Infrared and/or ultraviolet sample wafer pressing die

A tableting mold, infrared technology, applied in the field of infrared and/or ultraviolet tableting molds, can solve the problems of tableting failure, high friction resistance, difficulty in film pressing and demoulding, etc., and achieve convenient mold removal and molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

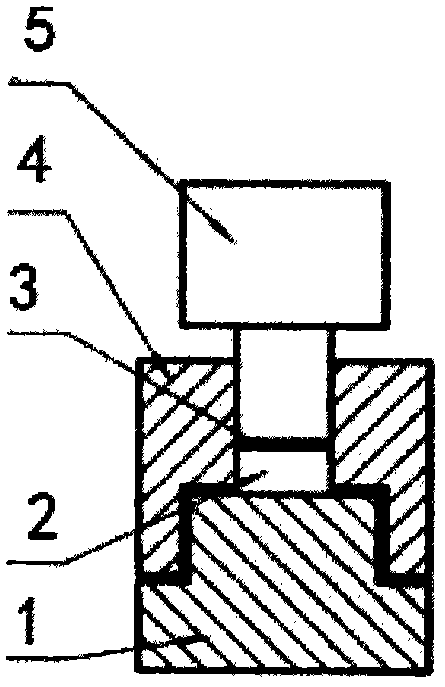

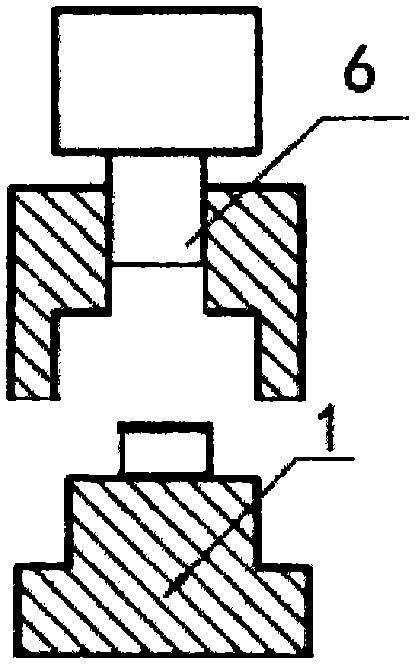

[0013] See Figure 1~2 , an infrared and / or ultraviolet tabletting mold, including a base 1 with a circular boss and a mold base 4 threadedly connected with the base, the central axis of the mold base is provided with a cylindrical hollow cavity, the The inner wall of the cylindrical hollow cavity has an internal thread, and the internal thread is threadedly connected to a cylindrical indenter 6, and the other end of the indenter is connected to the die sleeve 5; the central fixed connection of the circular boss of the base 1 A cylindrical post 2 that cooperates with the indenter to extrude powder molding, the post 2 is connected with the internal thread of the cylindrical hollow cavity, and a molding for powder molding is provided on the post Circle 3.

[0014] The diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com