Feed and discharge mechanism for plastic bottle cap extruding machine

The technology of a discharging mechanism and an extruder is applied in the field of the feeding of the plastic bottle cap extruder and the feeding mechanism of the formed bottle cap, which can solve the problems of incomplete blanking, inaccurate position, damage of the bottle cap, etc., so as to improve the product quality. Quality, ensure product quality, and avoid collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

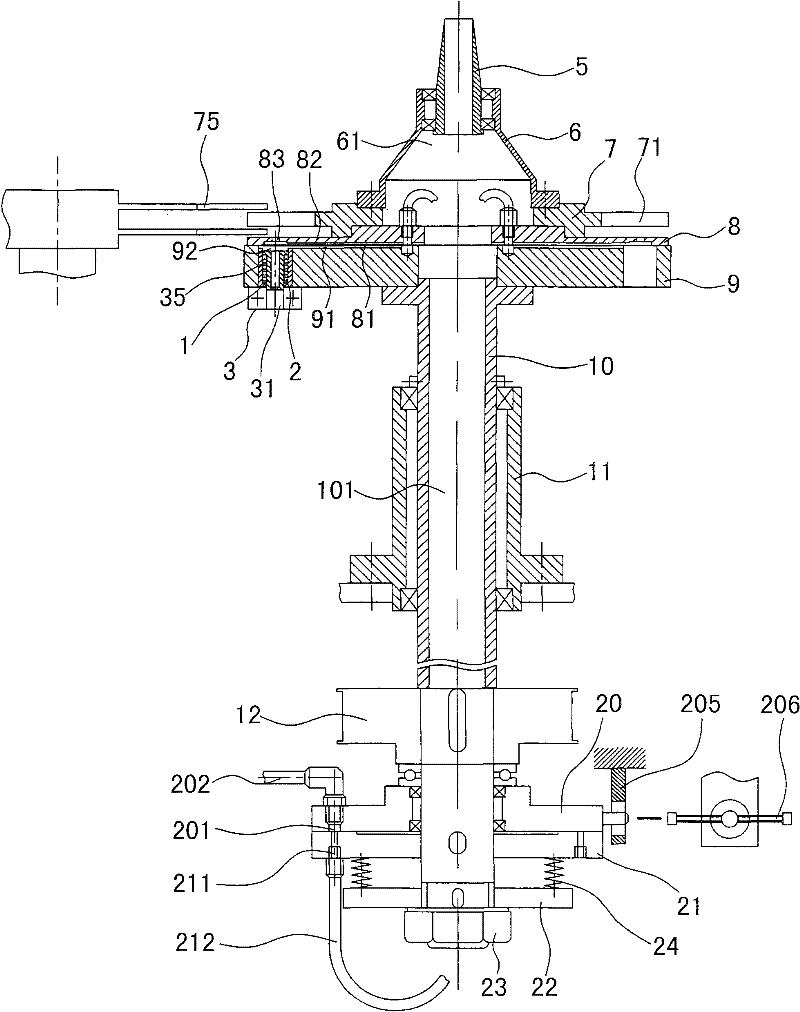

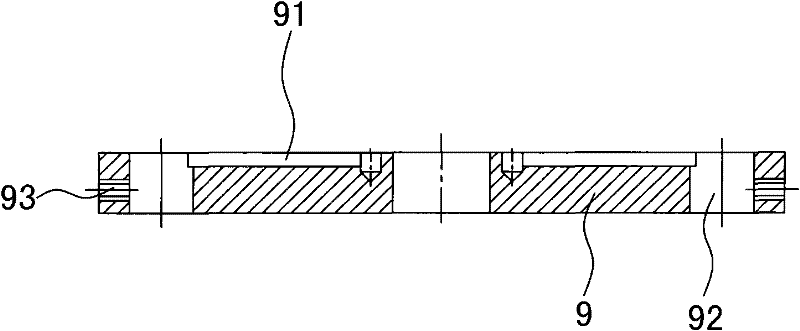

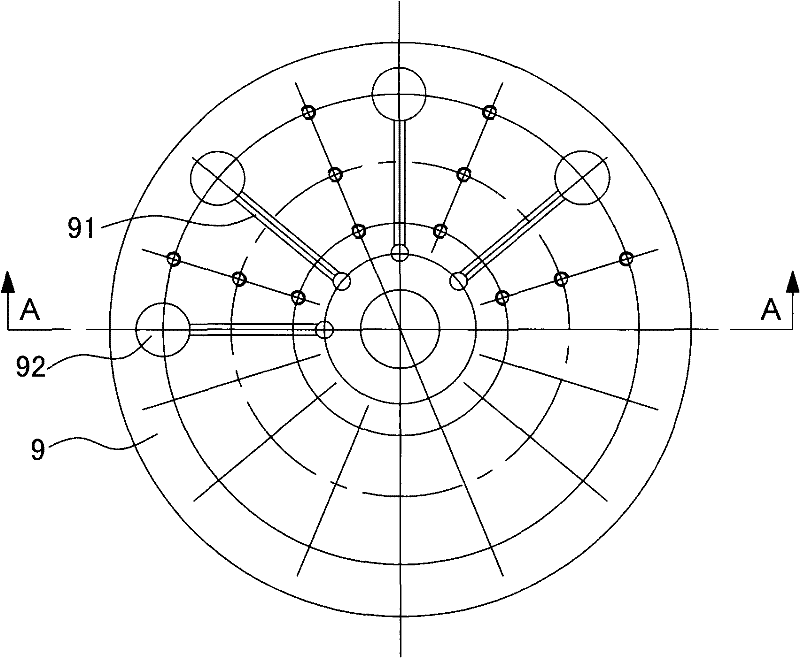

[0014] The invention relates to a feeding and discharging mechanism of a plastic bottle cap extruder, such as Figure 1-Figure 7 As shown, it includes a main shaft seat 11 installed on the frame, a main shaft 10 is installed in the main shaft seat 11, a rotating wheel 12 is installed outside the main shaft 10, and the rotating wheel 12 is driven by power, the lower part of the main shaft 10 is installed with an air circuit distributor, and the upper part of the main shaft is installed with an inlet The material tray 9 and the discharge flying disc 7 are characterized in that the air path distributor includes an air inlet plate 20 and an air outlet plate 21. For the air source of the air compressor, a plurality of air outlet holes 211 are made in the air outlet plate 21, and each air outlet hole 211 is respectively connected to an air delivery pipe 212. 91. The feed tray air passage 91 has a pressure port 92, and the feed plate 9 with the pressure port 92 is installed with a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com