Intelligent anti-deformation metal casting nozzle separation machine and its control method

A metal casting and nozzle separation technology, which is applied in the field of intelligent anti-deformation metal casting nozzle separation machine, can solve the problems of insufficient locking force and loosening, and achieve the effect of improving stability, simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

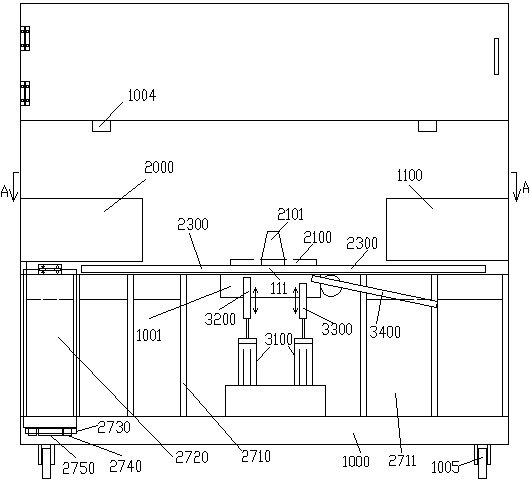

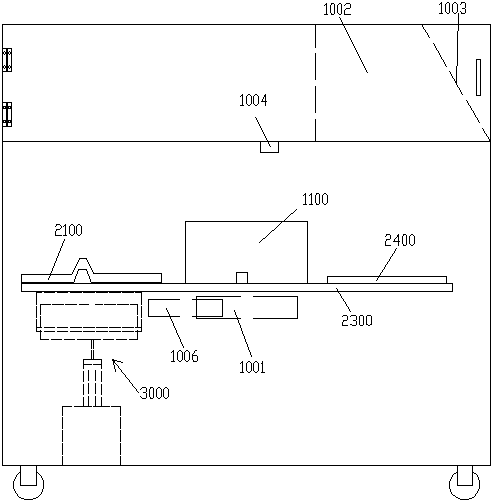

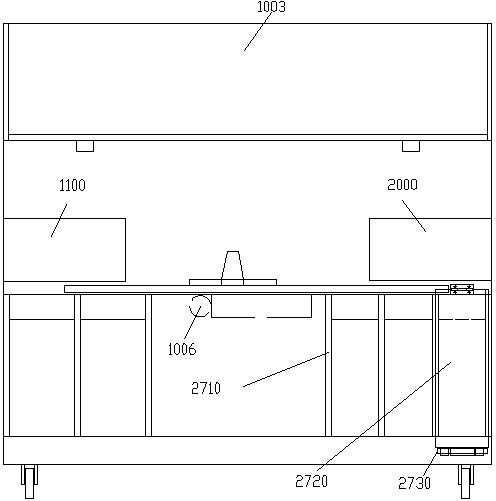

[0053] refer to Figure 1 to Figure 21

[0054] An intelligent impact-resistant metal casting nozzle separation machine, including a cabinet 1000 with casters 1005, the middle of the cabinet is provided with an electric indexing plate 1001 driven by a stepping motor 1006, and the electric indexing plate drives a horizontal The ring turntable 2300 rotates, and a positioning mechanism 2400 for installing the metal casting 2100 is provided at intervals of 90° on the circumference of the ring turntable. One station, the second station and the fourth station on both sides and the third station on the rear side, the first station is metal casting loading and unloading station, the second station is Metal casting noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com