One-time injection molding die of multi-face irregular workpieces

An injection molding and regular technology, applied in the field of one-shot injection molding molds, can solve the problems of low qualification rate, cumbersome production process, low production efficiency, etc., and achieve the effects of convenient mold removal, low cost, and improved precision and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

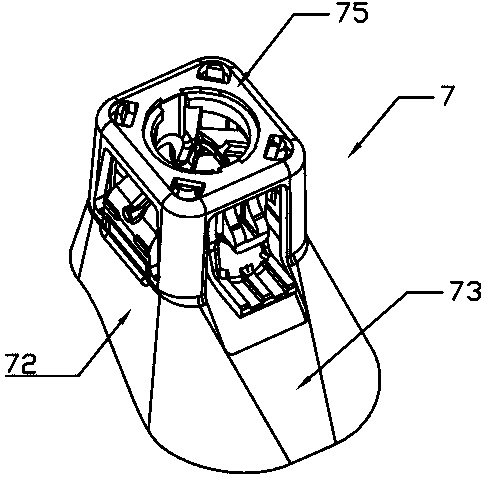

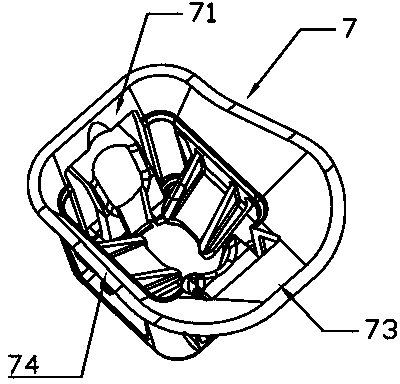

[0017] The invention has a specific design for the special structure of multi-faceted irregular workpieces, adopts a three-dimensional and multi-faceted mold opening method to solve the problem of difficult injection molding of multi-faced irregular workpieces, and provides a one-time injection molding mold for multi-faced irregular workpieces.

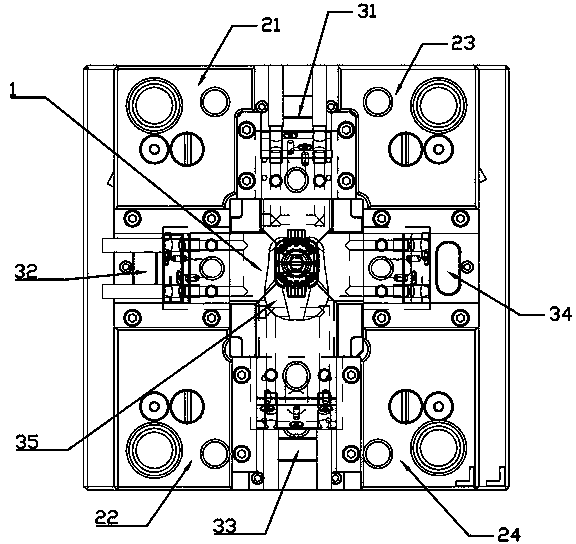

[0018] like Figure 3 to Figure 6 As shown, the one-time injection molding mold for multi-faceted irregular workpieces includes a lower mold base 1 and an upper mold base 5. In particular, the lower mold base 1 is provided with a lower mold center fixed mold base 35, four fixed mold bases 21 , 22, 23, 24 and four sliding mold bases 31, 32, 33, 34 between two fixed mold bases and all the mold bases are in a nine palace layout. Specifically, the lower mold base is in a square structure, and the four Fixed mold bases 21, 22, 23, 24 are located at square four corners respectively, thus then slide rails are set between two fixed mold bases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com