Plastic coating mold

A technology for molds and overmolding, applied in the field of overmolding molds, can solve the problems of occupation of manpower and material resources, low production efficiency, and fixed deviation, and achieve the effects of simple structure, diversified finished products of injection molded parts, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

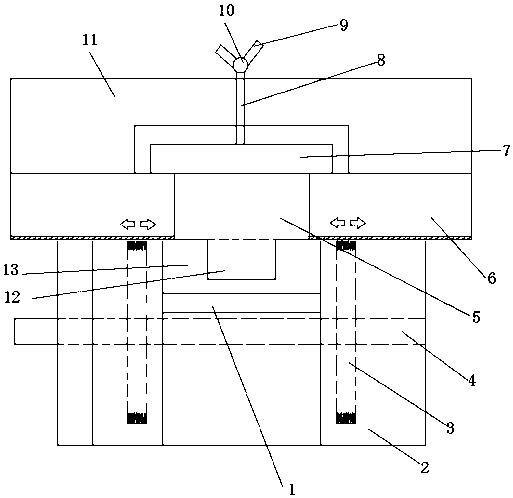

[0020] A plastic overmolding mold is composed of a base 2, an insert 13, a slider 6 and a movable mold 11.

[0021] The block 13 with the slot 12 is accommodated in the base 2 , and the top edge of the slot 12 is flush with the top edge of the base 2 .

[0022] A pair of sliders 6 are set on the top of the base 2, and are respectively placed on both sides of the socket 12, sliding along the top of the base 2, the bottom of which is connected with the rotating tooth 3 in the base 2, and passed by the screw rod 4 The rotating gears 3 are respectively driven, and the threads on the screw mandrel 4 are mirror-image symmetric.

[0023] The movable mold 11 inside accommodates a plurality of stacked moving blocks 7 to cover the top of the slider 6 , and forms a mold cavity 5 with the slider 6 and the slot 12 .

[0024] The pedestal 2 at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com