges, bridge construction, formwork shell processing, etc., can solve the problems of cast body damage, difficulty in adapting to different mold removal occasions, etc., to improve applicability, improve use convenience, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

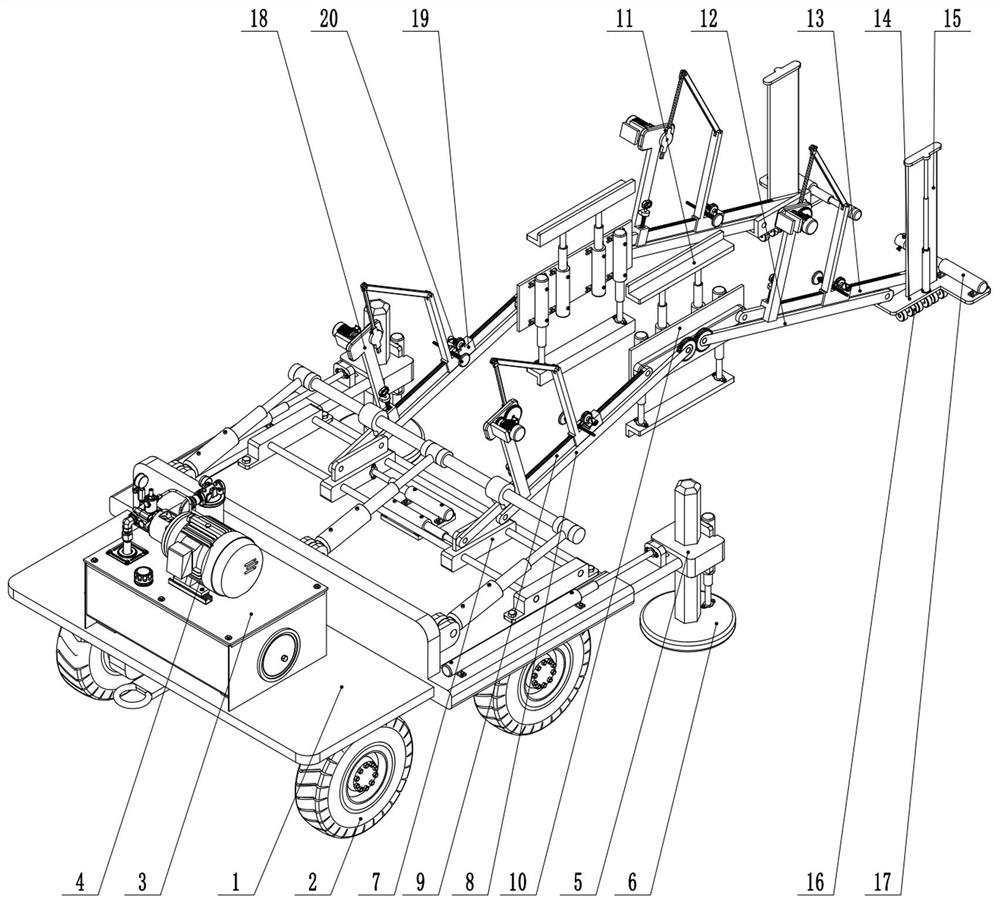

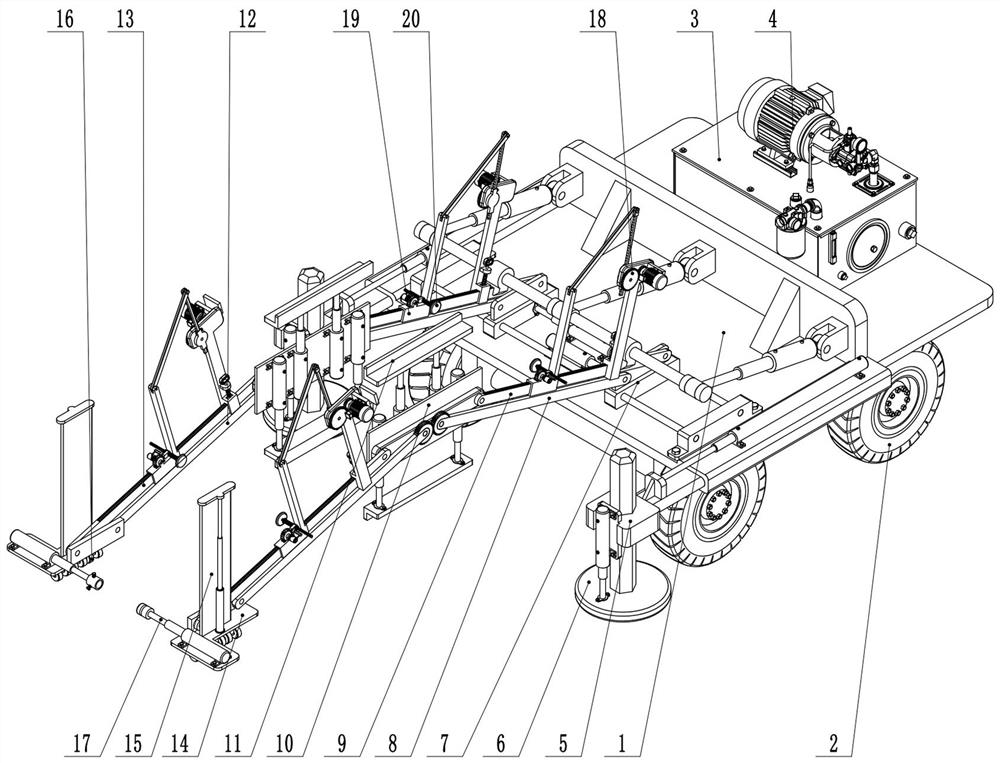

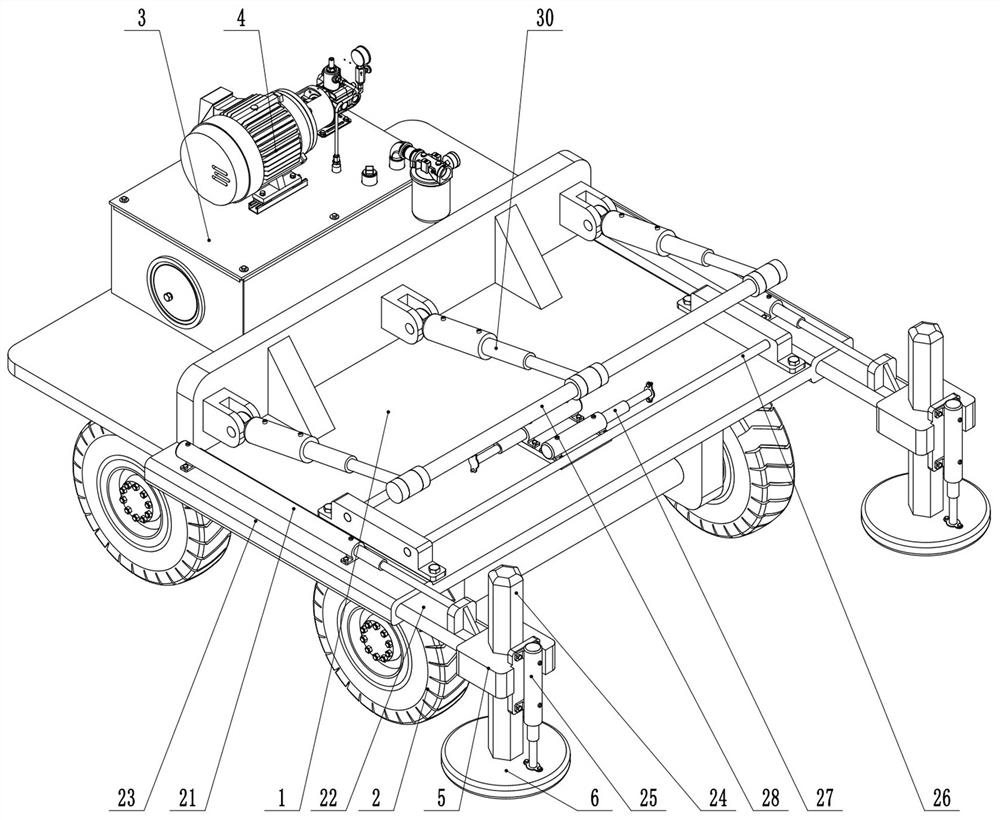

[0045] Such as Figure 1-13 As shown, the present invention provides a road and bridge steel formwork ejection device, including a main board 1 with wheels 2, a hydraulic pump 4 and an oil tank 3 are arranged on the top of the rear side of the main board 1, and two left and right movable parts are arranged on the front side of the main board 1. Adjust the stable seat 5 of the front and rear positions, the front side of the stable seat 5 is provided with a leg 6 that can adjust the vertical position; the front side of the main board 1 is provided with two left and right modules 7 that can be relatively close or far away; The top of the retreat module 7 is provided with a second strut 9 that can adjust the front and rear inclinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com