Clamped position removal process of special-shaped aluminum alloy workpiece

An aluminum alloy and special-shaped technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of scrapped parts, failure, and deformation of parts, and achieve the effects of convenient operation, lower requirements, and improved production efficiency

Inactive Publication Date: 2018-11-06

SHENYANG FORTUNE PRECISION EQUIP CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

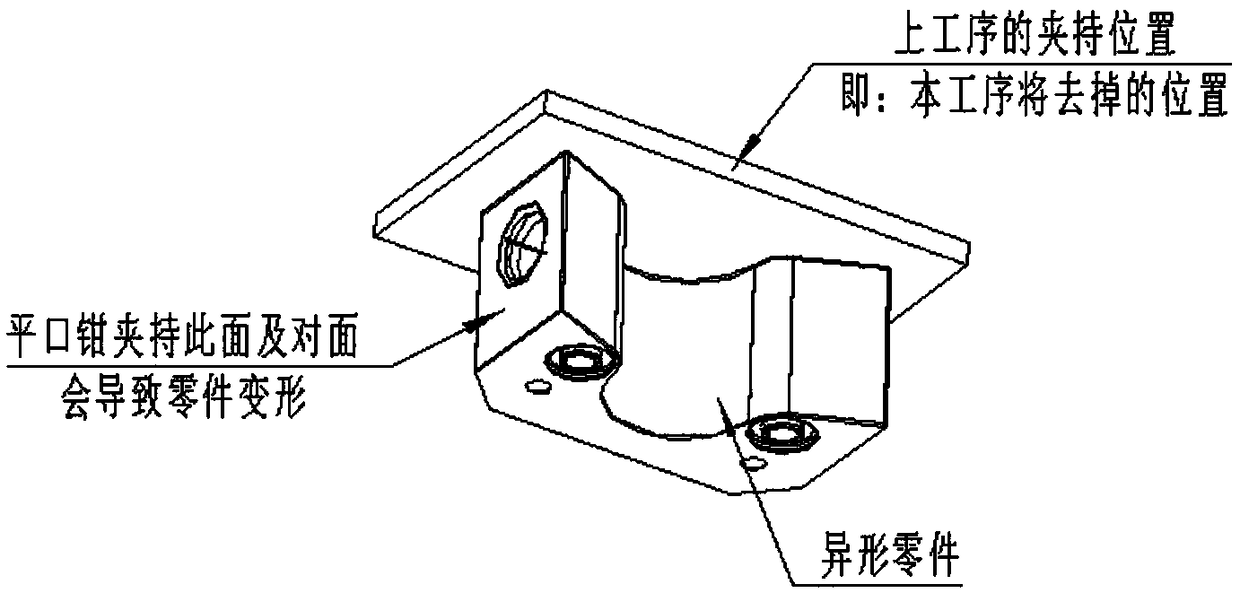

However, for the de-clamping of special-shaped aluminum alloy workpieces, the flat-nose pliers are turned over to clamp the processed position, and the de-clamping is not feasible, which will easily cause the deformation of the parts and lead to the scrapping of the parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

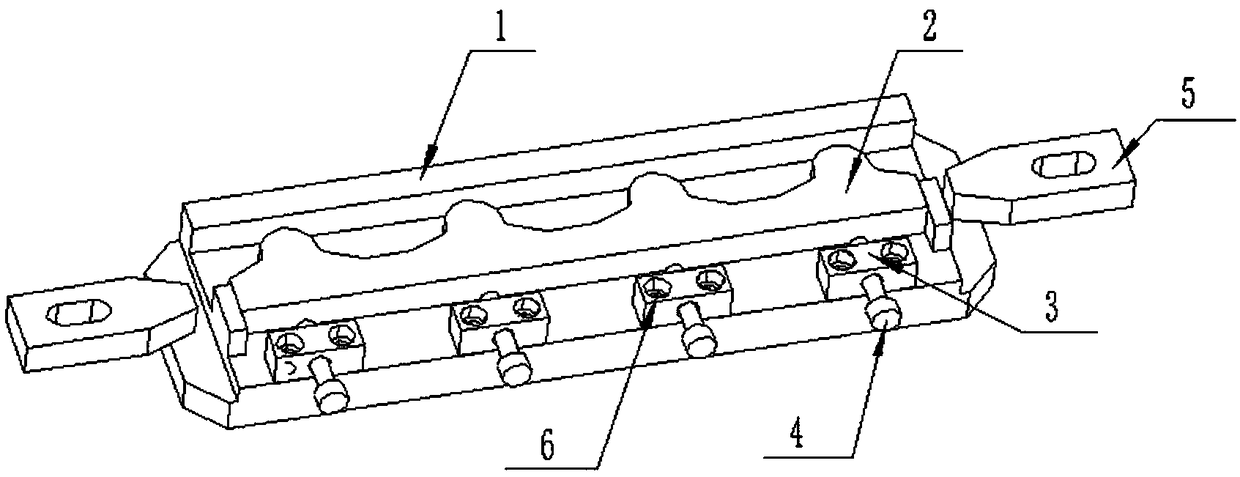

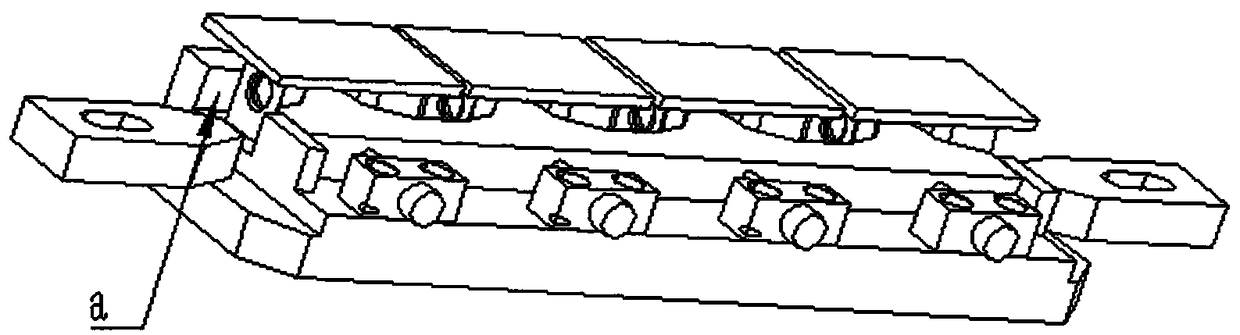

[0028] Straighten the surface a of the base of the tooling, the runout is within 0.03mm, the pressure plate is pressed on both sides of the base, the fixing block of the top screw is locked with M8 screws, and the parts are clamped according to the shape of the sliding side top tooling, and the 4 jacking screws push the sliding side top tooling , and tighten the parts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a clamped position removal process of a special-shaped aluminum alloy workpiece. A profiled side jacking tool is manufactured according to the appearance of an irregular part,the part is clamped, and part deformation is avoided in the clamped position removal process. The profiled side jacking tool manufactured according to the appearance of the irregular part comprises abase, a side jacking sliding plate, jackscrew fixing blocks, jackscrews, pressing plates and screws. The base is fixed to a machining platform through the pressing plates, the side jacking sliding plate is arranged on the base and connected with the jackscrews, and the jackscrews are fixed to the base by the jackscrew fixing blocks through the screws. The base is provided with a protruding block,the end face of the special-shaped part is limited, the side jacking sliding plate is provided with profiled end faces on the same face with the special-shaped part, and the special-shaped part is pushed by the jackscrews to be fixed between the side jacking sliding plate and the protruding block of the base. The multiple profiled end faces are arranged, multiple parts can be machined at the sametime, and the clamped position removal efficiency of the special-shaped part is greatly improved. The multiple parts are subjected to side jacking at the same time, and clamped position removal is achieved efficiently without deformation. According to the process, the deformation problem of the workpiece after common clamped position removal is relieved.

Description

technical field [0001] This patent belongs to the field of cold processing industry, and in particular relates to a de-clamping process for special-shaped aluminum alloy workpieces. It is suitable for the de-clamping process of all the special-shaped parts with flat-nose pliers clamped and processed in the previous process. Background technique [0002] In the field of semiconductor processing, there are many single-sided station parts that are suitable for flat-nose pliers to clamp and process all at one time, which can effectively shorten the tool clamping length and clamping time, thereby improving processing efficiency. For a relatively regular workpiece surface, the flat-nose pliers should be turned over and clamped, and the clamping position can be removed. However, for the de-clamping of special-shaped aluminum alloy workpieces, the flat-nose pliers are turned over to clamp the processed position, and the de-clamping is not feasible, which will easily cause deformati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25B11/00

CPCB25B11/00

Inventor 李翠郑广文谷明君

Owner SHENYANG FORTUNE PRECISION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com