Powder slice pressing forming die capable of being disassembled conveniently

A technology of powder pressing and forming molds, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., and can solve the problems of easily damaged flakes after forming, large frictional resistance, and tableting failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

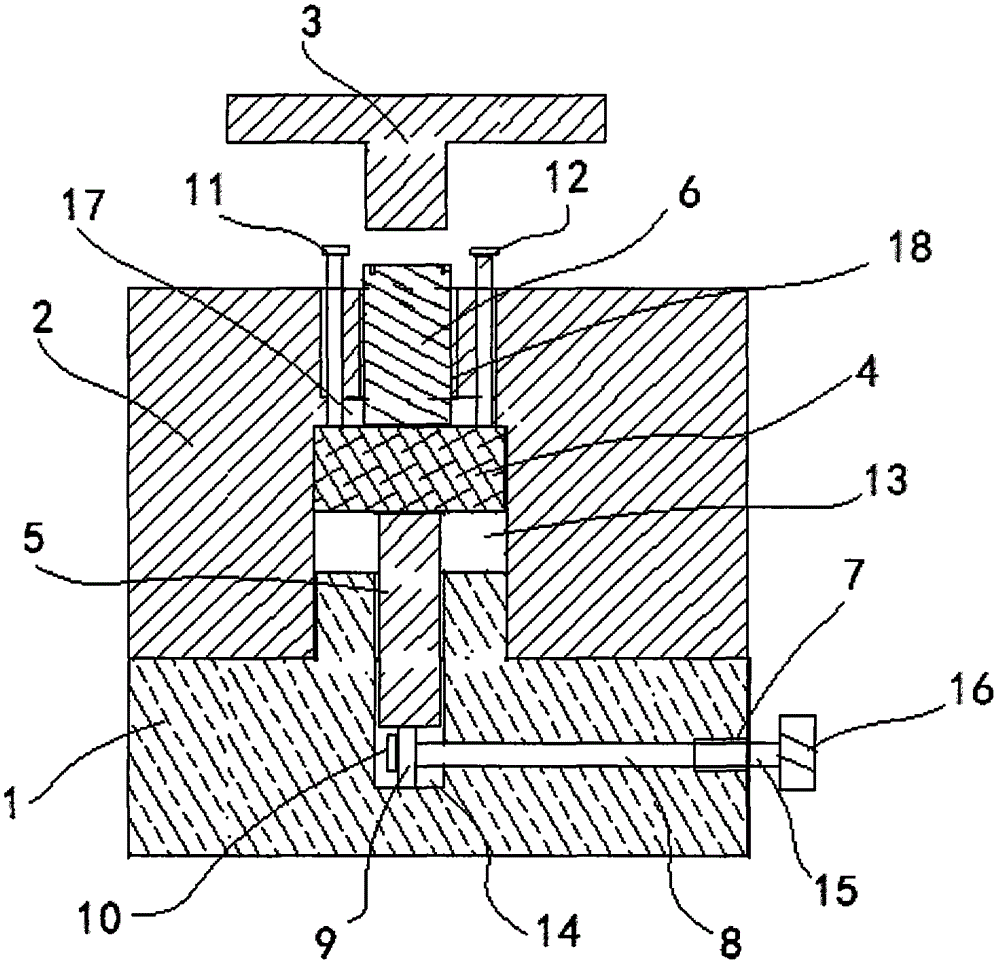

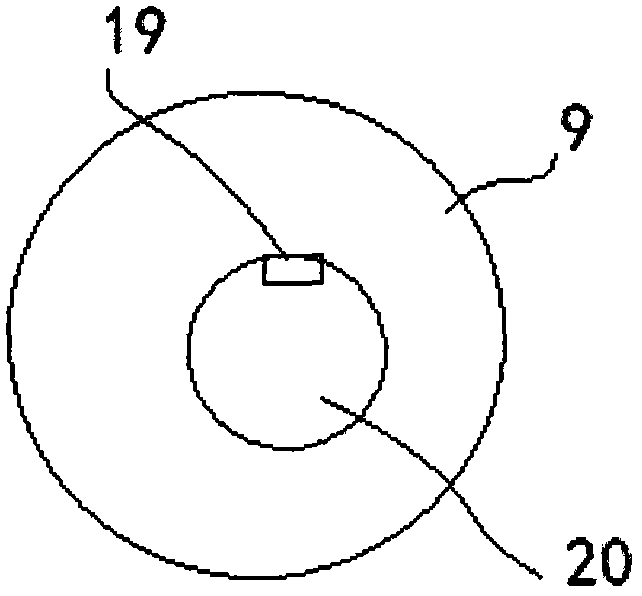

[0014] See Figure 1~2 , a powder compression mold for easy mold unloading, comprising a base 1 with a circular boss in the central part and a mold base 2 connected to the base, the central coaxial line of the mold base is provided with a communicating The first guide hole 13 and the second guide hole 18, the lifting seat 4 that is in sliding contact with the inner wall of the first guide hole is installed in the first guide hole, and a lifting seat 4 that is in contact with the inner wall of the first guide hole is installed in the second guide hole. The lower pressure head 6 connected to the seat, the bottom of the lifting seat is connected with the lifting adjustment rod 5, the lifting adjustment rod is installed in the base guide hole 14 and connected with an eccentric adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com