Aluminum foil rewinding machine

A technology of rewinding machine and aluminum foil, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of easy edge warping, inaccurate operation and positioning, increase energy consumption, etc., and achieve fast and convenient feeding process. , The effect of high operation positioning accuracy and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

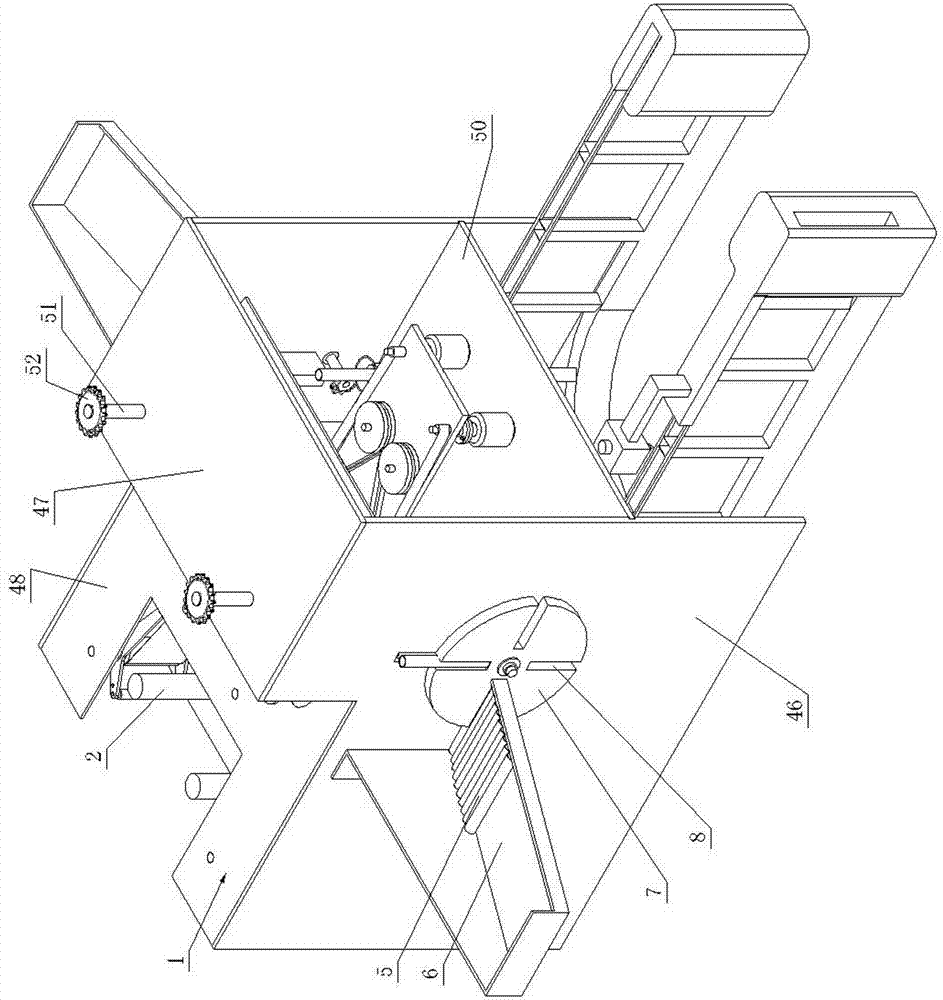

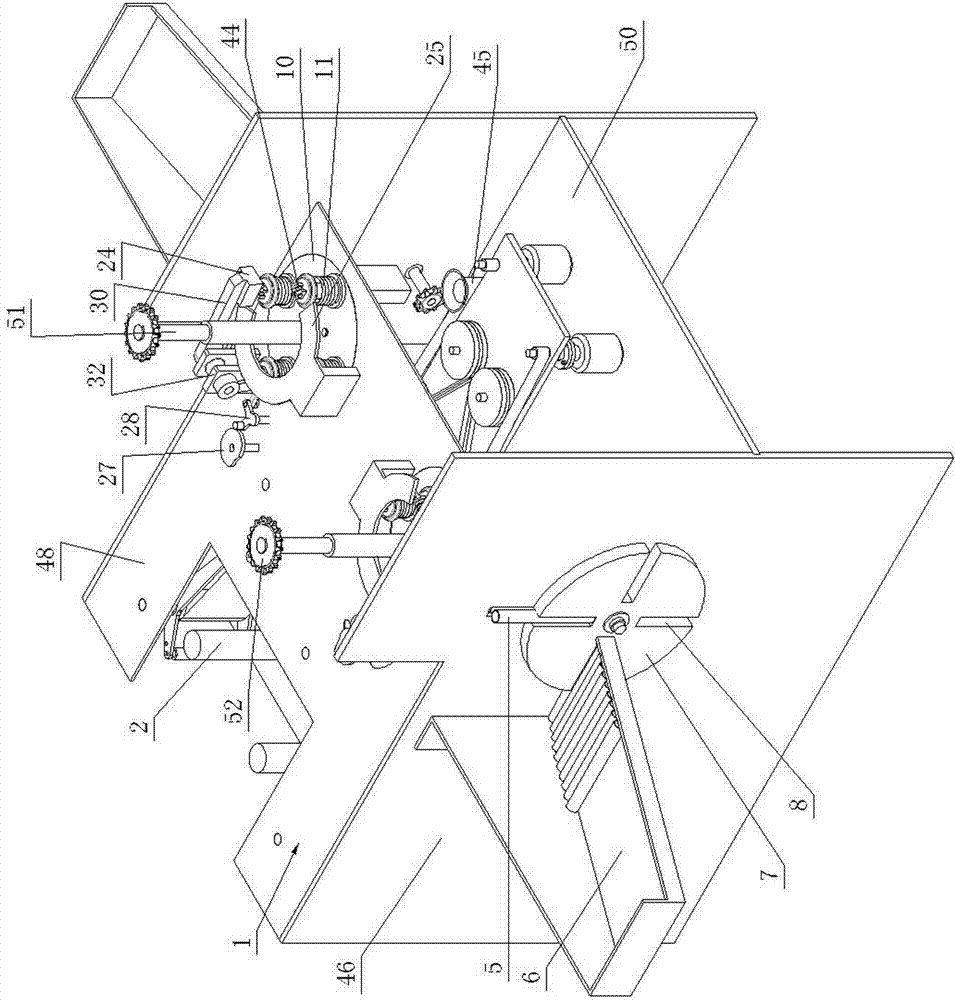

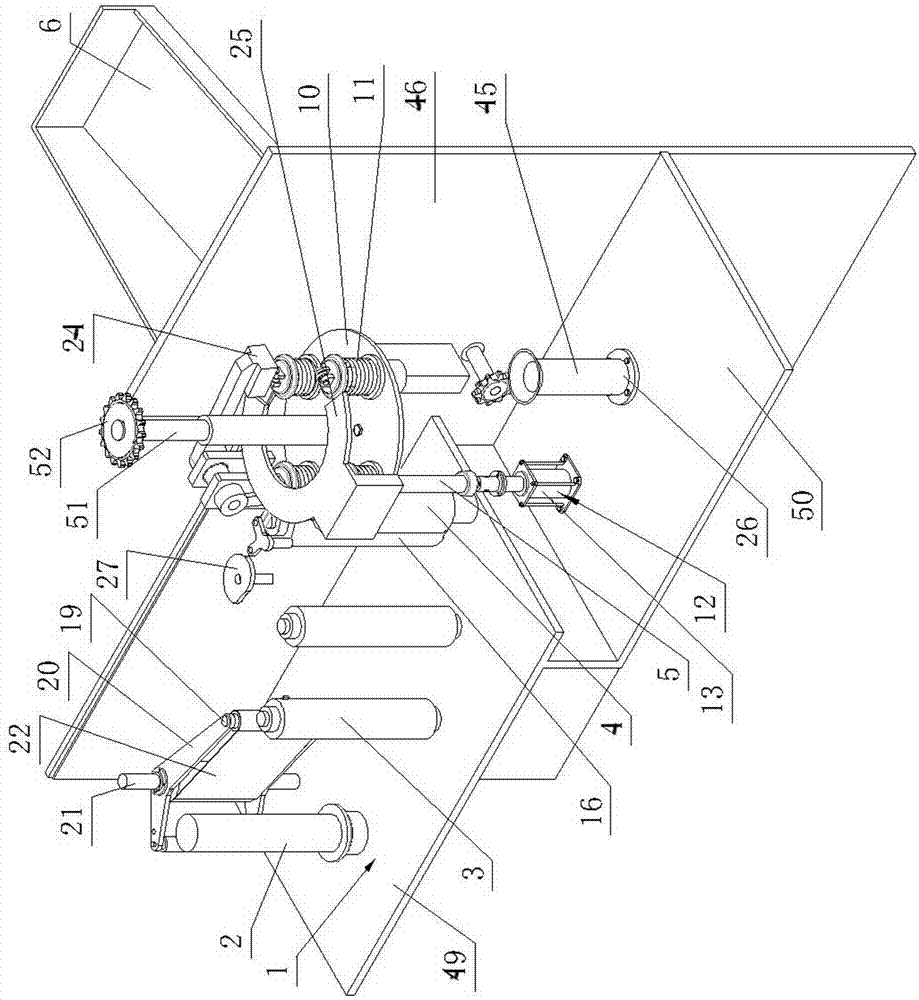

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the aluminum foil rewinding machine of the present invention includes a frame 1, and the frame includes two side plates 46, a top plate 47, an upper support plate 48, a middle support plate 49 and a lower support plate 50, a top plate 47 and three Both ends of the support plate are respectively fixed to the two side plates 46 .

[0030] This aluminum foil rewinding machine also includes a feed channel 6 for shelving a plurality of side-by-side paper cylinders 5 fixed on the side plate 46 of the frame 1, a rotatably fitted on the side plate 46 of the frame 1 and controlled by Feed carousel 7 driven by electric motor. The feed channel 6 is inclined, which is convenient for the paper tube 5 to rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com