Intelligent electromechanical automatic feeding control system

A control system, intelligent electromechanical technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as affecting processing efficiency and unsatisfactory control effects, improving feeding effects, reducing idle time periods, Ensure the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

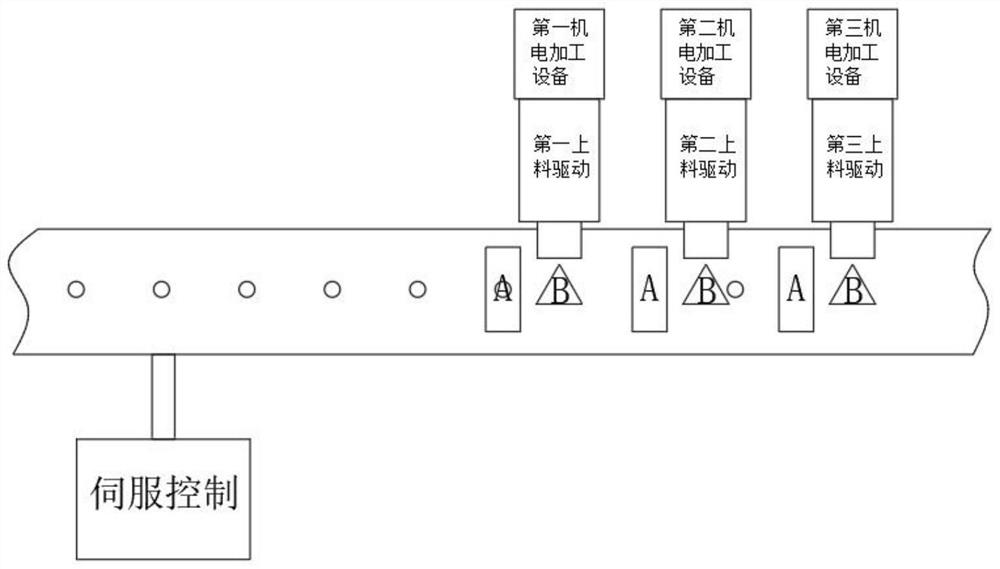

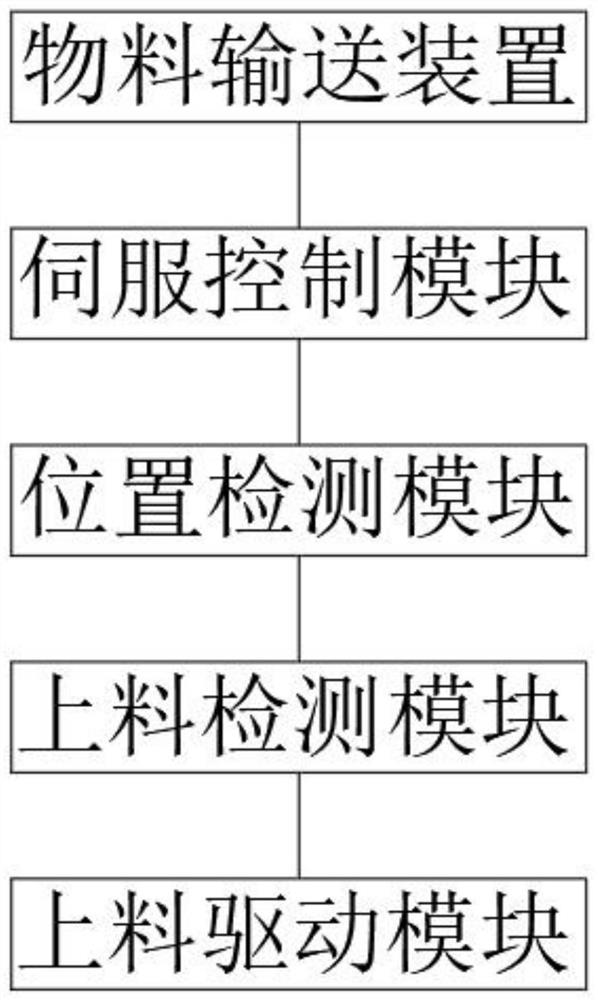

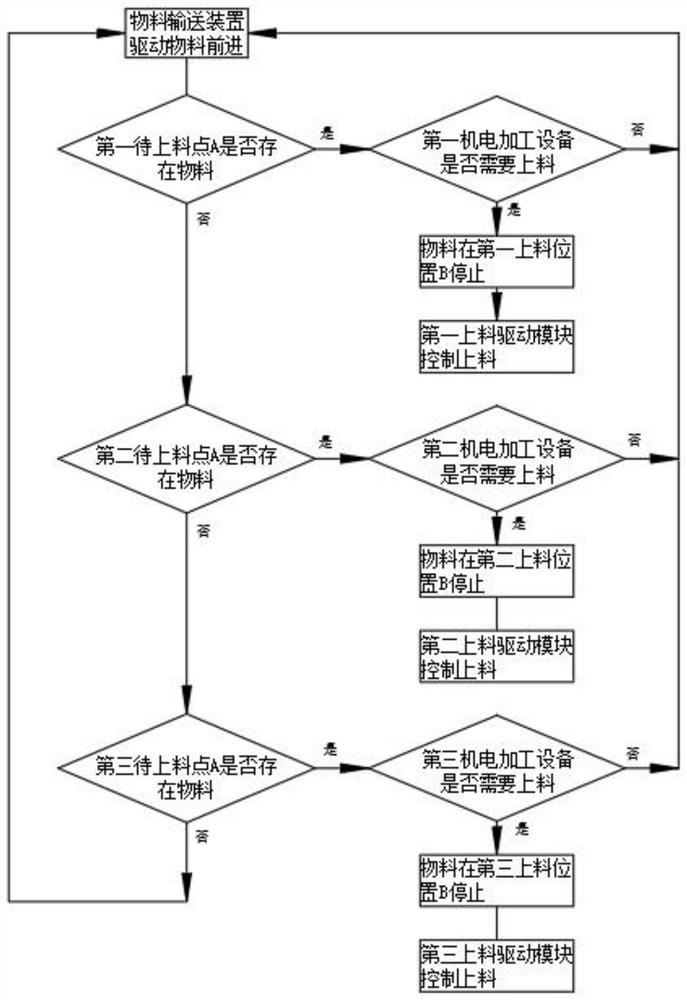

[0026] see Figure 1-3 , an intelligent electromechanical automatic feeding control system, comprising:

[0027] The material conveying device is arranged in a ring shape. The material conveying device includes an endless conveyor belt, and also includes a circular track and a track support for supporting the conveyor belt, and a drive servo for driving the conveyor belt. The drive servo and the servo control module Electrical connection, used to transport materials, and transport materials from the machine to the loading place of the electromechanical processing equipment.

[0028] The servo control module is used to control the driving servo of the material conveying device, including controlling the stop and start of the driving servo;

[0029] It also includes electromechanical processing equipment. The electromechanical processing equipment is arranged on the outside of the material conveying device. The electromechanical processing equipment is used to complete the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com