stamping die

A technology for stamping molds and mold shells, applied in the field of molds, which can solve the problems of inability to continuously stamp and form, inconvenient demoulding process, time-consuming, etc., and achieve the effect of convenient and quick feeding process, small mold opening range, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

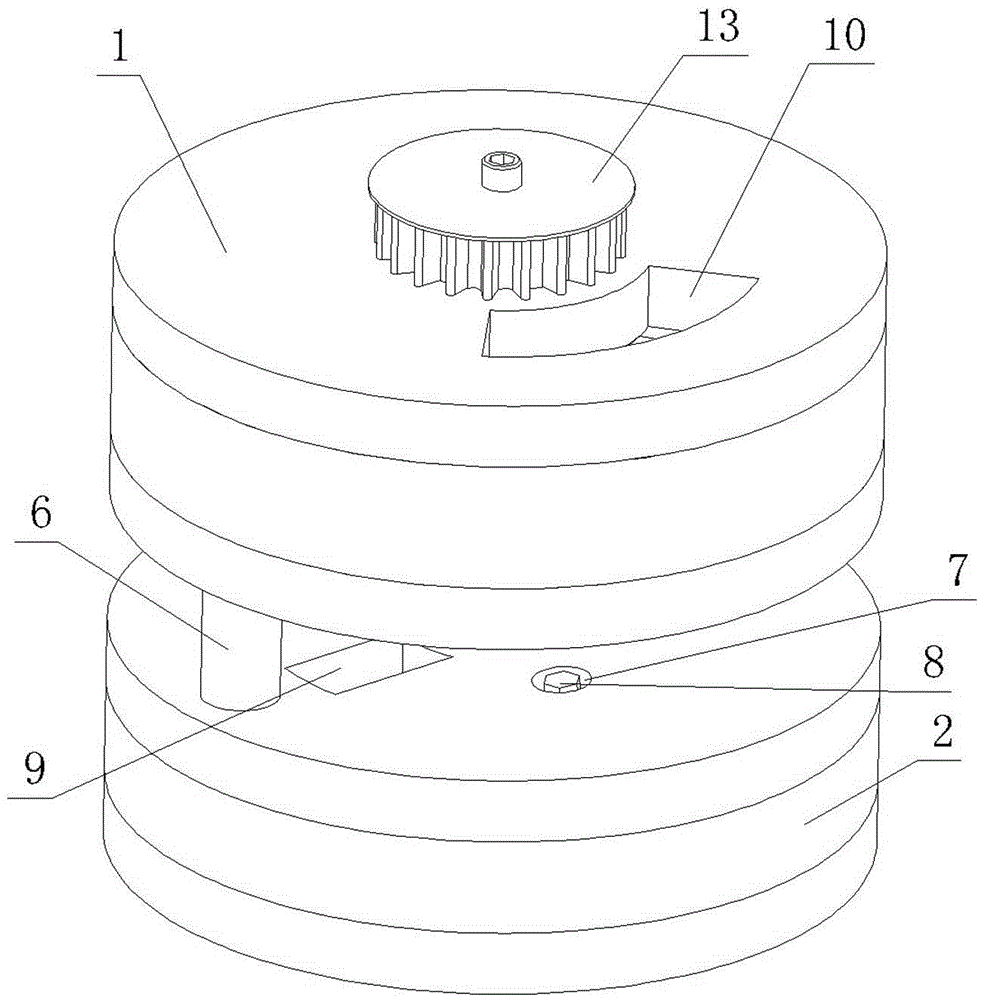

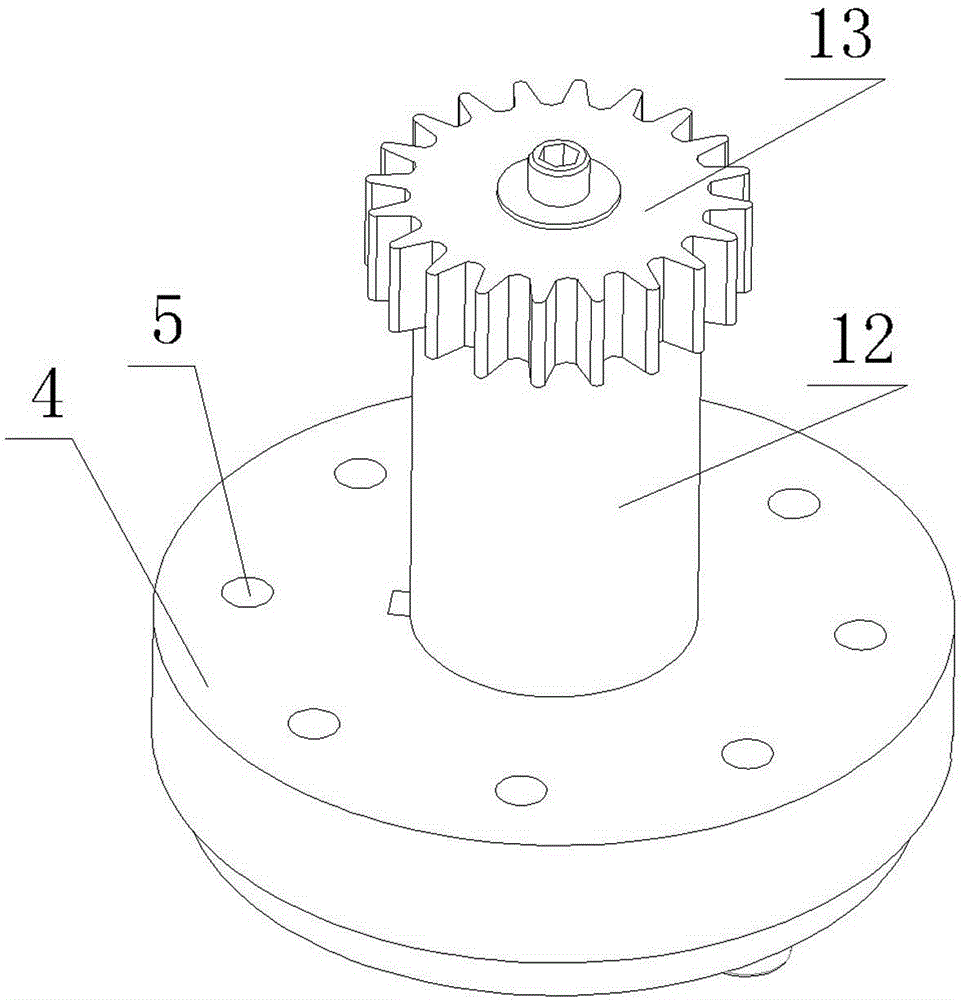

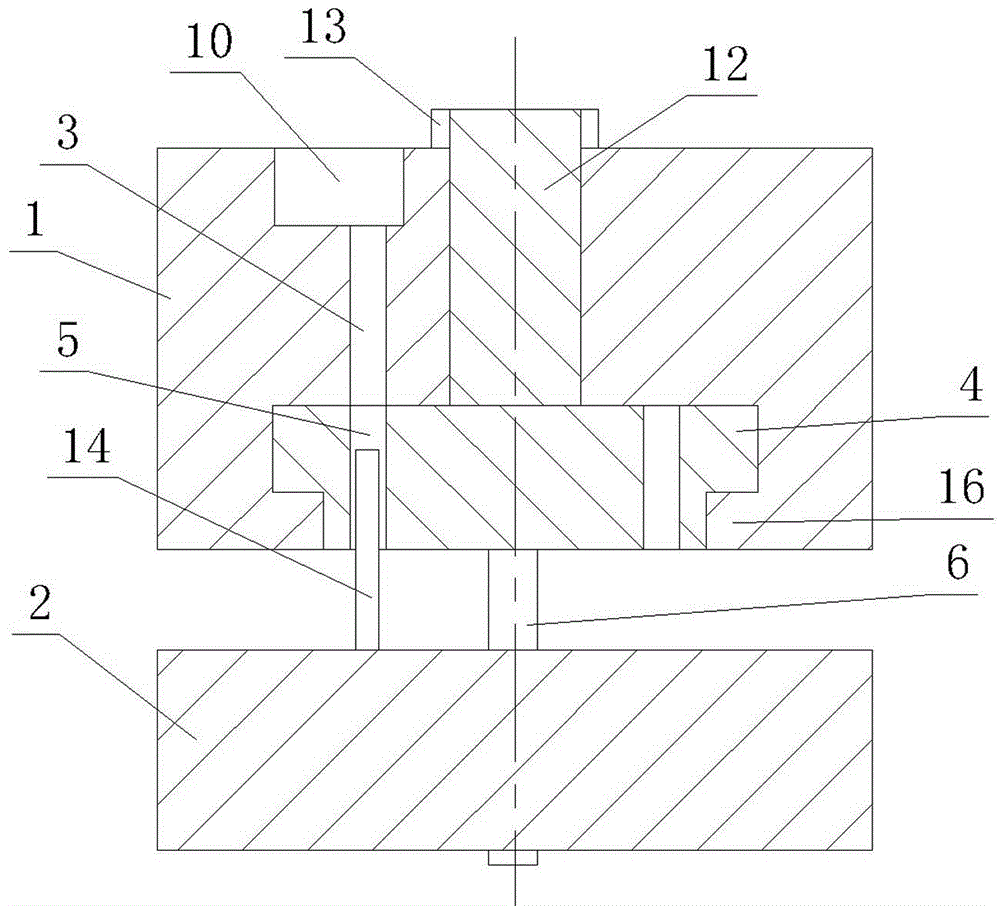

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the stamping die of the present invention includes an upper cylindrical formwork 1 and a lower punch 2 . The upper end surface of the upper cylindrical formwork 1 is provided with a feed trough 10 , and the bottom of the feed trough 10 of the upper cylindrical formwork 1 is provided with a blanking channel 3 vertically penetrating the upper cylindrical formwork 1 . The lower end surface of the upper cylindrical formwork 1 is provided with a first cylindrical pit, and a turntable 4 is rotatably fitted in the first cylindrical pit. Specifically, a stop ring 16 is provided at the opening of the first cylindrical pit, and The circumferential surface of the turntable 4 is provided with a limit step 17 abutting against the limit ring 19, and the limit step 17 preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com