Bottom discharging type metal smelting feeding hopper

A technology of metal smelting and feeding hoppers, which is applied in the field of feeding hoppers, can solve the problems of large openings, complex structures, and large volumes of hoppers, and achieve the effect of accurate blanking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

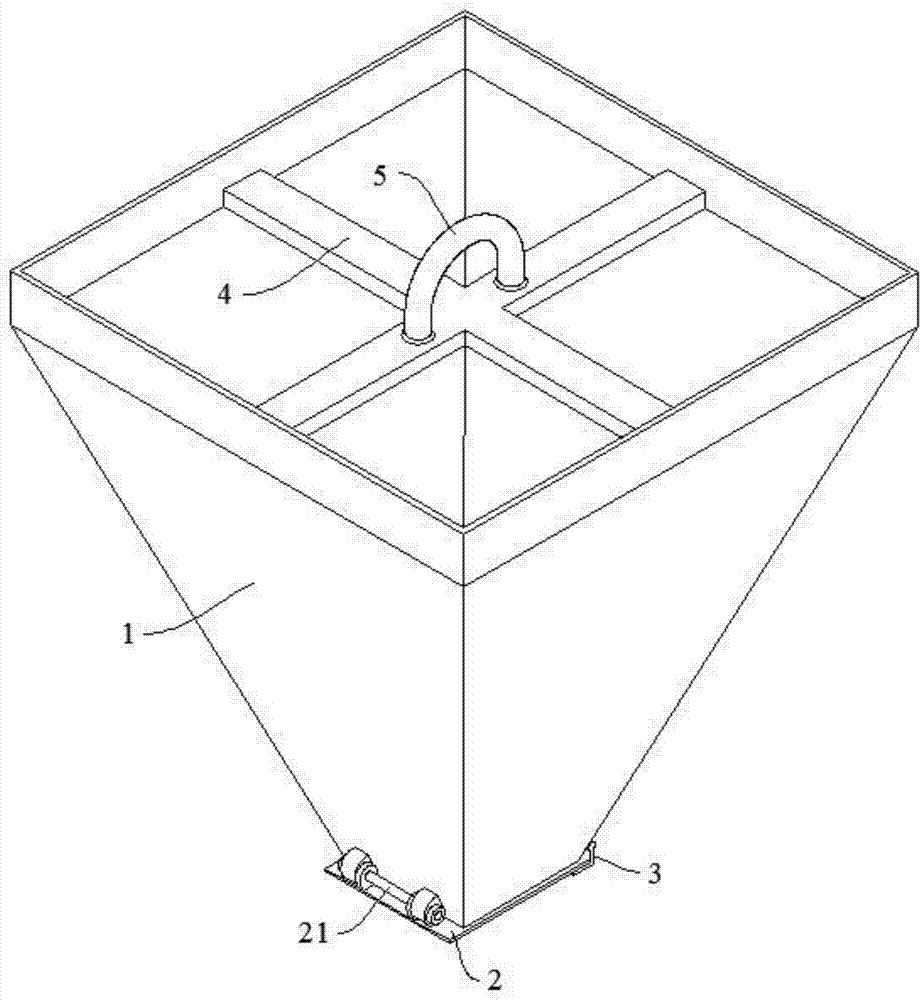

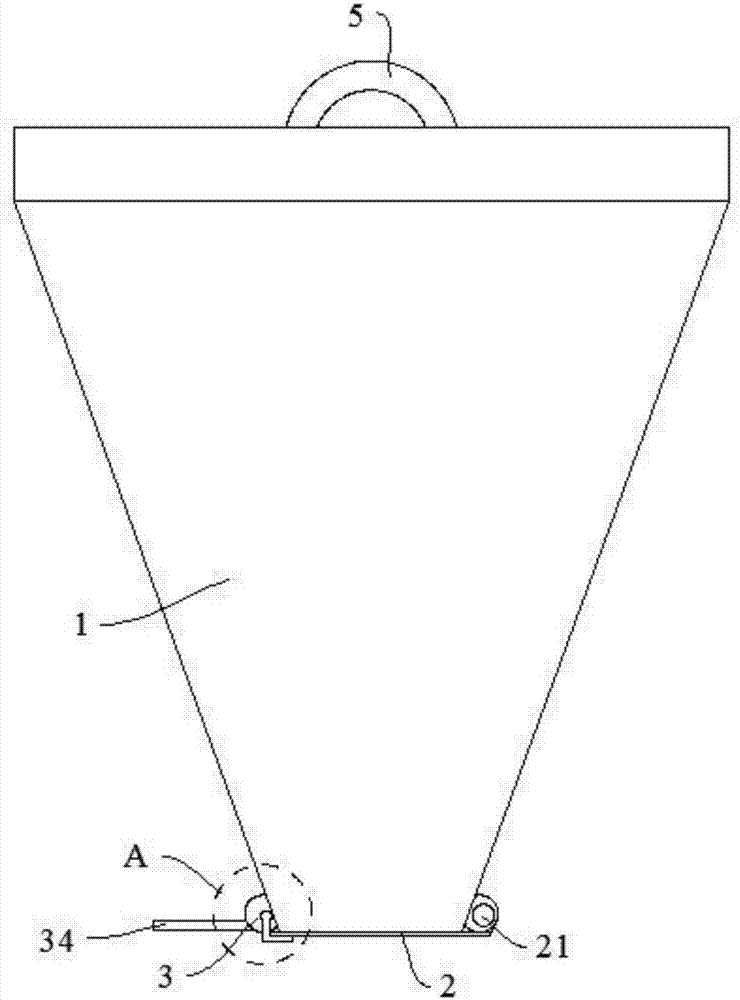

[0028] as attached Figure 1-5 As shown, a bottom discharge type metal smelting hopper includes: a bucket body 1, a bucket bottom door 2, a buckle lock mechanism 3, a top beam 4, and a suspension ring 5; The bucket bottom door 2 is hinged on the outer wall of the lower end of the bucket body 1, and the buckle lock mechanism 3 is also hinged on the outer wall of the lower end of the bucket body 1. The hinge shaft 31 of the buckle lock mechanism 3 and the hinge of the bucket bottom door 2 The shafts 21 are parallel, the top beam 4 is fixed on the top of the bucket body 1, the top beam 4 is cross-shaped, and the suspension ring 5 is fixed at the center of the top beam 4;

[0029] The buckle lock mechanism 3 comprises a table portion 32, a connecting portion 33 and a foot-operated counterweight bar 34. The table portion 32 is a strip-shaped flat plate, and the table portion 32 is located below the hinge shaft 31 of the buckle lock mechanism 3, and the side wall of the table portio...

Embodiment 2

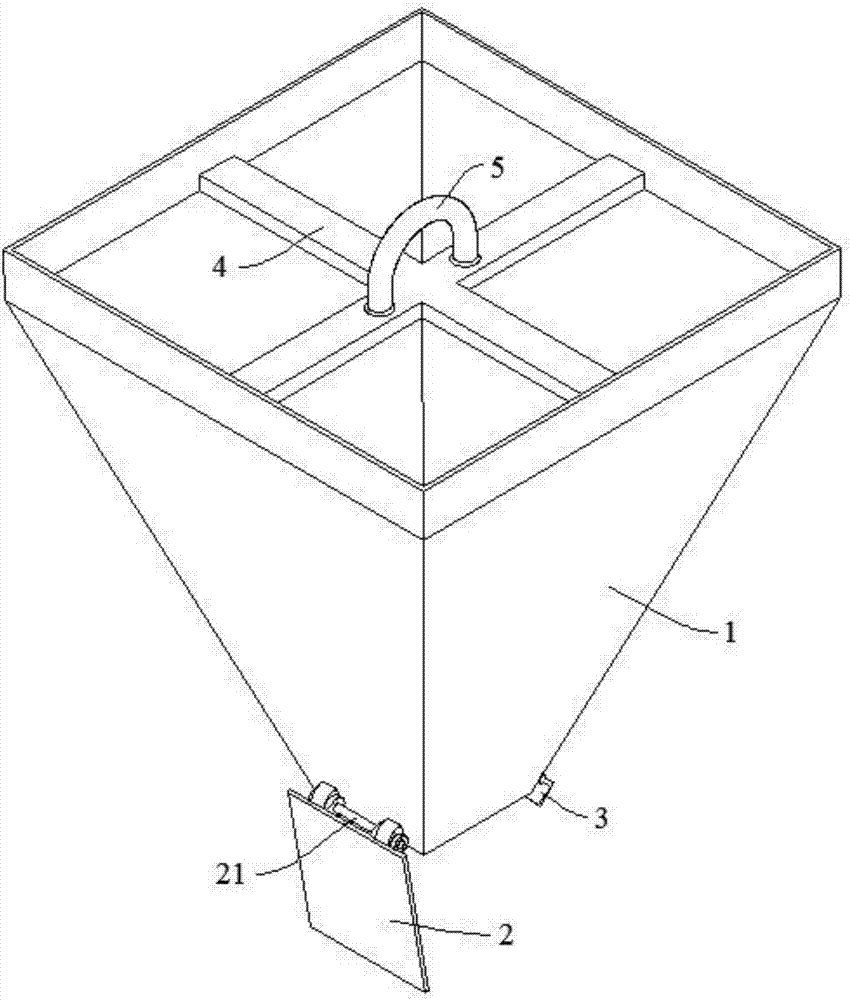

[0032] combined with Figure 6 , 7 As shown, a bottom discharge type metal smelting hopper includes: a bucket body 1, a bucket bottom door 2, a buckle lock mechanism 3, a top beam 4, and a suspension ring 5; Big and small opening, bucket bottom door 2 is hinged on the outer wall of the lower end of the bucket body 1, a boss 22 is provided on the outside of the free end of the bucket bottom door 2, and the buckle lock mechanism 3 is also hinged on the outer wall of the lower end of the bucket body 1. The hinge shaft 31 of the lock mechanism 3 is parallel to the hinge shaft 21 of the bucket bottom door 2, the top beam 4 is fixed on the top of the bucket body 1, the top beam 4 is cross-shaped, and the suspension ring 5 is fixed at the center of the top beam 4;

[0033] The buckle lock mechanism 3 comprises a table portion 32, a connecting portion 33 and a foot-operated counterweight bar 34. The table portion 32 is a strip-shaped flat plate, and the table portion 32 is located be...

Embodiment 3

[0035] combined with Figure 8 As shown, a bottom discharge type metal smelting hopper includes: a bucket body 1, a bucket bottom door 2, a buckle lock mechanism 3, a top beam 4, and a suspension ring 5; The bucket bottom door 2 is hinged on the outer wall of the lower end of the bucket body 1, and the buckle lock mechanism 3 is also hinged on the outer wall of the lower end of the bucket body 1. The hinge shaft 31 of the buckle lock mechanism 3 and the hinge of the bucket bottom door 2 The shafts 21 are parallel, the top beam 4 is fixed on the top of the bucket body 1, the top beam 4 is cross-shaped, and the suspension ring 5 is fixed at the center of the top beam 4;

[0036] The buckle lock mechanism 3 comprises a table portion 32, a connecting portion 33 and a foot-operated counterweight bar 34. The table portion 32 is a strip-shaped flat plate, and the table portion 32 is located below the hinge shaft 31 of the buckle lock mechanism 3, and the side wall of the table portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com