Making system for pitaya-flavored Chinese hamburgers

A production system, the technology of Roujiamo, which is applied in the direction of metal processing, etc., can solve the problems of high labor intensity, low production efficiency of Roujiamo, and the inapplicability of automatic Roujiamo production, so as to reduce the labor intensity and improve the production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

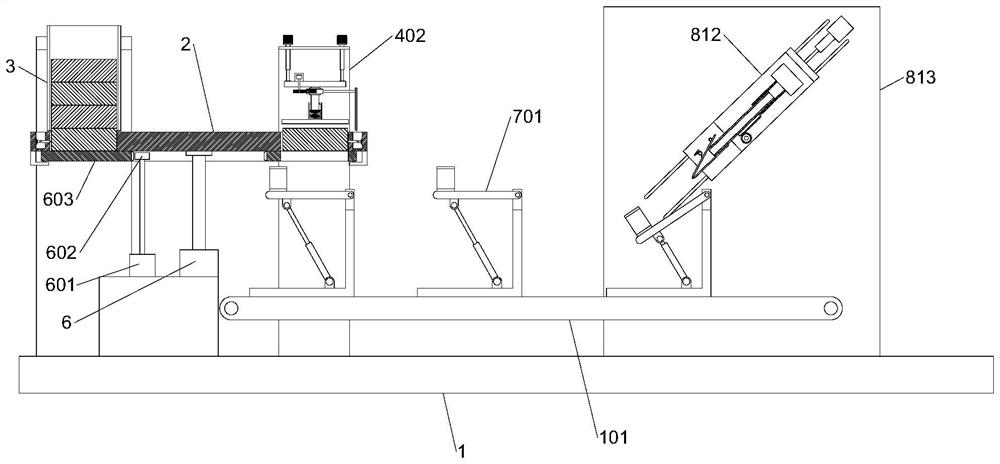

[0038] The production system for pitaya-flavored meat buns of the present invention includes a workbench 1, a turntable 2 that can be rotated is arranged on the upper end of the workbench 1, a plurality of through grooves 201 are opened through the turntable 2, and a feeding structure is arranged above the turntable 2, The biscuits 301 in the feeding structure can enter the through groove 201 , a cutting assembly 4 for cutting the biscuits 301 in the through groove 201 is also arranged above the turntable 2 , and a conveyor is provided between the worktable 1 and the turntable 2 . The belt 101 and the conveyor belt 101 are provided with a receiving component 7 for receiving the cut biscuits 301 , and a feeding component 8 is also provided above the workbench 1 , and the feeding component 8 is used to feed the biscuits 301 on the receiving component 7 .

[0039] After the above technical solution is adopted: the present invention is provided with a turntable 2 above the workbenc...

Embodiment 2

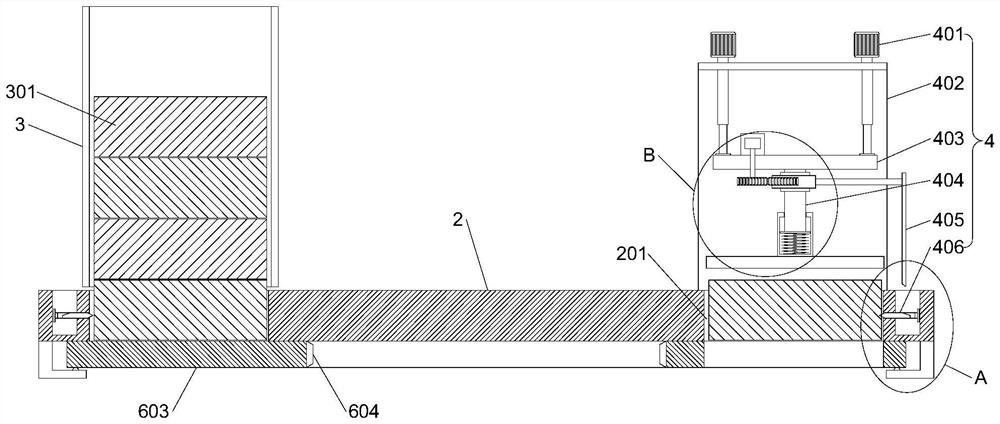

[0041] This embodiment is further optimized on the basis of Embodiment 1 as follows: a plurality of through grooves 201 are distributed in a circular array, the feeding structure includes a feeding cylinder 3, and the feeding cylinder 3 is provided with a support force by the workbench 1, and several The biscuits 301 are stacked horizontally in the upper cylinder 3, the lower end of the upper cylinder 3 can be aligned with the through groove 201, and a gap is reserved between the lower end surface of the upper cylinder 3 and the upper end surface of the turntable 2, and the gap is smaller than the biscuits. The thickness of the biscuits 301 is greater than the thickness of the turntable 2 .

[0042] After the above technical solution is adopted: the outer wall of the upper material cylinder 3 is provided with a support structure, and the lower end of the support structure is connected with the worktable 1 to realize the support for the upper material cylinder 3, and the lower e...

Embodiment 3

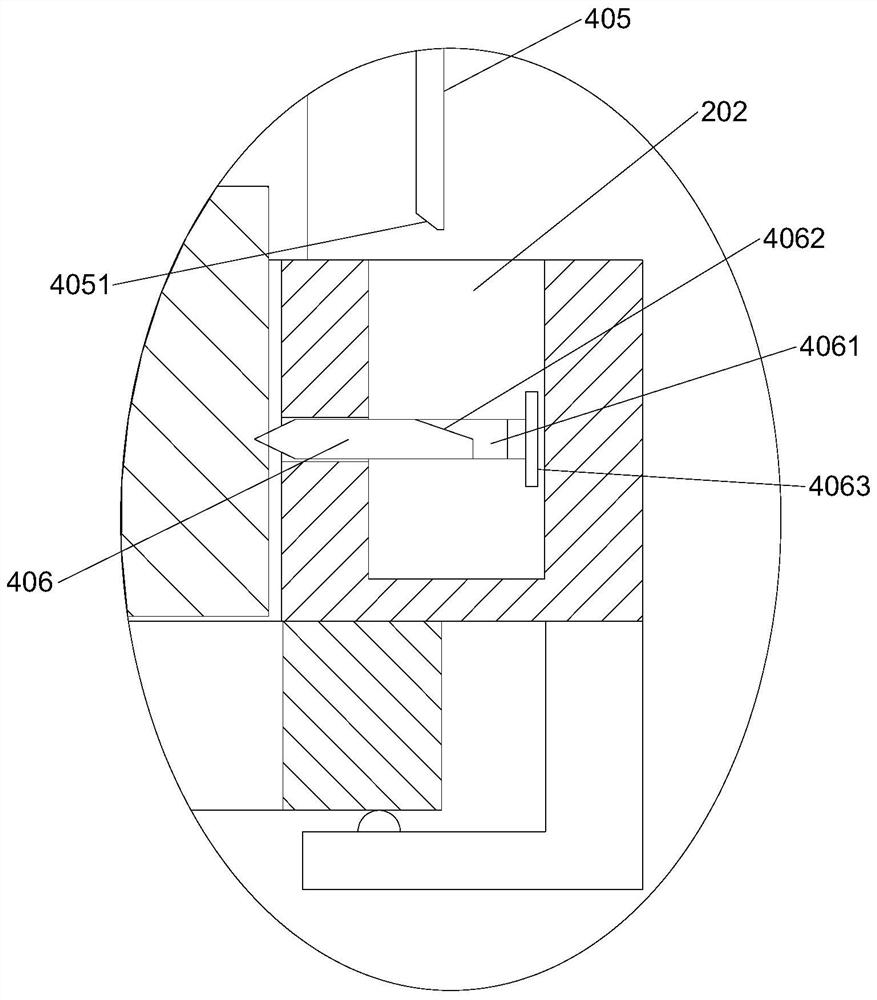

[0044] This embodiment is further optimized on the basis of Embodiment 1 as follows: the cutting assembly 4 includes a cutter 406, a support frame 402, a lifting plate 403, a pressing plate 407, a guide post 404, a guide rod 405 and a compression spring 4064; The outer side of the groove 201 is provided with an arc-shaped guide groove 202, and a let-away groove is formed between the guide groove 202 and the through groove 201. The cutting knife 406 runs through the let-away groove, and the outer end of the cutting knife 406 is located in the guide groove 202. There is a baffle 4063, a compression spring 4064 is arranged between the baffle 4063 and a side wall of the guide slot 202 close to the through slot 201, the lower end of the support frame 402 is arranged on the workbench 1, and the upper end of the support frame 402 is arranged with a hydraulic cylinder 401 , the telescopic shaft of the hydraulic cylinder 401 and the lifting plate 403 are connected to each other, the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com